ASTM D1559-89

(Test Method)Test Method for Resistance of Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (Withdrawn 1998)

Test Method for Resistance of Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (Withdrawn 1998)

General Information

Standards Content (Sample)

-

IND-STD ASTM D1557-ô7 NOTICE 1 56 7777798 0000095 7

~ ~ ~~ ~~

COI111 I NOTICE OF I ADOPTION NOTICE 1

I ADOPTION I

9 February 1990 for

w

ASTM D 1559-89

October 18. 1989

SUPEHSEülNG

AS'IM D 1559-82

. 8 April 1983

..

.

AS'FM U 1559-89 was adopted on 9 February '1990 and is approved For use by the

Department OF Defense (DOU).

ASTM has îurnished the cleartrnce required by

existing regulations. Copies OF this document are stocked by the DoD Single

St'ock Point, Military Specifications and Standards, ï00 Robbins Avenue,

Bldg. 40, Philadelphia, PA 19111-5094, for issue to DoD act.ivities only. All

other requestors must obtain documents from:

AST w

'19'16 Race Street

Philadelphia, PA 19103

litle of Document:

Standard Test Method for Resistance

to Plastic Flow of Bituminous

Mixtures Using Marshall

Appa ra tus a

Date OF Specific Issue Adopted: October 18, 1989

Releasing Non-Government Standards Body: ASTH

Custodians: Mi litary Coordinating Activity:

Navy - Yü Navy - YD

Air Force - 99

(Project 5610-0658)

Review Activity:

Navy - PIC

User Activity:

Army -,CL'

FSC 5610

DISTRIBUTZON STATEMENT A. Approved For public release; distribution is

uril imi ted. .

---------------------- Page: 1 ----------------------

AMERICAN SOCIETY FOR TESTING AND MATERIALS

ACTh Desianation: D 1559 - 89 1916 Ram SI. Philadelohla. Pa. 19103

"

Reprinted from the Annual Book of ASTM Standards. Copyriaht ASTM

'[U I I' -

If nol listed in the current combined index, will appear in th natl Hiibn.

Standard Test Method for

Resistance to Plastic Flow of Bituminous Mixtures Using

Marshall Apparatus'

This standard is issued under the fixed designation D 1559; the number immediately following the designation indicates the year of

original adoption or. in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (c) indicates an editorial change since the last revision or reapproval.

Tliìs srandard lias been appror-edjbr rise by agencies of the Departmeni of Ddetrse. Consult the DoD index of Spec$calions and

Slatidardsfor the specflc year of issue ivliìcfi kas been adopted by the Deparltnetil of Defense.

