ASTM E854-03(2009)

(Test Method)Standard Test Method for Application and Analysis of Solid State Track Recorder (SSTR) Monitors for Reactor Surveillance, E706(IIIB)

Standard Test Method for Application and Analysis of Solid State Track Recorder (SSTR) Monitors for Reactor Surveillance, E706(IIIB)

SIGNIFICANCE AND USE

The SSTR method provides for the measurement of absolute-fission density per unit mass. Absolute-neutron fluence can then be inferred from these SSTR-based absolute fission rate observations if an appropriate neutron spectrum average fission cross section is known. This method is highly discriminatory against other components of the in-core radiation field. Gamma rays, beta rays, and other lightly ionizing particles do not produce observable tracks in appropriate LWR SSTR candidate materials. However, photofission can contribute to the observed fission track density and should therefore be accounted for when nonnegligible. For a more detailed discussion of photofission effects, see 13.4.

In this test method, SSTR are placed in surface contact with fissionable deposits and record neutron-induced fission fragments. By variation of the surface mass density (μg/cm2) of the fissionable deposit as well as employing the allowable range of track densities (from roughly 1 event/cm2 up to 105 events/cm2 for manual scanning), a range of total fluence sensitivity covering at least 16 orders of magnitude is possible, from roughly 102 n/cm 2 up to 5 × 1018 n/cm2. The allowable range of fission track densities is broader than the track density range for high accuracy manual scanning work with optical microscopy cited in 1.2. In particular, automated and semi-automated methods exist that broaden the customary track density range available with manual optical microscopy. In this broader track density region, effects of reduced counting statistics at very low track densities and track pile-up corrections at very high track densities can present inherent limitations for work of high accuracy. Automated scanning techniques are described in Section 11.

For dosimetry applications, different energy regions of the neutron spectrum can be selectively emphasized by changing the nuclide used for the fission deposit.

It is possible to use SSTR directly for neutron dosimetry as described ...

SCOPE

1.1 This test method describes the use of solid-state track recorders (SSTRs) for neutron dosimetry in light-water reactor (LWR) applications. These applications extend from low neutron fluence to high neutron fluence, including high power pressure vessel surveillance and test reactor irradiations as well as low power benchmark field measurement. (1) This test method replaces Method E 418. This test method is more detailed and special attention is given to the use of state-of-the-art manual and automated track counting methods to attain high absolute accuracies. In-situ dosimetry in actual high fluence-high temperature LWR applications is emphasized.

1.2 This test method includes SSTR analysis by both manual and automated methods. To attain a desired accuracy, the track scanning method selected places limits on the allowable track density. Typically good results are obtained in the range of 5 to 800 000 tracks/cm2 and accurate results at higher track densities have been demonstrated for some cases. (2) Track density and other factors place limits on the applicability of the SSTR method at high fluences. Special care must be exerted when measuring neutron fluences (E>1MeV) above 1016 n/cm2. (3)

1.3 High fluence limitations exist. These limitations are discussed in detail in Section 13 and in references (3-5).

1.4 SSTR observations provide time-integrated reaction rates. Therefore, SSTR are truly passive-fluence detectors. They provide permanent records of dosimetry experiments without the need for time-dependent corrections, such as decay factors that arise with radiometric monitors.

1.5 Since SSTR provide a spatial record of the time-integrated reaction rate at a microscopic level, they can be used for “fine-structure” measurements. For example, spatial distributions of isotopic fission rates can be obtained at very high resolution with SSTR.

1.6 This standard does not purport to address the safety problems as...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E854 −03(Reapproved 2009)

Standard Test Method for

Application and Analysis of Solid State Track Recorder

(SSTR) Monitors for Reactor Surveillance, E706(IIIB)

This standard is issued under the fixed designation E854; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope butions of isotopic fission rates can be obtained at very high

resolution with SSTR.

1.1 This test method describes the use of solid-state track

1.6 This standard does not purport to address the safety

recorders (SSTRs) for neutron dosimetry in light-water reactor

problems associated with its use. It is the responsibility of the

(LWR) applications. These applications extend from low

user of this standard to establish appropriate safety and health

neutron fluence to high neutron fluence, including high power

practices and determine the applicability of regulatory limita-

pressurevesselsurveillanceandtestreactorirradiationsaswell

tions prior to use.

as low power benchmark field measurement. (1) This test

method replaces Method E418. This test method is more

2. Referenced Documents

detailed and special attention is given to the use of state-of-

2.1 ASTM Standards:

the-art manual and automated track counting methods to attain

high absolute accuracies. In-situ dosimetry in actual high E418Test Method for Fast-Neutron Flux Measurements by

Track-Etch Techniques (Withdrawn 1984)

fluence-high temperature LWR applications is emphasized.

