ASTM F1566-99(2004)

(Test Method)Standard Test Methods for Evaluation of Innersprings and Boxsprings

Standard Test Methods for Evaluation of Innersprings and Boxsprings

SIGNIFICANCE AND USE

Four separate test methods are outlined for use in evaluation of mattress innerspring or boxspring units, or both.

These test methods include measurements of firmness, firmness retention, durability, effect of impact, etc.

One or more of the test methods shall be used separately or in combination to provide for appropriate evaluations.

SCOPE

1.1 These test methods cover nationally recognized methods for testing mattress innersprings and boxsprings to ensure uniformity of results.

1.2 These test methods are applicable to un-upholstered innersprings and boxsprings only and are not applicable to finished upholstered mattresses or boxsprings. Any conclusions covering such items are outside the scope of these test methods.

1.3 The durability test (Section 7), impact test (Section 8) and firmness retention test (Section 9) require the use of an upholstered innerspring or boxspring, or both. A standardized upholstery is specified in each case.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1566–99(Reapproved 2004)

Standard Test Methods for

Evaluation of Innersprings and Boxsprings

This standard is issued under the fixed designation F 1566; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 contract units, n—term used to indicate units mar-

keted in large quantities, usually by contract, to quantity users,

1.1 Thesetestmethodscovernationallyrecognizedmethods

that is, hotel, motel, institutional, etc.

for testing mattress innersprings and boxsprings to ensure

3.1.4 innerspring unit, n—interconnection of wire spring

uniformity of results.

elements other than mounting on a frame that forms a single

1.2 These test methods are applicable to un-upholstered

unit that can be incorporated into a mattress.

innersprings and boxsprings only and are not applicable to

3.1.5 mattress, innerspring, n—any mattress containing an

finishedupholsteredmattressesorboxsprings.Anyconclusions

innerspring unit.

covering such items are outside the scope of these test

3.1.6 posturized innerspring, n—innerspring assembly with

methods.

thecenterthirdhavingahighercoildensityorlargerwiregage.

1.3 The durability test (Section 7), impact test (Section 8)

and firmness retention test (Section 9) require the use of an

4. Significance and Use

upholstered innerspring or boxspring, or both. A standardized

4.1 Four separate test methods are outlined for use in

upholstery is specified in each case.

evaluation of mattress innerspring or boxspring units, or both.

1.4 The values stated in inch-pound units are to be regarded

4.2 These test methods include measurements of firmness,

as the standard. The values given in parentheses are for

firmness retention, durability, effect of impact, etc.

information only.

4.3 One or more of the test methods shall be used separately

1.5 This standard does not purport to address all of the

or in combination to provide for appropriate evaluations.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Conditioning

priate safety and health practices and determine the applica-

5.1 Prior to testing, condition units for at least8hat23 6

bility of regulatory limitations prior to use.

5°C in accordance with Test Method D 648.

2. Referenced Documents

6. Firmness Rating

2.1 ASTM Standards:

6.1 Specimen—The unit to be tested is an un-upholstered

D 648 Test Method for Deflection Temperature of Plastics

mattress innerspring or boxspring unit.

Under Flexural Load in the Edgewise Position

6.2 Apparatus:

E 4 Practices for Force Verification of Testing Machines

6.2.1 Platen—The platen shall be a round aluminum disk

3. Terminology weighing 8 6 0.2 lb (3.6 6 0.1 kg) with a diameter of 13.54

6 0.2 in. (344 6 5 mm) connected to the loading mechanism

3.1 Definitions:

with a flexible connection (see Fig. 1).

3.1.1 boxspring unit, n—foundation for the mattress con-

6.2.2 Loading Mechanism —Adevice capable of providing

sisting of wire spring elements mounted on a frame.

a load of 300 lbf (1335 N) or more with accuracy of 61%.

3.1.2 boxspring, upholstered, n—foundation for the mat-

6.2.3 Deflection Device—For use in determining deflection,

tress consisting of wire spring elements mounted on a frame,

that is, ruler or electronic device accurate to ⁄32 in. (1 mm).

generally upholstered and covered on top and sides with

6.3 Test Procedure:

ticking, and bottom with a dust cover.

