ASTM D2625-20

(Test Method)Standard Test Method for Endurance (Wear) Life and Load-Carrying Capacity of Solid Film Lubricants (Falex Pin and Vee Method)

Standard Test Method for Endurance (Wear) Life and Load-Carrying Capacity of Solid Film Lubricants (Falex Pin and Vee Method)

SIGNIFICANCE AND USE

5.1 This test method differentiates between bonded solid lubricants with respect to their wear life and load-carrying capacity. If the test conditions are changed, wear life may change and relative ratings of the bonded solid film lubricants may be different.

SCOPE

1.1 This test method (see Note 1) covers the determination of the endurance (wear) life and load-carrying capacity of dry solid film lubricants in sliding steel-on-steel applications.

Note 1: Reference may be made to Coordinating Research Council, Inc. (CRC) Report No. 419, “Development of Research Technique for Measuring Wear Life of Bonded Solid Lubricant Coatings for Airframes, Using the Falex Tester.” See also SAE Aerospace Standard AS5272.

1.2 The values stated in SI units are to be regarded as the standard except where equipment is supplied using inch-pound units and would then be regarded as standard. The metric equivalents of inch-pound units given in such cases in the body of the standard may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2625 − 20

Standard Test Method for

Endurance (Wear) Life and Load-Carrying Capacity of Solid

1

Film Lubricants (Falex Pin and Vee Method)

This standard is issued under the fixed designation D2625; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* and Shapes for Use in Screw Machines

F22Test Method for Hydrophobic Surface Films by the

1.1 This test method (see Note 1) covers the determination

Water-Break Test

of the endurance (wear) life and load-carrying capacity of dry

3

2.2 U.S. Military Specifications:

solid film lubricants in sliding steel-on-steel applications.

MIL-DTL-16232PhosphateCoatings,Heavy,Manganeseor

NOTE 1—Reference may be made to Coordinating Research Council,

Zinc Base

Inc. (CRC) Report No. 419, “Development of Research Technique for

2.3 Other Standards:

Measuring Wear Life of Bonded Solid Lubricant Coatings forAirframes,

4

42USC7671aClean Air Act Amendments of 1990

Using the Falex Tester.” See also SAE Aerospace Standard AS5272.

SAE AS5272Lubricant, Solid Film, Heat Cured, Corrosion

1.2 The values stated in SI units are to be regarded as the

5

Inhibiting, Procurement Specification

standardexceptwhereequipmentissuppliedusinginch-pound

units and would then be regarded as standard. The metric

3. Terminology

equivalentsofinch-poundunitsgiveninsuchcasesinthebody

3.1 Definitions:

of the standard may be approximate.

