ASTM E2539-14

(Test Method)Standard Test Method for Multiangle Color Measurement of Interference Pigments

Standard Test Method for Multiangle Color Measurement of Interference Pigments

SIGNIFICANCE AND USE

5.1 This test method is designed to provide color data obtained from spectral reflectance factors at specific illumination and detection angles for interference pigments. Information presented in this test method is based upon data taken on materials exclusively pigmented with interference pigments.

5.2 These data can be used for acceptance testing, design purposes, research, manufacturing control, and quality control.

5.3 Specimens must be statistically representative of the end use.

5.4 Applicability of this test method for other materials, including combining interference pigments with absorbing and scattering pigments should be confirmed by the user.

SCOPE

1.1 This test method covers the instrumental requirements and required parameters needed to make instrumental color measurements of thin film interference pigments. This test method is designed to encompass interference pigments used in architectural applications, automobiles, coatings, cosmetics, inks, packaging, paints, plastics, printing, security, and other applications.

1.2 Characterization of the optical behavior of materials colored with interference pigments requires measurement at multiple angles of illumination and detection.

1.3 Data taken utilizing this test method are quantitative and are appropriate for quality control of interference pigment color.

1.4 The measurement results are usually expressed as reflectance factors, tristimulus color values, or as CIE L*a*b* color coordinates and color difference.

1.5 The totality of data taken may not be necessary for evaluating mixtures also containing non-interference pigments. The committee is investigating and evaluating the appropriateness of this test method for those materials. It is the responsibility of the users to determine the applicability of this test method for their specific applications.

1.6 Interference pigments are typically evaluated for color and color appearance in a medium, such as paint or ink. The gonioapparent effect depends strongly on the physical and chemical properties of the medium. Some of the properties affecting color and color appearance include vehicle viscosity, thickness, transparency, and volume solids. As a general rule, for quality control purposes, interference pigments are best evaluated in a masstone product form. In some cases this product form may be the final product form, or more typically a qualified simulation of the intended product form (such as a paint drawdown) that in terms of color and appearance correlates to final product application.

1.7 This standard does not address the requirements for characterizing materials containing metal flake pigments. Measurements of the optical characteristics of materials containing metal flake pigments are described in Test Method E2194.

1.8 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2539 − 14

Standard Test Method for

Multiangle Color Measurement of Interference Pigments

This standard is issued under the fixed designation E2539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Objects that exhibit a change in color with different angles of illumination and view are said to be

“gonioapparent.” The tristimulus colorimetric values of gonioapparent objects are derived using the

spectral reflectance factors obtained from spectrometric measurements or colorimetric measurements

atvariousanglesofilluminationanddetection.Thetristimuluscolorimetricvaluesarecomputedusing

the spectral reflectance factors of the object, the CIE Standard Observer, and the spectral power

distribution of the illuminant, as described in Practice E308. This Test Method, E2539, specifies the

color measurement of interference pigments at various illumination and detection angles.

1. Scope chemical properties of the medium. Some of the properties

affecting color and color appearance include vehicle viscosity,

1.1 This test method covers the instrumental requirements

thickness, transparency, and volume solids. As a general rule,

and required parameters needed to make instrumental color

for quality control purposes, interference pigments are best

measurements of thin film interference pigments. This test

evaluated in a masstone product form. In some cases this

methodisdesignedtoencompassinterferencepigmentsusedin

product form may be the final product form, or more typically

architectural applications, automobiles, coatings, cosmetics,

a qualified simulation of the intended product form (such as a

inks, packaging, paints, plastics, printing, security, and other

paint drawdown) that in terms of color and appearance

applications.

correlates to final product application.