6.3.1 Place specimen directly onto a rigid, flat surface.

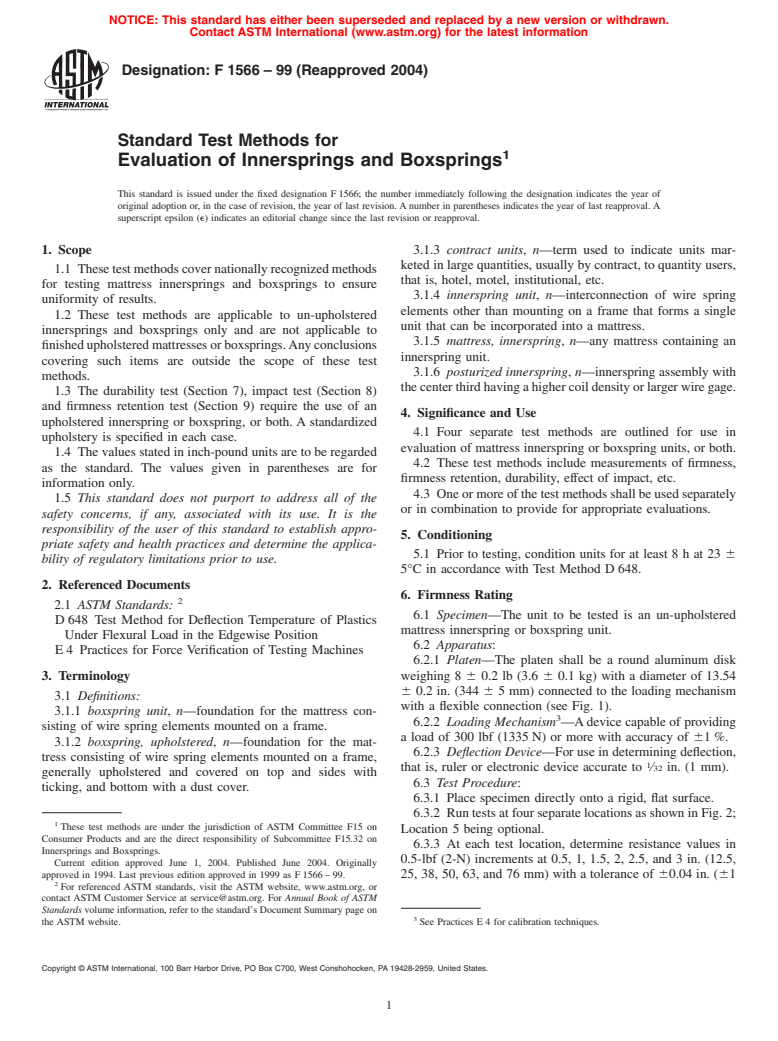

6.3.2 Run tests at four separate locations as shown in Fig. 2;

These test methods are under the jurisdiction of ASTM Committee F15 on

Location 5 being optional.

Consumer Products and are the direct responsibility of Subcommittee F15.32 on

6.3.3 At each test location, determine resistance values in

Innersprings and Boxsprings.

0.5-lbf (2-N) increments at 0.5, 1, 1.5, 2, 2.5, and 3 in. (12.5,

Current edition approved June 1, 2004. Published June 2004. Originally

approved in 1994. Last previous edition approved in 1999 as F 1566 – 99.

25, 38, 50, 63, and 76 mm) with a tolerance of 60.04 in. (61

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. See Practices E 4 for calibration techniques.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1566–99 (2004)

7.1.2 The border wire on the innerspring and boxspring

units shall be a minimum of 6-gage, 0.192-in. (4.9-mm)

diameter.

7.1.3 Thetestupholsteryfortheinnerspringmattresswillbe

2 2

a 1.85 6 0.15 oz/ft (565 6 45 g/m ) synthetic fiber pad

primary insulation layer positioned next to the subject on both

flat surfaces.A0.75-in. (19-mm) thick 1.1 6 0.1-lb/ft (17.5 6

1.5-kg/m ) density, 25 to 35-lbf (110 to 155-N) polyurethane

foam cushioning layer shall be placed on top of the primary

insulator pad on each side.Aquilt assembly sandwich shall be

constructed consisting of a top layer of 100-end damask fabric

ticking. The middle layer of 0.5-in. (13-mm) thick, 1.1 6

0.1-lb/ft density, 25 to 35-lbf polyurethane foam and the

2 2

bottom layer is of 1.0 6 0.5-oz/yd (34 6 17-g/m ) quilt

backing.