E844Guide for Sensor Set Design and Irradiation for

1.2 This test method includes SSTR analysis by both

Reactor Surveillance, E 706 (IIC)

manual and automated methods. To attain a desired accuracy,

the track scanning method selected places limits on the

3. Summary of Test Method

allowable track density. Typically good results are obtained in

2 3.1 SSTR are usually placed in firm surface contact with a

the range of 5 to 800 000 tracks/cm and accurate results at

fissionable nuclide that has been deposited on a pure nonfis-

higher track densities have been demonstrated for some cases.

sionable metal substrate (backing). This typical SSTR geom-

(2) Track density and other factors place limits on the appli-

etry is depicted in Fig. 1. Neutron-induced fission produces

cability of the SSTR method at high fluences. Special care

latent fission-fragment tracks in the SSTR. These tracks may

must be exerted when measuring neutron fluences (E>1MeV)

16 2 be developed by chemical etching to a size that is observable

above 10 n/cm . (3)

with an optical microscope. Microphotographs of etched fis-

1.3 High fluence limitations exist. These limitations are

siontracksinmica,quartzglass,andnaturalquartzcrystalscan

discussed in detail in Section 13 and in references (3-5).

be seen in Fig. 2.

3.1.1 While the conventional SSTR geometry depicted in

1.4 SSTR observations provide time-integrated reaction

Fig. 1 is not mandatory, it does possess distinct advantages for

rates. Therefore, SSTR are truly passive-fluence detectors.

dosimetry applications. In particular, it provides the highest

They provide permanent records of dosimetry experiments

efficiency and sensitivity while maintaining a fixed and easily

withouttheneedfortime-dependentcorrections,suchasdecay

reproducible geometry.

factors that arise with radiometric monitors.

3.1.2 Thetrackdensity(thatis,thenumberoftracksperunit

1.5 Since SSTR provide a spatial record of the time-

area) is proportional to the fission density (that is, the number

integratedreactionrateatamicroscopiclevel,theycanbeused

of fissions per unit area). The fission density is, in turn,

for “fine-structure” measurements. For example, spatial distri-

proportionaltotheexposurefluenceexperiencedbytheSSTR.

The existence of nonuniformity in the fission deposit or the

presence of neutron flux gradients can produce non-uniform

ThistestmethodisunderthejurisdictionofASTMCommitteeE10onNuclear

Technology and Applicationsand is the direct responsibility of Subcommittee

E10.05 on Nuclear Radiation Metrology. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 1, 2009. Published June 2009. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1981. Last previous edition approved in 2003 as E854–03. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E0854-03R09. the ASTM website.

2 4

The boldface numbers in parentheses refer to the list of references appended to The last approved version of this historical standard is referenced on

this test method. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E854−03 (2009)

tions for work of high accuracy. Automated scanning tech-

niques are described in Section 11.

4.3 For dosimetry applications, different energy regions of

the neutron spectrum can be selectively emphasized by chang-

ing the nuclide used for the fission deposit.

4.4 ItispossibletouseSSTRdirectlyforneutrondosimetry

as described in 4.1 or to obtain a composite neutron detection

efficiency by exposure in a benchmark neutron field. The

fluenceandspectrum-averagedcrosssectioninthisbenchmark

fieldmustbeknown.Furthermore,applicationinotherneutron

fields may require adjustments due to spectral deviation from

the benchmark field spectrum used for calibration. In any

event, it must be stressed that the SSTR-fission density

FIG. 1 Typical Geometrical Configuration Used for SSTR Neutron

measurements can be carried out completely independent of

Dosimetry

any cross-section standards (6). Therefore, for certain

applications, the independent nature of this test method should

not be compromised. On the other hand, many practical

track density. Conversely, with fission deposits of proven

applications exist wherein this factor is of no consequence so

uniformity, gradients of the neutron field can be investigated

that benchmark field calibration would be entirely appropriate.

with very high spatial resolution.

