ASTM F1085-03a(2007)

(Specification)Standard Specification for Mattress and Box Springs for Use in Berths in Marine Vessels

Standard Specification for Mattress and Box Springs for Use in Berths in Marine Vessels

SCOPE

1.1 This specification provides the requirements for mattresses and box springs that are for use in berths for officers, crew, and passengers in marine vessels. This shall be considered a minimum standard.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses, in inch-pound units, are for information only.

1.3 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials, products, or assemblies under actual fire conditions.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1085 – 03a (Reapproved 2007)

Standard Specification for

Mattress and Box Springs for Use in Berths in Marine

Vessels

This standard is issued under the fixed designation F 1085; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 6193 Practice for Stitches and Seams

D 6413 Test Method for Flame Resistance of Textiles (Ver-

1.1 This specification provides the requirements for mat-

tical Test)

tresses and box springs that are for use in berths for officers,

E 162 Test Method for Surface Flammability of Materials

crew, and passengers in marine vessels. This shall be consid-

Using a Radiant Heat Energy Source

ered a minimum standard.

E 176 Terminology of Fire Standards

1.2 The values stated in SI units are to be regarded as the

E 662 Test Method for Specific Optical Density of Smoke

standard.The values given in parentheses, in inch-pound units,

Generated by Solid Materials

are for information only.

E 1354 Test Method for Heat and Visible Smoke Release

1.3 This standard is used to measure and describe the

Rates for Materials and Products Using an Oxygen Con-

response of materials, products, or assemblies to heat and

sumption Calorimeter

flame under controlled conditions, but does not by itself

E 1590 Test Method for Fire Testing of Mattresses

incorporate all factors required for fire-hazard or fire-risk

F 1566 Test Methods for Evaluation of Innersprings and

assessment of the materials, products, or assemblies under

Boxsprings

actual fire conditions.

2.2 ANSI Standards:

1.4 This standard does not purport to address all of the

ANSI Z357.1-1981 American National Standard for Bed-

safety concerns, if any, associated with its use. It is the

ding Products and Components

responsibility of the user of this standard to establish appro-

ANSI/ASQC Z1.4 Sampling Procedures and Tables for In-

priate safety and health practices and determine the applica-

spection by Attributes

bility of regulatory limitations prior to use.

2.3 California Bureau of Home Furnishings and Thermal

2. Referenced Documents Insulation Standard:

CATechnical Bulletin 129, (CATB 129) FlammabilityTest

2.1 ASTM Standards:

Procedure for Mattresses for Use in Public Buildings—

D 123 Terminology Relating to Textiles

October 1992

D 1424 Test Method for Tearing Strength of Fabrics by

2.4 Federal Standards:

Falling-Pendulum Type (Elmendorf) Apparatus

Code of Federal Regulations Title 16, Vol 2, Part 1632

D 3574 TestMethodsforFlexibleCellularMaterials—Slab,

Purchase Description—Mattress—Innerspring, Flame-

Bonded, and Molded Urethane Foams

Resistant, Shipboard—NAVSEA 05L PD 4-02 (May

D 3951 Practice for Commercial Packaging

2002)

D 5034 Test Method for Breaking Strength and Elongation

of Textile Fabrics (Grab Test)

1 3

This specification is under the jurisdiction of ASTM Committee F25 on Ships Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on 4th Floor, New York, NY 10036, http://www.ansi.org.

Outfitting and Deck Machinery. Available from California Bureau of Home Furnishings and Thermal Insula-

Current edition approved Dec. 1, 2007. Published January 2008. Originally tion, 3483 Orange Grove Ave., North Highlands, CA 95660.

approved in 1988. Last previous edition approved in 2003 as F1085 - 03a. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.access.gpo.gov.

Standards volume information, refer to the standard’s Document Summary page on Available from Naval Sea Systems Command (NAVSEA), 1333 Isaac Hull

the ASTM website. Ave., SE, Washington, DC 20376, http://www.navsea.navy.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1085 – 03a (2007)

2.5 NFPA Standard: 4.1.3 Upholstery material selections are to be offered as

NFPA 301 Code for Safety to Life from Fire on Merchant choicesbythemanufacturerordistributortothepurchaser.The

Vessels selection shall be of good quality suitable for commercial use

and for use aboard U.S. Navy vessels.

