ASTM A853-04(2017)

(Specification)Standard Specification for Steel Wire, Carbon, for General Use

Standard Specification for Steel Wire, Carbon, for General Use

ABSTRACT

This specification covers carbon steel wire coils for general use. Steel samples shall be hard drawn, annealed in process, or annealed at finish size. The steel shall either be ingot cast or strand cast. The carbon steel shall also undergo tensile tests and shall conform to the required values of tensile strength. Final products shall be marked either by a tag or bar code.

SCOPE

1.1 This specification covers carbon steel wire, supplied in coils, for general use. It may be produced hard drawn, annealed in process, or annealed at finish size.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A853 −04 (Reapproved 2017)

Standard Specification for

Steel Wire, Carbon, for General Use

This standard is issued under the fixed designation A853; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2.4 AIAG Standard:

AIAGB-5 02.00 Primary Metals Identification Tag Applica-

1.1 This specification covers carbon steel wire, supplied in

tion Standard

coils,forgeneraluse.Itmaybeproducedharddrawn,annealed

in process, or annealed at finish size.

3. Terminology

1.2 The values stated in inch-pound units are to be regarded

3.1 Definitions of Terms Specific to This Standard:

as standard. No other units of measurement are included in this

3.1.1 annealed-in-process wire—steel wire that was ther-

standard.

mally treated and subsequently redrawn.

3.1.2 annealed wire—wire that was drawn to size and

2. Referenced Documents

annealed at finish size.

2.1 ASTM Standards: 3.1.3 carbon steel—steel is considered to be carbon steel

when no minimum content is specified or required for

A370 Test Methods and Definitions for Mechanical Testing

aluminum, chromium, cobalt, columbium, molybdenum,

of Steel Products

nickel,titanium,tungsten,vanadium,orzirconiumoranyother

A510 Specification for General Requirements forWire Rods

element added to obtain a desired alloying effect; when the

and Coarse Round Wire, Carbon Steel

specified minimum copper content does not exceed 0.40 %; or

A700 Guide for Packaging, Marking, and Loading Methods

when the maximum content for any of the following elements

for Steel Products for Shipment

does not exceed these percentages: manganese 1.65, silicon

A751 Test Methods, Practices, and Terminology for Chemi-

0.60, or copper 0.60 (see Specification A510).

cal Analysis of Steel Products

E29 Practice for Using Significant Digits in Test Data to

3.1.4 hard drawn wire—wire drawn without the use of

Determine Conformance with Specifications

thermal treatment.

2.2 Military Standards:

4. Ordering Information

MIL-STD-129 Marking for Shipment and Storage

4.1 It shall be the responsibility of the purchaser to specify

MIL-STD-163 Steel Mill Products, Preparation for Ship-

all requirements that are necessary for material under this

ment and Storage

specification.Suchrequirementsinclude,butarenotlimitedto,

2.3 Federal Standard:

the following:

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

4.1.1 Quantity (weight in pounds),

4.1.2 Name of material (carbon steel wire),

4.1.3 Wire diameter in inches, to the third decimal point,

4.1.4 Chemical composition grade number,

4.1.5 Condition (hard drawn, annealed in process, annealed

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

at finished size),

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.03 on Steel Rod and Wire. 4.1.6 Finish (see Section 10),

Current edition approved March 15, 2017. Published March 2017. Originally

4.1.7 Packaging, and

approved in 1985. Last previous edition approved in 2010 as A853 – 04 (2010).

4.1.8 ASTM designation and year of issue.

DOI: 10.1520/A0853-04R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 1—A typical ordering description is as follows: 40 000 lb, 0.148

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in., Bright Hard Drawn Carbon Steel Wire, Grade 1008, in 600-lb.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http:// Available fromAutomotive IndustryAction Group (AIAG), 26200 Lahser Rd.,

dodssp.daps.dla.mil. Suite 200, Southfield, MI 48033, http://www.aiag.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A853−04 (2017)

catch-weight coils on tubular carriers to ASTM ACSW.

10. Finish

10.1 Hard drawn wire may be furnished with a variety of

5. Materials and Manufacture

finishes depending upon the drawing practices used by the

5.1 The steel shall be made by any commercially accepted

manufacturer.Unlessotherwisespecifiedinthepurchaseorder,

steel making process. The steel may be either ingot cast or

the wire is normally produced with a common dry drawn

strand cast.

finish, usually referred to as a bright finish. Other finishes are

also available such as clean and extra smooth wire, requiring

6. Chemical Composition

special drafting practices.