3.2 The total uncertainty of SSTR fission rates is comprised

5. Apparatus

of two independent sources.These two error components arise

5.1 Optical Microscopes, with a magnification of 200×or

from track counting uncertainties and fission-deposit mass

higher, employing a graduated mechanical stage with position

uncertainties. For work at the highest accuracy levels, fission-

readout to the nearest 1 µm and similar repositioning accuracy.

deposit mass assay should be performed both before and after

Acalibrated stage micrometer and eyepiece scanning grids are

the SSTR irradiation. In this way, it can be ascertained that no

also required.

significant removal of fission deposit material arose in the

course of the experiment. 5.2 Constant-Temperature Bath, for etching, with tempera-

ture control to 0.1°C.

4. Significance and Use

5.3 Analytical Weighing Balance, for preparation of etching

4.1 The SSTR method provides for the measurement of

bath solutions, with a capacity of at least 1000 g and an

absolute-fission density per unit mass. Absolute-neutron flu-

accuracy of at least 1 mg.

ence can then be inferred from these SSTR-based absolute

fission rate observations if an appropriate neutron spectrum 6. Reagents and Materials

average fission cross section is known. This method is highly

6.1 Purity of Reagents—Distilled or demineralized water

discriminatory against other components of the in-core radia-

and analytical grade reagents should be used at all times. For

tion field. Gamma rays, beta rays, and other lightly ionizing

high fluence measurements, quartz-distilled water and ultra-

particles do not produce observable tracks in appropriate LWR

pure reagents are necessary in order to reduce background

SSTR candidate materials. However, photofission can contrib-

fission tracks from natural uranium and thorium impurities.

utetotheobservedfissiontrackdensityandshouldthereforebe

This is particularly important if any pre-irradiation etching is

accounted for when nonnegligible. For a more detailed discus-

performed (see 8.2).

sion of photofission effects, see 13.4.

6.2 Reagents:

4.2 In this test method, SSTR are placed in surface contact

6.2.1 Hydrofluoric Acid (HF), weight 49%.

with fissionable deposits and record neutron-induced fission

6.2.2 Sodium Hydroxide Solution (NaOH), 6.2 N.

fragments.Byvariationofthesurfacemassdensity(µg/cm )of

6.2.3 Distilled or Demineralized Water.

the fissionable deposit as well as employing the allowable

6.2.4 Potassium Hydroxide Solution (KOH), 6.2 N.

2 5

range of track densities (from roughly 1 event/cm up to 10

6.2.5 Sodium Hydroxide Solution (NaOH), weight 65%.

events/cm for manual scanning), a range of total fluence

6.3 Materials:

sensitivitycoveringatleast16ordersofmagnitudeispossible,

2 2 18 2

6.3.1 Glass Microscope Slides.

from roughly 10 n/cm up to 5×10 n/cm . The allowable

6.3.2 Slide Cover Glasses.

rangeoffissiontrackdensitiesisbroaderthanthetrackdensity

range for high accuracy manual scanning work with optical

7. SSTR Materials for Reactor Applications

microscopy cited in 1.2. In particular, automated and semi-

automated methods exist that broaden the customary track 7.1 Required Properties—SSTR materials for reactor appli-

densityrangeavailablewithmanualopticalmicroscopy.Inthis cations should be transparent dielectrics with a relatively high

broader track density region, effects of reduced counting ionization threshold, so as to discriminate against lightly

statistics at very low track densities and track pile-up correc- ionizing particles. The materials that meet these prerequisites

tions at very high track densities can present inherent limita- most closely are the minerals mica, quartz glass, and quartz

E854−03 (2009)

