ASTM E2602-22

(Test Method)Standard Test Methods for Assignment of the Glass Transition Temperature by Modulated Temperature Differential Scanning Calorimetry

Standard Test Methods for Assignment of the Glass Transition Temperature by Modulated Temperature Differential Scanning Calorimetry

SIGNIFICANCE AND USE

5.1 Materials undergo an increase in molecular mobility at the glass transition seen as a sigmoidal step increase in the heat capacity. This mobility increase may lead to kinetic events such as enthalpic recovery, chemical reaction or crystallization at temperatures near the glass transition. The heat flow associated with the kinetic events may interfere with the determination of the glass transition.

5.2 The glass transition is observed in differential scanning calorimetry as a sigmoidal or step change in specific heat capacity.

5.3 MTDSC provides a test method for the separation of the heat flow due to heat capacity and that associated with kinetic events making it possible to determine the glass transition in the presence of interfering kinetic event.

5.4 These test methods are useful in research and development, quality assurance and control and specification acceptance.

5.5 Other methods for assigning the glass transition temperature include differential scanning calorimetry (Test Method E1356), thermomechanical analysis (Test Method E1545) and dynamic mechanical analysis (Test Method E1640).

SCOPE

1.1 These test methods describe the assignment of the glass transition temperature of materials using modulated temperature differential scanning calorimetry (MTDSC) over the temperature range from –120 °C to +600 °C. The temperature range may be extended depending upon the instrumentation used.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2602 − 22

Standard Test Methods for

Assignment of the Glass Transition Temperature by

1

Modulated Temperature Differential Scanning Calorimetry

This standard is issued under the fixed designation E2602; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1356 Test Method for Assignment of the Glass Transition

Temperatures by Differential Scanning Calorimetry

1.1 These test methods describe the assignment of the glass

E1545 Test Method for Assignment of the Glass Transition

transition temperature of materials using modulated tempera-

Temperature by Thermomechanical Analysis

ture differential scanning calorimetry (MTDSC) over the

E1640 Test Method for Assignment of the Glass Transition

temperature range from –120 °C to +600 °C. The temperature

Temperature By Dynamic Mechanical Analysis

range may be extended depending upon the instrumentation

used.

3. Terminology

1.2 The values stated in SI units are to be regarded as

3.1 Definitions—Specific technical terms found in these test

standard. No other units of measurement are included in this

methods are defined in Terminologies E473 and E1142 includ-

standard.

ing differential scanning calorimetry, extrapolated onset, glass

1.3 This standard does not purport to address all of the

transition, glass transition temperature, non-reversing,

safety concerns, if any, associated with its use. It is the

reversing, specific heat capacity, and thermal curve.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

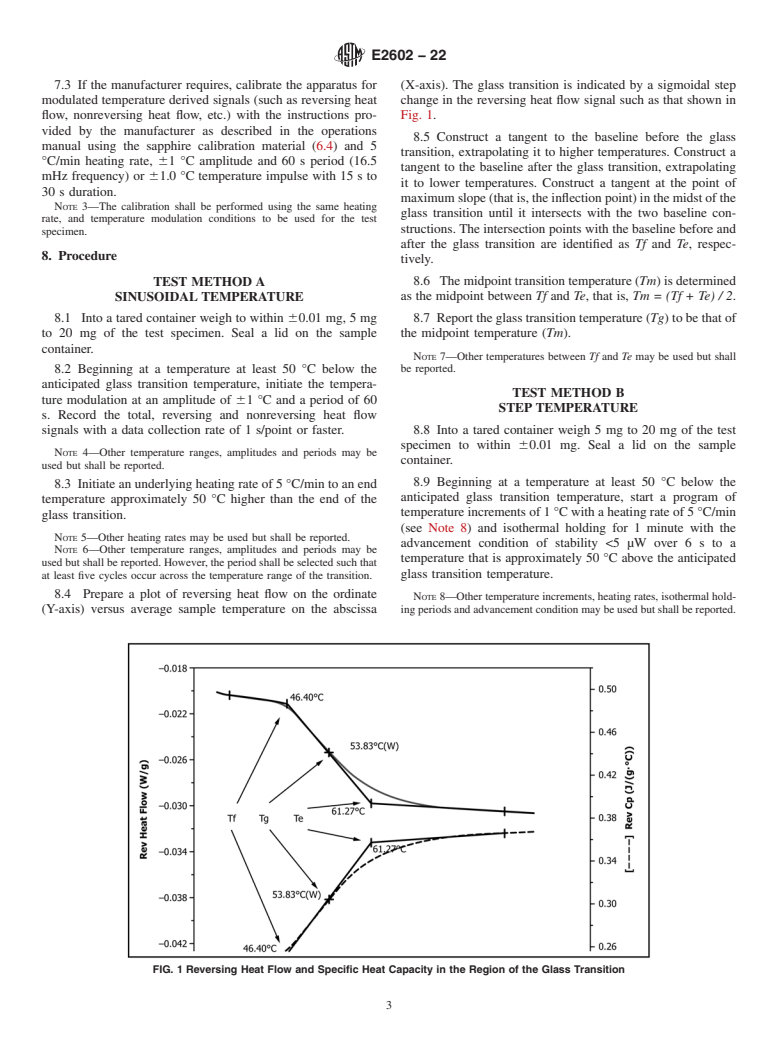

3.2.1 extrapolated end temperature (Te), n—the point of

mine the applicability of regulatory limitations prior to use.

intersection of the tangent drawn at the point of greatest slope

1.4 This international standard was developed in accor-

(that is, the inflection point) in the transition region with the

dance with internationally recognized principles on standard-

extrapolated baseline following the transition.

ization established in the Decision on Principles for the

3.2.2 extrapolated onset temperature (Tf), n—the point of

Development of International Standards, Guides and Recom-

intersection of the tangent drawn at the point of greatest slope

mendations issued by the World Trade Organization Technical

(that is, the inflection point) in the transition region with the

Barriers to Trade (TBT) Committee.

extrapolated baseline prior to the transition.