3.1.1 dry solid film lubricants, n—drycoatingsconsistingof

1.3 This standard does not purport to address all of the

lubricating powders in a solid matrix bonded to one or both

safety concerns, if any, associated with its use. It is the

surfaces to be lubricated.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

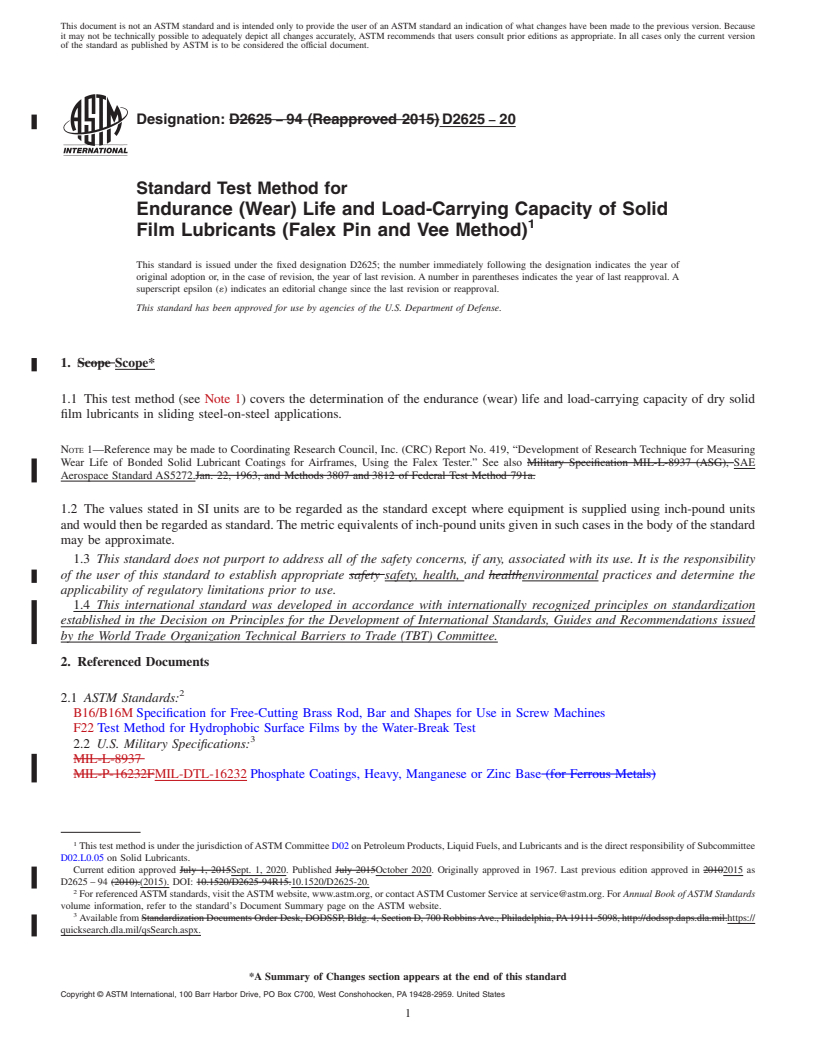

3.2.1 direct load, n—theloadthatisappliedlinearly,bisect-

mine the applicability of regulatory limitations prior to use.

ing the angle of the vee block corrected to either the 800lbf

1.4 This international standard was developed in accor-

(3550N) gauge reference or the 3000lbf (13300N) gauge

dance with internationally recognized principles on standard-

reference.

ization established in the Decision on Principles for the

3.2.1.1 Discussion—This load is equivalent to the true load

Development of International Standards, Guides and Recom-

times the cos 42°.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 3.2.2 endurance (wear) life, n—the length of test time

beforefailureunderaconstantloadedcondition,inminutes,in

2. Referenced Documents

which the applied test lubricant performs its function.

2

2.1 ASTM Standards: 3.2.3 gauge load, n—the value obtained from the gauge

B16/B16MSpecification for Free-Cutting Brass Rod, Bar

while running the test after being corrected to the standard

curve using the calibration procedure for the 4500 lbf

(20000N) reference gauge.

1

This test method is under the jurisdiction of ASTM Committee D02 on

3.2.3.1 Discussion—Thegaugereadingisirrespectiveofthe

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

particulargaugeused,andcorrectionsaremadebycomparison

Subcommittee D02.L0.05 on Solid Lubricants.

totheBrinellballimpressiondiametersonastandardreference

Current edition approved Sept. 1, 2020. Published October 2020. Originally

approved in 1967. Last previous edition approved in 2015 as D2625–94 (2015).

DOI: 10.1520/D2625-20.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from https://quicksearch.dla.mil/qsSearch.aspx.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from U.S. Environmental Protection Agency, http://epa.gov.

5

Standards volume information, refer to the standard’s Document Summary page on AvailablefromSAEInternational(SAE),400CommonwealthDr.,Warrendale,

the ASTM website. PA 15096, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2625 − 20