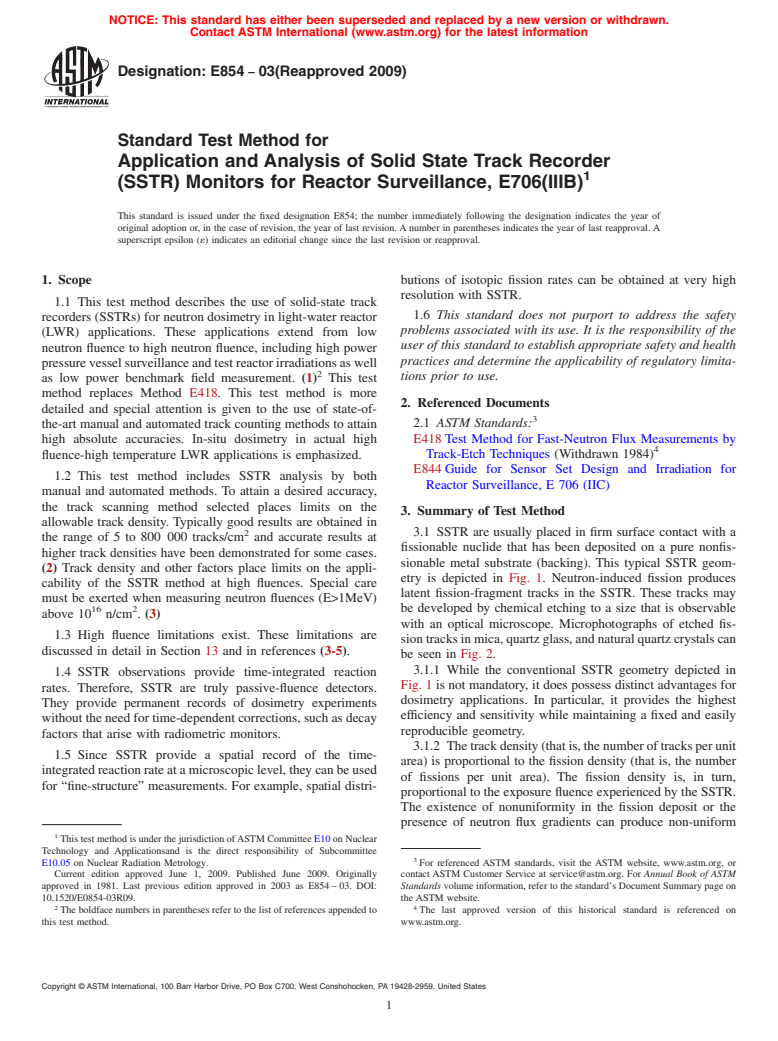

NOTE 1—The track designated by the arrow in the mica SSTR is a fossil fission track that has been enlarged by suitable preirradiation etching.

FIG. 2 Microphotograph of Fission Fragment Tracks in Mica

crystals. Selected characteristics for these SSTR are summa- presence of neutron-induced recoil tracks from elements such

rized in Table 1. Other minerals such as apatite, sphene, and ascarbonandoxygenpresentintheSSTR.Thesedetectorsare

zirconarealsosuitable,butarenotusedduetoinferioretching

also more sensitive (in the form of increased bulk etch rate) to

properties compared to mica and quartz. These alternative the β and γ components of the reactor radiation field (13).

SSTR candidates often possess either higher imperfection

Also, they are more sensitive to high temperatures, since the

density or poorer contrast and clarity for scanning by optical onset of track annealing occurs at a much lower temperature

microscopy.Micaandparticularlyquartzcanbefoundwiththe

for plastic SSTR materials.

additional advantageous property of low natural uranium and

7.2 Limitations of SSTR in LWR Environments:

thorium content. These heavy elements are undesirable in

7.2.1 Thermal Annealing—High temperatures result in the

neutron-dosimetry work, since such impurities lead to back-

erasure of tracks due to thermal annealing. Natural quartz

groundtrackdensitieswhenSSTRareexposedtohighneutron

crystal is least affected by high temperatures, followed by

fluence. In the case of older mineral samples, a background of

mica. Lexan and Makrofol are subject to annealing at much

fossil fission track arises due mainly to the spontaneous fission

lower temperatures. An example of the use of natural quartz

decay of U. Glasses (and particularly phosphate glasses)

crystal SSTRs for high-temperature neutron dosimetry mea-

are less suitable than mica and quartz due to higher uranium

surements is the work described in reference (14).

and thorium content. Also, the track-etching characteristics of

many glasses are inferior, in that these glasses possess higher 7.2.2 Radiation Damage—Lexan and Makrofol are highly

bulk etch rate and lower registration efficiency. Other SSTR

sensitive to other components of the radiation field. As men-

5 6

materials, such as Lexan and Makrofol are also used, but are tioned in 7.1, the bulk-etch rates of plastic SSTR are increased

less convenient in many reactor applications due to the

by exposure to β and γ radiation. Quartz has been observed to

have a higher bulk etch rate after irradiation with a fluence of

21 2

4×10 neutrons/cm , but both quartz and mica are very

Lexan is a registered trademark of the General Electric Co., Pittsfield, MA.

6 insensitive to radiation damage at lower fluences (<10

Makrofol is a registered trademark of Farbenfabriken Bayer AG, U. S.

representative Naftone, Inc., New York, NY. neutrons/cm ).

