ASTM C1494-01(2007)

(Test Method)Standard Test Methods for Determination of Mass Fraction of Carbon, Nitrogen, and Oxygen in Silicon Nitride Powder

Standard Test Methods for Determination of Mass Fraction of Carbon, Nitrogen, and Oxygen in Silicon Nitride Powder

SCOPE

1.1 These test methods cover the determination of mass fraction % of carbon, nitrogen and oxygen in silicon nitride powder having chemical compositions within the following limits:ElementMass Fraction % RangeCarbon0.05 to 5.0Nitrogen30 to 45Oxygen0.1 to 1.5

1.2 Two test methods appear in this standard.

1.2.1 Total Carbon by the Direct Combustion-Infrared Measurement Method.

1.2.2 Nitrogen and oxygen by the Inert Gas Fusion-Thermal Conductivity Measurement Method.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 6 .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1494 − 01(Reapproved 2007)

Standard Test Methods for

Determination of Mass Fraction of Carbon, Nitrogen, and

Oxygen in Silicon Nitride Powder

This standard is issued under the fixed designation C1494; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope gen in Titanium and Titanium Alloys by the Inert Gas

Fusion Technique

1.1 These test methods cover the determination of mass

E1569 Test Method for Determination of Oxygen in Tanta-

fraction % of carbon, nitrogen and oxygen in silicon nitride

lum Powder by Inert Gas Fusion Technique

powder having chemical compositions within the following

E1806 Practice for Sampling Steel and Iron for Determina-

limits:

tion of Chemical Composition

Element Mass Fraction % Range

E1941 Test Method for Determination of Carbon in Refrac-

Carbon 0.05 to 5.0 tory and Reactive Metals andTheirAlloys by Combustion

Nitrogen 30 to 45

Analysis

Oxygen 0.1 to 1.5

3. Significance and Use

1.2 Two test methods appear in this standard.

1.2.1 Total Carbon by the Direct Combustion-Infrared Mea-

3.1 Thesetestmethodsareforthechemicalanalysisofmass

surement Method.

fraction of carbon, nitrogen and oxygen in silicon nitride

1.2.2 Nitrogen and oxygen by the Inert Gas Fusion-Thermal

powder. It is assumed that all who use these test methods will

Conductivity Measurement Method.

be trained analysts, capable of performing common laboratory

proceduresskillfullyandsafely.Itisexpectedthatworkwillbe

1.3 This standard does not purport to address all of the

performed in a properly equipped laboratory.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Apparatus and Reagents

priate safety and health practices and determine the applica-

4.1 The procedure was written with commercial carbon and

bility of regulatory limitations prior to use. Specific hazard

nitrogen/oxygen analyzers in mind. For any other analyzer, the

statements are given in Section 6.

instrument manual specific to that analyzer shall be consulted

for instrument set-up.

2. Referenced Documents

4.2 Specific apparatus and reagents required for each deter-

2.1 ASTM Standards:

minationarelistedinseparatesectionsprecedingtheprocedure

E29 Practice for Using Significant Digits in Test Data to

.

Determine Conformance with Specifications

E50 Practices for Apparatus, Reagents, and Safety Consid-

5. Sampling

erations for Chemical Analysis of Metals, Ores, and

5.1 Procedures for sampling the materials refer to those

Related Materials

parts of Practice E1806 pertaining to solid form samples of the

E1019 Test Methods for Determination of Carbon, Sulfur,

type used for instrumental analysis.

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

Alloys by Various Combustion and Fusion Techniques

6. Hazards

E1409 Test Method for Determination of Oxygen and Nitro-

6.1 For hazards to be observed in the use of certain reagents

in this test method, refer to Practice E50.

These test methods are under the jurisdiction of ASTM Committee C28 on

6.2 Use care when handling hot crucibles and operating

Advanced Ceramics and are the direct responsibility of Subcommittee C28.03 on

furnaces to avoid personal injury by either burn or electrical

Physical Properties and Non-Destructive Evaluation.

shock.

Current edition approved Nov. 1, 2007. Published December 2007. Originally

approved in 2001. Last previous edition approved in 2001 as C1494 – 01. DOI:

7. Total Carbon in Silicon Nitride Powder by Direct

10.1520/C1494-01R07.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Combustion—Infrared Detection Method

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 Scope—This test method covers the determination of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. carbon in concentrations from 0.05 to 5.0 % mass fraction.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1494 − 01 (2007)

7.2 Summary of Test Method —The carbon is converted to (e) Enter blank value following routine outlined in opera-

carbon dioxide by combustion in a stream of oxygen. The tor’s instruction manual.

amount of carbon dioxide is measured by infrared (IR)

7.7 Instrument Calibration Procedure :

absorption.

