ASTM E1181-02(2008)e1

(Test Method)Standard Test Methods for Characterizing Duplex Grain Sizes

Standard Test Methods for Characterizing Duplex Grain Sizes

SIGNIFICANCE AND USE

5.1 Duplex grain size may occur in some metals and alloys as a result of their thermomechanical processing history. For comparison of mechanical properties with metallurgical features, or for specification purposes, it may be important to be able to characterize grain size in such materials. Assigning an average grain size value to a duplex grain size specimen does not adequately characterize the appearance of that specimen, and may even misrepresent its appearance. For example, averaging two distinctly different grain sizes may result in reporting a size that does not actually exist anywhere in the specimen.

5.2 These test methods may be applied to specimens or products containing randomly intermingled grains of two or more significantly different sizes (henceforth referred to as random duplex grain size). Examples of random duplex grain sizes include: isolated coarse grains in a matrix of much finer grains, extremely wide distributions of grain sizes, and bimodal distributions of grain size.

5.3 These test methods may also be applied to specimens or products containing grains of two or more significantly different sizes, but distributed in topologically varying patterns (henceforth referred to as topological duplex grain sizes). Examples of topological duplex grain sizes include: systematic variation of grain size across the section of a product, necklace structures, banded structures, and germinative grain growth in selected areas of critical strain.

5.4 These test methods may be applied to specimens or products regardless of their state of recrystallization.

5.5 Because these test methods describe deviations from a single, log-normal distribution of grain sizes, and characterize patterns of variation in grain size, the total specimen cross-section must be evaluated.

5.6 These test methods are limited to duplex grain sizes as identifiable within a single polished and etched metallurgical specimen. If duplex grain size is suspected in a product too ...

SCOPE

1.1 These test methods provide simple guidelines for deciding whether a duplex grain size exists. The test methods separate duplex grain sizes into one of two distinct classes, then into specific types within those classes, and provide systems for grain size characterization of each type.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard to consult appropriate safety and health practices and determine the applicability of regulatory limitations prior to its use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E1181 − 02(Reapproved 2008)

Standard Test Methods for

Characterizing Duplex Grain Sizes

This standard is issued under the fixed designation E1181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Footnote 1 was editorially corrected in February 2015.

INTRODUCTION

Test methods are well established for the determination of average grain size, and estimation of

largest grain size, in products assumed to contain a single log-normal distribution of grain sizes. The

test methods in this standard are set forth to characterize grain size in products with any other

distributions of grain size.

The term “duplex grain size” is chosen to describe any of these other distributions of grain size,

because of its common usage and familiarity. However, the use of that term does not imply that only

two grain size distributions exist.

These test methods are equally aimed at describing the nature of the deviation from a single

log-normal distribution of grain sizes, and at describing with reasonable accuracy the distributions of

sizes that actually exist.

1. Scope E7 Terminology Relating to Metallography

E112 Test Methods for Determining Average Grain Size

1.1 These test methods provide simple guidelines for decid-

E407 Practice for Microetching Metals and Alloys

ing whether a duplex grain size exists. The test methods

E562 Test Method for Determining Volume Fraction by

separate duplex grain sizes into one of two distinct classes,

Systematic Manual Point Count

then into specific types within those classes, and provide

E883 Guide for Reflected–Light Photomicrography

systems for grain size characterization of each type.

E930 Test Methods for Estimating the Largest Grain Ob-

1.2 Units—The values stated in SI units are to be regarded

served in a Metallographic Section (ALA Grain Size)

as standard. No other units of measurement are included in this

2.2 ASTM Adjuncts:

standard.

Comparison Chart for Estimation of Area Fractions

1.3 This standard may involve hazardous materials,

3. Terminology

operations, and equipment. This standard does not purport to

address all of the safety concerns associated with its use. It is

3.1 Definitions:

the responsibility of the user of this standard to consult

3.1.1 All terms used in these test methods are either defined

appropriate safety and health practices and determine the in Terminology E7, or are discussed in 3.2.

applicability of regulatory limitations prior to its use.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 bands or banding— in grain size, alternating areas of

2. Referenced Documents

significantly different grain sizes. These areas are usually

elongated in a direction parallel to the direction of working.

