ASTM D3181-95(2002)

(Guide)Standard Guide for Conducting Wear Tests on Textiles

Standard Guide for Conducting Wear Tests on Textiles

SIGNIFICANCE AND USE

This guide may be used to evaluate textiles used in apparel, upholstered furniture, floor coverings, window treatments, and bed, bath and table linens.

This guide may be used for several purposes:

5.2.1 To determine the comparative performance of new or existing products,

5.2.2 To determine the suitability of current products in different end-uses, and

5.2.3 To evaluate and compare the effect of wear of construction details as well as specific fabrics, fibers, dyeings, finishing, fabrication techniques, etc.

This guide provides for flexibility in design and evaluation since the information sought from each wear test will vary (see Appendix X1).

This guide may be used to compare the wear performance of two or more textiles when these are included in the same test, or to compare a textile whose properties have not been evaluated with one having a known performance history.

SCOPE

1.1 This guide is designed to provide data on which a prediction can be based concerning the expected wear performance of a wide variety of textiles in end-use conditions.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3181–95 (Reapproved 2002)

Standard Guide for

Conducting Wear Tests on Textiles

This standard is issued under the fixed designation D 3181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 3514 Test Method for Resistance of Apparel Fabrics to

Pilling (Elastomeric Pad Method)

1.1 This guide is designed to provide data on which a

D 3597 Performance Specification for Woven Upholstery

prediction can be based concerning the expected wear perfor-

Fabrics—Plain, Tufted, or Flocked

mance of a wide variety of textiles in end-use conditions.

D 3884 Test Method for Abrasion Resistance of Textile

1.2 This standard does not purport to address all of the

Fabrics (Rotary Platform, Double-Head Method)

safety concerns, if any, associated with its use. It is the

D 3885 Test Method for Abrasion Resistance of Textile

responsibility of the user of this standard to establish appro-

Fabrics (Flexing and Abrasion Method)

priate safety and health practices and determine the applica-

D 3886 Test Method for Abrasion Resistance of Textile

bility of regulatory limitations prior to use.

Fabrics (Inflated Diaphragm Method)

2. Referenced Documents

D 3936 Test Method for Delamination Strength of Second-

ary Backing of Pile Floor Coverings

2.1 ASTM Standards:

D 3938 GuideforEvaluationofTextileProductsinRelation

D 123 Terminology Relating to Textiles

to Refurbishing Described on Care Labels

D 1335 Test Method for Tuft Bind of Pile Floor Coverings

D 3939 Test Method for Snagging Resistance of Fabrics

D 1683 Test Method for Failure in Sewn Seams of Woven

(Mace Test Method)

Fabrics

D 4157 Test Method for Abrasion Resistance of Textile

D 2051 Test Method for Durability of Finish of Zippers to

Fabrics (Oscillatory Cylinder Method)

Laundering

D 4158 Test Method for Abrasion Resistance of Textile

D 2052 Test Method for Colorfastness of Zippers to Dry-

Fabrics (Uniform Abrasion Method)

cleaning

D 4231 Practice for Evaluation of Men’s and Boy’s Home

D 2057 Test Method for Colorfastness of Zippers to Laun-

Launderable Woven Dress Shirts and Sport Shirts

dering

D 4390 Practice for Evaluating of the Performance of Terry

D 2058 Test Method for Durability of Finish of Zippers to

Bathroom Products for Household Use

Drycleaning

D 4720 Practice for Evaluation of the Performance of Soft

D 2062 Test Method for Operability of Zippers

Window Coverings

D 2401 Test Method for Service Change of Appearance of

D 4721 Practice for Evaluating the Performance of Woven

Pile Floor Coverings

and Knit Machine Washable and Drycleanable Bedcover-

D 2960 Test Method of Controlled Laundering Test Using

ings and Accessories

Naturally Soiled Fabrics and Household Appliances

D 4852 Practice for Evaluation of Attached Upholstery

D 3511 Test Method for Pilling Resistance and Other Re-

Fabrics

lated Surface Changes of Textile Fabrics: Brush Pilling

2.2 AATCC Standards:

Tester Method

5 Evaluation Procedure: Subjective Evaluation of Fabric

D 3512 Test Method for Pilling Resistance and Other Re-

Hand

lated Surface Changes of Textile Fabrics: Random Tumble

8 Colorfastness to Crocking: AATCC Crockmeter Method

Pilling Tester Method

88B Appearance of Seams in Wash-and-Wear Items After

Home Laundering

This guide is under the jurisdiction of ASTM Committee D13 on Textiles and

88C Appearance of Creases in Wash-and-Wear Items After

is the direct responsibility of Subcommittee D13.53 on Practices.