1.2 Characterization of the optical behavior of materials

1.7 This standard does not address the requirements for

colored with interference pigments requires measurement at

characterizingmaterialscontainingmetalflakepigments.Mea-

multiple angles of illumination and detection.

surements of the optical characteristics of materials containing

1.3 Datatakenutilizingthistestmethodarequantitativeand

metal flake pigments are described in Test Method E2194.

are appropriate for quality control of interference pigment

1.8 The values stated in SI units are to be regarded as the

color.

standard. The values given in parentheses are for information

1.4 The measurement results are usually expressed as re-

only.

flectance factors, tristimulus color values, or as CIE L*a*b*

1.9 This standard does not purport to address all of the

color coordinates and color difference.

safety concerns, if any, associated with its use. It is the

1.5 The totality of data taken may not be necessary for

responsibility of the user of this standard to establish appro-

evaluatingmixturesalsocontainingnon-interferencepigments.

priate safety and health practices and determine the applica-

The committee is investigating and evaluating the appropriate-

bility of regulatory limitations prior to use.

ness of this test method for those materials. It is the responsi-

bility of the users to determine the applicability of this test

2. Referenced Documents

method for their specific applications.

2.1 ASTM Standards:

1.6 Interference pigments are typically evaluated for color

E284Terminology of Appearance

and color appearance in a medium, such as paint or ink. The

E308PracticeforComputingtheColorsofObjectsbyUsing

gonioapparent effect depends strongly on the physical and

the CIE System

E805Practice for Identification of Instrumental Methods of

This test method is under the jurisdiction of ASTM Committee E12 on Color

and Appearance and is the direct responsibility of Subcommittee E12.12 on

Gonioapparent Color. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2014. Published November 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2008. Last previous edition approved in 2012 as E2539– 12. DOI: Standards volumeinformation,refertothestandard’sDocumentSummarypageon

10.1520/E2539-14. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2539 − 14

Color or Color-Difference Measurement of Materials 6. Environmental Conditions

E1164PracticeforObtainingSpectrometricDataforObject-

6.1 If the standard laboratory conditions listed below

Color Evaluation

change during the test or from test to test by an appreciable

E1345Practice for Reducing the Effect of Variability of

amount,theseconditionsmayreduceaccuracyandprecisionof

Color Measurement by Use of Multiple Measurements

this test method. In some cases these effects may only be

E1708Practice for Electronic Interchange of Color and

observed during the performance of the test.

Appearance Data

6.2 Factors affecting test results—The following factors are

E1767Practice for Specifying the Geometries of Observa-

known to affect the test results.

tion and Measurement to Characterize the Appearance of

6.2.1 Extraneous radiation—light from sources other than

Materials

theilluminator(s)andanynear-infrared(NIR)mustbeshielded

E2194Test Method for Multiangle Color Measurement of

from entering the test apparatus.

Metal Flake Pigmented Materials

6.2.2 Vibrations—mechanical oscillations that cause com-

E2480Practice for Conducting an Interlaboratory Study to

ponents of the apparatus to move relative to one another may

Determine the Precision of a Test Method with Multi-

cause errors in test results.

Valued Measurands

6.2.3 Thermal changes—temperature changes occurring

2.2 ISCC Publications:

during a test or differences in temperature between testing

Technical Report 2003–1Guide to Material Standards and

locations may affect calibration.

Their Use in Color Measurement

6.2.4 Power input fluctuations—large changes in the line

frequency or supply voltage may cause the apparatus to report

3. Terminology

erroneous results.

3.1 Terms and definitions in Terminology E284, and Prac-

6.3 Standardization—The system must allow for successful

tice E1767 and Test Method E2194 are applicable to this test

standardization. If the system cannot be standardized, consult

method. See Section 5 of E284 for “Specialized Terminology

the manufacturer’s user guide.

on Gonioapparent Phenomena.”