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

3.2.2 grain size—equivalent in meaning to the average of a

distribution of grain sizes.

3.2.3 necklace or necklace structure—individual coarse

These test methods are under the jurisdiction of ASTM Committee E04 on

grains surrounded by rings of significantly finer grains.

Metallography and are the direct responsibility of Subcommittee E04.08 on Grain

Size.

3.2.4 topologically varying—varying nonrandomly, in some

Current edition approved June 1, 2008. Published October 2008. Originally

definablepattern;thatpatternmayberelatedtotheshapeofthe

approved in 1987. Last previous edition approved in 2002 as E1181–02. DOI:

10.1520/E1181-02R08E01.

specimen or product being examined.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on This comparison chart shows different area percentages of light grains among

the ASTM website. dark grains. Available from ASTM Headquarters. Order Adjunct: ADJE1181.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

´1

E1181 − 02 (2008)

4. Summary of Test Method does not adequately characterize the appearance of that

specimen, and may even misrepresent its appearance. For

4.1 These test methods provide means for recognizing the

example, averaging two distinctly different grain sizes may

presenceofduplexgrainsize.Thetestmethodsseparateduplex

result in reporting a size that does not actually exist anywhere

grain sizes into two classes (randomly varying, and topologi-

in the specimen.

cally varying), and define specific types of duplex grain sizes

within these classes. The test methods provide means for

5.2 These test methods may be applied to specimens or

estimating area fractions occupied by distinct grain sizes, and

products containing randomly intermingled grains of two or

offer existing standard methods (Test Methods E112, Test

more significantly different sizes (henceforth referred to as

Methods E930) for determining grain size in specific identified

random duplex grain size). Examples of random duplex grain

areas. The test methods provide for reporting of specific,

sizes include: isolated coarse grains in a matrix of much finer

distinctive information for each type of duplex grain size.And,

grains,extremelywidedistributionsofgrainsizes,andbimodal

as an alternative, the test methods offer a procedure for

distributions of grain size.

statistically determining the distribution of all the grain sizes

5.3 These test methods may also be applied to specimens or

present in a duplex grain size specimen.

products containing grains of two or more significantly differ-

5. Significance and Use

ent sizes, but distributed in topologically varying patterns

(henceforth referred to as topological duplex grain sizes).

5.1 Duplex grain size may occur in some metals and alloys

Examples of topological duplex grain sizes include: systematic

as a result of their thermomechanical processing history. For

variation of grain size across the section of a product, necklace

comparison of mechanical properties with metallurgical

structures, banded structures, and germinative grain growth in

features, or for specification purposes, it may be important to

selected areas of critical strain.

be able to characterize grain size in such materials. Assigning

an average grain size value to a duplex grain size specimen

5.4 These test methods may be applied to specimens or

products regardless of their state of recrystallization.

5.5 Because these test methods describe deviations from a

single, log-normal distribution of grain sizes, and characterize

patterns of variation in grain size, the total specimen cross-

section must be evaluated.

5.6 These test methods are limited to duplex grain sizes as

identifiable within a single polished and etched metallurgical

specimen. If duplex grain size is suspected in a product too

large to be polished and etched as a single specimen, mac-

roetchingshouldbeconsideredasafirststepinevaluation.The

entire macroetched cross-section should be used as a basis for

estimating area fractions occupied by distinct grain sizes, if

possible. If microscopic examination is subsequently

necessary, individual specimens must be taken to allow esti-

mation of area fractions for the entire product cross-section,

and to allow determination of grain sizes representing the

entire cross-section as well.

5.7 These test methods are intended to be applied to duplex

grain sizes. Duplex grain structures (for example, multiphase

alloys) are not necessarily duplex in grain size, and as such are

not the subject of these methods. However, the test methods

described here for area fraction estimation may be of use in

describing duplex grain structures.

6. Apparatus

6.1 Certain items may be helpful or necessary in applying

the various procedures of these test methods. These items are

briefly described below, under the headings of the specific

procedures to which they apply.

