ASTM F2084/F2084M-01(2012)e1

(Guide)Standard Guide for Collecting Containment Boom Performance Data in Controlled Environments

Standard Guide for Collecting Containment Boom Performance Data in Controlled Environments

SIGNIFICANCE AND USE

This guide defines a series of test methods to determine the oil containment effectiveness of containment booms when they are subjected to a variety of towing and wave conditions. The test methods measure the tow speed at which the boom first loses oil (both in calm water and in various wave conditions), the tow speed at which the boom reaches a gross oil loss condition (both in calm water and in various wave conditions), boom conformance to the surface wave conditions for various wave heights, wavelengths and frequencies, (qualitatively), resulting tow forces when encountering various speeds and wave conditions, identifies towing ability at high speeds in calm water and waves, boom sea-worthiness relative to its hardware (i.e., connectors, ballast members), and general durability.

Users of this guide are cautioned that the ratio of boom draft to tank depth can affect test results, in particular the tow loads (see Appendix X1 discussion).

Other variables such as ease of repair and deployment, required operator training, operator fatigue, and transportability also affect performance in an actual spill but are not measured in this guide. These variables should be considered along with the test data when making comparisons or evaluations of containment booms.

SCOPE

1.1 This guide covers the evaluation of the effectiveness of full-scale oil spill containment booms in a controlled test facility.

1.2 This guide involves the use of specific test oils that may be considered hazardous materials. It is the responsibility of the user of this guide to procure and abide by the necessary permits for disposal of the used test oil.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F2084/F2084M − 01 (Reapproved 2012)

Standard Guide for

Collecting Containment Boom Performance Data in

Controlled Environments

ThisstandardisissuedunderthefixeddesignationF2084/F2084M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made in Sections 4, 7, 11, and Table 2 in June 2012.

1. Scope ucts by Hydrometer Method

D1796 Test Method for Water and Sediment in Fuel Oils by

1.1 This guide covers the evaluation of the effectiveness of

the Centrifuge Method (Laboratory Procedure)

full-scale oil spill containment booms in a controlled test

D2983 Test Method for Low-Temperature Viscosity of Lu-

facility.

bricants Measured by Brookfield Viscometer

1.2 This guide involves the use of specific test oils that may

D4007 Test Method forWater and Sediment in Crude Oil by

be considered hazardous materials. It is the responsibility of

the Centrifuge Method (Laboratory Procedure)

the user of this guide to procure and abide by the necessary

D4052 Test Method for Density, Relative Density, and API

permits for disposal of the used test oil.

Gravity of Liquids by Digital Density Meter

1.3 The values stated in either SI units or inch-pound units F631 Guide for Collecting Skimmer Performance Data in

are to be regarded separately as standard. The values stated in Controlled Environments

F818 Terminology Relating to Spill Response Barriers

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance 3. Terminology

with the standard.

3.1 Boom Performance Data Terminology—Terms associ-

1.4 This standard does not purport to address all of the

ated with boom performance tests conducted in controlled

safety concerns, if any, associated with its use. It is the

environments:

responsibility of the user of this standard to establish appro-

3.1.1 boom submergence (aka submarining)—containment

priate safety and health practices and determine the applica-

failure due to loss of freeboard.

bility of regulatory requirements prior to use.

3.1.2 first-loss tow/current velocity—minimum tow/current

velocity normal to the membrane at which oil continually

2. Referenced Documents

2 escapes past a boom This applies to the boom in the catenary

2.1 ASTM Standards:

position.

D97 Test Method for Pour Point of Petroleum Products

D445 Test Method for Kinematic Viscosity of Transparent 3.1.3 gross loss tow/current velocity—theminimumspeedat

and Opaque Liquids (and Calculation of Dynamic Viscos- which massive continual oil loss is observed escaping past the

ity) boom.

D971 Test Method for Interfacial Tension of Oil Against

3.1.4 harbor chop—a condition of the water surface pro-

Water by the Ring Method

duced by an irregular pattern of waves.

D1298 Test Method for Density, Relative Density, or API

3.1.5 preload—during testing, the quantity of test fluid

Gravity of Crude Petroleum and Liquid Petroleum Prod-

distributed in front of and contained by the boom prior to the

onset of a test.