6.4 Controlling factors—Accuracy and precision can be

enhanced by controlling and regulating each factor within the

4. Summary of Test Method

constraintsoftheallowableexperimentalerror.Thevaluesand

4.1 This test method describes the instrumental geometries,

limitsforthesefactorsaretypicallydeterminedexperimentally

including abridged goniospectrometry, used to measure inter-

by the user.

ference pigments. Optical characterization requires color mea-

7. Apparatus

surementatmultipleilluminationandmultipledetectionangles

specified in this procedure. These sets of illumination and

7.1 Multiangle Spectrometer—Thistestmethodspecifiesthe

detection angles are specified in the test method. Standardiza-

required illumination and detection angles of multiangle spec-

tion and verification of the instrument used to measure these

trometers. These multiangle spectrometers are designed spe-

materials are defined. The requirements for selection of speci-

cifically to characterize the optical behavior of materials

mens and measurement procedures are provided. The results

coloredwithinterferencepigments.Geometriesarespecifiedin

are reported in terms of reflectance factors, CIE tristimulus

Section8.Thespectrometermayeitherbeagoniospectrometer

values,andothercolorcoordinatesystemsthatdefinethecolor

or an abridged goniospectrometer.

of the object. Expected values of precision are presented.

7.1.1 Bi-directional spectrometers or colorimeters with a

single angle of measurement; such as 45°:0° or 0°:45°, and

5. Significance and Use

spectrometers using hemispherical geometry cannot ad-

equately characterize the gonioapparency of these materials.

5.1 This test method is designed to provide color data

7.1.2 Multiangle spectrometers or colorimeters similar to

obtained from spectral reflectance factors at specific illumina-

those specified in Test Method E2194 cannot adequately

tion and detection angles for interference pigments. Informa-

characterize the gonioapparency of these materials.

tion presented in this test method is based upon data taken on

materials exclusively pigmented with interference pigments.

7.2 System Validation Materials—The precision and bias of

the entire measurement system, including calculation of CIE

5.2 These data can be used for acceptance testing, design

tristimulus values, should be determined by periodic measure-

purposes, research, manufacturing control, and quality control.

ment of known, calibrated, verification standards. These stan-

5.3 Specimensmustbestatisticallyrepresentativeoftheend

dards are supplied by instrument manufacturers or obtained

use. 4

separately.