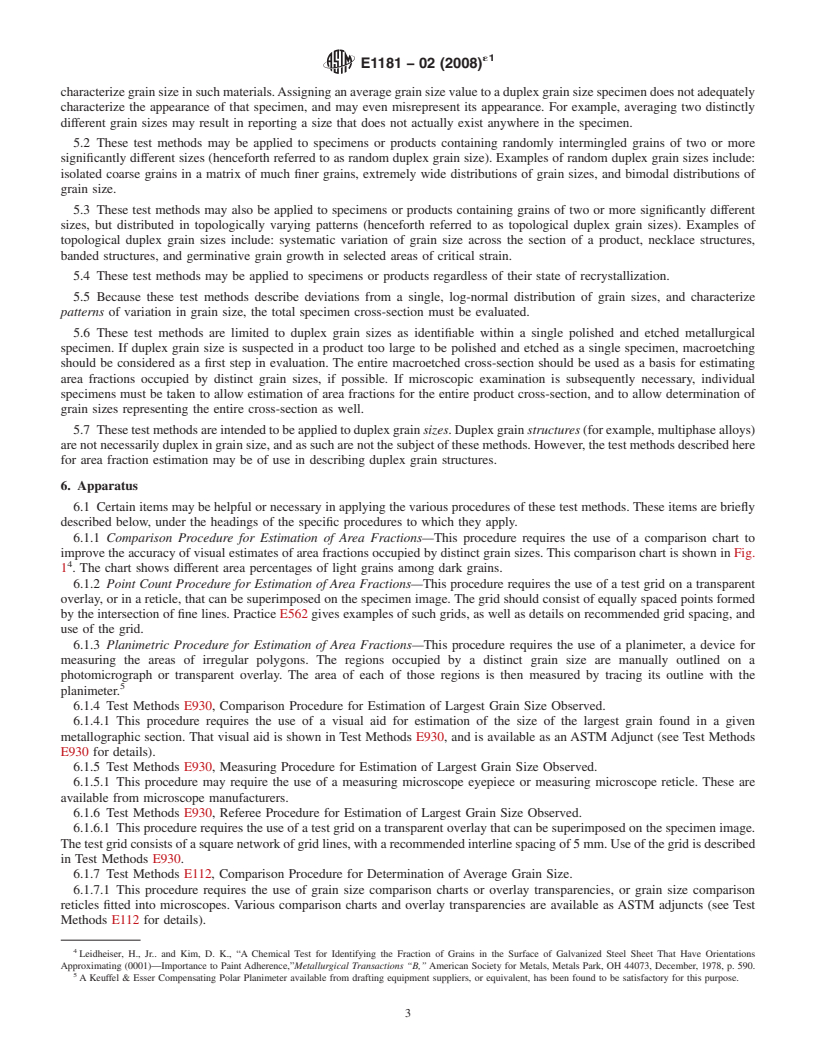

6.1.1 Comparison Procedure for Estimation of Area

Fractions—This procedure requires the use of a comparison

chart to improve the accuracy of visual estimates of area

FIG. 1 Comparison Chart for Estimation of Area Fractions

(Showing area percentages of light grains among dark grains) fractions occupied by distinct grain sizes. This comparison

´1

E1181 − 02 (2008)

chart is shown in Fig. 1 . The chart shows different area 6.1.9 Statistical Determination of Grain Size Distribution:

percentages of light grains among dark grains. 6.1.9.1 This procedure requires the use of a test grid on a

6.1.2 Point Count Procedure for Estimation of Area transparent overlay that can be superimposed on the specimen

Fractions—This procedure requires the use of a test grid on a image. The test grid consists of a series of fine, parallel lines,

transparentoverlay,orinareticle,thatcanbesuperimposedon with an interline spacing of 5 mm. Use of the grid is described

the specimen image. The grid should consist of equally spaced in 8.7.