7.7.1 This procedure was written specially for a carbon

7.3 Apparatus—This test method is written for use with analyzer.Thetypeandamountsofacceleratortobeaddedshall

commercial carbon analyzers, equipped to carry out the analy- be adjusted according to the manufacturers recommendations

ses operations automatically and calibrated using steel stan- for the other instrumentation.

dards with known concentrations of carbon. The operating 7.7.2 Weigh 0.1 to 0.5 g of calibration standard to the

principles, specifications and descriptions of commercial car- nearest mg into a prebaked ceramic or similar refractory

bon analyzers are given in the Practice of E1019. crucible and enter appropriate weight into weight stack.

7.7.3 Add approx. 1.0 6 0.005 g of tungsten/tin accelerator

7.4 Reagents and Materials:

and approx. 1.0 6 0.005 g of iron chips accelerator.

7.4.1 Crucibles—Expendable ceramic (alumina) or similar

7.7.4 Place crucible on pedestal and analyze.

refractory crucibles as specified by commercial carbon analyz-

7.7.5 Repeattheabovesteps

7.7.2-7.7.4aminimumofthree

ers’ manufacturers. Both the crucible and cover, if used, must

times for each standard, and calibrate the instrument following

be prebaked for a sufficient time to produce constant blank

the auto calibration procedure as outlined in the operator’s

values. Use the prebake schedule recommended by the instru-

instruction manual.

ment manufacturer.

7.7.6 Check calibration by analyzing the calibration stan-

7.4.2 Crucible Tongs—Capable of handling recommended

dard again if it is not within the reported range. If it is not,

crucibles with respect to their sizes, shape and temperature.

repeat steps 7.7.2-7.7.4.

7.4.3 Accelerators—Carbon free (or containing a known

amount of carbon) granular tungsten/tin and iron chip accel- 7.8 Sample Analysis Procedure:

erators shall be used. 7.8.1 Weigh 0.1 to 0.5 g of sample to the nearest mg into a

7.4.4 Carbon Standard Material—NIST SRM 8j prebaked expendable ceramic or a similar refractory crucible

(0.081 %C), SRM 1 lh (0.2 %C), SRM 12h (0.407 %C), and and add appropriate weight to the weight stack.

NIST RM 8983 (0.107 %C). 7.8.2 Repeat steps 7.7.3 and 7.7.4 in the calibration proce-

7.4.5 Oxygen—Ultra High Purity (99.95 % minimum pu- dure.

rity) or Regular grade (99.5 %) purified by passing over heated 7.8.3 Each sample shall be analyzed in triplicate and record

CuO and through CO /H 0 absorbents. (When the instrument the integral values of the sample.

2 2

has a built in purifier, regular grade oxygen can be used.)

7.9 Calculation—Most commercially available instruments

7.5 Preparation of Apparatus—Follow the operating in- calculate percent concentration directly. If the instrument does

structions for the specific equipment used. After having prop- not give percent concentration, please follow the manufactur-

erly set the operating controls of the instrument system, er’s directions to ensure all the essential variables in the

condition the apparatus by combustion of several blanks calculation of analysis results have been included.

prepared with sample crucible and accelerator in the amounts Or perform the following calculation to determine percent

to be used with the test specimen analyses. Successive blanks concentration (% mass):

should achieve a steady state value. a. Calibration Constant:

7.6 Blank Determination: G 3P/100

K 5 (1)

7.6.1 Prebake ceramic crucibles in a muffle or tube furnace A 2 A

c b

at 1350° C for not less than 15 min or at 1000° C for not less

where:

than 40 minutes. The crucibles shall be removed from the

K = calibration constant (g/integral value),

furnace, allowed to cool for 1-2 min and placed in a desiccator

G = mass of calibration sample (g),

for storage. If the crucibles are not used within four hours, they

P = total carbon content of the calibration sample (%

must be prebaked again. This prebaking procedure is to burn

mass),

off any organic contaminates.

