ASTM C849-88(1999)

(Test Method)Standard Test Method for Knoop Indentation Hardness of Ceramic Whitewares

Standard Test Method for Knoop Indentation Hardness of Ceramic Whitewares

SCOPE

1.1 This test method covers the determination of the Knoop indentation hardness of ceramic whitewares and the verification of Knoop indentation hardness testing machines using standard glasses.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C849–88(Reapproved 1999)

Standard Test Method for

Knoop Indentation Hardness of Ceramic Whitewares

This standard is issued under the fixed designation C 849; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This test method covers the determination of the Knoop 5.1 The Knoop indentation hardness is one of many prop-

indentation hardness of ceramic whitewares and the verifica- ertiesthatisusedtocharacterizeceramicwhitewares.Attempts

tion of Knoop indentation hardness testing machines using have been made to relate Knoop indentation hardness to tensile

standard glasses. strength, grinding speeds, and other hardness scales, but no

1.2 This standard does not purport to address all of the generally accepted methods are available. Such conversions

safety concerns, if any, associated with its use. It is the arelimitedinscopeandshouldbeusedwithcaution,exceptfor

responsibility of the user of this standard to establish appro- special cases where a reliable basis for the conversion has been

priate safety and health practices and determine the applica- obtained by comparison tests.

bility of regulatory limitations prior to use.

6. Apparatus

2. Referenced Documents

6.1 Testing Machines:

2.1 ASTM Standards: 6.1.1 There are two general types of machines available for

E 4 Practices for Force Verification of Testing Machines making this test. One type is a self-contained unit built for this

E 384 Test Method for Microhardness of Materials purpose,andtheothertypeisanaccessoryavailabletoexisting

microscopes. Usually, this second type is fitted on an inverted-

3. Terminology

stage microscope. Good descriptions of the various machines

,

3 4

3.1 Definitions:

are available.

3.1.1 Knoop hardness number ( KHN)—a number obtained 6.1.2 Design of the machine should be such that the loading

by dividing the applied load in kilograms-force by the pro-

rate, dwell time, and applied load can be standardized within

jected area of the indentation in square millimetres, computed the limits set forth in 3.1.1. It is an advantage to eliminate the

from the measured long diagonal of the indentation and the human element whenever possible by appropriate machine

included edge angles of the diamond. It is assumed that the

design. The machine should be designed so that vibrations

indentation is an imprint of the undeformed indenter. induced at the beginning of a test will be damped out by the

time the indenter touches the sample.

4. Summary of Test Method

6.1.3 Thecalibrationofthebalancebeamshouldbechecked

4.1 This test method describes an indentation hardness test

monthly or as needed. Indentations in standard glasses are also

using a calibrated machine to force a pointed, rhombic-base,

used to check calibration when needed.

pyramidal diamond indenter having specified face angles,

6.2 Indenter:

under a predetermined load, into the surface of the material

6.2.1 The indenter shall meet the specifications for Knoop

under test and to measure the long diagonal of the resulting

indenters. See Test Method E 384.

impression after removal of the load.