E854−03 (2009)

FIG. 2 Quartz Glass (continued)

FIG. 2 Quartz Crystal (001 Plane) (continued)

7.2.3 Background Tracks—Plastic track detectors will reg-

from the much smaller induced tracks revealed by a 90-min

ister recoil carbon and oxygen ions resulting from neutron post-etch (see Fig. 2)).

scattering on carbon and oxygen atoms in the plastic. These

8.2.2 Quartz Crystals—Pre-etching is needed to chemically

fastneutron-inducedrecoilscanproduceabackgroundofshort polish the surface. Polish a crystal mechanically on the 001 or

tracks.Quartzandmicawillnotregistersuchlightionsandare

100 plane so that it appears smooth under microscopical

not subject to such background tracks.

examination, etch for 10 min in 49% HF at room temperature,

then boil in 65% NaOH solution for 25 min. Examine the

8. SSTR Pre- and Post-Irradiation Processing

crystal surface microscopically. If it is sufficiently free of pits,

8.1 Pre-Irradiation Annealing:

select it for use as an SSTR.

8.1.1 In the case of mica SSTR, a pre-annealing procedure 8.2.3 Quartz Glass—If the glass has been polished

designed to remove fossil track damage is advisable for work mechanically, or has a smooth surface, then pre-etch in 49%

at low neutron fluences. The standard procedure is annealing HF for 5 min at room temperature. Upon microscopical

for6hat 600°C (longer time periods may result in dehydra- examination a few etch pits may be present even in good-

tion). Fossil track densities are so low in good Brazilian quartz qualityquartzglass.Ifso,theywillbelargerthantracksdueto

crystals that pre-annealing is not generally necessary. Anneal- fission fragments revealed in the post-etch, and readily distin-

ingisnotadvisedforplasticSSTRbecauseofthepossibilityof guished from them.

thermal degradation of the polymer or altered composition, 8.2.4 Plastic-Track Recorders—If handled properl

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E854–98 Designation: E 854 – 03 (Reapproved 2009)

Standard Test Method for

Application and Analysis of Solid State Track Recorder

(SSTR) Monitors for Reactor Surveillance, E706(IIIB)

This standard is issued under the fixed designation E854; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethoddescribestheuseofsolid-statetrackrecorders(SSTRs)forneutrondosimetryinlight-waterreactor(LWR)

applications. These applications extend from low neutron fluence to high neutron fluence, including high power pressure vessel

surveillance and test reactor irradiations as well as low power benchmark field measurement. (1) This test method replaces

MethodE418.Thistestmethodismoredetailedandspecialattentionisgiventotheuseofstate-of-the-artmanualandautomated

track counting methods to attain high absolute accuracies. In-situ dosimetry in actual high fluence-high temperature LWR

applications is emphasized.

1.2 This test method includes SSTR analysis by both manual and automated methods. To attain a desired accuracy, the track

scanning method selected places limits on the allowable track density. Typically good results are obtained in the range of 5 to

800 000 tracks/cm and accurate results at higher track densities have been demonstrated for some cases. (2) Track density and

other factors place limits on the applicability of the SSTR method at high fluences. Special care must be exerted when measuring

16 2

neutron fluences (E>1MeV) above 10 n/cm . (3)

1.3 High fluence limitations exist. These limitations are discussed in detail in Section 13 and in references (3-5).

1.4 SSTR observations provide time-integrated reaction rates. Therefore, SSTR are truly passive-fluence detectors. They

provide permanent records of dosimetry experiments without the need for time-dependent corrections, such as decay factors that

arise with radiometric monitors.

1.5 Since SSTR provide a spatial record of the time-integrated reaction rate at a microscopic level, they can be used for

“fine-structure” measurements. For example, spatial distributions of isotopic fission rates can be obtained at very high resolution

with SSTR.

1.6 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of

this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2.1 ASTM Standards:

E418 Method for Fast-Neutron Flux Measurements by Track-Etch Techniques

E844 Guide for Sensor Set Design and Irradiation for Reactor Surveillance, E 706(IIC)

3. Summary of Test Method

3.1 SSTR are usually placed in firm surface contact with a fissionable nuclide that has been deposited on a pure nonfissionable

metal substrate (backing). This typical SSTR geometry is depicted in Fig. 1. Neutron-induced fission produces latent

fission-fragmenttracksintheSSTR.Thesetracksmaybedevelopedbychemicaletchingtoasizethatisobservablewithanoptical

microscope. Microphotographs of etched fission tracks in mica, quartz glass, and natural quartz crystals can be seen in Fig. 2.