A = integral value of the calibration sample (7.7.6), and

c

7.6.2 Prepare instrument as outlined in the operator’s in-

A = integral value of the blank (7.6.3e).

b

struction manual.

b. Total Carbon Content:

7.6.3 Determine the instrument blank.

A 2 A 3K 3100

(a) Enter 1.000 g weight into weight stack. ~ !

s b

C 5 (2)

(b) Add 1.000 g (6 0.005 g) of tungsten/tin accelerator and m

1.000 g (6 0.005 g) of iron chip accelerator.

where:

(c) Place crucible on furnace pedestal and analyze.

C = carbon content (mass %),

(d) Repeat steps 7.6.3a through 7.6.3c a minimum of three

A = integral value of the sample (7.8.3),

s

times.

The test method procedure was adapted from (a)ASTM E1019-94 , “Standard

Test Methods for Determination of C, S, N, and O in Iron, Nickel and Cobalt The weight of sample is chosen based on the expected amount of carbon

Alloys” and ( b) Application Bulletin: “Carbon and Sulfur in Ceramic and Similar present and so the CO produced will fall within the detection range of the IR

Materials,” LECO Corp., St. Joseph, MI. detector.

C1494 − 01 (2007)

This test method also covers the determination of oxygen (O)

A = integral value of the blank (7.6.3e),

b

in concentrations from 0.1 to 1.5 % mass fraction.

K = calibration constant (g/integral value), and

m = mass of the sample (g).

8.2 Summary of Test Method —The specimen, contained in

a small single-use graphite crucible, is fused under a flowing

7.10 Report—Report carbon concentration as mass fraction

percentage to the desired decimal places as directed in Practice helium atmosphere at a minimum temperature of 1900° C

E29, as well as times of replication of analysis and any which is sufficient to release oxygen, nitrogen and hydrogen

from the sample. The oxygen combines with carbon from the

deviations from the standard analysis procedure.

crucible to form carbon monoxide (CO) which is carried by the

7.11 Precision and Bias:

helium inert gas stream to a thermal conductivity (TC) detec-

7.11.1 Precision:

tor. Nitrogen present in the sample is released as molecular

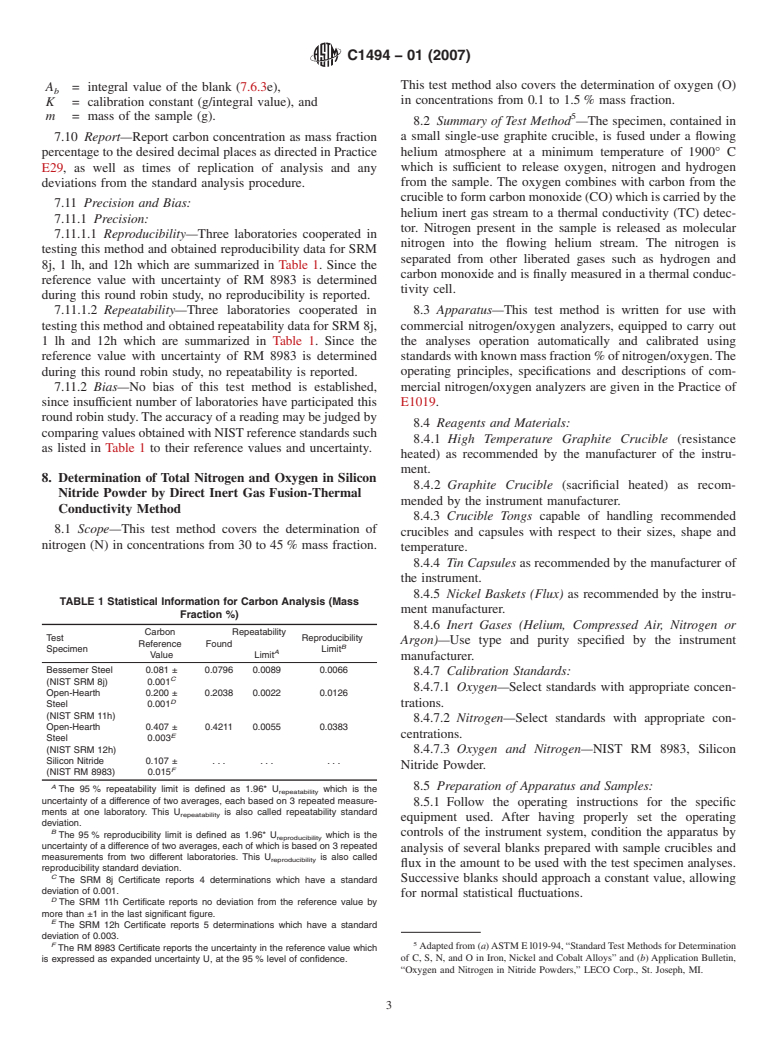

7.11.1.1 Reproducibility—Three laboratories cooperated in

nitrogen into the flowing helium stream. The nitrogen is

testing this method and obtained reproducibility data for SRM

separated from other liberated gases such as hydrogen and

8j, 1 lh, and 12h which are summarized in Table 1. Since the

carbon monoxide and is finally measured in a thermal conduc-

reference value with uncertainty of RM 8983 is determined

tivity cell.

during this round robin study, no reproducibility is reported.