3. Terminology

4.1.4 When first article of inspection is required, it shall be

3.1 Definitions—For definitions of terms used in this speci-

spelled out in the paperwork.

fication associated with textiles, see Terminology D 123. For

definitions of terms used in this specification associated with

5. Materials and Manufacture

fire issues, see Terminology E 176.

5.1 Innerspring Mattress—The essential components of an

3.2 Definitions of Terms Specific to This Standard:

innerspring mattress are: an innerspring core, cushioning,

3.2.1 border, n—a material that forms the side panel that

upholstery ticking (either quilted or with a smooth top, and

surrounds the perimeter of the mattress and defines its depth.

potentially including a flange), and a border. Optional compo-

3.2.2 box spring, n—a foundation for a mattress, consisting

nents include various insulating layers or pads, flanges, and

of wire spring elements mounted on a frame, generally

tapes. All materials used shall meet the mechanical property

upholstered and covered on the top and sides with ticking, and

and fire performance requirements of Table 1. All materials

on the bottom with a dust cover.

used shall comply with appropriate commercial bedding indus-

3.2.3 box spring assembly, n—an interconnection of coil

try standards of manufacture and durability. Any construction

springs, border wire, and top wire assembly contained within a

of an innerspring mattress that is suitable for its intended use

box spring.

and that complies with the performance requirements shown

3.2.4 flaming droplets, n—flaming molten or flaming lique-

herein shall be permitted to be used.

fied droplets which fall from the test specimen during the fire

5.1.1 Innerspring Core—The innerspring core shall be con-

test and continue to burn.

structed from an all-wire carbon steel. The coils shall extend

3.2.5 flange, n—strip of material secured to the perimeter of

the full length and width of the mattress. The coils shall be

an upholstery panel to secure to the innerspring core.

permanently secured to provide long-term structural stability.

3.2.6 innerspring unit, n—an interconnection of wire spring

Various core designs shall be permitted.The support properties

elements other than mounting on a frame that forms a single

of the innerspring core, in terms of firmness rating, durability,

unit that can be incorporated into a mattress.

resistance to impact, firmness retention, and surface deforma-

3.2.7 insulator pad, n—one or more layers of a cushioning

tion, shall be assessed by Test Methods F 1566. The coils, or

system between the upholstery and mattress core, which

the complete spring unit assembly, shall be given suitable

consist of foam or other cushioning or filling materials.

thermaltreatmenttorelieveresidualstressescausedbycoiling.

3.2.8 mattress, n—ticking filled with a resilient material

5.1.2 Cushioning and Insulator Layers—An insulator pad

used alone or in combination with other products intended or

shall be placed over each sleeping surface of the innerspring

promoted for sleeping upon.

core to insulate the upholstery from the core. The various

3.2.9 mattress core, n—the main support system that may

cushioning layers shall be constructed of materials that meet

be present in a mattress, such as springs, foam, or resilient

the performance requirements of Table 1.

filling.

5.1.3 Ticking and Cover Assembly—The cover construction

3.2.10 mattress, innerspring, n—any mattress containing an

shall be suitable for the type of mattress construction used.

innerspring unit.

Upholstery ticking materials shall be durable, per common

3.2.11 mattress, solid core, n—any mattress containing

bedding industry practices. The ticking for each sleeping

padding, but not an innerspring unit.

surface shall be cut in one piece without fabric splices. The

3.2.12 quilted, adj—stitched with any thread or by fusion

ticking for the mattress border shall be made of not more than

through the ticking and one or more layers of upholstery

two pieces of ticking, with the ends spliced and sewn together

material.

in a continuous manner leaving no gaps or voids in uniformity

3.2.13 tape edge, n—seam or border edge of a mattress.

and finish.The border assembly shall be secured to the top and

3.2.14 ticking, n—the outermost layer of fabric or related

bottom sleeping surfaces of the mattress, by automatic sewing,

material that encloses the core and upholstery materials of a

per common bedding industry practices.

mattress or mattress pad.

