ASTM D7207-05

(Test Method)Standard Test Method for Determination of Unvegetated Rolled Erosion Control Product (RECP) Ability to Protect Sand from Hydraulically-Induced Shear Stresses under Bench-Scale Conditions (Withdrawn 2014)

Standard Test Method for Determination of Unvegetated Rolled Erosion Control Product (RECP) Ability to Protect Sand from Hydraulically-Induced Shear Stresses under Bench-Scale Conditions (Withdrawn 2014)

SIGNIFICANCE AND USE

This index test method indicates an unvegetated RECP’s ability to reduce soil erosion caused by shear stress induced by moving water under bench-scale conditions. Only tangential shear is measured in this method. Radial and uplift forces generated by the circular motion of the water are not measured.

This test method is bench-scale and therefore, appropriate as an index test for general soil/product composite behavior under hydraulic shear conditions, and for product quality assurance/conformance testing. The results of this test shall not be interpreted as indicative of field performance.

SCOPE

1.1 This index test method establishes the guidelines, requirements and procedures for evaluating the ability of unvegetated Rolled Erosion Control Products (RECPs) to protect soil (sand) from hydraulically induced shear stress in a bench-scale apparatus.

1.2 This index test method utilizes bench-scale testing procedures and shall not be interpreted as indicative of field performance.

1.3 This index test is not intended to replace full-scale simulation or field testing in acquisition of performance values that are required in the design of erosion control measures utilizing unvegetated RECPs.

1.4 The values stated in SI units are to be regarded as standard. The inch-pound values given in parentheses are provided for information purposes only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This index test method establishes the guidelines, requirements and procedures for evaluating the ability of unvegetated Rolled Erosion Control Products (RECPs) to protect soil (sand) from hydraulically induced shear stress in a bench-scale apparatus.

Formerly under the jurisdiction of Committee D18 on Soil and Rock, this test method was withdrawn in February 2014 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7207 − 05

StandardTest Method for

Determination of Unvegetated Rolled Erosion Control

Product (RECP) Ability to Protect Sand from Hydraulically-

Induced Shear Stresses under Bench-Scale Conditions

This standard is issued under the fixed designation D7207; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6460 Test Method for Determination of Rolled Erosion

Control Product (RECP) Performance in Protecting

1.1 This index test method establishes the guidelines, re-

Earthen Channels from Stormwater-Induced Erosion

quirements and procedures for evaluating the ability of unveg-

etated Rolled Erosion Control Products (RECPs) to protect soil

3. Terminology

(sand) from hydraulically induced shear stress in a bench-scale

3.1 For definitions of terms used in this method, see

apparatus.

Terminology D653.

1.2 This index test method utilizes bench-scale testing

procedures and shall not be interpreted as indicative of field

4. Summary of Test Method

performance.

4.1 Soil cores consisting of containers with bare soil and/or

1.3 This index test is not intended to replace full-scale

RECP-protected soil are immersed in water and subjected to

simulation or field testing in acquisition of performance values

shear stresses caused by the rotation of an impeller with three

that are required in the design of erosion control measures

blades. At a minimum, testing of containers with bare soil

utilizing unvegetated RECPs.

should be performed when a new or renewed soil stockpile is

1.4 The values stated in SI units are to be regarded as used.

standard. The inch-pound values given in parentheses are

4.2 The amount of soil that erodes at each of three shear

provided for information purposes only.

stress levels is measured.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 ThisindextestmethodindicatesanunvegetatedRECP’s

priate safety and health practices and determine the applica-

ability to reduce soil erosion caused by shear stress induced by

bility of regulatory limitations prior to use.

moving water under bench-scale conditions. Only tangential

shear is measured in this method. Radial and uplift forces

2. Referenced Documents

generatedbythecircularmotionofthewaterarenotmeasured.