3.1.1 While the conventional SSTR geometry depicted in Fig. 1 is not mandatory, it does possess distinct advantages for

ThistestmethodisunderthejurisdictionofASTMCommitteeE-10E10onNuclearTechnologyandApplicationsandisthedirectresponsibilityofSubcommitteeE10.05

on Nuclear Radiation Metrology.

Current edition approved Jan. 10, 1998. Published May 1998. Originally published as E854–81. Last previous edition E854–90.

Current edition approved June 1, 2009. Published June 2009. Originally approved in 1981. Last previous edition approved in 2003 as E854–03.

Discontinued; see 1983 Annual Book of ASTM Standards, Vol 12.02.

The boldface numbers in parentheses refer to the list of references appended to this test method.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 12.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Lexan is a registered trademark of the General Electric Co., Pittsfield, MA.

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 854 – 03 (2009)

FIG. 1 Typical Geometrical Configuration Used for SSTR Neutron

Dosimetry

NOTE 1—The track designated by the arrow in the mica SSTR is a fossil fission track that has been enlarged by suitable preirradiation etching.

FIG. 2 Microphotograph of Fission Fragment Tracks in Mica

dosimetry applications. In particular, it provides the highest efficiency and sensitivity while maintaining a fixed and easily

reproducible geometry.

3.1.2 The track density (that is, the number of tracks per unit area) is proportional to the fission density (that is, the number of

fissionsperunitarea).Thefissiondensityis,inturn,proportionaltotheexposurefluenceexperiencedbytheSSTR.Theexistence

ofnonuniformityinthefissiondepositorthepresenceofneutronfluxgradientscanproducenon-uniformtrackdensity.Conversely,

with fission deposits of proven uniformity, gradients of the neutron field can be investigated with very high spatial resolution.

3.2 ThetotaluncertaintyofSSTRfissionratesiscomprisedoftwoindependentsources.Thesetwoerrorcomponentsarisefrom

track counting uncertainties and fission-deposit mass uncertainties. For work at the highest accuracy levels, fission-deposit mass

E 854 – 03 (2009)

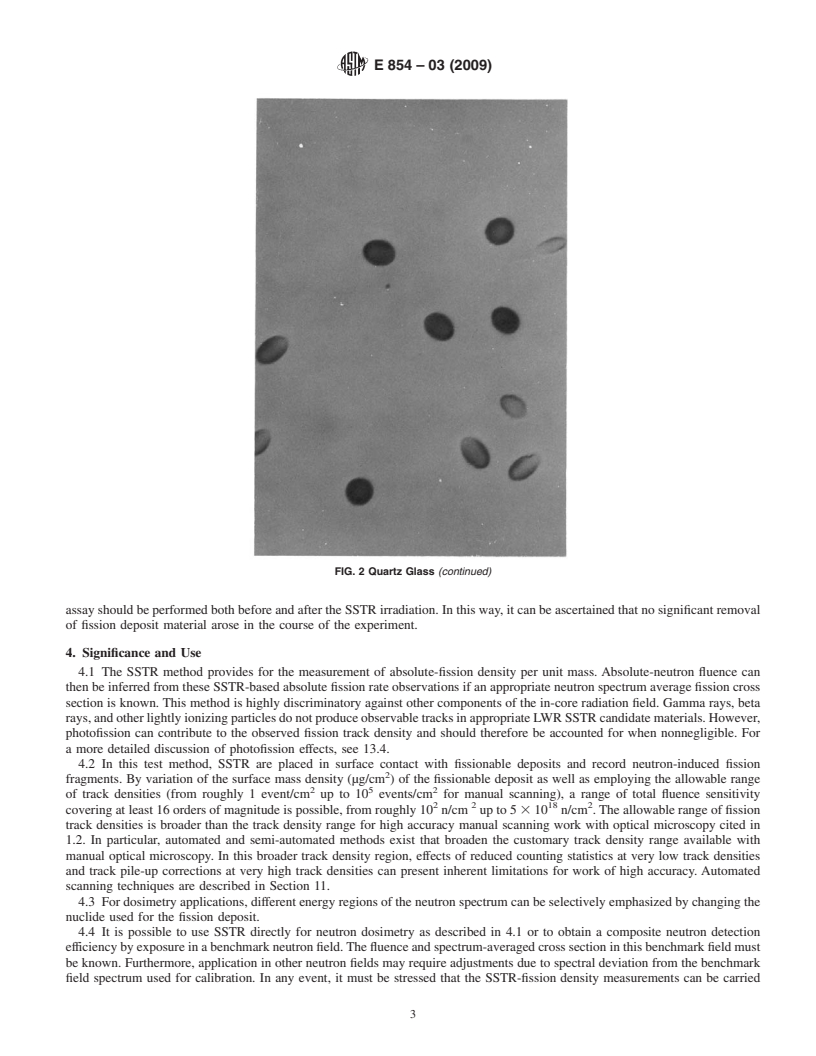

FIG. 2 Quartz Glass (continued)

