ASTM D2364-96

(Test Method)Standard Test Methods for Hydroxyethylcellulose

Standard Test Methods for Hydroxyethylcellulose

SCOPE

1.1 These test methods cover the testing of hydroxyethylcellulose.

1.2 The test procedures appear in the following order: SectionsMoisture4-9Ash10-17 Viscosity18-24Density25-31

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2364 – 96

Standard Test Methods for

Hydroxyethylcellulose

This standard is issued under the fixed designation D 2364; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope vided it is first ascertained that the reagent is of sufficiently

high purity to permit its use without lessening the accuracy of

1.1 These test methods cover the testing of hydroxyethyl-

the determination.

cellulose.

3.2 Unless otherwise indicated, reference to water shall be

1.2 The test procedures appear in the following order:

understood to mean reagent water, conforming to Specification

Sections

D 1193.

Moisture 4-9

Ash 10-17

Viscosity 18-24

MOISTURE

Density 25-31

Molar Substitution 32-42

4. Scope

1.3 This standard does not purport to address all of the

4.1 This test method covers the determination of the volatile

safety concerns, if any, associated with its use. It is the

content of hydroxyethylcellulose.

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.1 The results of this test are used for calculating the total

solids in the sample; and, by common usage, all materials

2. Referenced Documents

volatile at this test temperature are designated as moisture.

2.1 ASTM Standards:

5.2 Moisture analysis (along with sulfated ash) is a measure

D 1193 Specification for Reagent Water

of the amount of active polymer in the material and must be

D 1347 Test Methods for Methylcellulose

considered when determining the amount of hydroxyethyl

D 1695 Terminology of Cellulose and Cellulose Deriva-

cellulose to use in various formulations.

tives

6. Apparatus

D 2363 Test Methods for Hydroxypropyl Methylcellulose

D 4794 Test Method for Determination of Ethoxyl or Hy-

6.1 Oven, gravity-convection, capable of maintaining a

droxyethoxyl Substitution in Cellulose Ether Products by

temperature of 105 6 3°C.

Gas Chromatography

6.2 Weighing Bottles, low-form, 50 mm in inside diameter

E 1 Specification for ASTM Thermometers

by 30 mm in height, or equivalent.

6.3 Analytical Balance.

3. Purity of Reagents

7. Procedure

3.1 Reagent grade chemicals shall be used in all tests.

Unless otherwise indicated, it is intended that all reagents shall

7.1 Weigh5gof sample to the nearest 0.001 g in a tared and

conform to the specifications of the Committee on Analytical

covered weighing bottle.

Reagents of the American Chemical Society, where such

7.2 Place it in an oven at 105°C for 2 h with the cover

specifications are available. Other grades may be used, pro-

removed. Replace the cover, cool in a desiccator, and weigh.

8. Calculation

These test methods are under the jurisdiction of ASTM Committee D-1 on Paint

8.1 Calculate the percent moisture, M, as follows:

and Related Coatings, Materials, and Applications and are the direct responsibility

of Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

M 5 ~A/B! 3 100 (1)

Current edition approved Feb. 10, 1996. Published April 1996. Originally

published as D 2364 – 65 T. Last previous edition D 2364 – 89.

2 where:

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 06.03. A = mass loss on heating, g, and

Annual Book of ASTM Standards, Vol 14.03.

B = sample used, g.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

9. Precision and Bias

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia 9.1 Statistical analysis of intralaboratory (repeatability) test

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

results on samples containing from about 3.5 % moisture

MD.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2364

indicate a precision of 60.5 % absolute at the 95 % confidence VISCOSITY

level.

18. Scope

9.2 No statement on bias can be made as no suitable

18.1 This test method is an arbitrary method of determining

reference material is available as a standard.

the viscosity of aqueous solutions of hydroxyethylcellulose in

ASH—AS SULFATE

the viscosity range from 10 to 10 000 cP at 25°C.

