ASTM F1455-92(2011)

(Guide)Standard Guide for Selection of Structural Details for Ship Construction

Standard Guide for Selection of Structural Details for Ship Construction

ABSTRACT

This guide provides a recommended list of selected ship structure details for use in ship construction. Structural details which have failed in service and are not recommended for use in ship construction are included as well. This guide is intended to convey the lessons learned on different configurations of ship structure details, not the dimensions, thickness, or construction methods which would result from structural calculations. Details are shown for the ten families of structural details, which are: beam brackets, clearance cut-outs, gunwale connections, miscellaneous cut-outs, non-tight collars, panel stiffeners, stanchion ends, stiffener ends, tight collars, and tripping brackets. Evaluation of details is based on in-service experience as described in "Design Guide for Structural Details". Data for over 400 details is summarized and rated by observed relative successful performance. Each of the ten families of details includes configurations with no signs of failures. The details without failures within each family group are shown in descending order of numbers observed. Those details with failures are shown in ascending order of failures (percentages are indicated for each). Thus the first detail shown in each family group has the best observed service performance and is most highly recommended while the last has the highest failure rate and therefore least desirable. The details provide guidance in the selection of structural detail configurations in future design and repair of such details.

SCOPE

1.1 This guide provides a recommended list of selected ship structure details for use in ship construction.

1.2 Structural details which have failed in service and are not recommended for use in ship construction are included as well.

1.3 This guide is intended to convey the lessons learned on different configurations of ship structure details, not the dimensions, thickness, or construction methods which would result from structural calculations.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1455 − 92 (Reapproved 2011) An American National Standard

Standard Guide for

Selection of Structural Details for Ship Construction

This standard is issued under the fixed designation F1455; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The principal aim of this guide is to depict recommended practices related to the design of ship

structural details. The importance of structural details is clear:

1) Their layout and fabrication represent a sizable fraction of hull construction costs.

2) Details are often the source of cracks and other failures which, under certain circumstances,

could lead to serious damage to the ship hull girder.

3) Thetrendtowarddecreasingshiphullscantlings(thatis,increasingaveragehullstresses)hasthe

potential of increasing the damage to details.

4) Researchers have largely neglected the analysis of structural details at least in part because the

configuration and purpose of these details vary greatly and are not commonly described or discussed

in the literature.

Due to lack of analytical and experimental effort devoted to structural details, their determination

has been left up to draftsmen and designers, with very little engineering input.

2,3

In two comprehensive reviews of the performance of structural details, 86 ships were surveyed.

These included naval and commercial ship types. The commercial ships included both U.S. and

foreign built. The vessels ranged from 428 to 847 feet in length, from 18,000 to 90,000 tons in

displacement, and from five to twenty-six years in age. The details obtained were grouped into 12

typicalfamilies.KnifeEdgeCrossings(FamilyNo.6)andStructuralDeckCutoutDetails(FamilyNo.

9) are shown but not covered in detail in this guide. The remaining ten detail families were further

categorized into 53 groups comprising a total of 611 detail configurations. A number of these

configurations are very similar to others in detail geometry and such duplicates have been excluded

from this guide.Anumber of others were eliminated because of relatively infrequent observed use.As

a result, a total of 414 details are included herein. However, all 611 details can be found in “Structural

Details,” if desired.

In total, 607,584 details were observed with a total of 6,856 failures. Failures were attributed to one

or a combination of five categories: design, fabrication, welding, maintenance, and operation (see 4.1

through 4.1.5). This extensive, well documented research, together with engineering judgement,

provides the principal support for this guide.

1. Scope 1.2 Structural details which have failed in service and are

not recommended for use in ship construction are included as

1.1 This guide provides a recommended list of selected ship

well.

structure details for use in ship construction.

1.3 This guide is intended to convey the lessons learned on

different configurations of ship structure details, not the

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

dimensions, thickness, or construction methods which would

Marine Technology and is the direct responsibility of Subcommittee F25.01 on

result from structural calculations.

Structures.

Current edition approved Nov. 1, 2011. Published November 2011. Originally

approved in 1992. Last previous edition approved in 2007 as F1455 - 92(2007).

2. Terminology

DOI: 10.1520/F1455-92R11.