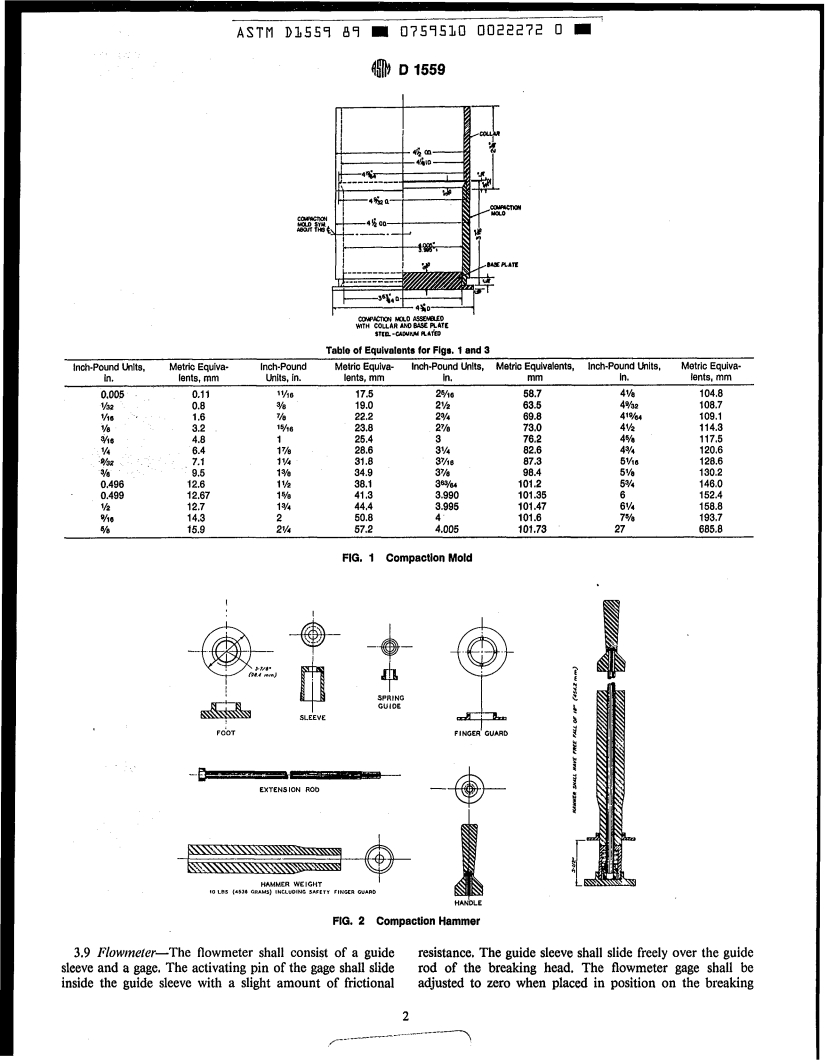

1. Scope Two compaction hammers are recommended.

1.I This test method covers the measurement of the

NOTE 1-The compaction hammer may be equipped with a finger

resistance to plastic flow of cylindrical specimens of bitumi-

safety guard as shown in Fig. 2.

nous paving mixture loaded on the lateral surface by means

3.4 Compaction Pedestal-The compaction pedestal shall

of the Marshall apparatus. This test method is for use with

consist of an 8 by 8 by 18411. (203.2 by 203.2 by 457.2-mm)

mixtures containing asphalt cement, asphalt cut-back or tar,

wooden post capped with a 12 by 12 by 1-in. (304.8 by 304.8

and aggregate up to I-in, (25.4-mm) maximum size.

by 25.4-mm) steel plate. The wooden post shall be oak, pine,

1.2 This standard may involve hazardous materials, oper-

or other wood having an average dry weight of 42 to 48 lb/ft3

ations, and equìprnent. This standard does iiot purport to

(0.67 to 0.77 g/cm3). The wooden post shall be secured by

address all of the safety problems associated with its use, It is

four angle brackets to a solid concrete slab. The steel cap

the responsibility of the user of this standard to establish

shall be firmly fastened to the post. The pedestal assembly

and health practices and determine the

appropriate safi&

shall be installed so that the post is plumb and the cap is

of regulatory limitations prior to use.

applicability

level.

3.5 Specimen Mold Holder, mounted on the compaction

2. Significance and Use

pedestal so as to center the compaction mold over the center

2.1 This test method is used in the laboratory mix design

of the post. It shall hold the compaction mold, collar, and

of bituminous mixtures. Specimens are prepared in accord-

base plate securely in position during compaction of the

ance with the method and tested for maximum load and

specimen.

flow. Density and voids properties may also be determined

3.6 Breaking Head-The breaking head (Fig. 3) shall

on specimens prepared in accordance with the test method.

consist of upper and lower cylindrical segments or test heads

The testing section of this method can also be used to obtain

having an inside radius of curvature of 2 in. (50.8 mm)

maximum load and flow for bituminous paving specimens

accurately machined. The lower segment shall be mounted

cored from pavements or prepared by other methods. These

on a base having two perpendicular guide rods or posts

results may differ from values obtained on specimens pre-

extending upward. Guide sleeves in the upper segment shall

pared by this test method. .

a position as to direct the two segments together

be in such

without appreciable binding or loose motion on the guide

3. Apparatus

rods.

3.7 Loading Jack-The loading jack (Fig. 4) shall cons

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.