Home Laundering

Current edition approved Sept. 10, 2002. Published April 1995. Originally

96 Dimensional Changes in Laundering of Woven and

published as D 3181 – 73 T. Last previous edition D 3181 – 89.

Annual Book of ASTM Standards, Vol 07.01.

Discontinued; see 1992 Annual Book of ASTM Standards , Vol 07.01.

4 6

Annual Book of ASTM Standards, Vol 15.04. Annual AATCC Technical Manual, available from American Association of

Annual Book of ASTM Standards, Vol 07.02. TextileChemistsandColorists,P.O.Box12215,ResearchTrianglePark,NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3181–95 (2002)

Knitted Textiles (Excluding Wool) 3.1.9 wear-refurbishing cycle, n—for a specific wear testing

119 Color Change Due to Flat Abrasion (Frosting): Screen program, one complete series of events that may be terminated

Wire Method by laundering or dry cleaning.

120 Color Change Due to Flat Abrasion (Frosting): Emery 3.1.9.1 Discussion—A description of a wear-refurbishing

Method cycle usually includes the number of hours worn or used and

121 Carpet Soiling: Visual Rating Method the number of wearing or uses an item receives prior to

122 Carpet Soiling: Service Soiling Method refurbishing (that is, laundering or drycleaning), or both.

123 Carpet Soiling: Accelerated Soiling Method 3.1.10 wear-service condition, n—the specific conditions

124 Appearance of Fabrics After Repeated Home Launder- under which a textile is used.

ings 3.1.11 wear test, n—a test in which textiles are subjected to

128 Wrinkle Recovery of Fabrics: Appearance Method wear-service conditions and evaluated for performance.

130 Soil Release: Oily Stain Release Method 3.1.12 For definitions of other textile terms used in this

150 Dimensional Changes in Automatic Home Laundering practice, refer to Terminology D 123.

of Woven Garments

4. Summary of Guide

158 Dimensional Changes on Drycleaning in Perchloroeth-

ylene: Machine Method 4.1 Textiles are subjected to actual wear under service

163 Color Fastness: Dye Transfer in Storage: Fabric-to- conditions. This practice recommends a control textile having

Fabric a known wear performance history to be included with other

2.3 Other Documents: items being tested. Statistical methods for design of test and

Knit Upholstery Fabric Standards and Guidelines analysis of data are included that are applicable to all wear

Woven Upholstery Fabric Standards and Guidelines tests. Standard procedures for evaluation of textiles are pro-

vided.

3. Terminology

5. Significance and Use

3.1 Definitions:

5.1 This guide may be used to evaluate textiles used in

3.1.1 control textile, n—a textile having a known history,

apparel, upholstered furniture, floor coverings, window treat-

the performance of which in a specific end-use has been

ments, and bed, bath and table linens.

established previously, and which is used as a standard of

5.2 This guide may be used for several purposes:

comparison.

5.2.1 To determine the comparative performance of new or

3.1.2 end-use, n—in wear testing,theuseforwhichatextile

existing products,

is intended.

5.2.2 To determine the suitability of current products in

3.1.3 evaluation period, n—the period of time an item is

different end-uses, and

used before being evaluated on the specific performance

5.2.3 To evaluate and compare the effect of wear of con-

properties.

struction details as well as specific fabrics, fibers, dyeings,

3.1.4 grade, n—in textile testing, the symbol for any step of

finishing, fabrication techniques, etc.

a multistep standard reference scale, for a quality characteris-

5.3 This guide provides for flexibility in design and evalu-

tic.

ation since the information sought from each wear test will

3.1.4.1 Discussion—The grade is assigned to test specimen

vary (see Appendix X1).

exhibitingadegreeofthequalitycomparabletothatstepofthe

5.4 This guide may be used to compare the wear perfor-

standard. Numerical grades assigned to different specimens

mance of two or more textiles when these are included in the

from a sample, or by different observers are commonly

same test, or to compare a textile whose properties have not

averaged (AATCC).

been evaluated with one having a known performance history.

3.1.5 participant, n— in wear testing, any individual that

uses a test or control textile during a wear test.

6. Apparatus

3.1.5.1 Discussion—The term does not include additional

6.1 Viewing Board, with standard lighting, as specified in

personnel contributing other services needed to carry out a test.

AATCC 124.

3.1.6 performance property, n— in wear testing,anychemi-

6.2 Smoothness Appearance Replicas, as specified in

cal or physical property of a fiber, yarn, or fabric that is

AATCC 124.

evaluated during the wear-refurbishing cycles.

