ASTM A579/A579M-04a

(Specification)Standard Specification for Superstrength Alloy Steel Forgings

Standard Specification for Superstrength Alloy Steel Forgings

ABSTRACT

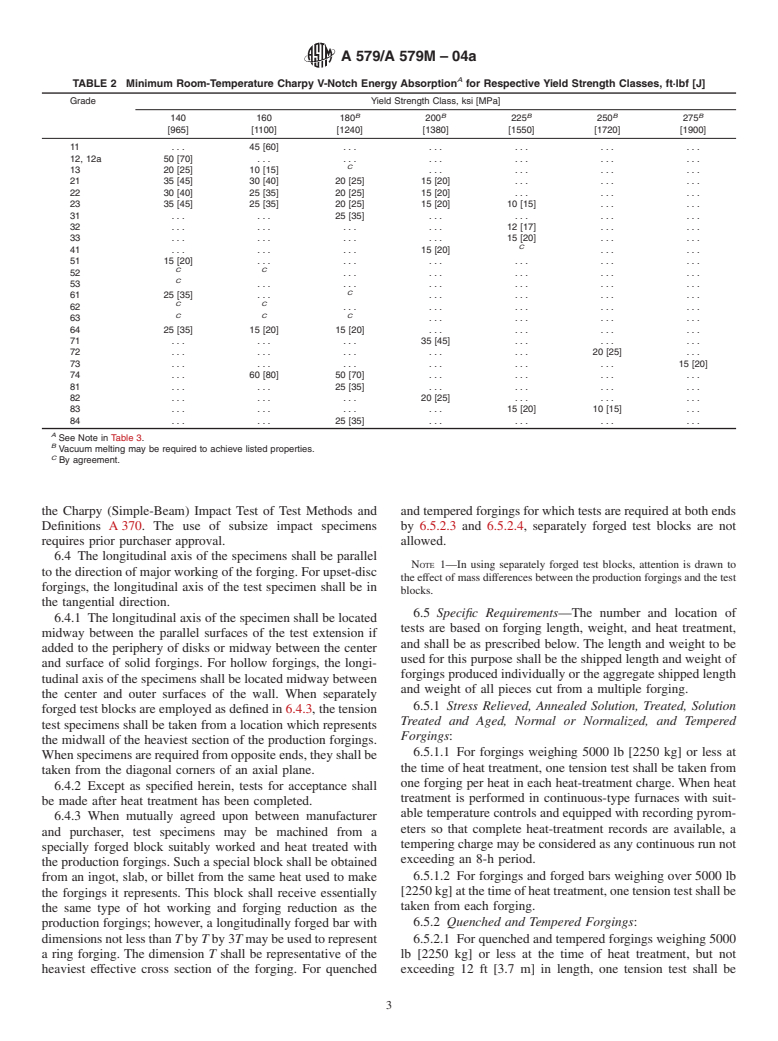

This specification deals with the standard requirements for superstrength alloy steel forgings for highly stressed structural members. Covered here are eight types (twenty-seven grades) of alloy steels, namely: quenched and tempered steels (Grades 11, 12, 12a, 13, 21, 22, 23, 31, 32, and 33); air hardened steel (Grade 41); martensitic stainless steels (Grades 51, 52, and 53); No. 1 precipitation hardened stainless steel (Grade 61); No. 2 precipitation hardened stainless steel (Grade 64); No. 3 precipitation hardened stainless steels (Grades 62 and 63); maraging steels (Grades 71, 72, 73, 74, and 75); and miscellaneous steels (Grades 81, 82, 83, and 84). The steels shall be manufactured by melting process and shall be finished by hot-worked forging. Forgings may be furnished in one of the following conditions: stress relieving; annealing; solution treatment; solution treatment and ageing; normalizing; normalizing and tempering; or quenching and tempering. Heat and product analyses shall be employed to assess the conformance of steels with required chemical compositions. Forgings shall examined by tension and Charpy impact tests and conform to required mechanical properties such as yield strength, tensile strength, elongation, reduction of area, minimum room-temperature Charpy V-notch energy absorption, maximum annealed hardness, and section size capability. Nondestructive tests, such as magnetic particle, liquid penetrant, and ultrasonic inspection procedures, shall also be performed.