2.1 ASTM Standards:

5.2 This test method is bench-scale and therefore, appropri-

D653 Terminology Relating to Soil, Rock, and Contained

ate as an index test for general soil/product composite behavior

Fluids

under hydraulic shear conditions, and for product quality

D698 Test Methods for Laboratory Compaction Character-

assurance/conformance testing.The results of this test shall not

istics of Soil Using Standard Effort (12 400 ft-lbf/ft (600

be interpreted as indicative of field performance.

kN-m/m ))

D4354 Practice for Sampling of Geosynthetics for Testing

6. Apparatus

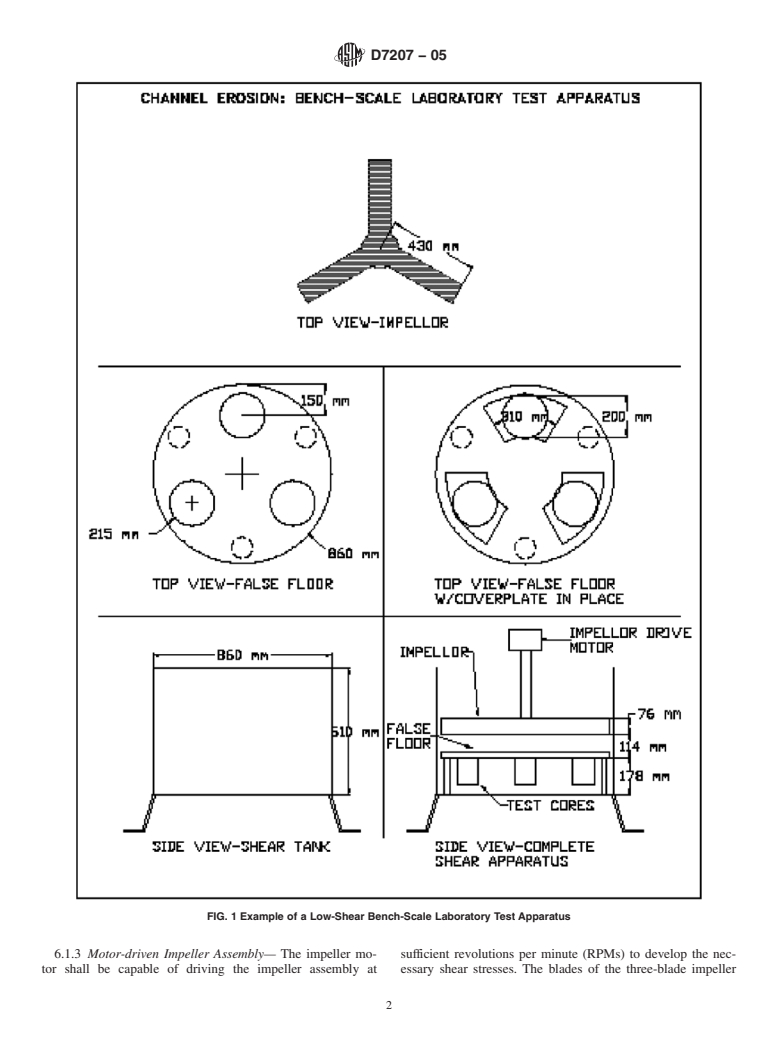

6.1 The shear stress test apparatus includes a shear tank,

false floor with test wells, transition cover plate, and motor-

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

driven impeller. (See Fig. 1.)

Rock and is the direct responsibility of Subcommittee D18.25 on Erosion and

6.1.1 Shear Tank—A cylindrical tank of sufficient diameter

Sediment Control Technology.

anddepthtodevelopthedesiredshearlevels.(SeeFig.1foran

Current edition approved Nov. 1, 2005. Published December 2005. DOI:

10.1520/D7207-05.

example.)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.2 False Floor—A false floor shall be positioned in the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tank with at least three test wells cut into the false floor to hold

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. soil cores. When soil cores are placed in the wells, the soil

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7207 − 05

surfaces must be flush with the false floor surface. (See Fig. 1.)

D7207 − 05

FIG. 1 Example of a Low-Shear Bench-Scale Laboratory Test Apparatus

6.1.3 Motor-driven Impeller Assembly— The impeller mo- sufficient revolutions per minute (RPMs) to develop the nec-

tor shall be capable of driving the impeller assembly at essary shear stresses. The blades of the three-blade impeller

D7207 − 05

level during weighing.Asimilar weighing is done at the end of the test to

must be sufficiently long enough to extend to within 25 mm (1

facilitate the determination of soil loss during the test.

