ASTM F1085-88(1994)e1

(Specification)Standard Specification for Mattress and Box Springs, Berths

Standard Specification for Mattress and Box Springs, Berths

SCOPE

1.1 This specification provides the minimum requirements for construction, materials, performance, and dimensional requirements of arch-type non-metallic expansion joints.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test method described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

e1

Designation: F 1085 – 88 (Reapproved 1994)

Standard Specification for

Mattress and Box Springs, Berths

This standard is issued under the fixed designation F 1085; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 12 was added editorially in June 1994.

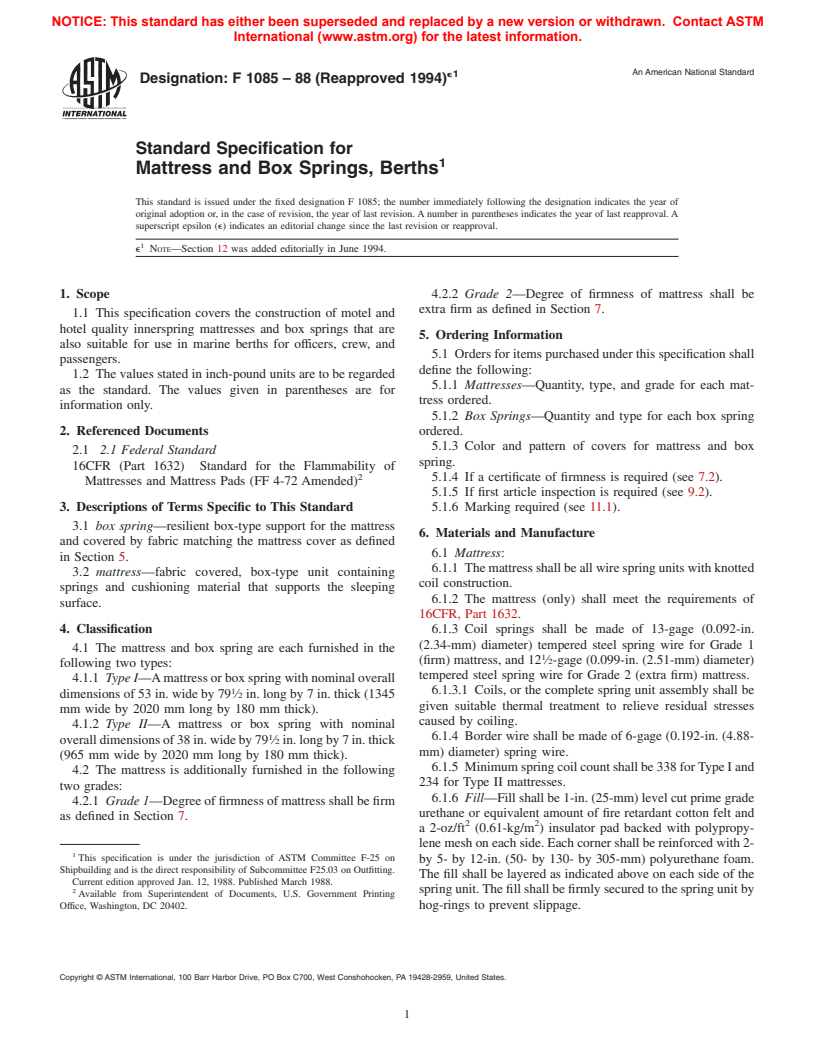

1. Scope 4.2.2 Grade 2—Degree of firmness of mattress shall be

extra firm as defined in Section 7.

1.1 This specification covers the construction of motel and

hotel quality innerspring mattresses and box springs that are

5. Ordering Information

also suitable for use in marine berths for officers, crew, and

5.1 Orders for items purchased under this specification shall

passengers.

define the following:

1.2 The values stated in inch-pound units are to be regarded

5.1.1 Mattresses—Quantity, type, and grade for each mat-

as the standard. The values given in parentheses are for

tress ordered.

information only.