2 2.1 Definitions of Terms Specific to This Standard:

Jordan, C. R., and Cochran, C. S., “In-service Performance of Structural

Details,” SSC-272, Ship Structure Committee Report, March 1977, available

2.1.1 Terms:

through the National Technical Information Service, Springfield, VA 22161.

Jordan, C. R., and Knight, L. T., “Further Survey of In-service Performance of

Structural Details,” SSC-294, Ship Structure Committee Report, May 1979, avail- Jordan, C. R., and Krumpen, P., Jr., “Structural Details,” American Welding

able through the National Technical Information Service, Springfield, VA 22161. Society Welding Journal, Vol 63, No. 1, January 1984.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1455 − 92 (2011)

2.1.2 beam bracket—a bracket at the end of framing or

stiffening members that is used for increased strength, conti-

nuity and end constraint.

2.1.2.1 Discussion—see Fig. 1.

2.1.3 clearance cut-outs—a hole or opening in a pierced

member to allow passage of a piercing member.

2.1.3.1 Discussion—see Fig. 2.

FIG. 2 Clearance Cut-outs (Family No. 8)

2.1.4 gunwale connection—the connection of the sheer

strake to the stringer strake of the uppermost deck of the hull.

2.1.4.1 Discussion—see Fig. 3.

2.1.5 knife edge crossing—the projected point intersection

of members (plate members, stiffeners or bulkheads) on

opposite sides of an intervening plate member.An undesirable

condition to be avoided.

2.1.5.1 Discussion—Included for information only, see 3.1.

2.1.5.2 Discussion—see Fig. 4.

2.1.6 miscellaneous cut-out—small holes or openings of a FIG. 3 Gunwale Connections (Family No. 5)

variety of sizes and shapes used for access, drainage, ease of

fabrication, stress relief, and so forth.

2.1.6.1 Discussion—see Fig. 5.

2.1.7 non-tight collar—a fitting at the cut-outs in way of the

intersection of two continuous members that provides lateral

support for the piercing member which does not fully fill the

cut-out area of the pierced member. May be a lug.

2.1.7.1 Discussion—see Fig. 6.

FIG. 4 Knife Edge Crossing (Family No. 6)

2.1.8 panel stiffeners—intercostal, non-load-carrying mem-

bers used to reduce the size of plate panels.