5.1.4 Border—The ticking for the mattress border shall be

made of not more than two pieces of ticking, with the ends

4. Ordering Information

spliced and sewn together in a continuous manner leaving no

4.1 Orders for items purchased under this specification shall

gaps or voids in uniformity and finish. The border assembly

define the following:

shall be secured to the top and bottom sleeping surfaces of the

4.1.1 Mattresses—Quantity,dimensionalrequirements,type

mattress, by automatic sewing, per common bedding industry

(solid core or innerspring), and weight per each size.

practices.

4.1.2 Box Springs—Quantity, dimensional requirements,

5.1.5 Tape—Atape shall be permitted to be used to conceal

and weight per each size.

the seams formed between the border, if present, and an

upholstery panel.The tape shall be continuously stitched along

the total length of each seam, with no gaps or voids between

Available from National Fire Protection Association (NFPA), 1 Batterymarch

Park, Quincy, MA 02269-9101. the upholstery panel and border surfaces.

F 1085 – 03a (2007)

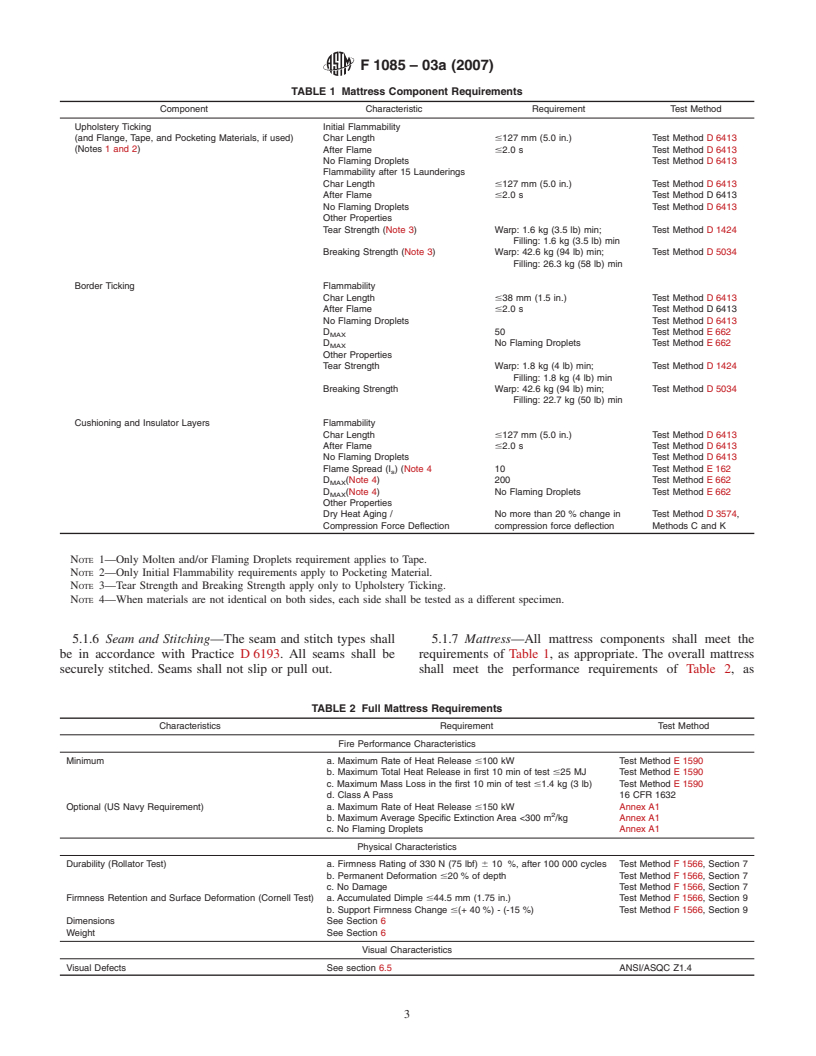

TABLE 1 Mattress Component Requirements

Component Characteristic Requirement Test Method

Upholstery Ticking Initial Flammability

(and Flange, Tape, and Pocketing Materials, if used) Char Length #127 mm (5.0 in.) Test Method D 6413