5.1.2 Box Springs—Quantity and type for each box spring

2. Referenced Documents ordered.

5.1.3 Color and pattern of covers for mattress and box

2.1 2.1 Federal Standard

spring.

16CFR (Part 1632) Standard for the Flammability of

5.1.4 If a certificate of firmness is required (see 7.2).

Mattresses and Mattress Pads (FF 4-72 Amended)

5.1.5 If first article inspection is required (see 9.2).

3. Descriptions of Terms Specific to This Standard 5.1.6 Marking required (see 11.1).

3.1 box spring—resilient box-type support for the mattress

6. Materials and Manufacture

and covered by fabric matching the mattress cover as defined

6.1 Mattress:

in Section 5.

6.1.1 Themattressshallbeallwirespringunitswithknotted

3.2 mattress—fabric covered, box-type unit containing

coil construction.

springs and cushioning material that supports the sleeping

6.1.2 The mattress (only) shall meet the requirements of

surface.

16CFR, Part 1632.

4. Classification 6.1.3 Coil springs shall be made of 13-gage (0.092-in.

(2.34-mm) diameter) tempered steel spring wire for Grade 1

4.1 The mattress and box spring are each furnished in the

(firm) mattress, and 12 ⁄2-gage (0.099-in. (2.51-mm) diameter)

following two types:

tempered steel spring wire for Grade 2 (extra firm) mattress.

4.1.1 Type I—Amattress or box spring with nominal overall

1 6.1.3.1 Coils, or the complete spring unit assembly shall be

dimensions of 53 in. wide by 79 ⁄2 in. long by 7 in. thick (1345

given suitable thermal treatment to relieve residual stresses

mm wide by 2020 mm long by 180 mm thick).

caused by coiling.

4.1.2 Type II—A mattress or box spring with nominal

1 6.1.4 Border wire shall be made of 6-gage (0.192-in. (4.88-

overalldimensionsof38in.wideby79 ⁄2in.longby7in.thick

mm) diameter) spring wire.

(965 mm wide by 2020 mm long by 180 mm thick).

6.1.5 Minimumspringcoilcountshallbe338forTypeIand

4.2 The mattress is additionally furnished in the following

234 for Type II mattresses.

two grades:

6.1.6 Fill—Fill shall be 1-in. (25-mm) level cut prime grade

4.2.1 Grade 1—Degree of firmness of mattress shall be firm

urethane or equivalent amount of fire retardant cotton felt and

as defined in Section 7.

2 2

a 2-oz/ft (0.61-kg/m ) insulator pad backed with polypropy-

lene mesh on each side. Each corner shall be reinforced with 2-

This specification is under the jurisdiction of ASTM Committee F-25 on

by 5- by 12-in. (50- by 130- by 305-mm) polyurethane foam.

Shipbuilding and is the direct responsibility of Subcommittee F25.03 on Outfitting.

The fill shall be layered as indicated above on each side of the

Current edition approved Jan. 12, 1988. Published March 1988.

2 spring unit.The fill shall be firmly secured to the spring unit by

Available from Superintendent of Documents, U.S. Government Printing

Office, Washington, DC 20402. hog-rings to prevent slippage.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

F 1085 – 88 (1994)

TABLE 1 Load versus Deflection for Each Firmness

6.1.7 Cover—The cover shall be a minimum of 6 ⁄5-oz/

2 2

ft (1.9-kg/m ) woven twill cotton-polyester blend ticking, with

Force, lbf (or N)

flanged construction to prevent slippage, that meets the re-

Deflection,

Grade A Grade B

in. (mm)

quirements of 6.1.2.

(Firm) (Extra Firm)

6.1.8 Border—The border shall be multi-needled to the

1 (25) 40–55 (180–240) 55–70 (240–310)

urethane foam fill. The urethane foam fill shall have a

1 ⁄2 (38) 65–75 (290–330) 75–100 (330–440)

minimum thickness of ⁄4 in. (6 mm).

2 (50) 83–100 (370–440) 110–135 (490–600)

6.1.9 Tape—The tape shall be ⁄8-in. (20-mm) fire-retardant

type.