18.2 The concentration to be used for the test shall be

10. Scope

agreed upon between the purchaser and the seller. It shall be

10.1 This test method covers the determination of the

such that the viscosity of the solution will fall within the range

residue on ignition of hydroxyethylcellulose after a specimen

of this test.

has been treated with sulfuric acid.

18.3 The results for the viscosity of hydroxyethylcellulose

by this test method will not necessarily check with results from

11. Summary of Test Method

other types of instruments used for viscosity measurements.

11.1 A specimen is moistened with sulfuric acid, the excess

18.4 The determinations are run on a calculated dry basis;

acid evaporated, the carbonaceous matter burned off, and the

that is, the amount of hydroxyethylcellulose required for the

residue ignited in a muffle furnace, cooled, and weighed.

desired concentration on a dry basis is calculated from the

known moisture content.

12. Significance and Use

19. Significance and Use

12.1 Excessive ash can affect solution clarity and film

properties. The ash (along with moisture) is a measure of the

19.1 This test method is intended for referee purposes. The

amount of active polymer in the material and must be consid-

Brookfield spindles and speeds given in Table 1 are recom-

ered when determining the amount of hydroxyethyl cellulose to

mended for this purpose, but slight deviations from Table 1

use in various formulations.

may occasionally be found convenient for individual applica-

tion.

13. Apparatus

19.2 This test method determines the relative ability of the

13.1 Dishes, platinum, 50 to 75-mL capacity.

polymer to thicken aqueous solutions and is therefore related to

13.2 Muffle Furnace, maintained at 825 6 25°C.

the concentration required in various formulations to achieve

the desired finished product viscosity.

14. Reagents

20. Apparatus

14.1 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid

(H SO ).

20.1 Viscometer, Rotational type.

2 4

NOTE 1—Manufacturers of cellulose derivatives usually specify the

15. Procedure

viscometer make, model, spindle, and speed to be used with their

15.1 Weigh, to the nearest 0.0001 g, about2gofthe dried

products. It is highly recommended that these specifications be followed.

sample into a tared platinum dish. Moisten the entire specimen

Use of a viscometer made by another company or even a different model

with about 2 mL of H SO . Then cautiously heat over a small

by the same company will result in slightly different results.

2 4

flame until sulfur trioxide (SO ) fumes cease to be evolved. 3

20.2 Container, glass jar, 350-cm approximately 64 mm in

15.2 Increase the heat, ignite the specimen, and heat as

outside diameter and 152 mm high.

necessary to burn off the volatile matter. Avoid spattering.