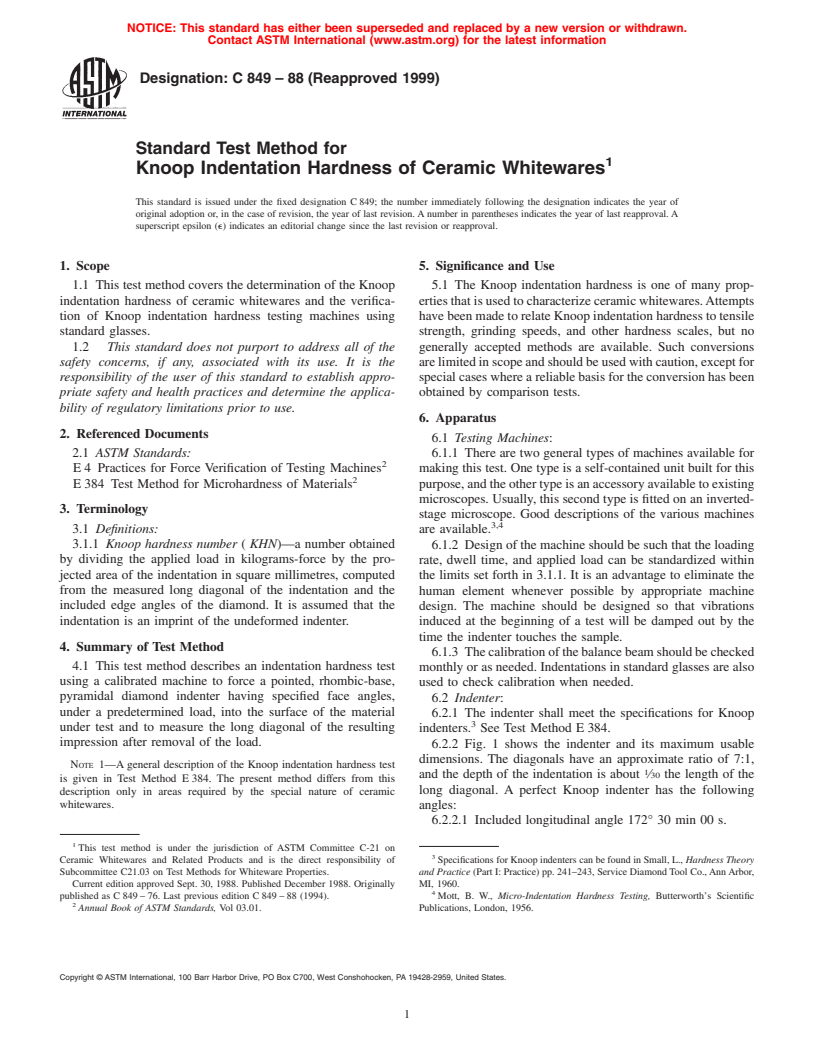

6.2.2 Fig. 1 shows the indenter and its maximum usable

dimensions. The diagonals have an approximate ratio of 7:1,

NOTE 1—A general description of the Knoop indentation hardness test

and the depth of the indentation is about ⁄30 the length of the

is given in Test Method E 384. The present method differs from this

long diagonal. A perfect Knoop indenter has the following

description only in areas required by the special nature of ceramic

whitewares. angles:

6.2.2.1 Included longitudinal angle 172° 30 min 00 s.

This test method is under the jurisdiction of ASTM Committee C-21 on

Ceramic Whitewares and Related Products and is the direct responsibility of Specifications for Knoop indenters can be found in Small, L., Hardness Theory

Subcommittee C21.03 on Test Methods for Whiteware Properties. and Practice (Part I: Practice) pp. 241–243, Service Diamond Tool Co.,AnnArbor,

Current edition approved Sept. 30, 1988. Published December 1988. Originally MI, 1960.

published as C 849 – 76. Last previous edition C 849 – 88 (1994). Mott, B. W., Micro-Indentation Hardness Testing, Butterworth’s Scientific

Annual Book of ASTM Standards, Vol 03.01. Publications, London, 1956.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

C849

FIG. 1 Knoop Indenter Showing Maximum Usable Dimension

6.2.2.2 Included transverse angle 130° 00 min 00 s. 7.1.3 Radius of Curvature—The KHN obtained will be

6.2.3 The constant C for a perfect indenter is 0.070 28, and affected even when the curvature is only in the direction of the

p

thespecificationsrequireavariationofnotmorethan1 %from short diagonal. Care should be used when relating KHN values

this value. obtained on curved surfaces to those obtained on polished flat

6.3 Measuring Microscope—Themeasurementsystemshall surfaces.

be so constructed that the length of the diagonals can be

8. Preparation of Apparatus

determined with errors not exceeding 60.0005 mm. The

apparent length of the diagonal is corrected in the calculations

8.1 Verification of Load—Most of the machines available

for the limit of resolution of the objective being used in the

for Knoop hardness testing use a loaded beam. This beam

microscope.

should be tested for zero load. An indentation should not be

visible with zero load, but the indenter should contact the

7. Test Specimens

sample.Avisible indentation should be obtained with a load of

0.1 gf. Other methods of verifying the load application are

7.1 The Knoop indentation hardness test is adaptable to a

given in Practice E 4.