7.1.4 This assembly shall be unitized by automatic sewing

and then placed over the foam cushioning layer on both sides

and attached to the subject mattress innerspring, using tech-

niques commonly accepted by the bedding industry.

7.1.5 The boxspring assembly shall be upholstered with a

2 2

1.85 6 0.15-oz/ft (52.4 6 4.0-g/m ) synthetic fiber pad

primary insulator next to the subject boxspring. The fabric of

NOTE 1—Platen material: aluminum.

Weight: 8 6 0.2 lb (3.6 6 0.1 kg)

commercially acceptable grades shall be placed directly over

FIG. 1 ILD Platen

the pad and attached to the spring and wood assembly, using

techniques commonly accepted by the bedding industry.

7.2 Apparatus:

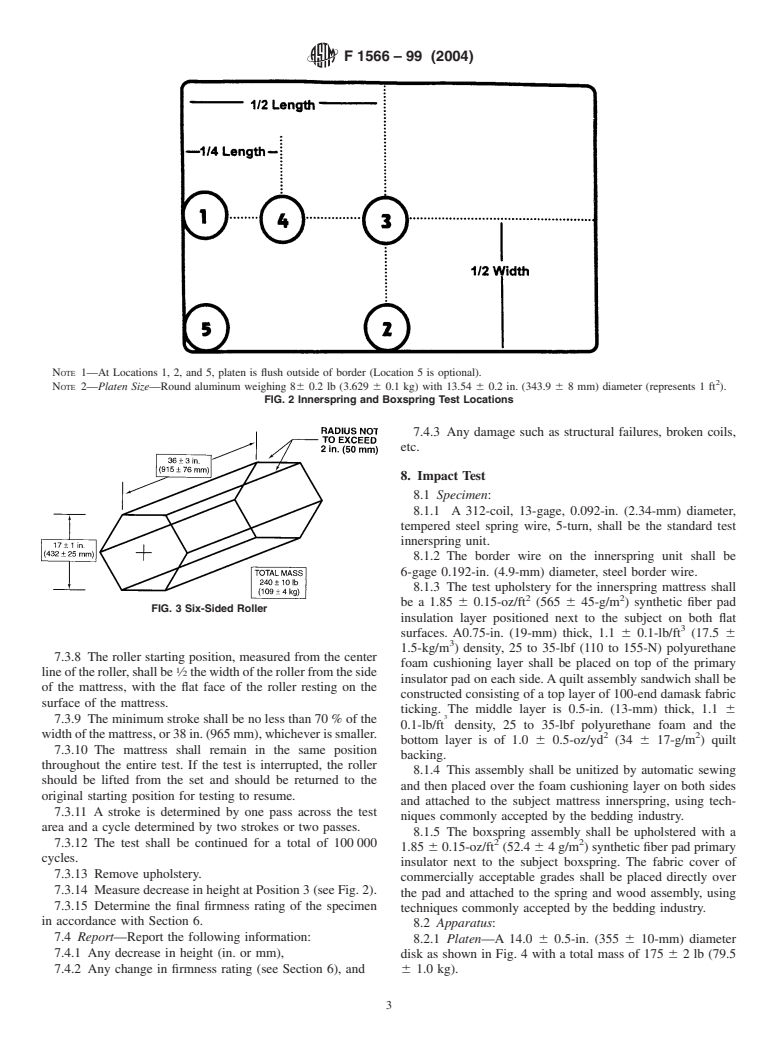

mm) of deflection of the top surface for innersprings and 0.5 7.2.1 Juggernaut Roller (see Fig. 3),

7.2.1.1 Shape of Roller, 6-sided,

and 1 in. (12.5 and 25 mm) with a tolerance of 60.04 in. (61

mm) of deflection of the top surface for boxsprings. 7.2.1.2 Length,36 6 3 in. (915 6 75 mm),

7.2.1.3 Weight, 240 6 10 lb (109 6 4.5 kg),

6.4 Calculation/Results:

7.2.1.4 Diameter of Roller (Flat to Flat),17 6 1 in. (430 6

6.4.1 Determine a firmness rating for uniformly constructed

25 mm),

innerspring units by totaling resistance values at Locations 3

7.2.1.5 All Sharp-Edged Radiuses, not to exceed 2 in. (50

and 4 for all deflections and dividing the total by 2 (for an

mm),

average).