5.4 Applicability of this test method for other materials,

8. Geometric Conditions

includingcombininginterferencepigmentswithabsorbingand

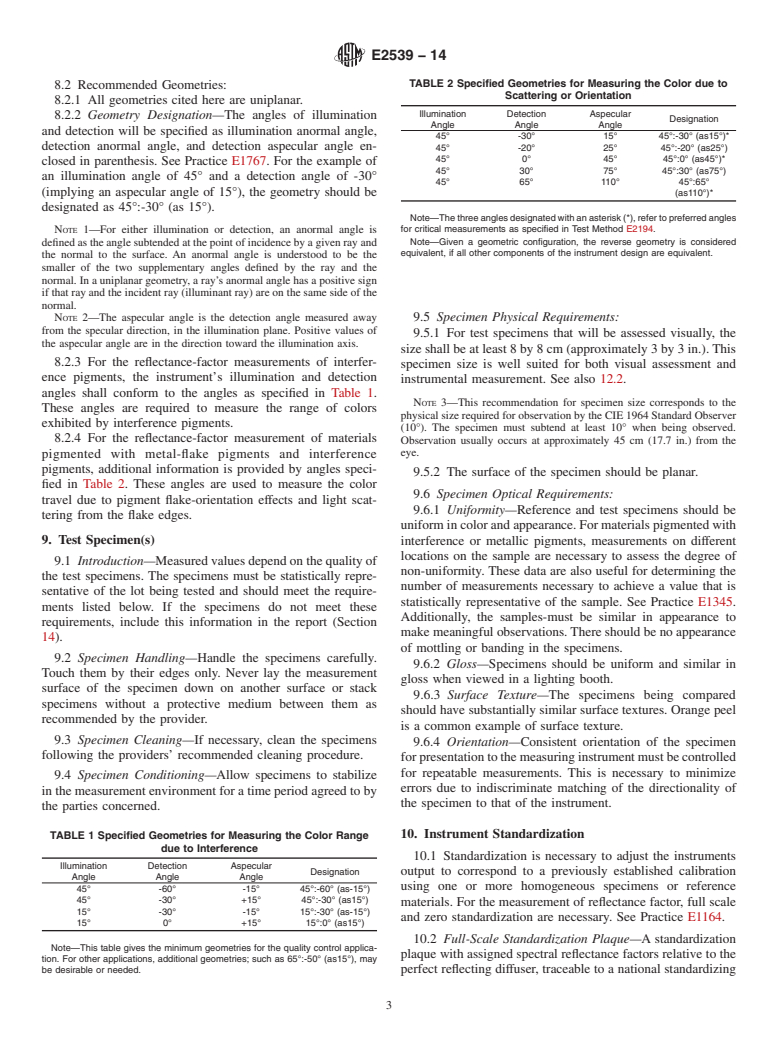

scattering pigments should be confirmed by the user. 8.1 The angles of illumination and detection are critical to

multiangle measurements of materials pigmented with inter-

ference pigments.

Available from the Inter-Society Color Council, 1191 Sunset Hills Road,

Reston, VA 20190, www.iscc.org. ISCC Technical Report 2003–1.

E2539 − 14

TABLE 2 Specified Geometries for Measuring the Color due to

8.2 Recommended Geometries:

Scattering or Orientation

8.2.1 All geometries cited here are uniplanar.

Illumination Detection Aspecular

8.2.2 Geometry Designation—The angles of illumination

Designation

Angle Angle Angle

and detection will be specified as illumination anormal angle,

45° -30° 15° 45°:-30° (as15°)*

detection anormal angle, and detection aspecular angle en-

45° -20° 25° 45°:-20° (as25°)

45° 0° 45° 45°:0° (as45°)*

closed in parenthesis. See Practice E1767. For the example of

45° 30° 75° 45°:30° (as75°)

an illumination angle of 45° and a detection angle of -30°

45° 65° 110° 45°:65°

(implying an aspecular angle of 15°), the geometry should be (as110°)*

designated as 45°:-30° (as 15°).

Note—The three angles designated with an asterisk (*), refer to preferred angles

for critical measurements as specified in Test Method E2194.

NOTE 1—For either illumination or detection, an anormal angle is

definedastheanglesubtendedatthepointofincidencebyagivenrayand Note—Given a geometric configuration, the reverse geometry is considered

equivalent, if all other components of the instrument design are equivalent.

the normal to the surface. An anormal angle is understood to be the

smaller of the two supplementary angles defined by the ray and the

normal. In a uniplanar geometry, a ray’s anormal angle has a positive sign

if that ray and the incident ray (illuminant ray) are on the same side of the

normal.

NOTE 2—The aspecular angle is the detection angle measured away 9.5 Specimen Physical Requirements:

from the specular direction, in the illumination plane. Positive values of

9.5.1 For test specimens that will be assessed visually, the

the aspecular angle are in the direction toward the illumination axis.

sizeshallbeatleast8by8cm(approximately3by3in.).This

8.2.3 For the reflectance-factor measurements of interfer-

specimen size is well suited for both visual assessment and

ence pigments, the instrument’s illumination and detection

instrumental measurement. See also 12.2.

angles shall conform to the angles as specified in Table 1.

NOTE 3—This recommendation for specimen size corresponds to the

These angles are required to measure the range of colors

physicalsizerequiredforobservationbytheCIE1964StandardObserver

exhibited by interference pigments.

(10°). The specimen must subtend at least 10° when being observed.

8.2.4 For the reflectance-factor measurement of materials

Observation usually occurs at approximately 45 cm (17.7 in.) from the

eye.

pigmented with metal-flake pigments and interference

pigments, additional information is provided by angles speci-

9.5.2 The surface of the specimen should be planar.

fied in Table 2. These angles are used to measure the color

9.6 Specimen Optical Requirements:

travel due to pigment flake-orientation effects and light scat-

9.6.1 Uniformity—Reference and test specimens should be

tering from the flake edges.

uniformincolorandappearance.Formaterialspigmentedwith

9. Test Specimen(s) interference or metallic pigments, measurements on different

locations on the sample are necessary to assess the degree of

9.1 Introduction—Measuredvaluesdependonthequalityof

non-uniformity. These data are also useful for determining the

the test specimens. The specimens must be statistically repre-

number of measurements necessary to achieve a value that is

sentative of the lot being tested and should meet the require-

statistically representative of the sample. See Practice E1345.

ments listed below. If the specimens do not meet these

Additionally, the samples-must be similar in appearance to

requirements, include this information in the report (Section

makemeaningfulobservations.Thereshouldbenoappearance

14).

of mottling or banding in the specimens.