(Notes 1 and 2) After Flame #2.0 s Test Method D 6413

No Flaming Droplets Test Method D 6413

Flammability after 15 Launderings

Char Length #127 mm (5.0 in.) Test Method D 6413

After Flame #2.0 s Test Method D 6413

No Flaming Droplets Test Method D 6413

Other Properties

Tear Strength (Note 3) Warp: 1.6 kg (3.5 lb) min; Test Method D 1424

Filling: 1.6 kg (3.5 lb) min

Breaking Strength (Note 3) Warp: 42.6 kg (94 lb) min; Test Method D 5034

Filling: 26.3 kg (58 lb) min

Border Ticking Flammability

Char Length #38 mm (1.5 in.) Test Method D 6413

After Flame #2.0 s Test Method D 6413

No Flaming Droplets Test Method D 6413

D 50 Test Method E 662

MAX

D No Flaming Droplets Test Method E 662

MAX

Other Properties

Tear Strength Warp: 1.8 kg (4 lb) min; Test Method D 1424

Filling: 1.8 kg (4 lb) min

Breaking Strength Warp: 42.6 kg (94 lb) min; Test Method D 5034

Filling: 22.7 kg (50 lb) min

Cushioning and Insulator Layers Flammability

Char Length #127 mm (5.0 in.) Test Method D 6413

After Flame #2.0 s Test Method D 6413

No Flaming Droplets Test Method D 6413

Flame Spread (I)(Note 4 10 Test Method E 162

s

D (Note 4) 200 Test Method E 662

MAX

D (Note 4) No Flaming Droplets Test Method E 662

MAX

Other Properties

Dry Heat Aging / No more than 20 % change in Test Method D 3574,

Compression Force Deflection compression force deflection Methods C and K

NOTE 1—Only Molten and/or Flaming Droplets requirement applies to Tape.

NOTE 2—Only Initial Flammability requirements apply to Pocketing Material.

NOTE 3—Tear Strength and Breaking Strength apply only to Upholstery Ticking.

NOTE 4—When materials are not identical on both sides, each side shall be tested as a different specimen.

5.1.6 Seam and Stitching—The seam and stitch types shall 5.1.7 Mattress—All mattress components shall meet the

be in accordance with Practice D 6193. All seams shall be requirements of Table 1, as appropriate. The overall mattress

securely stitched. Seams shall not slip or pull out. shall meet the performance requirements of Table 2,as

TABLE 2 Full Mattress Requirements

Characteristics Requirement Test Method

Fire Performance Characteristics

Minimum a. Maximum Rate of Heat Release#100 kW Test Method E 1590

b. Maximum Total Heat Release in first 10 min of test#25 MJ Test Method E 1590

c. Maximum Mass Loss in the first 10 min of test#1.4 kg (3 lb) Test Method E 1590

d. Class A Pass 16 CFR 1632

Optional (US Navy Requirement) a. Maximum Rate of Heat Release#150 kW Annex A1

b. Maximum Average Specific Extinction Area <300 m /kg Annex A1

c. No Flaming Droplets Annex A1

Physical Characteristics

Durability (Rollator Test) a. Firmness Rating of 330 N (75 lbf) 6 10 %, after 100 000 cycles Test Method F 1566, Section 7

b. Permanent Deformation#20 % of depth Test Method F 1566, Section 7

c. No Damage Test Method F 1566, Section 7

Firmness Retention and Surface Deformation (Cornell Test) a. Accumulated Dimple#44.5 mm (1.75 in.) Test Method F 1566, Section 9

b. Support Firmness Change#(+ 40 %) - (-15 %) Test Method F 1566, Section 9

Dimensions See Section 6

Weight See Section 6

Visual Characteristics

Visual Defects See section 6.5 ANSI/ASQC Z1.4

F 1085 – 03a (2007)

discussed in Section 6. For dimensional requirements, see 6.6. 5.1.8 Label—The label shall state that the mattress meets

one of the following sets of fire test requirements: (1) this

5.1.7.1 Upholstery ticking, as well as any flange, tape, and

pocketing materials used, shall exhibit a char length not specification(perTable1andTable2),(2)CaliforniaTechnical

exceeding 127 mm (5.0 in.), an after flame period not exceed- Bulletin 129, or (3), Purchase Description—Mattress—

ing 2.0 s, and shall not exhibit any molten or flaming droplets, Innerspring, Flame-Resistant, Shipboard—NAVSEA 05L PD

or both, when tested in accordance with Test Method D 6413. 4-02 (May 2002).