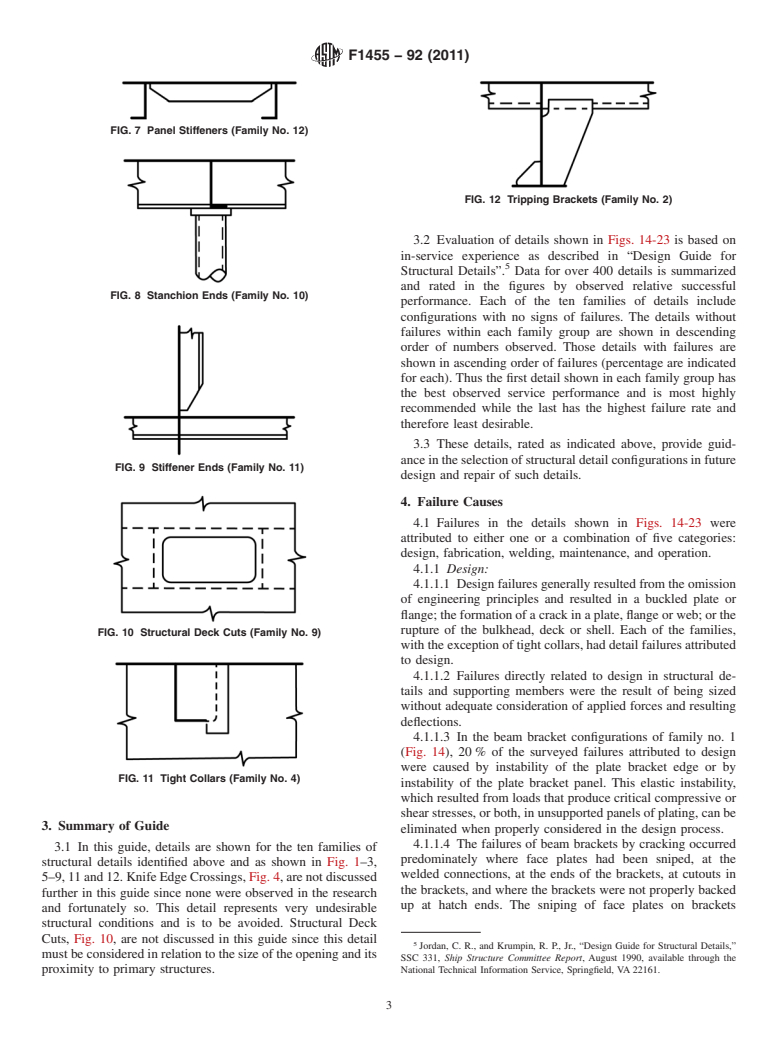

2.1.8.1 Discussion—see Fig. 7.

2.1.9 stanchion ends—structural fittings at the ends (top and

bottom) of a stanchion to transfer loads from the supported

member to the supporting member.

2.1.9.1 Discussion—see Fig. 8.

2.1.10 stiffener ends—the configuration of the end of an

FIG. 5 Miscellaneous Cut-outs (Family No. 7)

unbracketed, non-continuous stiffener.

2.1.10.1 Discussion—see Fig. 9.

2.1.11 structural deck cuts—allow passage through decks

for access, tank cleaning, piping, cable, and so forth.

2.1.11.1 Discussion—Includedforinformationonly,see3.1.

2.1.11.2 Discussion—see Fig. 10.

2.1.12 tight collar—as per non-tight collar but the cut-out in

the pierced member is fully filled and is air-, oil-, or watertight

as required. Tight collars may be lapped or flush fitted.

2.1.12.1 Discussion—see Fig. 11.

FIG. 6 Non-Tight Collars (Family No. 3)

2.1.13 tripping bracket—a bracket or chock that provides

lateral support to framing and stiffening members. Support

may be provided to either the web or the flange, or to both.

2.1.13.1 Discussion—see Fig. 12.

2.2 Symbols:

2.2.1 Symbols are as indicated in Fig. 13. The detail

identification symbol (Fig. 13, 1-J-1 for example) is the same

as that assigned in the original research reports and is retained

throughout for all details for ease in referring back to the

FIG. 1 Beam Brackets (Family No. 1) reports if desired.

F1455 − 92 (2011)

FIG. 7 Panel Stiffeners (Family No. 12)

FIG. 12 Tripping Brackets (Family No. 2)

3.2 Evaluation of details shown in Figs. 14-23 is based on

in-service experience as described in “Design Guide for

Structural Details”. Data for over 400 details is summarized

and rated in the figures by observed relative successful

FIG. 8 Stanchion Ends (Family No. 10)

performance. Each of the ten families of details include

configurations with no signs of failures. The details without

failures within each family group are shown in descending

order of numbers observed. Those details with failures are

shown in ascending order of failures (percentage are indicated

for each). Thus the first detail shown in each family group has

the best observed service performance and is most highly

recommended while the last has the highest failure rate and

therefore least desirable.

3.3 These details, rated as indicated above, provide guid-

anceintheselectionofstructuraldetailconfigurationsinfuture

FIG. 9 Stiffener Ends (Family No. 11)

design and repair of such details.

4. Failure Causes

4.1 Failures in the details shown in Figs. 14-23 were

attributed to either one or a combination of five categories:

design, fabrication, welding, maintenance, and operation.

4.1.1 Design:

4.1.1.1 Design failures generally resulted from the omission

of engineering principles and resulted in a buckled plate or

flange; the formation of a crack in a plate, flange or web; or the

rupture of the bulkhead, deck or shell. Each of the families,

FIG. 10 Structural Deck Cuts (Family No. 9)

with the exception of tight collars, had detail failures attributed

to design.

4.1.1.2 Failures directly related to design in structural de-

tails and supporting members were the result of being sized

without adequate consideration of applied forces and resulting

deflections.

4.1.1.3 In the beam bracket configurations of family no. 1

(Fig. 14), 20 % of the surveyed failures attributed to design

were caused by instability of the plate bracket edge or by

FIG. 11 Tight Collars (Family No. 4)

instability of the plate bracket panel. This elastic instability,

which resulted from loads that produce critical compressive or

shear stresses, or both, in unsupported panels of plating, can be

3. Summary of Guide

eliminated when properly considered in the design process.