9.2 Specimen Handling—Handle the specimens carefully.

9.6.2 Gloss—Specimens should be uniform and similar in

Touch them by their edges only. Never lay the measurement

gloss when viewed in a lighting booth.

surface of the specimen down on another surface or stack

9.6.3 Surface Texture—The specimens being compared

specimens without a protective medium between them as

should have substantially similar surface textures. Orange peel

recommended by the provider.

is a common example of surface texture.

9.3 Specimen Cleaning—If necessary, clean the specimens

9.6.4 Orientation—Consistent orientation of the specimen

following the providers’ recommended cleaning procedure.

forpresentationtothemeasuringinstrumentmustbecontrolled

for repeatable measurements. This is necessary to minimize

9.4 Specimen Conditioning—Allow specimens to stabilize

errors due to indiscriminate matching of the directionality of

inthemeasurementenvironmentforatimeperiodagreedtoby

the specimen to that of the instrument.

the parties concerned.

10. Instrument Standardization

TABLE 1 Specified Geometries for Measuring the Color Range

due to Interference

10.1 Standardization is necessary to adjust the instruments

Illumination Detecti

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2539 − 12 E2539 − 14

Standard Practice for Test Method for

Multiangle Color Measurement of Interference Pigments

This standard is issued under the fixed designation E2539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Objects that exhibit a change in color with different angles of illumination and view are said to be

“gonioapparent.” The tristimulus colorimetric values of gonioapparent objects are derived using the

spectral reflectance factors obtained from spectrometric measurements or colorimetric measurements

at various angles of illumination and detection. The tristimulus colorimetric values are computed using

the spectral reflectance factors of the object, the CIE Standard Observer, and the spectral power

distribution of the illuminant, as described in Practice E308. This Practice, Test Method, E2539,

specifies the color measurement of interference pigments at various illumination and detection angles.

1. Scope

1.1 This practice covers the instrumental requirements and required parameters needed to make instrumental color

measurements of thin film interference pigments. This practice is designed to encompass interference pigments used in

architectural applications, automobiles, coatings, cosmetics, inks, packaging, paints, plastics, printing, security, and other

applications.

1.2 Characterization of the optical behavior of materials colored with interference pigments requires measurement at multiple

angles of illumination and detection.

1.3 Data taken utilizing this practice are quantitative and are appropriate for quality control of interference pigment color.

1.4 The measurement results are usually expressed as reflectance factors, tristimulus color values, or as CIE L*a*b* color

coordinates and color difference.

1.5 The totality of data taken may not be necessary for evaluating mixtures also containing non-interference pigments. The

committee is investigating and evaluating the appropriateness of this practice for those materials. It is the responsibility of the users

to determine the applicability of this practice for their specific applications.

1.6 Interference pigments are typically evaluated for color and color appearance in a medium, such as paint or ink. The

gonioapparent effect depends strongly on the physical and chemical properties of the medium. Some of the properties affecting

color and color appearance include vehicle viscosity, thickness, transparency, and volume solids. As a general rule, for quality

control purposes, interference pigments are best evaluated in a masstone product form. In some cases this product form may be

the final product form, or more typically a qualified simulation of the intended product form (such as a paint drawdown) that in

terms of color and appearance correlates to final product application.

1.7 This standard does not address the requirements for characterizing materials containing metal flake pigments. Measurements

of the optical characteristics of materials containing metal flake pigments are described in Practice E2194.