The char length and after flame requirements shall not apply to

5.2 Solid Core Mattress—The required components of a

tape.

solid core mattress are cushioning and upholstery ticking.

5.1.7.2 Upholstery ticking, as well as any flange, tape, and

5.2.1 All materials used shall meet the mechanical property

pocketing materials used, shall exhibit a char length not

and fire performance requirements of Table 1, as indicated in

exceeding 127 mm (5.0 in.), an after flame period

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

e1

Designation:F1085–03 Designation: F 1085 – 03a (Reapproved 2007)

Standard Specification for

Mattress and Box Springs for Use in Berths in Marine

Vessels

This standard is issued under the fixed designation F 1085; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made throughout in May 2003.

1. Scope

1.1 This specification provides the requirements for mattresses and box springs that are for use in berths for officers, crew, and

passengers in marine vessels. This shall be considered a minimum standard.

1.2The values stated in inch-pound units are to be regarded as the standard (except where such units are not present, when

discussing fire test methods). The values given in parentheses, in SI units, are for information only.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses, in inch-pound units, are

for information only.

1.3 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D123 D 123 Terminology Relating to Textiles

D 1424 Test Method for Tearing Strength of Fabrics by Falling-Pendulum Type (Elmendorf) Apparatus

D3574Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams

D3951Practice for Commercial Packaging D 3574 Test Methods for Flexible Cellular MaterialsSlab, Bonded, and Molded

Urethane Foams

D 3951 Practice for Commercial Packaging

D5034D 5034 Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

D 6193 Practice for Stitches and Seams

D6413D 6413 Test Method for Flame Resistance of Textiles (Vertical Test)

E162E 162 Test Method for Surface Flammability of Materials Using a Radiant Heat Energy Source

E176Terminology of Fire Standards E 176 Terminology of Fire Standards

E662Test Method for Specific Optical Density of Smoke Generated by Solid Materials

F1566Test Methods for Evaluation of Innersprings and Box Springs E 662 Test Method for Specific Optical Density of Smoke

Generated by Solid Materials

E 1354 Test Method for Heat and Visible Smoke Release Rates for Materials and Products Using an Oxygen Consumption

Calorimeter

E1590 Test Method for Fire Testing of Mattresses E 1590 Test Method for Fire Testing of Mattresses

F 1566 Test Methods for Evaluation of Innersprings and Boxsprings

2.2 ANSI Standards:

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

Outfitting and Deck Machinery.

Current edition approved May 10, 2003. Published June 2003. Originally approved in 1988 and published as F1085–88. Discontinued December 2002 and reinstated as

e1

F1085–03 .

Current edition approved Dec. 1, 2007. Published January 2008. Originally approved in 1988. Last previous edition approved in 2003 as F1085 - 03a.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 07.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1085 – 03a (2007)

ANSI Z357.1-1981 American National Standard for Bedding Products and Components

ANSI/ASQC Z1.4 Sampling Procedures and Tables for Inspection by Attributes

2.3 California Bureau of Home Furnishings and Thermal Insulation Standard:

CA Technical Bulletin 129, (CA TB 129) Flammability Test Procedure for Mattresses for Use in Public Buildings—October

2.4 Federal Standards:

Code of Federal Regulations Title 16, Vol 2, Part 1632

Purchase Description—Mattress—Innerspring, Flame-Resistant, Shipboard—NAVSEA 05L PD 4-02 (May 2002)

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Annual Book of ASTM Standards, Vol 15.09.

Available from California Bureau of Home Furnishings and Thermal Insulation, 3483 Orange Grove Ave., North Highlands, CA 95660.

Annual Book of ASTM Standards, Vol 07.02.

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

Annual Book of ASTM Standards, Vol 04.07.

Available from Naval Sea Systems Command (NAVSEA), 1333 Isaac Hull Ave., SE, Washington, DC 20376, http://www.navsea.navy.mil.

F 1085 – 03a (2007)

2.5 NFPA Standard:

NFPA 301 Code for Safety to Life from Fire on Merchant Vessels

3. Terminology

3.1 Definitions—For definitions of terms used in this specification associated with textiles, see Terminology D 123. For

definitions of terms used in this specification associated with fire issues, see Terminology E 176.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 border, n—a material that forms the side panel that surrounds the perimeter of the mattress and defines its depth.