6.3 Gray Scale for Color Change, as specified in AATCC

3.1.7 rating, n—in textile testing, the process for determin-

Evaluation Procedure 1.

ing or assigning a grade to a material by comparing it to a

6.4 Soil Release Replicas, as specified inAATCC 130-1981.

standard reference scale.

6.5 Pilling Standards, as specified in Test Method D 3512.

3.1.8 wear level, n—thenumberofwear-refurbishingcycles

6.6 Seam Puckering Standards, as specified in AATCC

to which an item has been subjected.

88B-1984.

6.7 Crease Retention Standards, as specified in AATCC

88C.

Issued in 1982 by the Joint-Industry Fabric Standards Committee. Available

from the American Furniture Mfrs. Assc., P. O. Box Hp-7, High Point, NC 27261.

Re-issued in 1986 by the Joint-Industry Fabric Standards Committee.Available

from the American Furniture Mfrs. Assc., P. O. Box Hp-7, High Point, NC 27261. This is the same as ISO R105/1, Part 2.

D3181–95 (2002)

6.8 Photographic Standards for Evaluating Shirt Compo- 8.4 Selecttheperformancepropertiesthatmustbeevaluated

nents (collar, pocket, placket), as specified in Practice D 4231. to obtain the necessary information. See Table 1.

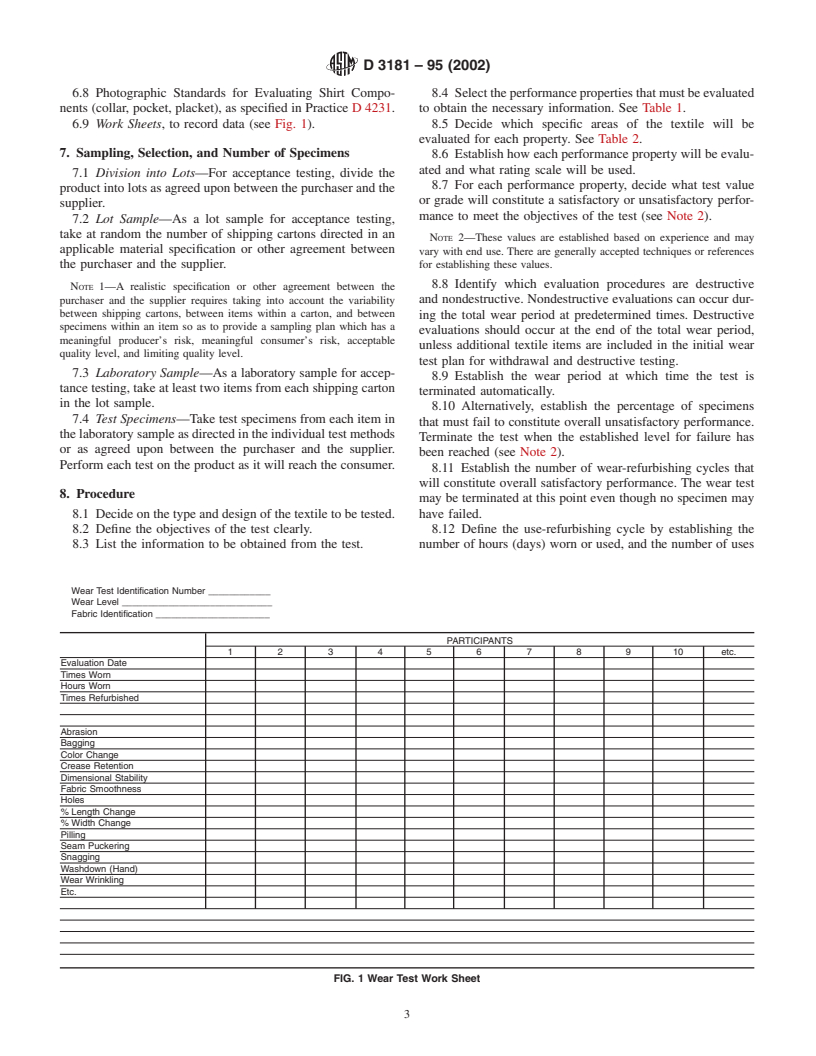

6.9 Work Sheets, to record data (see Fig. 1). 8.5 Decide which specific areas of the textile will be

evaluated for each property. See Table 2.

7. Sampling, Selection, and Number of Specimens 8.6 Establish how each performance property will be evalu-

ated and what rating scale will be used.