This guide is under the jurisdiction of ASTM Committee F20 on Hazardous

3.1.6 tow speed—the relative speed difference between a

Substances and Oil Spill Responseand is the direct responsibility of Subcommittee

F20.11 on Control.

boom and the water in which the boom is floating. In this

Current edition approved May 1, 2012. Published June 2012. Originally

standard guide relative current speed is equivalent.

ε2

approved in 2001. Last previous edition approved in 2007 as F2084 – 01(2007) .

DOI: 10.1520/F2084_F2084M-01R12E01.

3.1.7 wave height—(significant wave height) the average

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

height, measured crest to trough, of the one-third highest

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

waves, considering only short-period waves (i.e., period less

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. than 10 s).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2084/F2084M − 01 (2012)

3.1.8 wave period—(significant wave period) the average 6.2 Ancillary systems for facilities include, but are not

period of the one-third highest waves, measured as the elapsed limited to a distribution system for accurately delivering test

time between crests of succeeding waves. fluids to the water surface, skimming systems to assist in

cleaning the facility between tests, and adequate tankage for

4. Significance and Use

storing the test fluids.

4.1 This guide defines a series of test methods to determine

7. Test Configuration and Instrumentation

the oil containment effectiveness of containment booms when

they are subjected to a variety of towing and wave conditions.