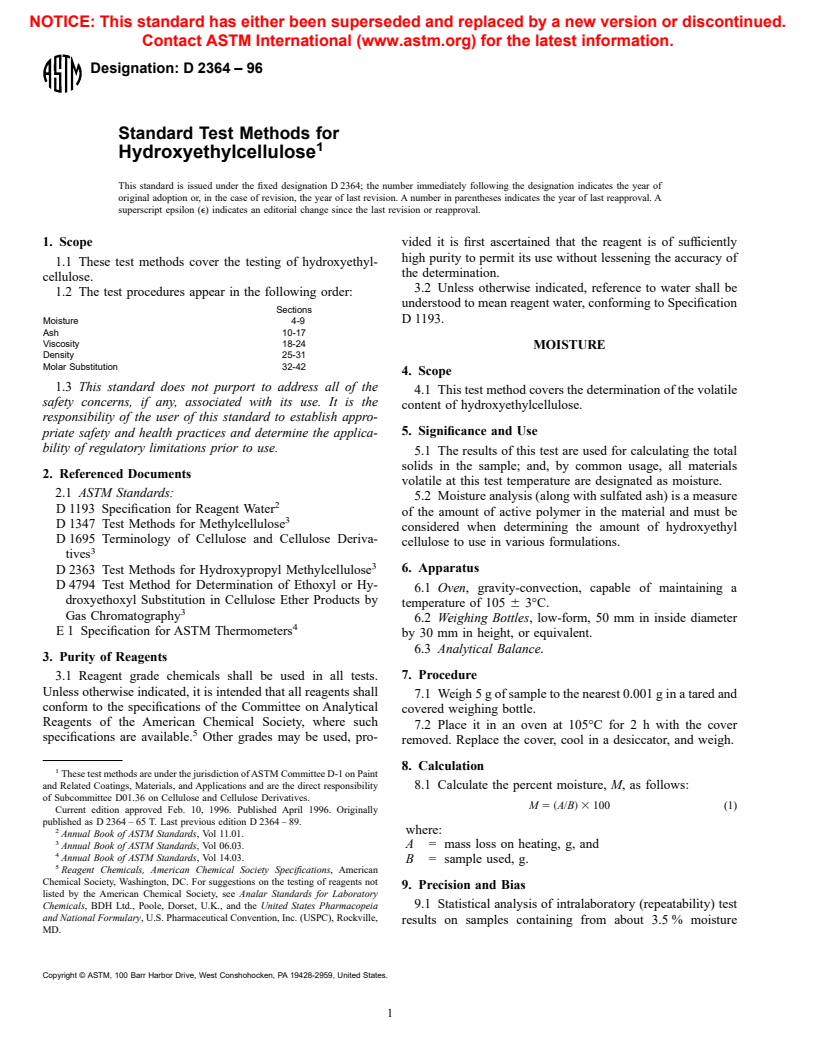

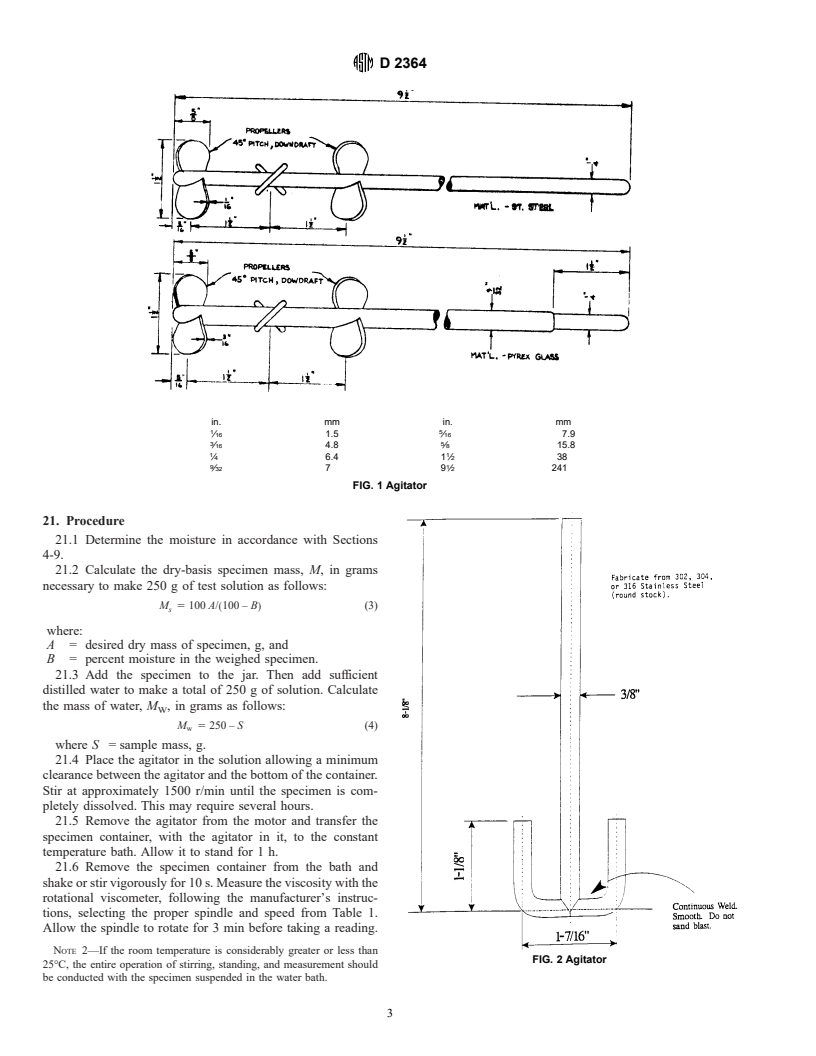

20.3 Mechanical Stirrer—Agitator as shown in Fig. 1 or

15.3 Place the dish in a 825°C muffle furnace for 1 h, or 6

Fig. 2, attached to a variable-speed motor capable of 1500

longer if required, to burn all of the carbon.

r/min.

15.4 Remove the dish, allow to cool somewhat, place in a

20.4 Water Bath, constant-temperature, set at 25°C and

desiccator, and cool to room temperature. Weigh the dish and

capable of maintaining that temperature to within 60.2°C.

residue to the nearest 0.0001 g.

20.5 Thermometer—An ASTM Saybolt Viscosity Ther-

mometer having a range from 19 to 27°C and conforming to

16. Calculation

the requirements for Thermometer 17C, as prescribed in

16.1 Calculate the percent of ash (as sulfate), C, as follows:

Specification E 1.

C 5 ~A/B!3 100 (2)

An agitator made with 1 1/2 in. (38 mm), three-bladed propellers, No. 9240K,

available from A. H. Thomas Co., P.O. Box 779, Philadelphia, PA 19105 has been

where:

found satisfactory for this purpose.

A = ash, g, and

B = sample used, g.

TABLE 1 Viscometer Spindles Required for Given Speeds

Viscosity Range,

17. Precision and Bias Spindle No. Speed, rpm Scale Factor

cP

17.1 Statistical analysis of interlaboratory (reproducibility)

10 to 100 1 60 100 1

test results on samples containing 2 to 5 % ash (as sulfate) 100 to 200 1 30 100 2

200 to 1000 2 30 100 10

indicates a precision of 60.3 % absolute at the 95 % level.

1000 to 4000 3 30 100 40

17.2 No statement on bias can be made as no suitable

4000 to 10 000 4 30 100 200