1.8 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

This practice test method is under the jurisdiction of ASTM Committee E12 on Color and Appearance and is the direct responsibility of Subcommittee E12.12 on

Gonioapparent Color.

Current edition approved April 1, 2012Nov. 1, 2014. Published May 2012November 2014. Originally approved in 2008. Last previous edition approved in 20082012 as

E2539 – 08.12. DOI: 10.1520/E2539-12.10.1520/E2539-14.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2539 − 14

2. Referenced Documents

2.1 ASTM Standards:

E284 Terminology of Appearance

E308 Practice for Computing the Colors of Objects by Using the CIE System

E805 Practice for Identification of Instrumental Methods of Color or Color-Difference Measurement of Materials

E1164 Practice for Obtaining Spectrometric Data for Object-Color Evaluation

E1345 Practice for Reducing the Effect of Variability of Color Measurement by Use of Multiple Measurements

E1708 Practice for Electronic Interchange of Color and Appearance Data

E1767 Practice for Specifying the Geometries of Observation and Measurement to Characterize the Appearance of Materials

E2194 Test Method for Multiangle Color Measurement of Metal Flake Pigmented Materials

E2480 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method with Multi-Valued

Measurands

2.2 ISCC Publications:

Technical Report 2003–1 Guide to Material Standards and Their Use in Color Measurement

3. Terminology

3.1 Terms and definitions in Terminology E284, and Practices E1767 and E2194 are applicable to this practice. See Section 5

of E284 for “Specialized Terminology on Gonioapparent Phenomena.”

4. Summary of Practice

4.1 This practice describes the instrumental geometries, including abridged goniospectrometry, used to measure interference

pigments. Optical characterization requires color measurement at multiple illumination and multiple detection angles specified in

this procedure. These sets of illumination and detection angles are specified in the practice. Standardization and verification of the

instrument used to measure these materials are defined. The requirements for selection of specimens and measurement procedures

are provided. The results are reported in terms of reflectance factors, CIE tristimulus values, and other color coordinate systems

that define the color of the object. Expected values of precision are presented.

5. Significance and Use

5.1 This practice is designed to provide color data obtained from spectral reflectance factors at specific illumination and

detection angles for interference pigments. Information presented in this test practice is based upon data taken on materials

exclusively pigmented with interference pigments.

5.2 These data can be used for acceptance testing, design purposes, research, manufacturing control, and quality control.

5.3 Specimens must be statistically representative of the end use.

5.4 Applicability of this practice for other materials, including combining interference pigments with absorbing and scattering

pigments should be confirmed by the user.

6. Environmental Conditions

6.1 If the standard laboratory conditions listed below change during the test or from test to test by an appreciable amount, these

conditions may reduce accuracy and precision of this test method. In some cases these effects may only be observed during the

performance of the test.

6.2 Factors affecting test results—The following factors are known to affect the test results.

6.2.1 Extraneous radiation—light from sources other than the illuminator(s) and any near-infrared (NIR) must be shielded from

entering the test apparatus.

6.2.2 Vibrations—mechanical oscillations that cause components of the apparatus to move relative to one another may cause

errors in test results.

6.2.3 Thermal changes—temperature changes occurring during a test or differences in temperature between testing locations

may affect calibration.

6.2.4 Power input fluctuations—large changes in the line frequency or supply voltage may cause the apparatus to report

erroneous results.

6.3 Standardization—The system must allow for successful standardization. If the system cannot be standardized, consult the

manufacturer’s user guide.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Available from the Inter-Society Color Council, 1191 Sunset Hills Road, Reston, VA 20190, www.iscc.org.

E2539 − 14

6.4 Controlling factors—Accuracy and precision can be enhanced by controlling and regulating each factor within the

constraints of the allowable experimental error. The values and limits for these factors are typically determined experimentally by

the user.