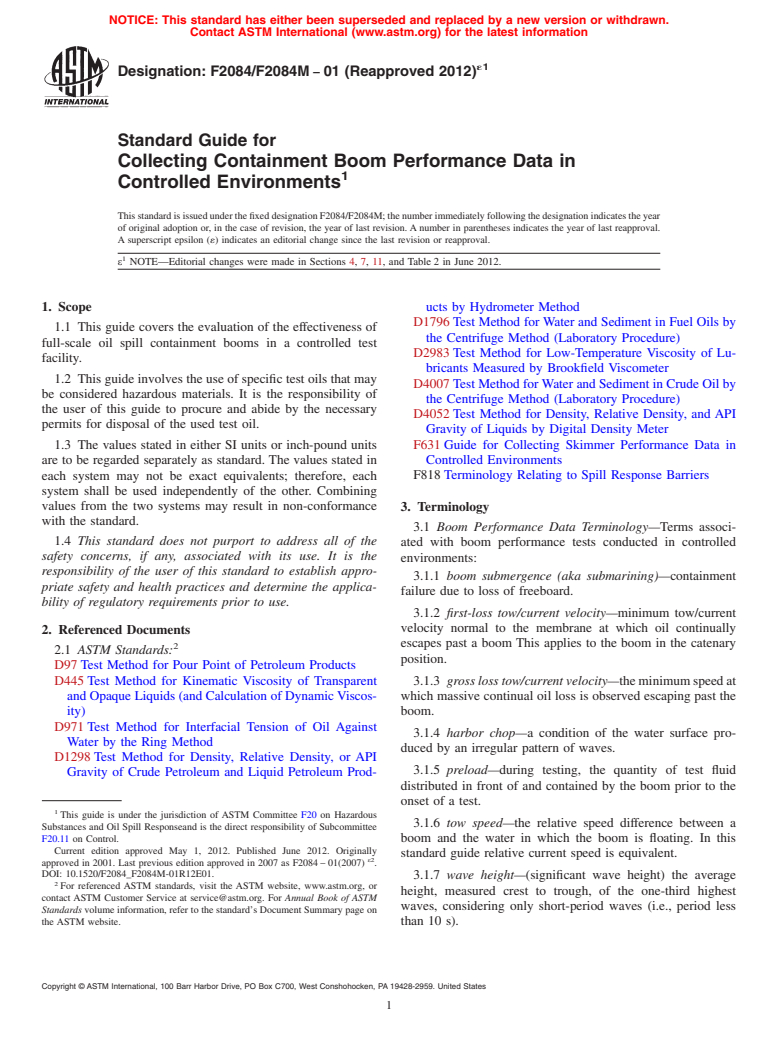

7.1 The boom should be rigged in a catenary configuration,

The test methods measure the tow speed at which the boom

with the gap equal to 33 % of the length; or boom gap-to-

first loses oil (both in calm water and in various wave

lengthratioof1:3.Towingbridlesaregenerallysuppliedbythe

conditions), the tow speed at which the boom reaches a gross

manufacturer for both ends of the boom which provide

oil loss condition (both in calm water and in various wave

attachmentpointsfortowing(Fig.1).Ateachendoftheboom,

conditions), boom conformance to the surface wave conditions

the towing apparatus shall be joined to the tow bridle or tow

for various wave heights, wavelengths and frequencies,

lead by a single point only. Boom towing force should be

(qualitatively), resulting tow forces when encountering various

measured with in-line load cells positioned between the boom

speeds and wave conditions, identifies towing ability at high

towing bridles and tow points.

speeds in calm water and waves, boom sea-worthiness relative

7.2 Preload oil should be pumped directly into the boom

to its hardware (i.e., connectors, ballast members), and general

apex.

durability.

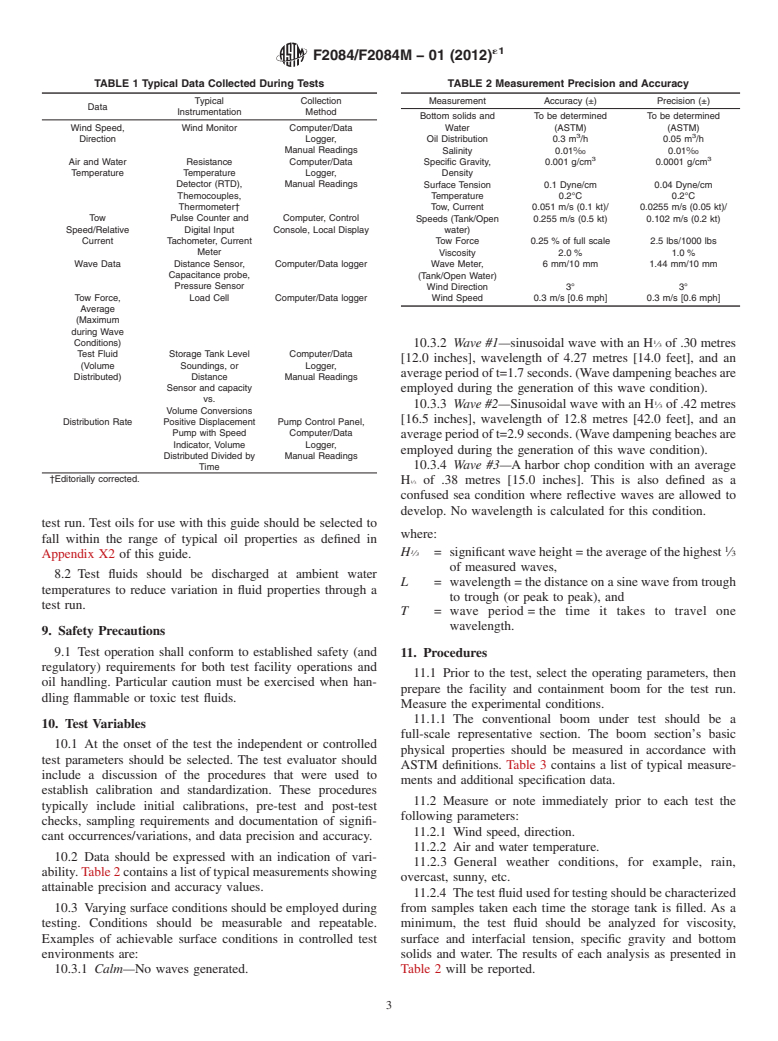

7.3 Data obtained during each test should include electroni-

4.2 Users of this guide are cautioned that the ratio of boom

cally collected data and manually collected data. Oil and water

draft to tank depth can affect test results, in particular the tow

propertydatashouldbebasedonfluidsamplesobtainedduring

loads (see Appendix X1 discussion).

the test period. Recommended data to be collected during

4.3 Other variables such as ease of repair and deployment,

testing, along with the method of collection, is listed in Table

required operator training, operator fatigue, and transportabil-

1.