points formed by the intersection of fine lines. Practice E562 6.1.9.2 This procedure may be carried out using manual

gives examples of such grids, as well as details on recom- measuring and counting techniques, but as such, will be very

mended grid spacing, and use of the grid. laborious and time-consuming. This procedure can be carried

6.1.3 Planimetric Procedure for Estimation of Area out much more efficiently through the use of an automated

Fractions—This procedure requires the use of a planimeter, a image analysis system with an electronic pencil or cursor, or

device for measuring the areas of irregular polygons. The through the use of a semi-automated image analysis system

regions occupied by a distinct grain size are manually outlined withadigitizingtabletandelectronicpencilorcursor. Theuse

on a photomicrograph or transparent overlay. The area of each of this equipment is also described in 8.7.

ofthoseregionsisthenmeasuredbytracingitsoutlinewiththe

planimeter. 7. Sampling and Test Specimens

6.1.4 Test Methods E930, Comparison Procedure for Esti-

7.1 Sampling:

mation of Largest Grain Size Observed.

7.1.1 These test methods are intended to characterize pat-

6.1.4.1 This procedure requires the use of a visual aid for

terns of variation in grain size, when they occur in a given

estimation of the size of the largest grain found in a given

specimen or product. To characterize these patterns accurately,

metallographic section. That visual aid is shown in Test

the entire cross-section of the specimen or product must be

Methods E930, and is available as anASTMAdjunct (see Test

evaluated.

Methods E930 for details).

7.1.2 If variations in grain size occur in a product too large

6.1.5 Test Methods E930, Measuring Procedure for Estima-

to be polished and etched as a single specimen, individual

tion of Largest Grain Size Observed.

specimens must be taken to allow estimation of area fractions

6.1.5.1 This procedure may require the use of a measuring

for the entire product cross-section, and to allow determination

microscope eyepiece or measuring microscope reticle. These

of grain sizes representing the entire cross-section as well.

are available from microscope manufacturers.

7.2 Specimen Orientation:

6.1.6 Test Methods E930, Referee Procedure for Estimation

7.2.1 All of the types of duplex grain size described in this

of Largest Grain Size Observed.

test method (see 3.2 and 8.3) can be detected in a longitudinal

6.1.6.1 This procedure requires the use of a test grid on a

specimenorientation(thatis,inaplaneparalleltothedirection

transparent overlay that can be superimposed on the specimen

of maximum product deformation, during manufacture).

image. The test grid consists of a square network of grid lines,

Accordingly, the longitudinal orientation is recommended,

witharecommendedinterlinespacingof5mm.Useofthegrid

with one exception. If the specimen being examined is the full

is described in Test Methods E930.

cross-sectionofaroundbar,thelongitudinalsectionshouldnot

6.1.7 Test Methods E112, Comparison Procedure for Deter-

beusedtoestimatetheareafractionoccupiedbydifferentgrain

mination of Average Grain Size.

sizes. That estimate can be made most accurately only on a

6.1.7.1 This procedure requires the use of grain size com-

transverse section. For a tubular product, estimates of area

parison charts or overlay transparencies, or grain size compari-

fractionsmadeonlongitudinalsectionsarereasonableapproxi-

son reticles fitted into microscopes. Various comparison charts

mationsofthesameestimatesmadeontransversesections.For

and overlay transparencies are available as ASTM adjuncts

all other products, area fraction estimates should be equally

(see Test Methods E112 for details).

accurate with either specimen orientation.

6.1.7.2 Grain size comparison reticles are available from

7.2.2 Other specimen orientations may be used, provided

various manufacturers of microscopes.

that their limitations are recognized. For instance, banding

6.1.8 Test Methods E112, Intercept Procedures for Determi-

present in a given specimen may not be easily recognizable in

nation of Average Grain Size,

a transverse orientation.

6.1.8.1 The Intercept Procedures of Test Methods E112

7.2.3 The specimen orientation used should be reported

require the use of patterns of test lines, usually on transparent

along with the duplex grain size characterization.

overlays. The use of these is described in detail in Test

Methods E112.Atransparency of one such pattern is available

8. Procedure

as an ASTM adjunct (see Test Methods E112 for details).