reference material is available as a standard.

D 2364

in. mm in. mm

1 5

⁄16 1.5 ⁄16 7.9

3 5

⁄16 4.8 ⁄8 15.8

1 1

⁄4 6.4 1 ⁄2 38

9 1

⁄32 79 ⁄2 241

FIG. 1 Agitator

21. Procedure

21.1 Determine the moisture in accordance with Sections

4-9.

21.2 Calculate the dry-basis specimen mass, M, in grams

necessary to make 250 g of test solution as follows:

M 5 100 A/~100 – B! (3)

s

where:

A = desired dry mass of specimen, g, and

B = percent moisture in the weighed specimen.

21.3 Add the specimen to the jar. Then add sufficient

distilled water to make a total of 250 g of solution. Calculate

the mass of water, M , in grams as follows:

W

M 5 250 – S (4)

w

where S = sample mass, g.

21.4 Place the agitator in the solution allowing a minimum

clearance between the agitator and the bottom of the container.

Stir at approximately 1500 r/min until the specimen is com-

pletely dissolved. This may require several hours.

21.5 Remove the agitator from the motor and transfer the

specimen container, with the agitator in it, to the constant

temperature bath. Allow it to stand for 1 h.

21.6 Remove the specimen container from the bath and

shake or stir vigorously for 10 s. Measure the viscosity with the

rotational viscometer, following the manufacturer’s instruc-

tions, selecting the proper spindle and speed from Table 1.

Allow the spindle to rotate for 3 min before taking a reading.

NOTE 2—If the room temperature is considerably greater or less than

FIG. 2 Agitator

25°C, the entire operation of stirring, standing, and measurement should

be conducted with the specimen suspended in the water bath.