6.1.10 Labels:

7.2 Load Deflection Test—The load versus deflection test

6.1.10.1 The label must indicate that the mattress meets the shall be conducted on an un-upholstered inner spring unit. A

1 1

requirements of 16CFR, Part 1632.

platen 11 ⁄2 by 11 ⁄2 in. (290 by 290 mm) shall be placed at the

6.1.10.2 The mattress must display trade labels as required center of the unit and a uniform load applied.Aload sufficient

to deflect the unit 2 in. (50 mm) shall be applied. This load

by law, and “Contract Bedding” label.

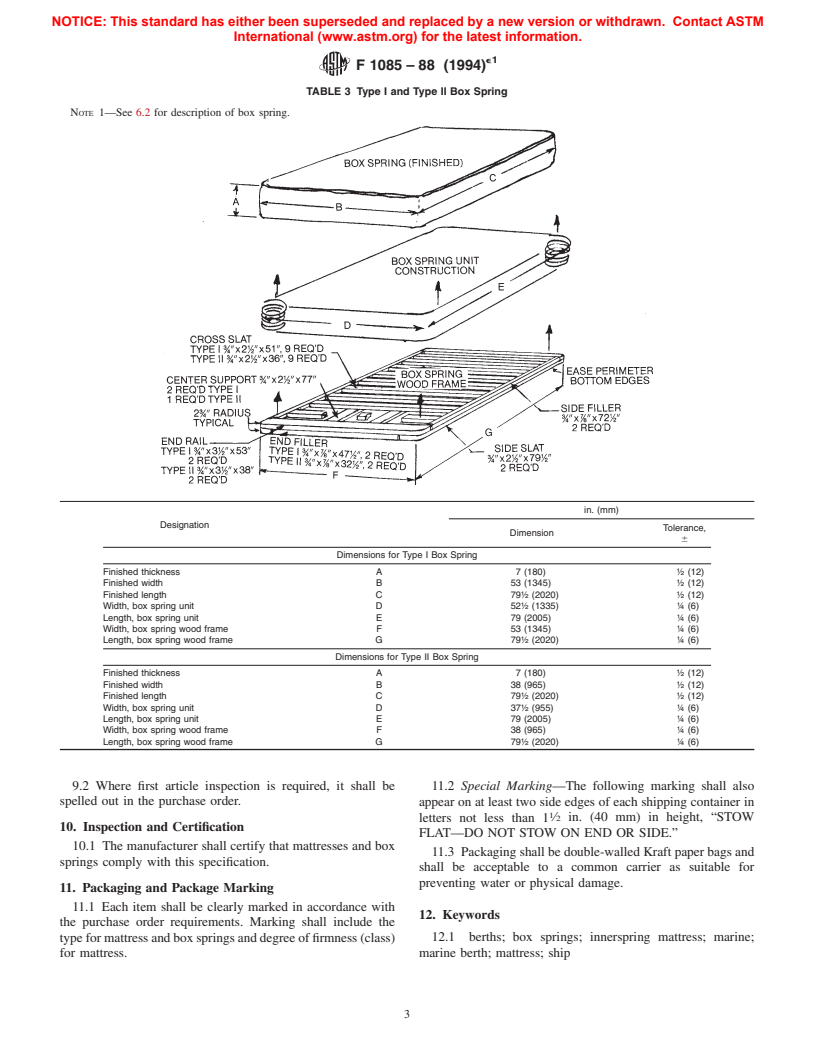

6.2 Box Spring: shallthenbereleasedandspringunitallowedtorelaxfor1min

1 1

after which the unit shall be compressed to 1, 1 ⁄2 , and 2 in.

6.2.1 Coil springs shall be made of 9 ⁄2-gage (0.142-in.

(3.61-mm) diameter) tempered steel spring wire. (25, 38, and 50 mm) with the loading required for these

deflections noted. The results shall be compared to the require-

6.2.1.1 Coils, or the complete spring unit assembly, shall be

given suitable thermal treatment to relieve residual stresses ments in Table 1. The manufacturer of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.