2. Referenced Documents

3.2.3 midpoint temperature (Tm), n—the point on the ther-

2

mal curve corresponding to the average of the extrapolated

2.1 ASTM Standards:

onset and extrapolated end temperatures.

E473 Terminology Relating to Thermal Analysis and Rhe-

ology 3.2.4 modulated, n—a prefix indicating that a parameter

E967 Test Method for Temperature Calibration of Differen-

changes in a periodic manner during the experiment.

tial Scanning Calorimeters and Differential Thermal Ana-

3.2.5 modulated heat flow, n—the heat flow resulting from

lyzers

an applied modulated temperature program.

E968 Practice for Heat Flow Calibration of Differential

3.2.6 modulated temperature differential scanning calorim-

Scanning Calorimeters

etry (MTDSC),n—a method of differential scanning calorim-

E1142 Terminology Relating to Thermophysical Properties

etry (DSC) that varies the temperature sinusoidally or with a

periodic step-and-hold or pulse program to the test specimen

1 over a traditional isothermal or temperature ramp program.

These test methods are under the jurisdiction of ASTM Committee E37 on

Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on Results from the experiment include reversing and nonrevers-

Calorimetry and Mass Loss.

ing heat flow and specimen temperature.

Current edition approved Feb. 1, 2022. Published May 2022. Originally

3.2.7 total heat flow, n—the value of the modulated heat

approved in 2009. Last previous edition approved in 2015 as E2602 – 09 (2015).

DOI: 10.1520/E2602-22.

flow averaged over one modulation period or impulse.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.7.1 Discussion—The total heat flow is equivalent to the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

heat flow signal of conventional differential scanning calorim-

Standards volume information, refer to the standard’s Document Summary page on

theASTM website. etry.

C

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2602 − 09 (Reapproved 2015) E2602 − 22

Standard Test Methods for

the Assignment of the Glass Transition Temperature by

1

Modulated Temperature Differential Scanning Calorimetry

This standard is issued under the fixed designation E2602; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods describe the assignment of the glass transition temperature of materials using modulated temperature

differential scanning calorimetry (MTDSC) over the temperature range from –120 °C to +600°C. +600 °C. The temperature range

may be extended depending upon the instrumentation used.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 There are no ISO equivalents to this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E473 Terminology Relating to Thermal Analysis and Rheology

E967 Test Method for Temperature Calibration of Differential Scanning Calorimeters and Differential Thermal Analyzers

E968 Practice for Heat Flow Calibration of Differential Scanning Calorimeters

E1142 Terminology Relating to Thermophysical Properties

E1356 Test Method for Assignment of the Glass Transition Temperatures by Differential Scanning Calorimetry

E1545 Test Method for Assignment of the Glass Transition Temperature by Thermomechanical Analysis

E1640 Test Method for Assignment of the Glass Transition Temperature By Dynamic Mechanical Analysis

3. Terminology

3.1 Definitions—Specific technical terms found in these test methods are defined in Terminologies E473 and E1142 including

differential scanning calorimetry, extrapolated onset, glass transition, glass transition temperature, non-reversing, reversing,

specific heat capacity, and thermal curve.

1

These test methods are under the jurisdiction of ASTM Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on Calorimetry

and Mass Loss.

Current edition approved May 1, 2015Feb. 1, 2022. Published May 2015May 2022. Originally approved in 2009. Last previous edition approved in 20092015 as E2602

– 09. 09 (2015). DOI: 10.1520/E2602-09R15.10.1520/E2602-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2602 − 22

3.2 Definitions of Terms Specific to This Standard:

3.2.1 extrapolated end temperature (Te), n—the point of intersection of the tangent drawn at the point of greatest slope (that is,

the inflection point) in the transition region with the extrapolated baseline following the transition.

3.2.2 extrapolated onset temperature (Tf), n—the point of intersection of the tangent drawn at the point of greatest slope (that is,

the inflection point) in the transition region with the extrapolated baseline prior to the transition.

3.2.3 midpoint temperature (Tm), n—the point on the thermal curve corresponding to the average of the extrapolated onset and

extrapolated end temperatures.

3.2.4 modulated, n—a prefix indicating that a parameter changes in a periodic manner during the experiment.

3.2.5 modulated heat flow, n—the heat flow resulting from an applied modulated temperature program.

3.2.6 modulated temperature differential scanning calorimetry (MTDSC),n—a method of differential scanning calorimetry (DSC)

that varies the temperature sinusoidally or with a periodic step-and-hol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.