assayshouldbeperformedbothbeforeandaftertheSSTRirradiation.Inthisway,itcanbeascertainedthatnosignificantremoval

of fission deposit material arose in the course of the experiment.

4. Significance and Use

4.1 The SSTR method provides for the measurement of absolute-fission density per unit mass. Absolute-neutron fluence can

thenbeinferredfromtheseSSTR-basedabsolutefissionrateobservationsifanappropriateneutronspectrumaveragefissioncross

section is known.This method is highly discriminatory against other components of the in-core radiation field. Gamma rays, beta

rays,andotherlightlyionizingparticlesdonotproduceobservabletracksinappropriateLWRSSTRcandidatematerials.However,

photofission can contribute to the observed fission track density and should therefore be accounted for when nonnegligible. For

a more detailed discussion of photofission effects, see 13.4.

4.2 In this test method, SSTR are placed in surface contact with fissionable deposits and record neutron-induced fission

fragments. By variation of the surface mass density (µg/cm ) of the fissionable deposit as well as employing the allowable range

2 5 2

of track densities (from roughly 1 event/cm up to 10 events/cm for manual scanning), a range of total fluence sensitivity

2 2 18 2

coveringatleast16ordersofmagnitudeispossible,fromroughly10 n/cm upto5 310 n/cm .Theallowablerangeoffission

track densities is broader than the track density range for high accuracy manual scanning work with optical microscopy cited in

1.2. In particular, automated and semi-automated methods exist that broaden the customary track density range available with

manual optical microscopy. In this broader track density region, effects of reduced counting statistics at very low track densities

and track pile-up corrections at very high track densities can present inherent limitations for work of high accuracy. Automated

scanning techniques are described in Section 11.

4.3 Fordosimetryapplications,differentenergyregionsoftheneutronspectrumcanbeselectivelyemphasizedbychangingthe

nuclide used for the fission deposit.

4.4 It is possible to use SSTR directly for neutron dosimetry as described in 4.1 or to obtain a composite neutron detection

efficiencybyexposureinabenchmarkneutronfield.Thefluenceandspectrum-averagedcrosssectioninthisbenchmarkfieldmust

be known. Furthermore, application in other neutron fields may require adjustments due to spectral deviation from the benchmark

field spectrum used for calibration. In any event, it must be stressed that the SSTR-fission density measurements can be carried

E 854 – 03 (2009)

FIG. 2 Quartz Crystal (001 Plane) (continued)

out completely independent of any cross-section standards (6). Therefore, for certain applications, the independent nature of this

test method should not be compromised. On the other hand, many practical applications exist wherein this factor is of no

consequence so that benchmark field calibration would be entirely appropriate.

5. Apparatus

5.1 Optical Microscopes, with a magnification of 200 3or higher, employing a graduated mechanical stage with position

readouttothenearest1µmandsimilarrepositioningaccuracy.Acalibratedstagemicrometerandeyepiecescanninggridsarealso

required.

5.2 Constant-Temperature BathsConstant-Temperature Bath, for etching, with temperature control to 0.1°C.

5.3 Analytical Weighing Balance , for preparation of etching bath solutions, with a capacity of at least 1000 g and an accuracy

of at least 1 mg.

6. Reagents and Materials

6.1 Purity of Reagents—Distilled or demineralized water and analytical grade reagents should be used at all times. For high

fluence measurements, quartz-distilled water and ultra-pure reagents are necessary in order to reduce background fission tracks

from natural uranium and thorium impurities. This is particularly important if any pre-irradiation etching is performed (see 8.2).