8.1 Specimen Preparation—Prepare specimens according to

Methods E3, and etch specimens in accordance with Practice

Leidheiser, H., Jr. and Kim, D. K., “A Chemical Test for Identifying the

E407. Etch specimens so that all grain boundaries are distinct

Fraction of Grains in the Surface of Galvanized Steel Sheet That Have Orientations

Approximating (0001)—Importance to Paint Adherence,”Metallurgical Transac- and easily visible.

tions “B,”American Society for Metals, Metals Park, OH 44073, December, 1978,

p. 590.

A Keuffel & Esser Compensating Polar Planimeter available from drafting

equipment suppliers, or equivalent, has been found to be satisfactory for this AZeissVideoplanSystem,oritsequivalent,hasbeenfoundsatisfactoryforthis

purpose. purpose.

´1

E1181 − 02 (2008)

8.2 Preparation of Photomicrographs—If photomicro- procedures for estimating area fraction are described, the

graphs are required for characterizing duplex grain siz

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E1181 − 02 (Reapproved 2008) E1181 − 02 (Reapproved 2008)

Standard Test Methods for

Characterizing Duplex Grain Sizes

This standard is issued under the fixed designation E1181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Footnote 1 was editorially corrected in February 2015.

INTRODUCTION

Test methods are well established for the determination of average grain size, and estimation of

largest grain size, in products assumed to contain a single log-normal distribution of grain sizes. The

test methods in this standard are set forth to characterize grain size in products with any other

distributions of grain size.

The term “duplex grain size” is chosen to describe any of these other distributions of grain size,

because of its common usage and familiarity. However, the use of that term does not imply that only

two grain size distributions exist.

These test methods are equally aimed at describing the nature of the deviation from a single

log-normal distribution of grain sizes, and at describing with reasonable accuracy the distributions of

sizes that actually exist.

1. Scope

1.1 These test methods provide simple guidelines for deciding whether a duplex grain size exists. The test methods separate

duplex grain sizes into one of two distinct classes, then into specific types within those classes, and provide systems for grain size

characterization of each type.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety concerns associated with its use. It is the responsibility of the user of this standard to consult appropriate safety and

health practices and determine the applicability of regulatory limitations prior to its use.

2. Referenced Documents

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

E112 Test Methods for Determining Average Grain Size

E407 Practice for Microetching Metals and Alloys

E562 Test Method for Determining Volume Fraction by Systematic Manual Point Count

E883 Guide for Reflected–Light Photomicrography

E930 Test Methods for Estimating the Largest Grain Observed in a Metallographic Section (ALA Grain Size)

2.2 ASTM Adjuncts:

Comparison Chart for Estimation of Area Fractions

These test methods are under the jurisdiction of ASTM Committee E04 on Metallography and are the direct responsibility of Subcommittee E04.08 on Grain Size.

Current edition approved June 1, 2008. Published October 2008. Originally approved in 1994.1987. Last previous edition approved in 2002 as E1181–02. DOI:

10.1520/E1181-02R08.10.1520/E1181-02R08E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

This comparison chart shows different area percentages of light grains among dark grains. Available from ASTM Headquarters. Order Adjunct: ADJE1181.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1181 − 02 (2008)

3. Terminology

3.1 Definitions:

3.1.1 All terms used in these test methods are either defined in Terminology E7, or are discussed in 3.2.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 bands or banding— in grain size, alternating areas of significantly different grain sizes. These areas are usually elongated

in a direction parallel to the direction of working.

3.2.2 grain size—equivalent in meaning to the average of a distribution of grain sizes.

3.2.3 necklace or necklace structure—individual coarse grains surrounded by rings of significantly finer grains.

3.2.4 topologically varying—varying nonrandomly, in some definable pattern; that pattern may be related to the shape of the

specimen or product being examined.