6.1 The grade designation shall be as specified in the

10.2 Annealed in process wire is furnished with a bright

purchase order.

finish.

6.2 Chemical ranges and limits, and procedures for analysis

10.3 Unlessotherwisenegotiatedbetweenthepurchaserand

shall be in accordance with Test Methods, Practices, and

manufacturer, annealed at finish size wire is supplied with a

Terminology A751.

black oxide finish resulting from regular annealing.

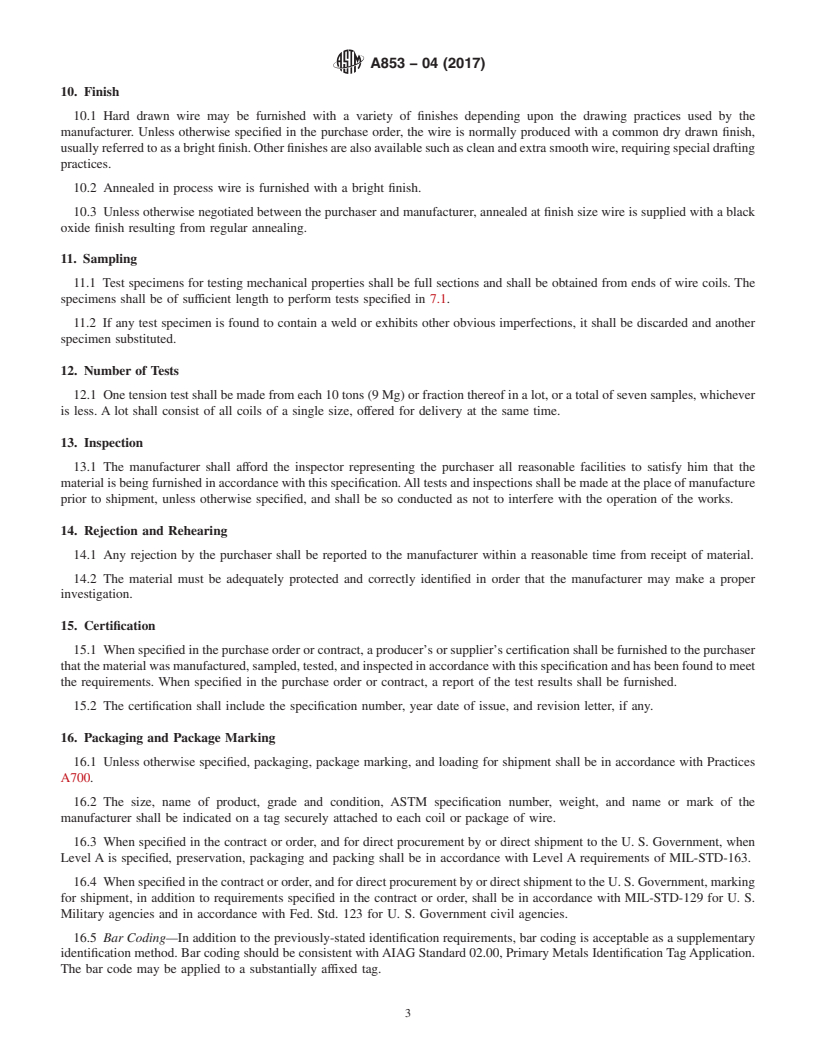

7. Mechanical Properties

11. Sampling

7.1 The carbon steel wire shall meet the tensile strength

11.1 Test specimens for testing mechanical properties shall

requirementsshowninTable1fortheconditionspecifiedwhen

be full sections and shall be obtained from ends of wire coils.

tested in accordance with Test Methods and Definitions A370.

The specimens shall be of sufficient length to perform tests

specified in 7.1.

8. Dimensions and Tolerances

11.2 If any test specimen is found to contain a weld or

8.1 The diameter and out of roundness shall not vary by

exhibits other obvious imperfections, it shall be discarded and

more than the tolerances specified in Specification A510.

another specimen substituted.

9. Workmanship

12. Number of Tests

9.1 The wire shall be free of detrimental imperfections. To

e

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A853 − 04 (Reapproved 2010) A853 − 04 (Reapproved 2017)

Standard Specification for

Steel Wire, Carbon, for General Use

This standard is issued under the fixed designation A853; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers carbon steel wire, supplied in coils, for general use. It may be produced hard drawn, annealed in

process, or annealed at finish size.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this

standard.

