ASTM G65-04

(Test Method)Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus

Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus

SIGNIFICANCE AND USE

The severity of abrasive wear in any system will depend upon the abrasive particle size, shape, and hardness, the magnitude of the stress imposed by the particle, and the frequency of contact of the abrasive particle. In this practice these conditions are standardized to develop a uniform condition of wear which has been referred to as scratching abrasion (1 and 2). The value of the practice lies in predicting the relative ranking of various materials of construction in an abrasive environment. Since the practice does not attempt to duplicate all of the process conditions (abrasive size, shape, pressure, impact, or corrosive elements), it should not be used to predict the exact resistance of a given material in a specific environment. Its value lies in predicting the ranking of materials in a similar relative order of merit as would occur in an abrasive environment. Volume loss data obtained from test materials whose lives are unknown in a specific abrasive environment may, however, be compared with test data obtained from a material whose life is known in the same environment. The comparison will provide a general indication of the worth of the unknown materials if abrasion is the predominant factor causing deterioration of the materials.

SCOPE

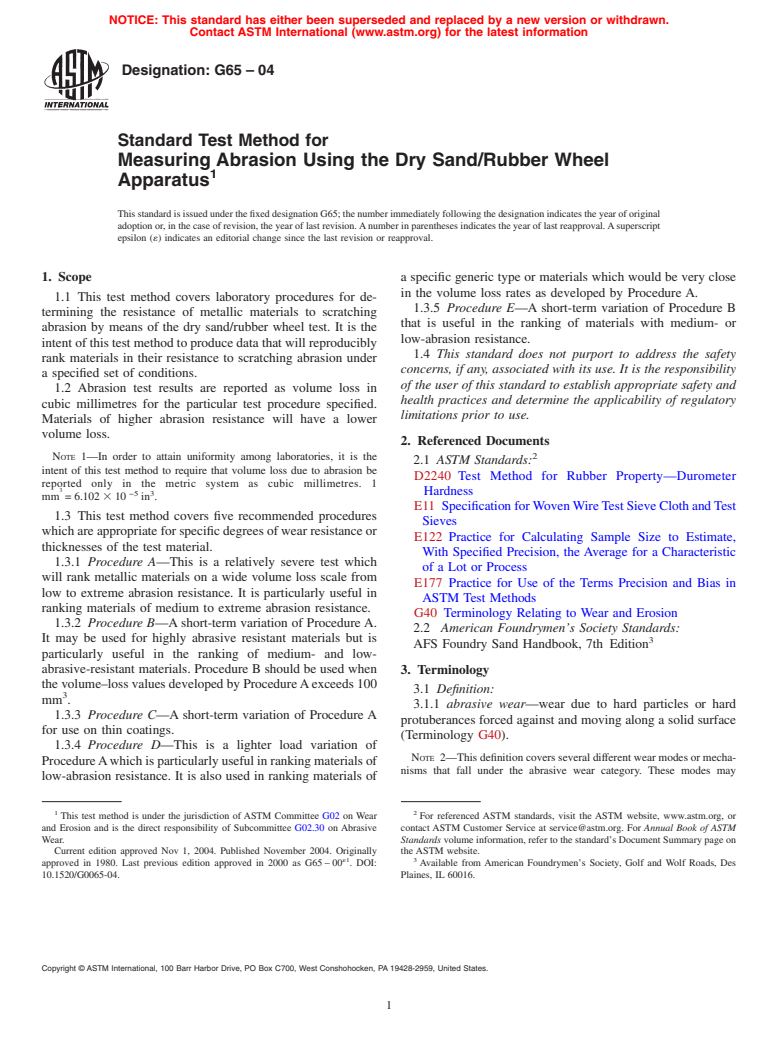

1.1 This test method covers laboratory procedures for determining the resistance of metallic materials to scratching abrasion by means of the dry sand/rubber wheel test. It is the intent of this test method to produce data that will reproducibly rank materials in their resistance to scratching abrasion under a specified set of conditions.

1.2 Abrasion test results are reported as volume loss in cubic millimetres for the particular test procedure specified. Materials of higher abrasion resistance will have a lower volume loss. Note 1In order to attain uniformity among laboratories, it is the intent of this test method to require that volume loss due to abrasion be reported only in the metric system as cubic millimetres. 1 mm3 = 6.102 10 5 in3.

1.3 This test method covers five recommended procedures which are appropriate for specific degrees of wear resistance or thicknesses of the test material.

1.3.1 Procedure AThis is a relatively severe test which will rank metallic materials on a wide volume loss scale from low to extreme abrasion resistance. It is particularly useful in ranking materials of medium to extreme abrasion resistance.