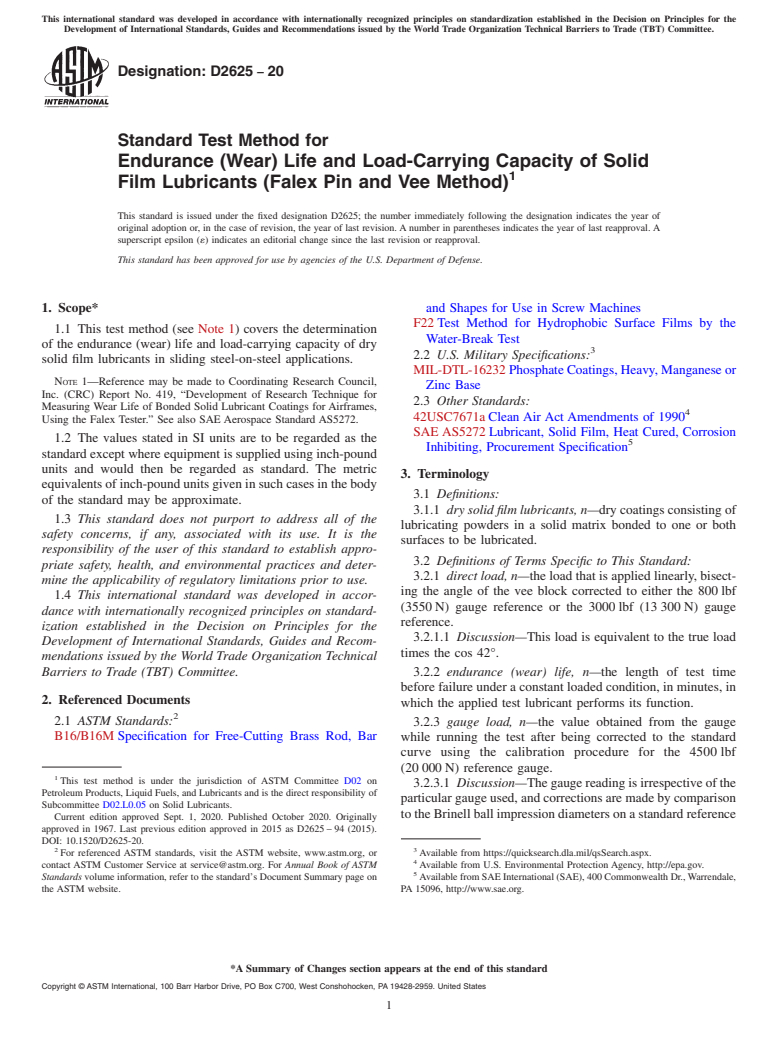

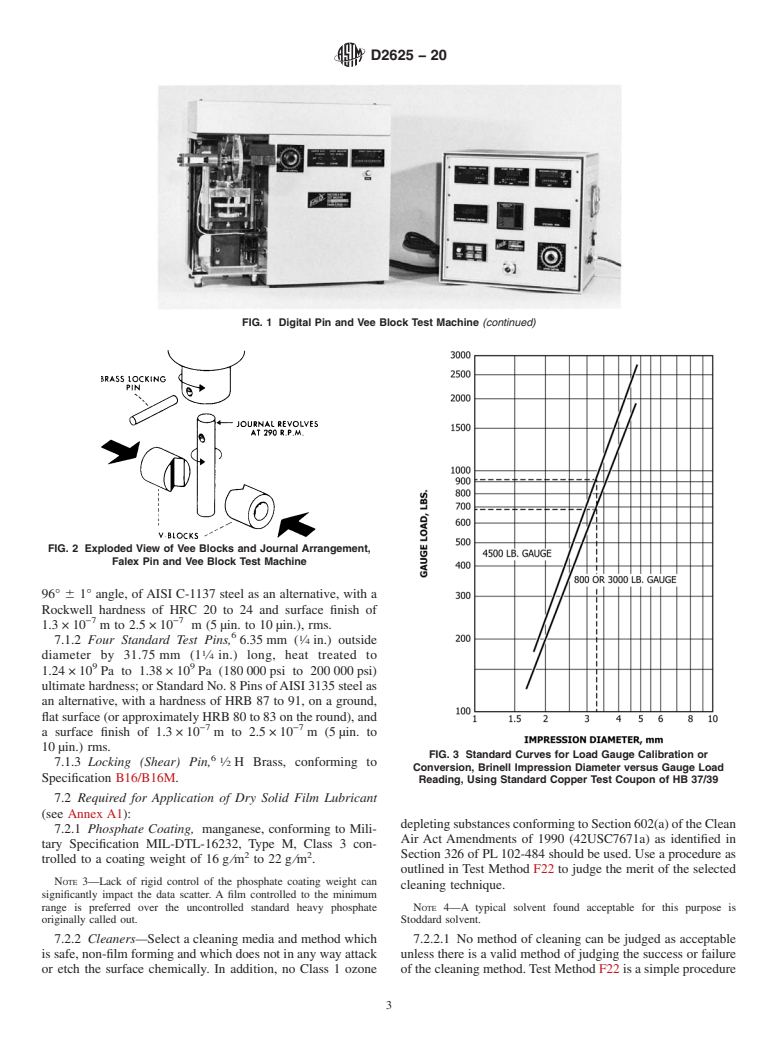

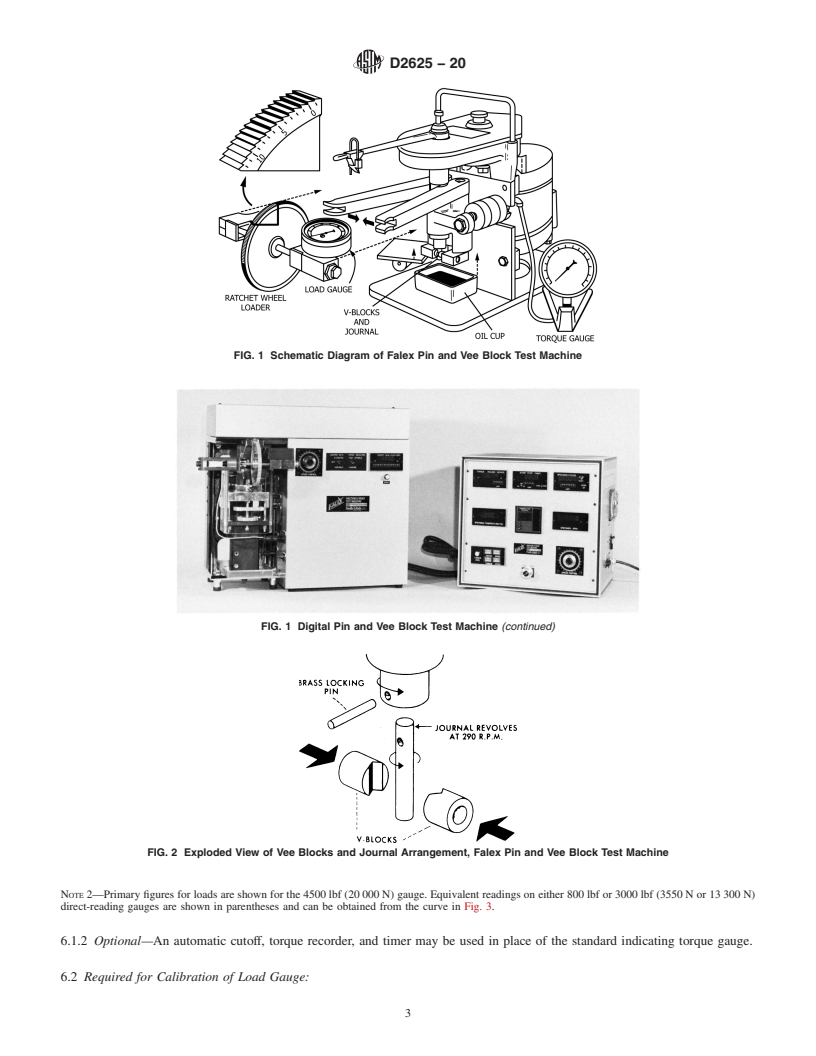

FIG. 1 Schematic Diagram of Falex Pin and Vee Block Test Machine

6

copper test coupon with a Rockwell hardness range of HB37 6.1.1 Load Gauge, 4500lbf (2

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2625 − 94 (Reapproved 2015) D2625 − 20

Standard Test Method for

Endurance (Wear) Life and Load-Carrying Capacity of Solid

1

Film Lubricants (Falex Pin and Vee Method)

This standard is issued under the fixed designation D2625; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 This test method (see Note 1) covers the determination of the endurance (wear) life and load-carrying capacity of dry solid

film lubricants in sliding steel-on-steel applications.

NOTE 1—Reference may be made to Coordinating Research Council, Inc. (CRC) Report No. 419, “Development of Research Technique for Measuring

Wear Life of Bonded Solid Lubricant Coatings for Airframes, Using the Falex Tester.” See also Military Specification MIL-L-8937 (ASG), SAE

Aerospace Standard AS5272.Jan. 22, 1963, and Methods 3807 and 3812 of Federal Test Method 791a.

1.2 The values stated in SI units are to be regarded as the standard except where equipment is supplied using inch-pound units

and would then be regarded as standard. The metric equivalents of inch-pound units given in such cases in the body of the standard

may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B16/B16M Specification for Free-Cutting Brass Rod, Bar and Shapes for Use in Screw Machines

F22 Test Method for Hydrophobic Surface Films by the Water-Break Test

3