6.2 Reagents:

6.2.1 Hydrofluoric Acid (HF), weight 49%.

6.2.2 Sodium Hydroxide Solution (NaOH) , 6.2 N.

6.2.3 Distilled or Demineralized Water.

6.2.4 Potassium Hydroxide Solution (KOH), 6.2 N.

6.2.5 Sodium Hydroxide Solution (NaOH) , weight 65%.

6.3 Materials:

6.3.1 Glass Microscope Slides.

6.3.2 Slide Cover Glasses.

E 854 – 03 (2009)

7. SSTR Materials for Reactor Applications

7.1 Required Properties—SSTR materials for reactor applications should be transparent dielectrics with a relatively high

ionizationthreshold,soastodiscriminateagainstlightlyionizingparticles.Thematerialsthatmeettheseprerequisitesmostclosely

are the minerals mica, quartz glass, and quartz crystals. Selected characteristics for these SSTR are summarized in Table 1. Other

minerals such as apatite, sphene, and zircon are also suitable, but are not used due to inferior etching properties compared to mica

and quartz. These alternative SSTR candidates often possess either higher imperfection density or poorer contrast and clarity for

scanning by optical microscopy. Mica and particularly quartz can be found with the additional advantageous property of low

naturaluraniumandthoriumcontent.Theseheavyelementsareundesirableinneutron-dosimetrywork,sincesuchimpuritieslead

tobackgroundtrackdensitieswhenSSTRareexposedtohighneutronfluence.Inthecaseofoldermineralsamples,abackground

offossilfissiontrackarisesduemainlytothespontaneousfissiondecayof U.Glasses(andparticularlyphosphateglasses)are

less suitable than mica and quartz due to higher uranium and thorium content. Also, the track-etching characteristics of many

glassesareinferior,inthattheseglassespossesshigherbulketchrateandlowerregistrationefficiency.OtherSSTRmaterials,such

5 6

as Lexanand Makrofol and Makrofol are also used, but are less convenient in many reactor applications due to the presence of

neutron-induced recoil tracks from elements such as carbon and oxygen present in the SSTR. These detectors are also more

sensitive(intheformofincreasedbulketchrate)tothe band gcomponentsofthereactorradiationfield (13).Also,theyaremore

sensitive to high temperatures, since the onset of track annealing occurs at a much lower temperature for plastic SSTR materials.

7.2 Limitations of SSTR in LWR Environments:

7.2.1 Thermal Annealing—High temperatures result in the erasure of tracks due to thermal annealing. Natural quartz crystal is

least affected by high temperatures, followed by mica. Lexan and Makrofol are subject to annealing at much lower temperatures.

AnexampleoftheuseofnaturalquartzcrystalSSTRsforhigh-temperatureneutrondosimetrymeasurementsistheworkdescribed

in reference (14) .

7.2.2 Radiation Damage—Lexan and Makrofol are highly sensitive to other components of the radiation field. As mentioned

in 7.1, the bulk-etch rates of plastic SSTR are increased by exposure to b and g radiation. Quartz has been observed to have a

21 2

higher bulk etch rate after irradiation with a fluence of 4 310 neutrons/cm , but both quartz and mica are very insensitive to

21 2

radiation damage at lower fluences (<10 neutrons/cm ).

7.2.3 Background Tracks—Plastic track detectors will register recoil carbon and oxygen ions resulting from neutron scattering

on carbon and oxygen atoms in the plastic. These fast neutron-induced recoils can produce a background of short tracks. Quartz

and mica will not register such light ions and are not subject to such background tracks.

8. SSTR Pre- and Post-Irradiation Processing

8.1 Pre-Irradiation Annealing:

8.1.1 InthecaseofmicaSSTR,apre-annealingproceduredesignedtoremovefossiltrackdamageisadvisableforworkatlow

neutronfluences.Thestandardprocedureisannealingfor6hat600°C(longertimeperiodsmayresultindehydration).Fossiltrack

densities are so low in good Brazilian quartz crystals that pre-annealing is not generally necessary. Annealing is not advised for

plastic SSTR because of the possibility of thermal degradation of the polymer or altered composition, both of which could effect

track registration properties of the plastic.

Makrofol is a registered trademark of Farbenfabriken Bayer AG, U. S. representative Naftone, Inc., New York, NY.

Lexan is a registered trademark of the General Electric Co., Pittsfield, MA.

Measurement uncertainty is described in terms of precision and bias in this standard.Another acceptable approach is to use TypeAand B uncertainty components (40,

41).ThisTypeA/B uncertainty specification is now used in International Organization for Standardization (ISO) standards, and this approach can be expected to play a more

prominent role in future uncertainty analyses.

Makrofol is a registered tradema

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.