ASTM F1455-92(2011)

(Guide)Standard Guide for Selection of Structural Details for Ship Construction

Standard Guide for Selection of Structural Details for Ship Construction

ABSTRACT

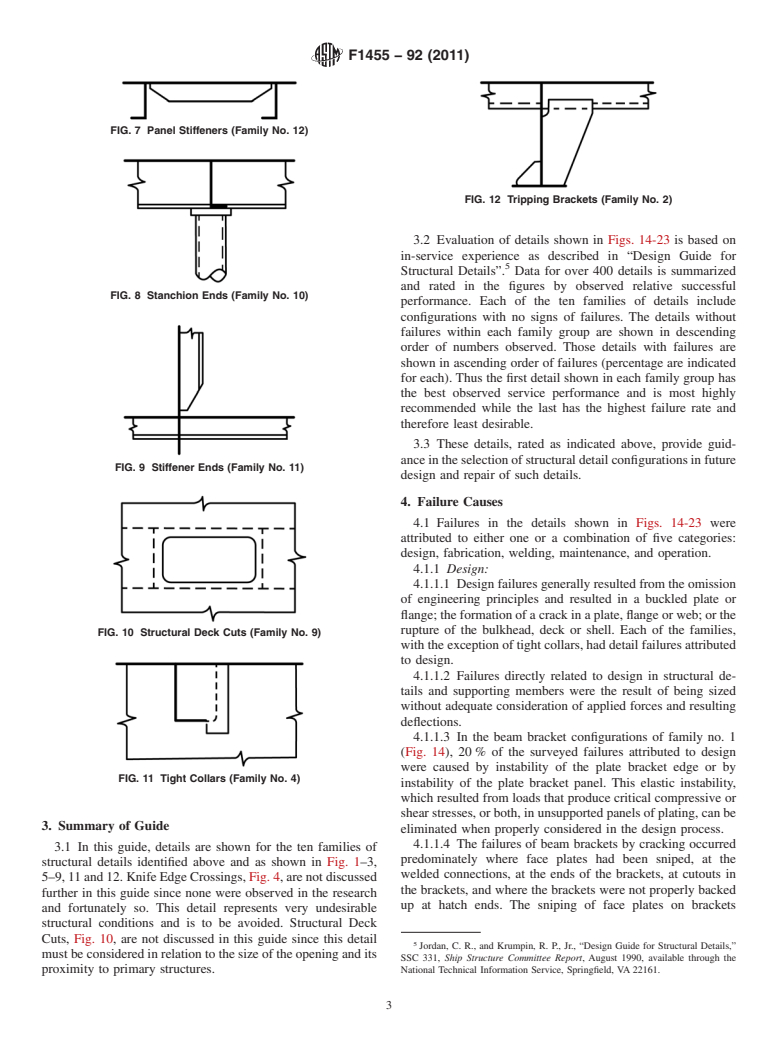

This guide provides a recommended list of selected ship structure details for use in ship construction. Structural details which have failed in service and are not recommended for use in ship construction are included as well. This guide is intended to convey the lessons learned on different configurations of ship structure details, not the dimensions, thickness, or construction methods which would result from structural calculations. Details are shown for the ten families of structural details, which are: beam brackets, clearance cut-outs, gunwale connections, miscellaneous cut-outs, non-tight collars, panel stiffeners, stanchion ends, stiffener ends, tight collars, and tripping brackets. Evaluation of details is based on in-service experience as described in "Design Guide for Structural Details". Data for over 400 details is summarized and rated by observed relative successful performance. Each of the ten families of details includes configurations with no signs of failures. The details without failures within each family group are shown in descending order of numbers observed. Those details with failures are shown in ascending order of failures (percentages are indicated for each). Thus the first detail shown in each family group has the best observed service performance and is most highly recommended while the last has the highest failure rate and therefore least desirable. The details provide guidance in the selection of structural detail configurations in future design and repair of such details.

SCOPE

1.1 This guide provides a recommended list of selected ship structure details for use in ship construction.

1.2 Structural details which have failed in service and are not recommended for use in ship construction are included as well.