4. Summary of Test Method

4.1 These test methods provide means for recognizing the presence of duplex grain size. The test methods separate duplex grain

sizes into two classes (randomly varying, and topologically varying), and define specific types of duplex grain sizes within these

classes. The test methods provide means for estimating area fractions occupied by distinct grain sizes, and offer existing standard

methods (Test Methods E112, Test Methods E930) for determining grain size in specific identified areas. The test methods provide

for reporting of specific, distinctive information for each type of duplex grain size. And, as an alternative, the test methods offer

a procedure for statistically determining the distribution of all the grain sizes present in a duplex grain size specimen.

5. Significance and Use

5.1 Duplex grain size may occur in some metals and alloys as a result of their thermomechanical processing history. For

comparison of mechanical properties with metallurgical features, or for specification purposes, it may be important to be able to

FIG. 1 Comparison Chart for Estimation of Area Fractions

(Showing area percentages of light grains among dark grains)

´1

E1181 − 02 (2008)

characterize grain size in such materials. Assigning an average grain size value to a duplex grain size specimen does not adequately

characterize the appearance of that specimen, and may even misrepresent its appearance. For example, averaging two distinctly

different grain sizes may result in reporting a size that does not actually exist anywhere in the specimen.

5.2 These test methods may be applied to specimens or products containing randomly intermingled grains of two or more

significantly different sizes (henceforth referred to as random duplex grain size). Examples of random duplex grain sizes include:

isolated coarse grains in a matrix of much finer grains, extremely wide distributions of grain sizes, and bimodal distributions of

grain size.

5.3 These test methods may also be applied to specimens or products containing grains of two or more significantly different

sizes, but distributed in topologically varying patterns (henceforth referred to as topological duplex grain sizes). Examples of

topological duplex grain sizes include: systematic variation of grain size across the section of a product, necklace structures,

banded structures, and germinative grain growth in selected areas of critical strain.

5.4 These test methods may be applied to specimens or products regardless of their state of recrystallization.

5.5 Because these test methods describe deviations from a single, log-normal distribution of grain sizes, and characterize

patterns of variation in grain size, the total specimen cross-section must be evaluated.

5.6 These test methods are limited to duplex grain sizes as identifiable within a single polished and etched metallurgical

specimen. If duplex grain size is suspected in a product too large to be polished and etched as a single specimen, macroetching

should be considered as a first step in evaluation. The entire macroetched cross-section should be used as a basis for estimating

area fractions occupied by distinct grain sizes, if possible. If microscopic examination is subsequently necessary, individual

specimens must be taken to allow estimation of area fractions for the entire product cross-section, and to allow determination of

grain sizes representing the entire cross-section as well.

5.7 These test methods are intended to be applied to duplex grain sizes. Duplex grain structures (for example, multiphase alloys)

are not necessarily duplex in grain size, and as such are not the subject of these methods. However, the test methods described here

for area fraction estimation may be of use in describing duplex grain structures.

6. Apparatus

6.1 Certain items may be helpful or necessary in applying the various procedures of these test methods. These items are briefly

described below, under the headings of the specific procedures to which they apply.

6.1.1 Comparison Procedure for Estimation of Area Fractions—This procedure requires the use of a comparison chart to

improve the accuracy of visual estimates of area fractions occupied by distinct grain sizes. This comparison chart is shown in Fig.

1 . The chart shows different area percentages of light grains among dark grains.

6.1.2 Point Count Procedure for Estimation of Area Fractions—This procedure requires the use of a test grid on a transparent

overlay, or in a reticle, that can be superimposed on the specimen image. The grid should consist of equally spaced points formed

by the intersection of fine lines. Practice E562 gives examples of such grids, as well as details on recommended grid spacing, and

use of the grid.

6.1.3 Planimetric Procedure for Estimation of Area Fractions—This procedure requires the use of a planimeter, a device for

measuring the areas of irregular polygons. The regions occupied by a distinct grain size are manually outlined on a

photomicrograph or transparent overlay. The area of each of those regions is then measured by tracing its outline with the

planimeter.

6.1.4 Test Methods E930, Comparison Procedure for Estimation of Largest Grain Size Observed.

6.1.4.1 This procedure requires the use of a visual aid for estimation of the size of the largest grain found in a given

metallographic section. That visual aid is shown in Test Methods E930, and is available as an ASTM Adjunct (see Test Methods

E930 for details).