7. Apparatus

7.1 Multiangle Spectrometer—This practice specifies the required illumination and detection angles of multiangle spectrom-

eters. These multiangle spectrometers are designed specifically to characterize the optical behavior of materials colored with

interference pigments. Geometries are specified in Section 8. The spectrometer may either be a goniospectrometer or an abridged

goniospectrometer.

7.1.1 Bi-directional spectrometers or colorimeters with a single angle of measurement; such as 45°:0° or 0°:45°, and

spectrometers using hemispherical geometry cannot adequately characterize the gonioapparency of these materials.

7.1.2 Multiangle spectrometers or colorimeters similar to those specified in Practice E2194 cannot adequately characterize the

gonioapparency of these materials.

7.2 System Validation Materials—The precision and bias of the entire measurement system, including calculation of CIE

tristimulus values, should be determined by periodic measurement of known, calibrated, verification standards. These standards are

supplied by instrument manufacturers or obtained separately.

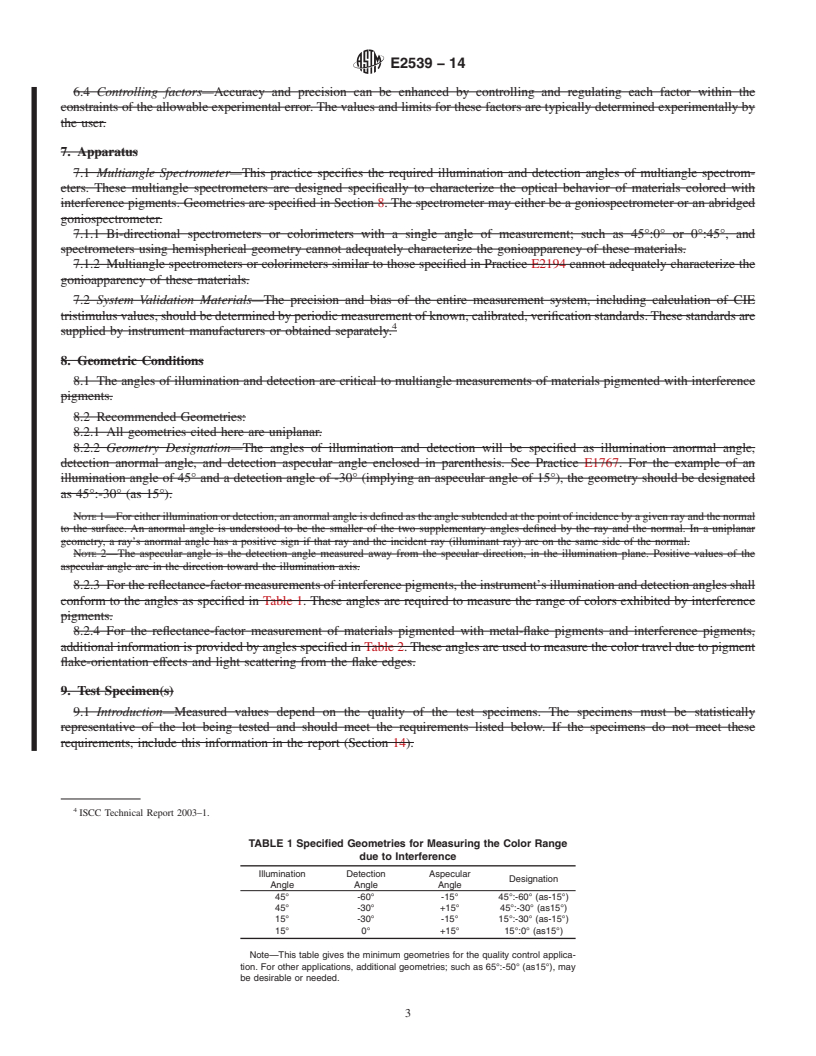

8. Geometric Conditions

8.1 The angles of illumination and detection are critical to multiangle measurements of materials pigmented with interference

pigments.