7.2.1.6 Operating Speed, not to exceed 20 cycles/min, and

6.4.2 Determine firmness rating for non-uniformly con-

7.2.1.7 Roller, should float free of arm.

structed (posturized) innerspring units by using resistance

7.2.2 Deflection Device—A method of determining deflec-

values at Location 3 only.

tion, that is, ruler or electronic device accurate to ⁄32 in. (1

6.4.3 Determine a firmness rating for the calf/shoulder area

mm).

using the values at Location 4 only. Any difference between

7.3 Test Procedure:

readings 3 and 4 will be calculated as a percentage of increase

7.3.1 Determine a firmness rating of the un-upholstered

of Location 3 over the readings at Location 4.

specimen in accordance with Section 6.

6.4.4 Determine a firmness rating for the edge by totaling

7.3.2 Place unupholstered specimen directly on a rigid, flat

theresistancevaluesatLocations1and2foralldeflectionsand

surface.

dividing the total by 2 (for an average).

7.3.3 Measure height of unupholstered specimen at Position

6.4.5 Optional—Determine a firmness rating of the corner

3 (see Fig. 2).

bytotalingastheresistancevalueforalldeflectionsatLocation

7.3.4 Upholster specimens as described in 7.1.3-7.1.5.

5.

7.3.5 Testing shall be done in the center of the mattress

(measured from head to foot) across the mattress surface from

7. Durability Test

side to side.

7.1 Specimen:

NOTE 1—This simulates sleeper action most realistically.

7.1.1 When testing innerspring units, standard upholstered

7.3.6 Ahold down device shall be used outside of the roller

boxsprings shall be used for the comparison. Conversely, when

path to keep mattress from moving.

testing boxspring units, standard innerspring mattresses shall

7.3.7 Themaximumstrokeoftherollershallbethewidthof

be used. A 312-coil, 13-gage, 0.092-in. (2.34-mm) diameter,

the mattress, minus the width of one flat side of the roller.

tempered steel spring wire, 5-turn, shall be the standard test

innerspring unit and an 81-coil, 10-gage, 0.135-in. (3.4-mm)

diameter,temperedsteelspringwireboxspringunitshallbethe

Detailed construction drawings for this equipment are available fromAmerican

standard foundation construction. Innerspring ManufacturersAssociation, 1918 North Parkway, Memphis, TN 38112.

F1566–99 (2004)

NOTE 1—At Locations 1, 2, and 5, platen is flush outside of border (Location 5 is optional).

NOTE 2—Platen Size—Round aluminum weighing 86 0.2 lb (3.629 6 0.1 kg) with 13.54 6 0.2 in. (343.9 6 8 mm) diameter (represents 1 ft ).

FIG. 2 Innerspring and Boxspring Test Locations

7.4.3 Any damage such as structural failures, broken coils,

etc.

8. Impact Test

8.1 Specimen:

8.1.1 A 312-coil, 13-gage, 0.092-in. (2.34-mm) diameter,

tempered steel spring wire, 5-turn, shall be the standard test

innerspring unit.

8.1.2 The border wire on the innerspring unit shall be

6-gage 0.192-in. (4.9-mm) diameter, steel border wire.

8.1.3 The test upholstery for the innerspring mattress shall

2 2

be a 1.85 6 0.15-oz/ft (565 6 45-g/m ) synthetic fiber pad

FIG. 3 Six-Sided Roller

insulation layer positioned next to the subject on both flat

surfaces. A0.75-in. (19-mm) thick, 1.1 6 0.1-lb/ft (17.5 6

1.5-kg/m ) density, 25 to 35-lbf (110 to 155-N) polyurethane

7.3.8 The roller starting position, measured from the center

foam cushioning layer shall be placed on top of the primary

lineoftheroller,shallbe ⁄2thewidthoftherollerfromtheside

insulator pad on each side.Aquilt assembly sandwich shall be

of the mattress, with the flat face of the roller resting on the

constructed consisting of a top layer of 100-end damask fabric

surface of the mattress.

ticking. The middle layer is 0.5-in. (13-mm) thick, 1.1 6

7.3.9 The minimum stroke shall be no less than 70 % of the

0.1-lb/ft density, 25 to 35-lbf polyurethane foam and the

widthofthemattress,or38in.(965mm),whicheverissmaller. 2 2

bottom layer is of 1.0 6 0.5-oz/yd (34 6 17-g/m ) quilt

7.3.10 The mattress shall remain in the same position

backing.

throughout the entire test. If the test is interrupted, the roller

8.1.4 This assembly shall be unitized by automatic sewing

should be lifted from the set and should be returned to the

and then placed over the foam cushioning layer on both sides

original starting position for testing to resume.

and attached to the subject mattress innerspring, using tech-

7.3.11 A stroke is determined by one pass across the test

niques commonly accepted by the bedding industry.

area and a cycle determined by two strokes or two passes.