3.2.2 box spring, n—a foundation for a mattress, consisting of wire spring elements mounted on a frame, generally upholstered

and covered on the top and sides with ticking, and on the bottom with a dust cover.

3.2.3 box spring assembly, n—an interconnection of coil springs, border wire, and top wire assembly contained within a box

spring.

3.2.4 flaming droplets, n—drops of material exhibiting evidence of flames when falling from a test specimen and that continues

exhibiting evidence of flames for a period of at least 10 s. —flaming molten or flaming liquefied droplets which fall from the test

specimen during the fire test and continue to burn.

3.2.5 flange, n—strip of material secured to the perimeter of an upholstery panel to secure to the innerspring core.

3.2.6 innerspring unit, n—an interconnection of wire spring elements other than mounting on a frame that forms a single unit

that can be incorporated into a mattress.

3.2.7 insulator pad, n—one or more layers of a cushioning system between the upholstery and mattress core, which consist of

foam or other cushioning or filling materials.

3.2.8 mattress, n—tickingfilledwitharesilientmaterialusedaloneorincombinationwithotherproductsintendedorpromoted

for sleeping upon.

3.2.9 mattress core, n—the main support system that may be present in a mattress, such as springs, foam, or resilient filling.

3.2.10 mattress, innerspring, n—any mattress containing an innerspring unit.

3.2.11 mattress, solid core, n—any mattress containing padding, but not an innerspring unit.

3.2.12 quilted, adj—stitched with any thread or by fusion through the ticking and one or more layers of upholstery material.

3.2.13 tape edge, n—seam or border edge of a mattress.

3.2.14 ticking, n—the outermost layer of fabric or related material that encloses the core and upholstery materials of a mattress

or mattress pad.

4. Ordering Information

4.1 Orders for items purchased under this specification shall define the following:

4.1.1 Mattresses—Quantity, dimensional requirements, type (solid core or innerspring), and weight per each size.

4.1.2 Box Springs— Quantity, dimensional requirements, and weight per each size.

4.1.3 Upholstery material selections are to be offered as choices by the manufacturer or distributor to the purchaser. The

selection shall be of good quality suitable for commercial use and for use aboard U.S. Navy vessels.

4.1.4 When first article of inspection is required, it shall be spelled out in the paperwork.

5. Materials and Manufacture

5.1 Innerspring Mattress—Theessentialcomponentsofaninnerspringmattressare:aninnerspringcore,cushioning,upholstery

ticking(eitherquiltedorwithasmoothtop,andpotentiallyincludingaflange), andaborder. Optional componentsincludevarious

insulating layers or pads, flanges, and tapes. All materials used shall meet the mechanical property and fire performance

requirements of Table 1.All materials used shall comply with appropriate commercial bedding industry standards of manufacture

and durability. Any construction of an innerspring mattress that is suitable for its intended use and that complies with the

performance requirements shown herein shall be permitted to be used.

5.1.1 Innerspring Core—The innerspring core shall be constructed from an all-wire carbon steel.The coils shall extend the full

length and width of the mattress. The coils shall be permanently secured to provide long-term structural stability. Various core

designs shall be permitted. The support properties of the innerspring core, in terms of firmness rating, durability, resistance to

impact, firmness retention, and surface deformation, shall be assessed by Test Methods F 1566. The coils, or the complete spring

unit assembly, shall be given suitable thermal treatment to relieve residual stresses caused by coiling.

5.1.2 Cushioning and Insulator Layers— An insulator pad shall be placed over each sleeping surface of the innerspring core

to insulate the upholstery from the core.The various cushioning layers shall be constructed of materials that meet the performance

requirements of Table 1.

5.1.3 Ticking and Cover Assembly—The cover construction shall be suitable for the type of mattress construction used.

Upholstery ticking materials shall be durable, per common bedding industry practices. The ticking for each sleeping surface shall

Annual Book of ASTM Standards, Vol 15.07.

Available from National Fire Protection Association (NFPA), 1 Batterymarch Park, Quincy, MA 02269-9101.