in.) of the side of the tank. The impeller is mounted in the tank

so that the lower edge of the blades is 115 mm 6 1 cm (4.5 6

8.2.1.3 Calculate the Submerged Mass of the Soil (SM)in

s

0.4 in.) above the false floor of the tank in which the test cores

each core by subtracting the submerged weight of the empty

are seated during testing. (See Fig. 1.)The apparatus should be

core from the submerged weight of the soil-filled core and

capable of producing shear stresses in 24 Pascal (pa) (0.5

record to 60.01 g.

pounds/square foot (psf)) increments below, near, and above

8.2.1.4 Calculate the Core linear Density (C ) by dividing

d

expected target shear stress levels.

the SM by the unit length of the core and record in g/mm).

s

NOTE 1—The shear stress apparatus shown in Fig. 1 has been found

8.3 Test Operation and Data Collection :

sufficient for achieving shear stresses between 24 and 72 pa (0.5 and 1.5

psf) usinga2hp motor on many degradable RECPs. A larger tank, 1.83

8.3.1 Place three prepared and weighed soil cores in the test

m (6 ft) diameter with 0.6 (2 ft) depth of water over the pots has been able

wells of the false floor.When soil cores are placed in the wells,

to achieve shear stresses as high as 0.4 kPa (8 psf) on rough RECPs.

the soil surfaces must be flush with the false floor surface.

6.1.4 Soil Cores—Consist of water-tight containers nomi-

8.3.2 ForRECPtesting,placetheRECPovertheentirefalse

nally 200 6 10 mm (8 6 0.4 in.) inside diameter plastic pipe

floor and hold it in place on the soil core surfaces by covering

section cylinders with height of 100 6 10 mm (4 6 0.4 in.)

it with a 1.0 mm (0.038 in.) cover plate. The cover plate shall

holding soil and test specimens.

have arc or trapezoidal-shaped openings approximately equal

7. Sampling

to the diameter of the test cores in width (the radial direction)

and approximately 75 mm (3.0 in.) larger in length (both

7.1 Take lot samples as directed in Practice D4354. The

2 2

upstream and downstream circumferentially) than the diameter

laboratory sample should be at least 2 m (6.5 ft ).

of the test cores to completely expose the protected soil

7.2 Cut a single semi-circular specimen having a diameter

surfaces of the cores. (See Fig. 1.) Firmly secure the cover

50 mm (2 in.) less than the tank diameter from the roll sample.

plate to the false floor to prevent the RECP from being pulled

This should be of sufficient size to cover half of the entire false

out from beyond the exposed surface. The specimen should be

floor and three soil cores when seated in the test wells. If a

marked to facilitate identification of any slippage from beneath

sufficiently large sample is not available, smaller specimens

the cover plate. Any slippage shall be noted.

may be used as long as they completely cover the soil pot and

8.3.3 Fill the tank with water so that the impeller blades are

extend far enough under the cover plate to be firmly secured so

covered.Aline should designate the initial height of water. Fill

as not to pull free under anticipated shear forces.

in such a way that the water does not disturb the surface of the

8. Procedure

RECP/soil.

8.1 Calibration of Test Apparatus :

8.3.4 Activate the shear stress apparatus to rotate the impel-

8.1.1 Calibration of the apparatus determines the impeller

ler assembly at the RPM level determined from the calibration

motor setting and associated revolutions per minute that exerts

procedures necessary to achieve the target shear stress. Unless

thedesiredtractiveforceonthetestsurfaces.SeeAnnexA1for

otherwise agreed to between the testing laboratory and user of

calibration guidance.

the test, the RECP / bare soil control cores shall be subjected

8.1.2 At a minimum, calibration should be conducted for

to a minimum of three flow tests at three different shear stress

each RECP tested and each time a new soil stockpile is used.

levels to encompass the shear stress at which 13 mm (0.5 in.)

of soil loss will occur in the test cores.

8.2 Test Set-up:

8.2.1 Prepare nine soil cores for each RECPto be tested and

NOTE 4—Commonly in channel erosion testing, 13 mm (0.5 in.) of soil

nine bare-soil control cores.

loss is considered a point of maximum allowable soil loss. Therefore, it is

8.2.1.1 Fill and compact the cores flush with soil. Unless

recommended that the first test run be at a shear stress level sufficient to

otherwise requested, compact soil to 90 6 3 % of Standard

invoke approximately 13 mm (0.5 in.) of soil loss from the soil core. This

may be accomplished by selecting a shear stress at or near the RECP’s

Proctor densi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.