7.1 Division into Lots—For acceptance testing, divide the

8.7 For each performance property, decide what test value

product into lots as agreed upon between the purchaser and the

or grade will constitute a satisfactory or unsatisfactory perfor-

supplier.

mance to meet the objectives of the test (see Note 2).

7.2 Lot Sample—As a lot sample for acceptance testing,

take at random the number of shipping cartons directed in an

NOTE 2—These values are established based on experience and may

applicable material specification or other agreement between

vary with end use. There are generally accepted techniques or references

the purchaser and the supplier. for establishing these values.

8.8 Identify which evaluation procedures are destructive

NOTE 1—A realistic specification or other agreement between the

purchaser and the supplier requires taking into account the variability and nondestructive. Nondestructive evaluations can occur dur-

between shipping cartons, between items within a carton, and between

ing the total wear period at predetermined times. Destructive

specimens within an item so as to provide a sampling plan which has a

evaluations should occur at the end of the total wear period,

meaningful producer’s risk, meaningful consumer’s risk, acceptable

unless additional textile items are included in the initial wear

quality level, and limiting quality level.

test plan for withdrawal and destructive testing.

7.3 Laboratory Sample—As a laboratory sample for accep-

8.9 Establish the wear period at which time the test is

tance testing, take at least two items from each shipping carton

terminated automatically.

in the lot sample.

8.10 Alternatively, establish the percentage of specimens

7.4 Test Specimens—Take test specimens from each item in

that must fail to constitute overall unsatisfactory performance.

the laboratory sample as directed in the individual test methods

Terminate the test when the established level for failure has

or as agreed upon between the purchaser and the supplier.

been reached (see Note 2).

Perform each test on the product as it will reach the consumer.

8.11 Establish the number of wear-refurbishing cycles that

will constitute overall satisfactory performance. The wear test

8. Procedure

may be terminated at this point even though no specimen may

8.1 Decide on the type and design of the textile to be tested. have failed.

8.2 Define the objectives of the test clearly. 8.12 Define the use-refurbishing cycle by establishing the

8.3 List the information to be obtained from the test. number of hours (days) worn or used, and the number of uses

Wear Test Identification Number ____________

Wear Level _____________________________

Fabric Identification ______________________

PARTICIPANTS

12 34 56 78 9 10 etc.

Evaluation Date

Times Worn

Hours Worn

Times Refurbished

Abrasion

Bagging

Color Change

Crease Retention

Dimensional Stability

Fabric Smoothness

Holes

% Length Change

% Width Change

Pilling

Seam Puckering

Snagging

Washdown (Hand)

Wear Wrinkling

Etc.

FIG. 1 Wear Test Work Sheet

D3181–95 (2002)

TABLE 1 Properties That May Be Examined After Each Wear- TABLE 2 Examples of Areas of Potential Wear That May Be

Refurbishing Cycle or Evaluation Period Evaluated

Existing Test Methods or Garment Area

Property

Other Standards

Shirts and blouses collar, right and left

Possibilities for Apparel Evaluation cuff, right and left

Abrasion Resistance D 3884, D 3885 elbow, right and left

D 3886, D 4157 underarm, right and left

Appearance of collar D 4231

pocket, right and left

Appearance of creases AATCC 88-C front, right and left

Appearance of pocket D 4231 back

Appearance of placket D 4231 placket

Appearance of seams AATCC 88-B, Trousers and ladies slacks front pocket area and below right and left

AATCC 119 fly

Appearance of zippers D 2051, D 2052 knee, right and left

D 2057, D 2058

crotch area

Color change, frosting AATCC 119, AATCC 120 back pocket area, right and left

Color change, crocking AATCC 8

seat

Dimensional stability AATCC 96 cuffs

Fabric smoothness AATCC 124 crease

Fabric hand AATCC Eval. 5 Dresses collar or neckline

Pilling resistance D 3511, D 3512 cuff, right and left

D 3514 elbow, right and left

Snagging resistance D 3939 underarm, right and left

Wear wrinkling

bodice, front and back

Possibilities for Carpet Evaluation skirt, front and back

Abrasion resistance D 3884 pocket

Delamination of backing D 3936 hem line

Shampooing AATCC 138 pleats

Soiling AATCC 121 Floor coverings traffic path areas

AATCC 122 seamed areas

AATCC 123 Upholstery armrest

Tuft bind D 1335 head rest

Possibilities for Upholstery Fabric Evaluation

seating area

Abrasion resistance D 4157, 63-110 Joint Ind edges in cushions and frame

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.