6.1.5 Test Methods E930, Measuring Procedure for Estimation of Largest Grain Size Observed.

6.1.5.1 This procedure may require the use of a measuring microscope eyepiece or measuring microscope reticle. These are

available from microscope manufacturers.

6.1.6 Test Methods E930, Referee Procedure for Estimation of Largest Grain Size Observed.

6.1.6.1 This procedure requires the use of a test grid on a transparent overlay that can be superimposed on the specimen image.

The test grid consists of a square network of grid lines, with a recommended interline spacing of 5 mm. Use of the grid is described

in Test Methods E930.

6.1.7 Test Methods E112, Comparison Procedure for Determination of Average Grain Size.

6.1.7.1 This procedure requires the use of grain size comparison charts or overlay transparencies, or grain size comparison

reticles fitted into microscopes. Various comparison charts and overlay transparencies are available as ASTM adjuncts (see Test

Methods E112 for details).

Leidheiser, H., Jr. and Kim, D. K., “A Chemical Test for Identifying the Fraction of Grains in the Surface of Galvanized Steel Sheet That Have Orientations

Approximating (0001)—Importance to Paint Adherence,”Metallurgical Transactions “B,” American Society for Metals, Metals Park, OH 44073, December, 1978, p. 590.

A Keuffel & Esser Compensating Polar Planimeter available from drafting equipment suppliers, or equivalent, has been found to be satisfactory for this purpose.

´1

E1181 − 02 (2008)

6.1.7.2 Grain size comparison reticles are available from various manufacturers of microscopes.

6.1.8 Test Methods E112, Intercept Procedures for Determination of Average Grain Size,

6.1.8.1 The Intercept Procedures of Test Methods E112 require the use of patterns of test lines, usually on transparent overlays.

The use of these is described in detail in Test Methods E112. A transparency of one such pattern is available as an ASTM adjunct

(see Test Methods E112 for details).

6.1.9 Statistical Determination of Grain Size Distribution:

6.1.9.1 This procedure requires the use of a test grid on a transparent overlay that can be superimposed on the specimen image.

The test grid consists of a series of fine, parallel lines, with an interline spacing of 5 mm. Use of the grid is described in 8.7.

6.1.9.2 This procedure may be carried out using manual measuring and counting techniques, but as such, will be very laborious

and time-consuming. This procedure can be carried out much more efficiently through the use of an automated image analysis

system with an electronic pencil or cursor, or through the use of a semi-automated image analysis system with a digitizing tablet

and electronic pencil or cursor. The use of this equipment is also described in 8.7.

7. Sampling and Test Specimens

7.1 Sampling:

7.1.1 These test methods are intended to characterize patterns of variation in grain size, when they occur in a given specimen

or product. To characterize these patterns accurately, the entire cross-section of the specimen or product must be evaluated.

7.1.2 If variations in grain size occur in a product too large to be polished and etched as a single specimen, individual specimens

must be taken to allow estimation of area fractions for the entire product cross-section, and to allow determination of grain sizes

representing the entire cross-section as well.

7.2 Specimen Orientation:

7.2.1 All of the types of duplex grain size described in this test method (see 3.2 and 8.3) can be detected in a longitudinal

specimen orientation (that is, in a plane parallel to the direction of maximum product deformation, during manufacture).

Accordingly, the longitudinal orientation is recommended, with one exception. If the specimen being examined is the full

cross-section of a round bar, the longitudinal section should not be used to estimate the area fraction occupied by different grain

sizes. That estimate can be made most accurately only on a transverse section. For a tubular product, estimates of area fractions

made on longitudinal sections are reasonable approximations of the same estimates made on transverse sections. For all other

products, area fraction estimates should be equally accurate with either specimen orientation.

7.2.2 Other specimen orientations may be used, provided that their limitations are recognized. For instance, banding present in

a given specimen may not be easily recognizable in a transverse orientation.

7.2.3 The specimen orientation used should be reported along with the duplex grain size characterization.

8. Procedure

8.1 Specime

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.