8.2 Recommended Geometries:

8.2.1 All geometries cited here are uniplanar.

8.2.2 Geometry Designation—The angles of illumination and detection will be specified as illumination anormal angle,

detection anormal angle, and detection aspecular angle enclosed in parenthesis. See Practice E1767. For the example of an

illumination angle of 45° and a detection angle of -30° (implying an aspecular angle of 15°), the geometry should be designated

as 45°:-30° (as 15°).

NOTE 1—For either illumination or detection, an anormal angle is defined as the angle subtended at the point of incidence by a given ray and the normal

to the surface. An anormal angle is understood to be the smaller of the two supplementary angles defined by the ray and the normal. In a uniplanar

geometry, a ray’s anormal angle has a positive sign if that ray and the incident ray (illuminant ray) are on the same side of the normal.

NOTE 2—The aspecular angle is the detection angle measured away from the specular direction, in the illumination plane. Positive values of the

aspecular angle are in the direction toward the illumination axis.

8.2.3 For the reflectance-factor measurements of interference pigments, the instrument’s illumination and detection angles shall

conform to the angles as specified in Table 1. These angles are required to measure the range of colors exhibited by interference

pigments.

8.2.4 For the reflectance-factor measurement of materials pigmented with metal-flake pigments and interference pigments,

additional information is provided by angles specified in Table 2. These angles are used to measure the color travel due to pigment

flake-orientation effects and light scattering from the flake edges.

9. Test Specimen(s)

9.1 Introduction—Measured values depend on the quality of the test specimens. The specimens must be statistically

representative of the lot being tested and should meet the requirements listed below. If the specimens do not meet these

requirements, include this information in the report (Section 14).

ISCC Technical Report 2003–1.

TABLE 1 Specified Geometries for Measuring the Color Range

due to Interference

Illumination Detection Aspecular

Designation

Angle Angle Angle

45° -60° -15° 45°:-60° (as-15°)

45° -30° +15° 45°:-30° (as15°)

15° -30° -15° 15°:-30° (as-15°)

15° 0° +15° 15°:0° (as15°)

Note—This table gives the minimum geometries for the quality control applica-

tion. For other applications, additional geometries; such as 65°:-50° (as15°), may

be desirable or needed.

E2539 − 14

TABLE 2 Specified Geometries for Measuring the Color due to

Scattering or Orientation

Illumination Detection Aspecular

Designation

Angle Angle Angle

45° -30° 15° 45°:-30° (as15°)*

45° -20° 25° 45°:-20° (as25°)

45° 0° 45° 45°:0° (as45°)*

45° 30° 75° 45°:30° (as75°)

45° 65° 110° 45°:65°

(as110°)*

Note—The three angles designated with an asterisk (*), refer to preferred angles

for critical measurements as specified in Practice Test Method E2194.

Note—Given a geometric configuration, the reverse geometry is considered

equivalent, if all other components of the instrument design are equivalent.

9.2 Specimen Handling—Handle the specimens carefully. Touch them by their edges only. Never lay the measurement surface

of the specimen down on another surface or stack specimens without a protective medium between them as recommended by the

provider.

9.3 Specimen Cleaning—If necessary, clean the specimens following the providers’ recommended cleaning procedure.

9.4 Specimen Conditioning—Allow specimens to stabilize in the measurement environment for a time period agreed to by the

parties concerned.

9.5 Specimen Physical Requirements:

9.5.1 For test specimens that will be assessed visually, the size shall be at least 8 by 8 cm (approximately 3 by 3 in.). This

specimen size is well suited for both visual assessment and instrumental measurement. See also 12.2.

NOTE 3—This recommendation for specimen size corresponds to the physical size required for observation by the CIE 1964 Standard Observer (10°).

The specimen must subtend at least 10° when being observed. Observation usually occurs at approximately 45 cm (17.7 in.) from the eye.

9.5.2 The surface of the specimen should be planar.

9.6 Specimen Optical Requirements:

9.6.1 Uniformity—Reference and test specimens should be uniform in color and appearance. For materials pigmented with

interference or metallic pigments, measurements on different locations on the sample are necessary to assess the degree of

non-uniformity. These data are also

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.