8.1.5 The boxspring assembly shall be upholstered with a

2 2

7.3.12 The test shall be continued for a total of 100 000

1.85 6 0.15-oz/ft (52.4 6 4 g/m ) synthetic fiber pad primary

cycles.

insulator next to the subject boxspring. The fabric cover of

7.3.13 Remove upholstery.

commercially acceptable grades shall be placed directly over

7.3.14 Measure decrease in height at Position 3 (see Fig. 2).

the pad and attached to the spring and wood assembly, using

7.3.15 Determine the final firmness rating of the specimen

techniques commonly accepted by the bedding industry.

in accordance with Section 6.

8.2 Apparatus:

7.4 Report—Report the following information:

8.2.1 Platen—A 14.0 6 0.5-in. (355 6 10-mm) diameter

7.4.1 Any decrease in height (in. or mm),

disk as shown in Fig. 4 with a total mass of 175 6 2 lb (79.5

7.4.2 Any change in firmness rating (see Section 6), and 6 1.0 kg).

F1566–99 (2004)

9.1.1 When testing innerspring units, standard upholstered

boxsprings shall be used for the comparison. Conversely, when

testing boxspring units, standard innerspring mattresses shall

be used. A 312-coil, 13-gage, 0.092-in. (2.34-mm) diameter,

tempered steel spring wire, 5-turn, shall be the standard test

innerspring unit and an 81-coil, 10-gage, 0.135-in. (3.4-mm)

diameter,temperedsteelspringwireboxspringunitshallbethe

standard foundation construction.

9.1.2 The border wire on the innerspring and boxspring

units shall be a minimum of 6-gage, 0.192-in. (4.9-mm)

diameter.

9.1.3 The test upholstery for the innerspring mattress shall

be a 1.85 6 0.15-oz/ft (565 6 45-g/m ) synthetic fiber pad

primary insulation layer positioned next to the subject on both

flat surfaces.A0.75-in. (19-mm) thick 1.1 6 0.1 lb/ft (17.5 6

1.5-kg/m ) density, 25 to 35 lbf (110 to 155-N) polyurethane

foam cushioning layer shall be placed on top of the primary

insulator pad on each side.Aquilt assembly sandwich shall be

NOTE 1—Weight: 175 6 2 lb (79.38 6 1 kg).

constructed consisting of a top layer of 100-end damask fabric

FIG. 4 Impact Test Platen

ticking. The middle layer of 0.5-in. (13-mm) thick, 1.1 6

0.1-lb/ft density, 25 to 35-lbf polyurethane foam and the

8.2.2 Drop Weight Equipment—A device capable of lifting

2 2

bottom layer is of 1.0 6 0.5-oz/yd (34 6 17-g/m ) quilt

the platen to a controlled height not to exceed 2 ft (610 mm)

backing.

overthetopsurfaceofthespecimenanddesignedtoreleasethe

9.1.4 This assembly shall be unitized by automatic sewing

platen in “free drop” such that the vertical component is free

but the horizontal component is restrained. and then placed over the foam cushioning layer on both sides

and attached to the subject mattress innerspring, using tech-

8.3 Test Procedure:

8.3.1 Place the specimen directly on a rigid, flat surface. niques commonly accepted by the bedding industry.

8.3.2 Select drop locations to compare performance at 9.1.5 The boxspring assembly shall be upholstered with a

2 2

various positions (1 through 5) as shown in Fig. 2: 1.85 6 0.15-oz/ft (52.4 6 4-g/m ) fiber pad primary insulator

next to the subject boxspring. The fabric of commercially

NOTE 2—For safety reasons, it is recommended that the platen not

acceptable grades shall be placed directly over the pad and

extendbeyondtheedge/endofthemattressduringanydroptesttopr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.