1.3.2 Procedure BA short-term variation of Procedure A. It may be used for highly abrasive resistant materials but is particularly useful in the ranking of medium- and low-abrasive-resistant materials. Procedure B should be used when the volume-loss values developed by Procedure A exceeds 100 mm3.

1.3.3 Procedure CA short-term variation of Procedure A for use on thin coatings.

1.3.4 Procedure DThis is a lighter load variation of Procedure A which is particularly useful in ranking materials of low-abrasion resistance. It is also used in ranking materials of a specific generic type or materials which would be very close in the volume loss rates as developed by Procedure A.

1.3.5 Procedure EA short-term variation of Procedure B that is useful in the ranking of materials with medium- or low-abrasion resistance.

This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G65 – 04

Standard Test Method for

Measuring Abrasion Using the Dry Sand/Rubber Wheel

1

Apparatus

ThisstandardisissuedunderthefixeddesignationG65;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope a specific generic type or materials which would be very close

in the volume loss rates as developed by Procedure A.

1.1 This test method covers laboratory procedures for de-

1.3.5 Procedure E—A short-term variation of Procedure B

termining the resistance of metallic materials to scratching

that is useful in the ranking of materials with medium- or

abrasion by means of the dry sand/rubber wheel test. It is the

low-abrasion resistance.

intentofthistestmethodtoproducedatathatwillreproducibly

1.4 This standard does not purport to address the safety

rank materials in their resistance to scratching abrasion under

concerns, if any, associated with its use. It is the responsibility

a specified set of conditions.

of the user of this standard to establish appropriate safety and

1.2 Abrasion test results are reported as volume loss in

health practices and determine the applicability of regulatory

cubic millimetres for the particular test procedure specified.

limitations prior to use.

Materials of higher abrasion resistance will have a lower

volume loss.

2. Referenced Documents

2

NOTE 1—In order to attain uniformity among laboratories, it is the

2.1 ASTM Standards:

intent of this test method to require that volume loss due to abrasion be

D2240 Test Method for Rubber Property—Durometer

reported only in the metric system as cubic millimetres. 1

3

Hardness

−5 3

mm =6.102 310 in .

E11 SpecificationforWovenWireTestSieveClothandTest

1.3 This test method covers five recommended procedures

Sieves

whichareappropriateforspecificdegreesofwearresistanceor

E122 Practice for Calculating Sample Size to Estimate,

thicknesses of the test material.

With Specified Precision, the Average for a Characteristic

1.3.1 Procedure A—This is a relatively severe test which

of a Lot or Process

will rank metallic materials on a wide volume loss scale from

E177 Practice for Use of the Terms Precision and Bias in

low to extreme abrasion resistance. It is particularly useful in

ASTM Test Methods

ranking materials of medium to extreme abrasion resistance.

G40 Terminology Relating to Wear and Erosion

1.3.2 Procedure B—Ashort-term variation of ProcedureA.

2.2 American Foundrymen’s Society Standards:

It may be used for highly abrasive resistant materials but is 3

AFS Foundry Sand Handbook, 7th Edition

particularly useful in the ranking of medium- and low-

abrasive-resistant materials. Procedure B should be used when 3. Terminology

thevolume–lossvaluesdevelopedbyProcedureAexceeds100

3.1 Definition:

3

mm .

3.1.1 abrasive wear—wear due to hard particles or hard

1.3.3 Procedure C—A short-term variation of Procedure A

protuberances forced against and moving along a solid surface

for use on thin coatings.

(Terminology G40).

1.3.4 Procedure D—This is a lighter load variation of

NOTE 2—Thisdefinitioncoversseveraldifferentwearmodesormecha-

ProcedureAwhichisparticularlyusefulinrankingmaterialsof

nisms that fall under the abrasive wear category. These modes may

low-abrasion resistance. It is also used in ranking materials of

1 2

This test method is under the jurisdiction of ASTM Committee G02 on Wear For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Erosion and is the direct responsibility of Subcommittee G02.30 on Abrasive contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Wear. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov 1, 2004. Published November 2004. Originally the ASTM website.

´1 3

approved in 1980. Last previous edition approved in 2000 as G65–00 . DOI: Available from American Foundrymen’s Society, Golf and Wolf Roads, Des

10.1520/G0065-04. Plaines, IL 60016.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

G65–04

duplicate all of the process conditions (abrasive size, shape,

pressure, impact, or corrosive elements), it should not be used

to predict the exact resistance of a given material in a specific

environment. Its value lies in predicting the ranking of mate-

rials in a similar relative order of merit as would occur in an

abrasive environment. Volume loss data obtained from test

materials whose lives are unknown in a specific abrasive

environment may, however, be compared with test data ob-

tained from a material whose life is known in t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.