F 1085 – 03a (2007)

TABLE 1 Mattress Component Requirements

Component Characteristic Requirement Test Method

Upholstery Ticking Initial Flammability

(and Flange, Tape, and Pocketing Materials, if used) Char Length #5.0 in. (127 mm) Test Method D 6413

(Notes 1 and 2) After Flame #2.0 s Test Method D 6413

No Flaming Droplets Test Method D 6413

Flammability after 15 Launderings

Char Length #5.0 in. (127 mm) Test Method D 6413

After Flame #2.0 s Test Method D 6413

No Flaming Droplets Test Method D 6413

Other Properties

Tear Strength (Note 3) Warp:3.5 lb min; Test Method D 1424

Filling:3.5 lb min

Tear Strength (Note 3) Warp: 1.6 kg (3.5 lb) min; Test Method D 1424

Filling: 1.6 kg (3.5 lb) min

Breaking Strength (Note 3) Warp:94 lb min; Test Method D 5034

Filling:58 lb min

Breaking Strength (Note 3) Warp: 42.6 kg (94 lb) min; Test Method D 5034

Filling: 26.3 kg (58 lb) min

Border Ticking Flammability

Char Length #1.5 in. (138 mm) Test Method D 6413

After Flame #2.0 s Test Method D 6413

No Flaming Droplets Test Method D 6413

D 50 Test Method E 662

MAX

D No Flaming Droplets Test Method E 662

MAX

Other Properties

Tear Strength Warp:4 lb min; Test Method D 1424

Filling:4 lb min

Tear Strength Warp: 1.8 kg (4 lb) min; Test Method D 1424

Filling: 1.8 kg (4 lb) min

Breaking Strength Warp:94 lb min; Test Method D 5034

Filling:50 lb min

Breaking Strength Warp: 42.6 kg (94 lb) min; Test Method D 5034

Filling: 22.7 kg (50 lb) min

Cushioning and Insulator Layers Flammability

Char Length #5.0 in. (127 mm) Test Method D 6413

After Flame #2.0 s Test Method D 6413

No Flaming Droplets Test Method D 6413

Flame Spread (I ) (Note 4 10 Test Method E 162

s

D (Note 4) 200 Test Method E 662

MAX

D (Note 4) No Flaming Droplets Test Method E 662

MAX

Other Properties

Dry Heat Aging / No more than 20 % change in Test Method D 3574,

Compression Force Deflection compression force deflection Methods C and K

NOTE 1—Only Molten and/or Flaming Droplets requirement applies to Tape.

NOTE 2—Only Initial Flammability requirements apply to Pocketing Material.

NOTE 3—Tear Strength and Breaking Strength apply only to Upholstery Ticking.

NOTE 4—When materials are not identical on both sides, each side shall be tested as a different specimen.

be cut in one piece without fabric splices.The ticking for the mattress border shall be made of not more than two pieces of ticking,

with the ends spliced and sewn together in a continuous manner leaving no gaps or voids in uniformity and finish. The border

assembly shall be secured to the top and bottom sleeping surfaces of the mattress, by automatic sewing, per common bedding

industry practices.

5.1.4 Border—The ticking for the mattress border shall be made of not more than two pieces of ticking, with the ends spliced

and sewn together in a continuous manner leaving no gaps or voids in uniformity and finish.The border assembly shall be secured

to the top and bottom sleeping surfaces of the mattress, by automatic sewing, per common bedding industry practices.

5.1.5 Tape—Atape shall be permitted to be used to conceal the seams formed between the border, if present, and an upholstery

panel. The tape shall be continuously stitched along the total length of each seam, with no gaps or voids between the upholstery

panel and border surfaces.

5.1.6 Seam and Stitching—The seam and stitch types shall be in accordance with Practice D 6193.All seams shall be securely

stitched. Seams shall not slip or pull out.

5.1.7 Mattress—AllmattresscomponentsshallmeettherequirementsofTable1,asappropriate.Theoverallmattressshallmeet

the performance requirements of Table 2, as discussed in Section 6. For dimensional requirements, see 6.6.

5.1.7.1 Upholstery ticking, as well as any flange, tape, and pocketing materials used, shall exhibit a char length not exceeding

5.0 in. (127 mm),127 mm (5.0 in.), an after flame period not exceeding 2.0 s, and shall not exhibit any molten or flaming droplets,

or both, when tested in accordance withTest Method D 6413.The char length and after flame requirements shall not apply to tape.

5.1.7.2 Upholstery tickin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.