ity also affect performance in an actual spill but are not

measured in this guide. These variables should be considered

8. Test Fluids

along with the test data when making comparisons or evalua-

8.1 Test fluids may be crude, refined, or simulated, but

tions of containment booms.

should be stable and have properties that do not vary during a

5. Summary of Guide

5.1 This guide provides standardized procedures for evalu-

ating any boom system and provides an evaluation of a

particular boom’s attributes in different environmental condi-

tionsandtheabilitytocomparetestresultsofaparticularboom

type with others having undergone these standard tests.

5.2 The maximum wave and tow speeds at which any boom

can effectively gather and contain oil are known as boundary

conditions. Booms that cannot maintain their design draft,

freeboard, profile, and buoyancy at these conditions may be

less effective. The boundary conditions depend on the charac-

teristics of oil viscosity, oil/water interfacial tension and

oil/water density gradient.

6. Test Facilities

6.1 Severaltypesoftestfacilitiescanbeusedtoconductthe

tests outlined in this guide:

6.1.1 Wave/Tow Tank—A wave/tow tank has a movable

bridge or other mechanism for towing the test device through

water for the length of the facility. A wave generator may be

installed on one end, or on the side of the facility, or both.

6.1.2 Current Tank—A current tank is a water-filled tank

equipped with a pump or other propulsion system for moving

the water through a test section where the test device is

mounted.Awavegeneratormaybeinstalledonthistypeoftest

facility.

6.1.3 Other facilities, such as private ponds or flumes, may

also be used, provided the test parameters can be suitably

controlled. FIG. 1 Typical Boom Test Setup in Tank

´1

F2084/F2084M − 01 (2012)

TABLE 1 Typical Data Collected During Tests TABLE 2 Measurement Precision and Accuracy

Typical Collection Measurement Accuracy (±) Precision (±)

Data

Instrumentation Method

Bottom solids and To be determined To be determined

Wind Speed, Wind Monitor Computer/Data Water (ASTM) (ASTM)

3 3

Direction Logger, Oil Distribution 0.3 m /h 0.05 m /h

0 0

Manual Readings Salinity 0.01 ⁄00 0.01 ⁄00

3 3

Air and Water Resistance Computer/Data

Specific Gravity, 0.001 g/cm 0.0001 g/cm

Temperature Temperature Logger, Density

Detector (RTD), Manual Readings

Surface Tension 0.1 Dyne/cm 0.04 Dyne/cm

Themocouples, Temperature 0.2°C 0.2°C

Thermometer†

Tow, Current 0.051 m/s (0.1 kt)/ 0.0255 m/s (0.05 kt)/

Tow Pulse Counter and Computer, Control Speeds (Tank/Open 0.255 m/s (0.5 kt) 0.102 m/s (0.2 kt)

Speed/Relative Digital Input Console, Local Display

water)

Current Tachometer, Current Tow Force 0.25 % of full scale 2.5 lbs/1000 lbs

Meter

Viscosity 2.0 % 1.0 %

Wave Data Distance Sensor, Computer/Data logger Wave Meter, 6 mm/10 mm 1.44 mm/10 mm

Capacitance probe,

(Tank/Open Water)

Pressure Sensor Wind Direction 3° 3°

Tow Force, Load Cell Computer/Data logger

Wind Speed 0.3 m/s [0.6 mph] 0.3 m/s [0.6 mph]

Average

(Maximum

during Wave

Conditions)

10.3.2 Wave #1—sinusoidal wave with an H ⁄3 of .30 metres

Test Fluid Storage Tank Level Computer/Data

[12.0 inches], wavelength of 4.27 metres [14.0 feet], and an

(Volume Soundings, or Logger,

averageperiodoft=1.7seconds.(Wavedampeningbeachesare

Distributed) Distance Manual Readings

Sensor and capacity

employed during the generation of this wave condition).

vs.