2.2 U.S. Military Specifications:

MIL-L-8937

MIL-P-16232FMIL-DTL-16232 Phosphate Coatings, Heavy, Manganese or Zinc Base (for Ferrous Metals)

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.L0.05 on Solid Lubricants.

Current edition approved July 1, 2015Sept. 1, 2020. Published July 2015October 2020. Originally approved in 1967. Last previous edition approved in 20102015 as

D2625 – 94 (2010).(2015). DOI: 10.1520/D2625-94R15.10.1520/D2625-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://dodssp.daps.dla.mil.https://

quicksearch.dla.mil/qsSearch.aspx.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2625 − 20

2.3 Other Standards:

4

42USC7671a Clean Air Act Amendments of 1990

Federal Test Method 791aSAE AS5272 Methods 3807 and 3812Lubricant, Solid Film, Heat Cured, Corrosion Inhibiting,

5

Procurement Specification

3. Terminology

3.1 Definitions:

3.1.1 dry solid film lubricants—lubricants, n—dry coatings consisting of lubricating powders in a solid matrix bonded to one or

both surfaces to be lubricated.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 direct load, n—the load that is applied linearly, bisecting the angle of the vee block corrected to either the 800 lbf (3550 N)

gauge reference or the 3000 lbf (13 300 N) gauge reference.

3.2.1.1 Discussion—

This load is equivalent to the true load times the cos 42°.

3.2.2 endurance (wear) life—life, n—the length of test time before failure under a constant loaded condition, in minutes, in which

the applied test lubricant performs its function.

3.2.3 gauge load, n—the value obtained from the gauge while r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.