wide variety of ceramic whiteware specimens. In general, the

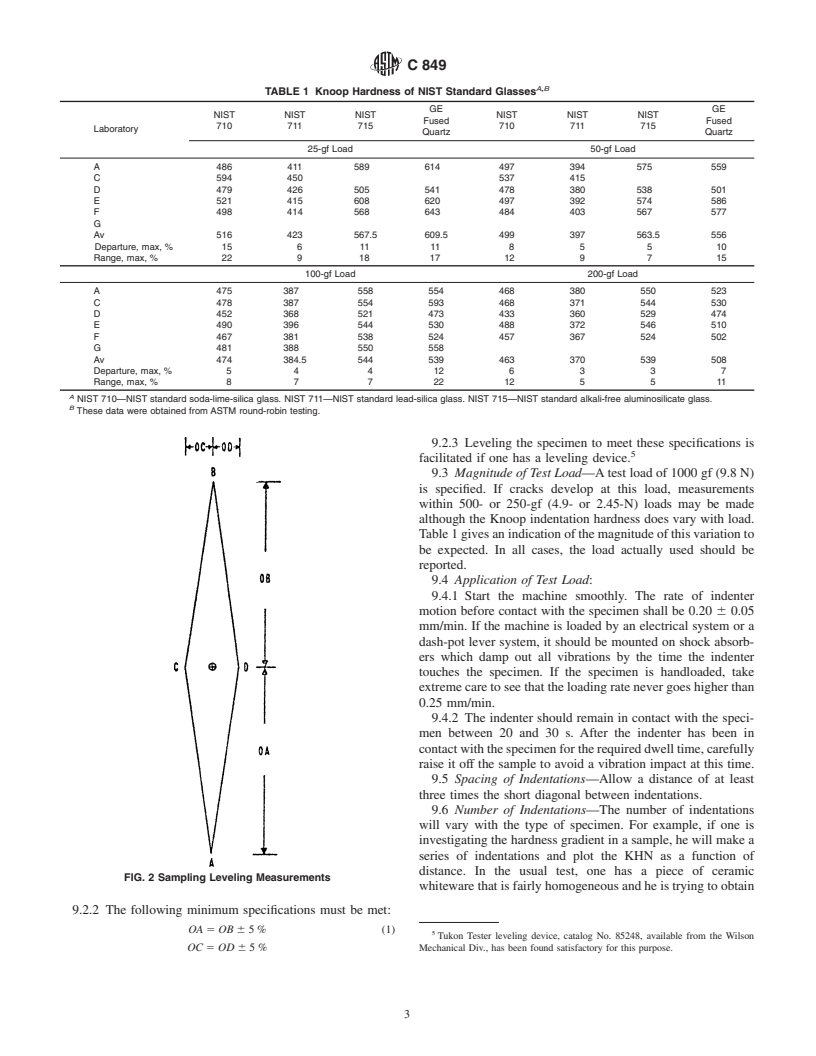

8.2 Verification by Standard Glasses—Table 1 gives the

accuracy of the test will depend on the smoothness of the

Knoop hardness of several National Institute of Standards and

surface and, whenever possible, ground and polished speci-

Technology (NIST) standard glasses. Knoop hardness mea-

mens should be used. The back of the specimen shall be fixed

surement on a piece of one of these glasses that has been

so that the specimen cannot rock or shift during the test.

ground and polished within the last 24 h should agree with the

7.1.1 Thickness—As long as the specimen is over ten times

value in the table 65 %. Tests should be made using 100 gf.

as thick as the indentation depth, this will not affect the test. In

general, if specimens are at least 0.10 mm thick, the hardness

9. Procedure

will not be affected by variations in the thickness.

7.1.2 Surface Finish—As pointed out above, the accuracy 9.1 Specimen Placement—Place the specimen on the stage

of the test depends on the surface finish. However, if one is of the machine in such a way so that the specimen will not be

investigating a surface coating or treatment, he cannot grind able to rock or shift during the measurement.

and polish the sample. Experience has shown that six inden- 9.2 Specimen Leveling:

tations on a ground and polished surface of glass will repro- 9.2.1 The surface of the specimen being tested must lie in a

duce within 61 %. Six indentations on an “as-received” plane normal to the axis of the indenter. Fig. 2 shows an

surfacemaybeasbadas 610 %.Groundandpolishedsurfaces indentation as it will appear through the microscope with five

should be used. If this is not possible, the number of indenta- points labeled. To level the specimen, make a test indentation

tions should be increased. using a 100-gf load.

--------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.