ASTM F1913-04

(Specification)Standard Specification for Vinyl Sheet Floor Covering Without Backing

Standard Specification for Vinyl Sheet Floor Covering Without Backing

ABSTRACT

This specification covers sheet floor covering having a vinyl wear layer without backing. Products also may contain a clear specialty performance top layers. This type of floor covering is intended for use in commercial and light commercial buildings. The wear layer shall have a vinyl plastic binder and may include pigments, fillers, extenders, and other ingredients. This layer shall be stabilized against heat and light deterioration. The binder content of the PVC-pattern portion of the wear layer such as vinyl resins, plasticizers, and stabilizers shall be a minimum of 50 %.

SCOPE

1.1 This specification covers sheet floor covering having a vinyl wear layer without backing. Products also may contain a clear specialty performance top layer(s).

1.2 This type of floor covering is intended for use in commercial and light commercial buildings. General information and performance characteristics, which determine service-ability and recommended use, are included in this specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F1913 – 04

Standard Specification for

1

Vinyl Sheet Floor Covering Without Backing

This standard is issued under the fixed designation F1913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F1914 Test Methods for Short-Term Indentation and Re-

sidual Indentation of Resilient Floor Covering

1.1 This specification covers sheet floor covering having a

2.2 ANSI/ASQC Standard:

vinyl wear layer without backing. Products also may contain a

ANS/ASQC Z1.4 Sampling Procedures and Tables for In-

clear specialty performance top layer(s).

3

spection by Attributes

1.2 This type of floor covering is intended for use in

commercial and light commercial buildings. General informa-

3. Terminology

tion and performance characteristics, which determine service-

3.1 Definitions— Terms used in this specification are de-

abilityandrecommendeduse,areincludedinthisspecification.

fined in accordance with Terminology F141.

1.3 The values stated in inch-pound units are to be regarded

3.2 Definitions of Terms Specific to This Standard:

as the standard. The values given in parentheses are for

3.2.1 wear layer, n—the portion of a resilient floor covering

information only.

that contains the pattern effect.

1.4 This standard does not purport to address all of the

3.2.1.1 Discussion—The wear layer thickness and total

safety concerns, if any, associated with its use. It is the

thickness of through pattern unbacked sheet vinyl flooring are

responsibility of the user of this standard to establish appro-

the same.Aclear specialty performance top layer may be used

priate safety and health practices and determine the applica-

to enhance specific properties and to protect the pattern effect

bility of regulatory limitations prior to use.

and shall be counted as part of the wear layer. The wear layer

does not include temporary finishes or maintenance coatings.

2. Referenced Documents

2

2.1 ASTM Standards:

4. Significance and Use

F137 Test Method for Flexibility of Resilient Flooring

4.1 The information in this specification is for use by

Materials with Cylindrical Mandrel Apparatus

specifiers as a reference when selecting unbacked resilient

F141 Terminology Relating to Resilient Floor Coverings

sheet vinyl flooring for areas within commercial and light

F386 Test Method for Thickness of Resilient Flooring

commercial buildings.

Materials Having Flat Surfaces

F410 Test Method for Wear Layer Thickness of Resilient

5. Classification

Floor Coverings by Optical Measurement

5.1 Sheet Vinyl floor covering shall conform to the follow-

F925 Test Method for Resistance to Chemicals of Resilient

ing.

Flooring

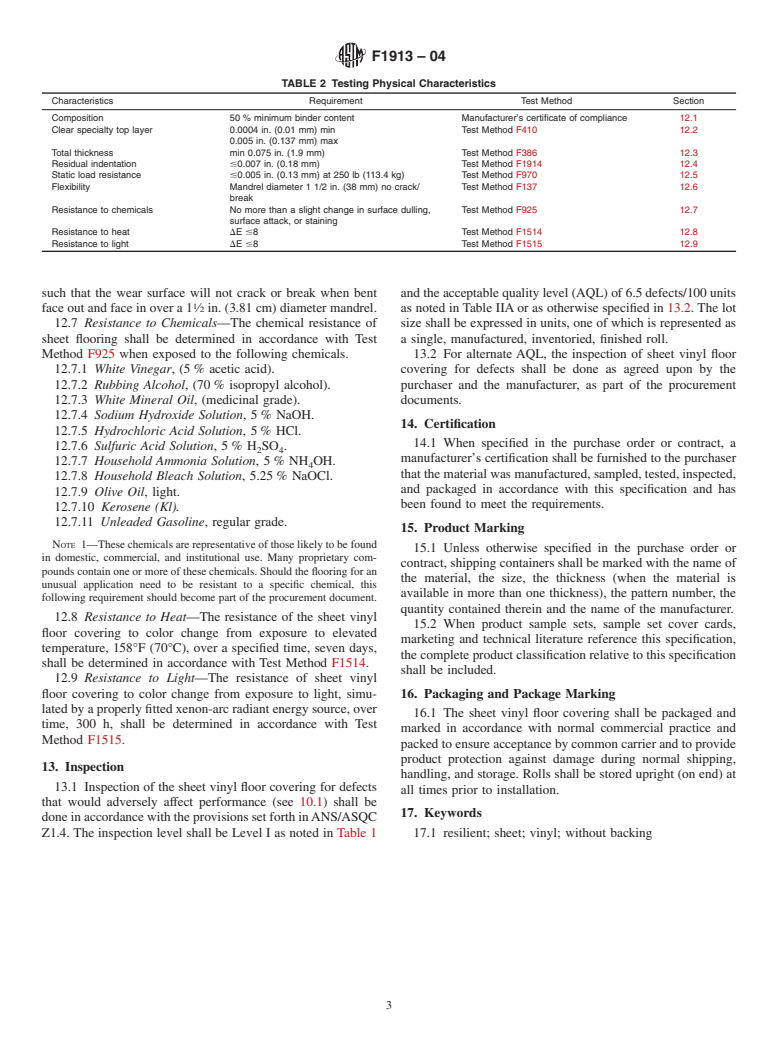

5.1.1 The binder content of the PVC-pattern portion of the

F970 Test Method for Static Load Limit

wear layer (vinyl resins, plasticizers, and stabilizers) shall be a

F1514 Test Method for Measuring Heat Stability of Resil-

minimum of 50 %.Aclear specialty performance layer(s) used

ient Flooring by Color Change

as the top layer is not described by binder limits.

F1515 Test Method for Measuring Light Stability of Resil-

PVC Binder Content

ient Flooring by Color Change

Minimum % PVC Wear Layer Description

50 % The material shall be a vinyl compound consisting

of a blended composition of pigments stabilized

1

against heat and light deterioration. The design,

This specification is under the jurisdiction of ASTM Committee F06 on

color and pattern extends throughout the thickness

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80

of the wear layer.

on Specifications.

Current edition approved March 1, 2004. Published April 2004. Originally

5.1.1.1 All flooring may have a clear specialty performance

approved in 1998. Last previous edition approved in 2002 as F1913-02. DOI:

toplayer(s)withanaverageminimumtotalthicknessof0.0004

10.1520/F1913-04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute, 25 W. 43rd St., 4th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1913 – 04

in. The specialty performance top layer(s) may consist of a 8. Physical Requirements

single layer or multiple layers, which do not delaminate under

8.1 Sheetvinylfloorcoveringshallmeettherequirementsin

normal use. Top layer(s) thinner than 0.0004 in. may be used

Ta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.