SCOPE

1.1 This specification covers requirements for forged steel shapes for highly stressed structural members requiring yield strengths in excess of 140 ksi [965 MPa].

1.2 This specification is not intended for applications limited by creep deformation.

1.3 Twenty-seven grades are covered by this specification. Selection will depend upon design, service conditions, and mechanical properties required.

1.4 Supplementary requirements are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

1.5 The values stated in either inch-pound or SI (metric) units are to be regarded separately as standards. Within the text and tables, the SI units are shown in brackets. The values in each system are not exact equivalents; therefore, each system must be used independently of each other. Combining values from the two systems may result in non-conformance with the specification.

1.6 Unless the order specifies the applicable "M" specification designation, the material shall be furnished to the inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 579/A 579M – 04a

Standard Specification for

1

Superstrength Alloy Steel Forgings

This standard is issued under the fixed designationA579/A579M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* E3 Methods of Preparation of Metallographic Specimens

E21 Test Methods for Elevated Temperature Tension Tests

1.1 This specification covers requirements for forged steel

of Metallic Materials

shapes for highly stressed structural members requiring yield

E45 Test Methods for Determining the Inclusion Content

strengths in excess of 140 ksi [965 MPa].

of Steel

1.2 This specification is not intended for applications lim-

E112 Test Methods for Determining Average Grain Size

ited by creep deformation.

E 165 Test Method for Liquid Penetrant Examination

1.3 Twenty-seven grades are covered by this specification.

Selection will depend upon design, service conditions, and

3. Ordering Information and General Requirements

mechanical properties required.

3.1 In addition to the ordering information required by

1.4 Supplementary requirements are provided for use when

Specification A 788, the purchaser shall include with the

additional testing or inspection is desired. These shall apply

inquiry and order a detailed drawing, sketch, or written

only when specified individually by the purchaser in the order.

description of the forging.

1.5 The values stated in either inch-pound or SI (metric)

3.2 Material supplied to this specification shall conform to

units are to be regarded separately as standards.Within the text

the requirements of Specification A 788, which outlines addi-

and tables, the SI units are shown in brackets. The values in

tional ordering information, manufacturing requirements, test-

each system are not exact equivalents; therefore, each system

ing and retesting methods and procedures, marking, certifica-

must be used independently of each other. Combining values

tion, product analysis variations, and additional supplementary

from the two systems may result in non-conformance with the

requirements.

specification.

3.3 If the requirements of this specification are in conflict

1.6 Unless the order specifies the applicable “M” specifica-

with the requirements of SpecificationA 788, the requirements

tion designation, the material shall be furnished to the inch-

of this specification shall prevail.

pound units.

4. Materials and Manufacture

2. Referenced Documents

2 4.1 The steel shall be made in accordance with the Melting

2.1 ASTM Standards:

Process Section of Specification A 788. A sufficient discard

A 255 Test Methods for Determining Hardenability of Steel

shall be made to secure freedom from injurious pipe and undue

A 275/A 275M Test Method for Magnetic Particle Exami-

segregation.

nation of Steel Forgings

4.2 The material shall be forged as close as practical to the

A 370 Test Methods and Definitions for MechanicalTesting

specified shape and size.

of Steel Products

4.3 The finished product shall be a hot-worked forging as

A 388/A 388M Practice for Ultrasonic Examination of

defined by Specification A 788.

Heavy Steel Forgings

4.4 Heat Treatment Performed by Forging Supplier—

A 788 Specification for Steel Forgings, General Require-

Forgings may be furnished in one of the following conditions

ments

as specified in the inquiry and purchase order (some conditions

are not applicable to all grades):

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

4.4.1 Stress relieved,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

4.4.2 Annealed,

A01.06 on Steel Forgings and Billets.

4.4.3 Solution treated,

CurrenteditionapprovedSeptember1,2004.PublishedOctober2004.Originally

approved in 1967. Last previous edition approved in 2004 as A 579 – 04.

4.4.4 Solution treated and aged,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.4.5 Normalized,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.4.6 Normalized and tempered, or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.4.7 Quenched and tempered.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 579/A 579M – 04a

4.5 Heat Treatment Performed by Purchaser—When final 6. Mechanical Properties

heat treatment is to be performed by the purchaser after

6.1 The material shall conform to the mechanical properties

machining or fabrication

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.