1.3 This guide is intended to convey the lessons learned on different configurations of ship structure details, not the dimensions, thickness, or construction methods which would result from structural calculations.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1455 − 92 (Reapproved 2011) An American National Standard

Standard Guide for

1

Selection of Structural Details for Ship Construction

This standard is issued under the fixed designation F1455; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The principal aim of this guide is to depict recommended practices related to the design of ship

structural details. The importance of structural details is clear:

1) Their layout and fabrication represent a sizable fraction of hull construction costs.

2) Details are often the source of cracks and other failures which, under certain circumstances,

could lead to serious damage to the ship hull girder.

3) Thetrendtowarddecreasingshiphullscantlings(thatis,increasingaveragehullstresses)hasthe

potential of increasing the damage to details.

4) Researchers have largely neglected the analysis of structural details at least in part because the

configuration and purpose of these details vary greatly and are not commonly described or discussed

in the literature.

Due to lack of analytical and experimental effort devoted to structural details, their determination

has been left up to draftsmen and designers, with very little engineering input.

2,3

In two comprehensive reviews of the performance of structural details, 86 ships were surveyed.

These included naval and commercial ship types. The commercial ships included both U.S. and

foreign built. The vessels ranged from 428 to 847 feet in length, from 18,000 to 90,000 tons in

displacement, and from five to twenty-six years in age. The details obtained were grouped into 12

typicalfamilies.KnifeEdgeCrossings(FamilyNo.6)andStructuralDeckCutoutDetails(FamilyNo.

9) are shown but not covered in detail in this guide. The remaining ten detail families were further

categorized into 53 groups comprising a total of 611 detail configurations. A number of these

configurations are very similar to others in detail geometry and such duplicates have been excluded

from this guide.Anumber of others were eliminated because of relatively infrequent observed use.As

a result, a total of 414 details are included herein. However, all 611 details can be found in “Structural

4

Details,” if desired.

In total, 607,584 details were observed with a total of 6,856 failures. Failures were attributed to one

or a combination of five categories: design, fabrication, welding, maintenance, and operation (see 4.1

through 4.1.5). This extensive, well documented research, together with engineering judgement,

provides the principal support for this guide.

1. Scope 1.2 Structural details which have failed in service and are

not recommended for use in ship construction are included as

1.1 This guide provides a recommended list of selected ship

well.

structure details for use in ship construction.

1.3 This guide is intended to convey the lessons learned on

different configurations of ship structure details, not the

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

dimensions, thickness, or construction methods which would

Marine Technology and is the direct responsibility of Subcommittee F25.01 on

4

result from structural calculations.

Structures.

Current edition approved Nov. 1, 2011. Published November 2011. Originally

approved in 1992. Last previous edition approved in 2007 as F1455 - 92(2007).

2. Terminology

DOI: 10.1520/F1455-92R11.

2 2.1 Definitions of Terms Specific to This Standard:

Jordan, C. R., and Cochran, C. S., “In-service Performance of Structural

Details,” SSC-272, Ship Structure Committee Report, March 1977, available

2.1.1 Terms:

through the National Technical Information Service, Springfield, VA 22161.

3

Jordan, C. R., and Knight, L. T., “Further Survey of In-service Performance of

4

Structural Details,” SSC-294, Ship Structure Committee Report, May 1979, avail- Jordan, C. R., and Krumpen, P., Jr., “Structural Details,” American Welding

able through the National Technical Information Service, Springfield, VA 22161. Society Welding Journal, Vol 63, No. 1, January 1984.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1455 − 92 (2011)

2.1.2 beam bracket—a bracket at the end of framing or

stiffening members that is used for increased strength, conti-

nuity and end constraint.

2.1.2.1 Discussion—see Fig. 1.

2.1.3 clearance cut-outs—a hole or opening in a pierced

member to allow passage of a piercing member.

2.1.3.1 Discussion—see Fig. 2.

FIG. 2 Clearance Cut-outs (Family No. 8)

2.1.4 gunw

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.