7.11.1.2 Repeatability—Three laboratories cooperated in 8.3 Apparatus—This test method is written for use with

testing this method and obtained repeatability data for SRM 8j, commercial nitrogen/oxygen analyzers, equipped to carry out

1 lh and 12h which are summarized in Table 1. Since the the analyses operation automatically and calibrated using

reference value with uncertainty of RM 8983 is determined standardswithknownmassfraction%ofnitrogen/oxygen.The

operating principles, specifications and descriptions of com-

during this round robin study, no repeatability is reported.

7.11.2 Bias—No bias of this test method is established, mercial nitrogen/oxygen analyzers are given in the Practice of

E1019.

since insufficient number of laboratories have participated this

round robin study.The accuracy of a reading may be judged by

8.4 Reagents and Materials:

comparingvaluesobtainedwithNISTreferencestandardssuch

8.4.1 High Temperature Graphite Crucible (resistance

as listed in Table 1 to their reference values and uncertainty.

heated) as recommended by the manufacturer of the instru-

ment.

8. Determination of Total Nitrogen and Oxygen in Silicon

8.4.2 Graphite Crucible (sacrificial heated) as recom-

Nitride Powder by Direct Inert Gas Fusion-Thermal

mended by the instrument manufacturer.

Conductivity Method

8.4.3 Crucible Tongs capable of handling recommended

8.1 Scope—This test method covers the determination of

crucibles and capsules with respect to their sizes, shape and

nitrogen (N) in concentrations from 30 to 45 % mass fraction.

temperature.

8.4.4 Tin Capsules as recommended by the manufacturer of

the instrument.

8.4.5 Nickel Baskets (Flux) as recommended by the instru-

TABLE 1 Statistical Information for Carbon Analysis (Mass

ment manufacturer.

Fraction %)

8.4.6 Inert Gases (Helium, Compressed Air, Nitrogen or

Carbon Repeatability

Test Reproducibility

Argon)—Use type and purity specified by the instrument

Reference Found

B

Specimen Limit

A

Value Limit

manufacturer.

Bessemer Steel 0.081 ± 0.0796 0.0089 0.0066

8.4.7 Calibration Standards:

C

(NIST SRM 8j) 0.001

8.4.7.1 Oxygen—Select standards with appropriate concen-

Open-Hearth 0.200 ± 0.2038 0.0022 0.0126

D

trations.

Steel 0.001

(NIST SRM 11h)

8.4.7.2 Nitrogen—Select standards with appropriate con-

Open-Hearth 0.407 ± 0.4211 0.0055 0.0383

E centrations.

Steel 0.003

(NIST SRM 12h) 8.4.7.3 Oxygen and Nitrogen—NIST RM 8983, Silicon

Silicon Nitride 0.107 ± . . .

Nitride Powder.

F

(NIST RM 8983) 0.015

A

8.5 Preparation of Apparatus and Samples:

The 95 % repeatability limit is defined as 1.96* U which is the

repeatability

uncertainty of a difference of two averages, each based on 3 repeated measure-

8.5.1 Follow the operating instructions for the specific

ments at one laboratory. This U is also called repeatability standard

repeatability

equipment used. After having properly set the operating

deviation.

B

controls of the instrument system, condition the apparatus by

The 95 % reproducibility limit is defined as 1.96* U which is the

reproducibility

uncertainty of a difference of two averages, each of which is based on 3 repeated

analysis of several blanks prepared with sample crucibles and

measurements from two different laboratories. This U is also called

reproducibility

flux in the amount to be used with the test specimen analyses.

reproducibility standard deviation.

C

The SRM 8j Certificate reports 4 determinations which have a standard Successive blanks should approach a constant value, allowing

deviation of 0.001.

for normal statistical fluctuations.

D

The SRM 11h Certificate reports no deviation from the reference value by

mor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.