4.1.1.4 The failures of beam brackets by cracking occurred

3.1 In this guide, details are shown for the ten families of

predominately where face plates had been sniped, at the

structural details identified above and as shown in Fig. 1–3,

welded connections, at the ends of the brackets, at cutouts in

5–9, 11 and 12. Knife Edge Crossings, Fig. 4, are not discussed

the brackets, and where the brackets were not properly backed

further in this guide since none were observed in the research

up at hatch ends. The sniping of face plates on brackets

and fortunately so. This detail represents very undesirable

structural conditions and is to be avoided. Structural Deck

Cuts, Fig. 10, are not discussed in this guide since this detail

Jordan, C. R., and Krumpin, R. P., Jr., “Design Guide for Structural Details,”

must be considered in relation to the size of the opening and its

SSC 331, Ship Structure Committee Report, August 1990, available through the

proximity to primary structures. National Technical Information Service, Springfield, VA 22161.

F1455 − 92 (2011)

FIG. 13 Symbols

prevents good transition of stress flow, creates hard spots and 2) Use cuts of sufficient size to provide proper welding

produces fatigue cracks due to the normally cyclic stresses of clearances.

these members. Care must be taken to ensure proper transition 3) Avoid locating holes in high tensile stress areas.

with the addition of chocks, back-up structure, reinforcement 4) Avoid square corners and sharp notches.

of hole cuts, and the elimination of notches. 5) Use adequate spacing between cuts.

4.1.1.5 To reduce the potential for lamellar tearings and 6) Properly reinforce cuts in highly stressed areas.

7) Locate cuts on or as near the neutral axis as possible in

fatigue cracks in decks, bulkheads, and beams, transition

brackets should be made continuous through the plating or beam structures.

supported by stiffeners rigid enough to transmit the loads. 8) Avoid cuts at the head or heel of a stanchion.

4.1.1.6 The greater number of failures in the tripping 9) Plug or reinforce structural erection cuts when located in

bracket configurations of family no. 2 (Fig. 15), occurred at highly stressed areas.

hatch side girders, particularly in containerships. This will be a 4.1.1.10 The most damaging crack observed during the

continuing problem unless the brackets are designed to carry survey was in the upper box girder of a containership. This

the large lateral loads due to rolling when containers are structure is part of the longitudinal strength structure of the

stacked two to four high on the hatches. The brackets must, in ship in addition to being subjected to high local stresses due to

turn, be supported by properly designed backing structure to the container loading in the upper deck. Openings in this

transmit the loads to the basic ship structure. structure must be located, reinforced, and analyzed for second-

4.1.1.7 Tripping brackets supported by panels of plating can ary bending stresses caused by high shear loads.

be potential problems depending on the plate thickness. Brack- 4.1.1.11 The clearance cutouts of family no. 8 (Fig. 16) are

ets landing on thick plating in relationship to its own thickness basically non-tight collars without the addition of the collar

may either buckle in the panel of the bracket, produce fatigue plate. Suggestions made for non-tight collars and miscella-

cracks along the toe of the weld, or cause lamellar tearing in neous cutouts are applicable for this family.

the supporting plate. Brackets landing on plating with a 4.1.1.12 Well rounded corners with radii equivalent to 25 %

thickness equal to, or less than its own thickness, may cause ofthewidthperpendiculartotheprimarystressflowsshouldbe

either fatigue cracks to develop or buckling of an unsupported used. Special reinforcements in the form of tougher or higher

panel of plating. strength steel, inserts, coamings, and combinations of the

4.1.1.8 The non-tight collar configurations of family no. 3 above should be used where fatigue and high stresses are a

(Fig. 17) experienced only a few failures. There are problem.

considerations, however, that must be used by the designer to 4.1.1.13 In general, failures in stanchion ends, family no. 10

ensure the continuation of this trend. The cutouts should be (Fig. 21), were cracks which developed in or at the connection

providedwithsmoothwellroundedradiitoreducestressrisers. to the attachment structure. The addition of tension brackets,

Where collars are cut in high stress areas, suitable replacement shear chocks, and the elimination of snipes would reduce the

material should be provided to eliminate the overstressing of incidents of structural failure. All stanchion end connections

the adjacent web plating. These considerations should reduce should be capable of carrying the full load of the stanchion in

the incidents of plate buckling, fatigue cracking, and stress tension or compression. Stanchions used for container stands

corrosion observed in this family. or to support such structure as deckhouses on the upper deck

4.1.1.9 F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.