2. Referenced Documents

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A510 Specification for General Requirements for Wire Rods and Coarse Round Wire, Carbon Steel

A700 Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

2.2 Military Standards:

MIL-STD-129 Marking for Shipment and Storage

MIL-STD-163 Steel Mill Products, Preparation for Shipment and Storage

2.3 Federal Standard:

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

2.4 AIAG Standard:

AIAGB-5 02.00 Primary Metals Identification Tag Application Standard

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 annealed-in-process wire—steel wire that was thermally treated and subsequently redrawn.

3.1.2 annealed wire—wire that was drawn to size and annealed at finish size.

3.1.3 carbon steel—steel is considered to be carbon steel when no minimum content is specified or required for aluminum,

chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium, or zirconium or any other element added to

obtain a desired alloying effect; when the specified minimum copper content does not exceed 0.40 %; or when the maximum

content for any of the following elements does not exceed these percentages: manganese 1.65, silicon 0.60, or copper 0.60 (see

Specification A510).

3.1.4 hard drawn wire—wire drawn without the use of thermal treatment.

4. Ordering Information

4.1 It shall be the responsibility of the purchaser to specify all requirements that are necessary for material under this

specification. Such requirements include, but are not limited to, the following:

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.03

on Steel Rod and Wire.

Current edition approved April 1, 2010March 15, 2017. Published April 2010March 2017. Originally approved in 1985. Last previous edition approved in 20042010 as

A853 – 04.A853 – 04 (2010). DOI: 10.1520/A0853-04R10.10.1520/A0853-04R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://dodssp.daps.dla.mil.

Available from Automotive Industry Action Group (AIAG), 26200 Lahser Rd., Suite 200, Southfield, MI 48033, http://www.aiag.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A853 − 04 (2017)

4.1.1 Quantity (weight in pounds),

4.1.2 Name of material (carbon steel wire),

4.1.3 Wire diameter in inches, to the third decimal point,

4.1.4 Chemical composition grade number,

4.1.5 Condition (hard drawn, annealed in process, annealed at finished size),

4.1.6 Finish (see Section 10),

4.1.7 Packaging, and

4.1.8 ASTM designation and year of issue.

NOTE 1—A typical ordering description is as follows: 40 000 lb, 0.148 in., Bright Hard Drawn Carbon Steel Wire, Grade 1008, in 600-lb. catch-weight

coils on tubular carriers to ASTM ACSW.

5. Materials and Manufacture

5.1 The steel shall be made by any commercially accepted steel making process. The steel may be either ingot cast or strand

cast.

6. Chemical Composition

6.1 The grade designation shall be as specified in the purchase order.

6.2 Chemical ranges and limits, and procedures for analysis shall be in accordance with Test Methods, Practices, and

Terminology A751.

7. Mechanical Properties

7.1 The carbon steel wire shall meet the tensile strength requirements shown in Table 1 for the condition specified when tested

in accordance with Test Methods and Definitions A370.

8. Dimensions and Tolerances

8.1 The diameter and out of roundness shall not vary by more than the tolerances specified in Specification A510.

9. Workmanship

9.1 The wire shall be free of detrimental imperfections. To ensure large continuous length coils, welds may be present in the

finished wire.

TABLE 1 Tensile Requirements

A

Diameter , in. (mm) Tensile Strength, psi (MPa)

B

Hard Drawn Annealed-In- Annealed

Maximum

Minimum Process Maximum

Grade AISI 1006 UNS G 10060

Less than 0.035(0.89) . . . 95 000(655) 60 000(415)

0.035–0.057(0.89–1.46) 105 000(725) 90 000(620) 60 000(415)

0.058–0.085(1.47–2.17) 90 000(620) 90 000(620) 60 000(415)

0.086–0.127(2.18–3.27) 80 000(550) 85 000(585) 60 000(415)

0.128–0.177(3.28–4.49) 70 000(485) 80 000(550) 60 000(415)

0.178–0.250(4.51–6.35) 60 000(415) 70 000(485) 60 000(415)

Grades AISI 1008 and 1010 UNS G 10080 and G 10100

Less than 0.035(0.89) . . . 95 000(655) 70 000(485)

0.035–0.057(0.89–1.46) . . . 90 000(620) 65 000(450)

0.058–0.085(1.47–2.17) 100 000(690) 90 000(620) 65 000(450)

0.086–0.127(2.18–3.27)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.