D 2364

NOTE 3—Shaking or stirring the sample may cause entrainment of air

breakage, cover the tapping surface witha3to 6-mm thick

bubbles. Caution: One must exercise care to avoid having a large air

rubber sheet, or use a plastic graduated cylinder.

bubble under the viscometer spindle when taking the measurement.

30. Calculation

22. Calculation

30.1 Calculate the density, D, in grams per millilitre as

22.1 Calculate the viscosity, V, in centipoises as follows:

follows:

V 5 r 3 f (5)

D 5 50/r (6)

o

where:

where R = observed reading, mL.

o

r = reading and

31. Precision and Bias

f = factor.

31.1 Precision—Statistical analysis of intralaboratory (re-

23. Report

peatability) test results indicates a precision of 60.04 g/mL at

23.1 Report the following information:

the 95 % confidence level.

23.1.1 Results, as viscosity at 25°C,

31.2 Bias—No justifiable statement on the bias of the

23.1.2 Solution concentration,

procedure for measuring density can be made because no

23.1.3 Spindle used, and

suitable reference material exists.

23.1.4 Speed used.

MOLAR SUBSTITUTION

24. Precision and Bias

32. Scope

24.1 Precision—Statistical analysis of interlaboratory (re-

producibility) test results indicates a precision of 610 % at the 32.1 This test method covers the determination of the molar

95 % confidence level when using the same viscometer make substitution (MS) of hydroxyethyloxyethylene pendant groups

and model. in purified hydroxyethylcellulose (HEC).

32.2 An alternative preferred method is found in Test

24.2 Bias—No justifiable statement can be made on the bias

of the procedure for measuring viscosity because no suitable Method D 4794.

reference material exists.

33. Terminology

DENSITY

33.1 Definitions:

33.1.1 molar substitution, MS—the average number of oxy-

25. Scope

ethylene groups substituted onto each anhydroglucose unit (see

25.1 This test method covers the determination of the bulk

also Terminology D 1695).

density of hydroxyethylcellulose.

34. Summary of Test Method

26. Summary of Test Method

34.1 In this test method, the pendant groups are cleaved

26.1 A weighed amount of hydroxyethylcellulose is trans-

from the cellulose by hydriodic acid and converted to volatile

ferred to a 100-mL graduated cylinder and the graduate

ethyl iodide and ethylene. These volatile products are collected

vibrated to settle the powder.

in alcoholic silver nitrate and bromine-bromide scrubbers,

respectively. The total hydroxyethyl content is calculated on

27. Significance and Use

the basis of the sum of both products.

27.1 Density can relate to dry flow properties, rate of

dissolution, lumping, packaging, and storage space require-

35. Significance and Use

ments.

35.1 This test method determines the amount of substituent

groups added to the cellulose backbone. The level can affect

28. Apparatus

solution properties, rheology, solubility parameters, and film

28.1 Vibrator—A magnetic-type electric vibrator attached

properties.

to the vertical support rod of a ring stand approximately 0.3 m

above the base. A condenser clamp of sufficient size to hold a

36. Interferences

100-mL graduated cylinder also shall be attached to the above

36.1 Interfering materials include glycols, low molecular

rod. The base of the stand should be weighted.

weight alcohols, and salts of oxidizing acids. Presence of

glycols or alcohols, or both, leads to high MS values since

29. Procedure

reaction of these compounds with hydriodic acid is similar to

29.1 Place 50.0 g of hydroxyethylcellulose in a 100-mL

that of HEC. If present, they must be either removed or

graduated cylinder and place in the condenser clamp. Turn on

determined separately with the results being included in the

the vibrator and allow the cylinder to vibrate for 3 min. Record

MS calculations. Large amounts of salts of oxidizing acids also

the level (in millilitres) to which the specimen has compacted.

interfere giving low MS values. If any such salt is present in

29.2 Alternatively, the specimen may be compacted manu-

ally. Tap it on a hard surface by dropping the cylinder

repeatedly from a height of about 25 mm until the volume of

This test method was first published by Morgan, P. W. in Industrial and

the sample remain

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.