10.3.3 Wave #2—Sinusoidal wave with an H ⁄3 of .42 metres

Volume Conversions

[16.5 inches], wavelength of 12.8 metres [42.0 feet], and an

Distribution Rate Positive Displacement Pump Control Panel,

Pump with Speed Computer/Data

averageperiodoft=2.9seconds.(Wavedampeningbeachesare

Indicator, Volume Logger,

employed during the generation of this wave condition).

Distributed Divided by Manual Readings

10.3.4 Wave #3—A harbor chop condition with an average

Time

†Editorially corrected.

H ⁄3 of .38 metres [15.0 inches]. This is also defined as a

confused sea condition where reflective waves are allowed to

develop. No wavelength is calculated for this condition.

test run. Test oils for use with this guide should be selected to

where:

fall within the range of typical oil properties as defined in

H ⁄3 = significantwaveheight = theaverageofthehighest ⁄3

Appendix X2 of this guide.

of measured waves,

8.2 Test fluids should be discharged at ambient water

L = wavelength = thedistanceonasinewavefromtrough

temperatures to reduce variation in fluid properties through a

to trough (or peak to peak), and

test run.

T = wave period = the time it takes to travel one

wavelength.

9. Safety Precautions

9.1 Test operation shall conform to established safety (and

11. Procedures

regulatory) requirements for both test facility operations and

11.1 Prior to the test, select the operating parameters, then

oil handling. Particular caution must be exercised when han-

prepare the facility and containment boom for the test run.

dling flammable or toxic test fluids.

Measure the experimental conditions.

11.1.1 The conventional boom under test should be a

10. Test Variables

full-scale representative section. The boom section’s basic

10.1 At the onset of the test the independent or controlled

physical properties should be measured in accordance with

test parameters should be selected. The test evaluator should

ASTM definitions. Table 3 contains a list of typical measure-

include a discussion of the procedures that were used to

ments and additional specification data.

establish calibration and standardization. These procedures

11.2 Measure or note immediately prior to each test the

typically include initial calibrations, pre-test and post-test

following parameters:

checks, sampling requirements and documentation of signifi-

11.2.1 Wind speed, direction.

cant occurrences/variations, and data precision and accuracy.

11.2.2 Air and water temperature.

10.2 Data should be expressed with an indication of vari-

11.2.3 General weather conditions, for example, rain,

ability.Table2containsalistoftypicalmeasurementsshowing

overcast, sunny, etc.

attainable precision and accuracy values.

11.2.4 Thetestfluidusedfortestingshouldbecharacterized

10.3 Varying surface conditions should be employed during from samples taken each time the storage tank is filled. As a

testing. Conditions should be measurable and repeatable. minimum, the test fluid should be analyzed for viscosity,

Examples of achievable surface conditions in controlled test surface and interfacial tension, specific gravity and bottom

environments are: solids and water. The results of each analysis as presented in

10.3.1 Calm—No waves generated. Table 2 will be reported.

´1

F2084/F2084M − 01 (2012)

TABLE 3 Typical Basic Physical Properties TABLE 4 Typical Test Schedule

Specification Data Preload

Tow Speed Wave

As reported by As measured by Test No. Test Type Volume

Measurement (kts) Conditions

Manufacturer Tester (gallons)

Boom Type Fence, curtain, fire containment, other 1 Dry Run 1 calm N/A

Length m [ft] Standard section length, total rigged section 2 Preload variable calm 60

3 Preload variable calm 120

Height mm [in] Standard section height

Freeboard mm [in] Distance above water line 4 Preload variable calm 180

Draft mm [in] Distance below water line 5 Preload variable calm 240

Weight of Section Boom Fabric Type (freeboard and skirt material) 6 Preload variable calm 300

kg/m [lb/ft] and Tensile Strength Characteristics 7 Preload variable calm 360

Ballast Bottom Tension Member Type/Break 8 Preload variable calm 420

Ballast Length m [ft]

A

Strength and Length 9 Gross Loss variable calm determined

Ballast Weight kg/m during

Chain, cable or weights

[lb/ft] Preload test

Gross Buoyancy Flotation/Buoyancy Type (Air inflatable/foam) 10 1st & Gross variable calm determined

Buoyancy to Weight Calculated/Measured (Method shall be Loss Speeds during

Ratio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.