ASTM F1292-99

(Specification)Standard Specification for Impact Attenuation of Surface Systems Under and Around Playground Equipment

Standard Specification for Impact Attenuation of Surface Systems Under and Around Playground Equipment

SCOPE

1.1 This specification establishes minimum impact attenuation requirements, when tested in accordance with Test Method F 355, for surface systems to be used under and around any piece of playground equipment from which a person may fall. This specification applies to all types of material that can be used under playground equipment.

1.2 This specification does not imply that an injury cannot be incurred if the surface system complies with this specification.

1.3 The values stated in inch-pound units are to be regarded as standard. The SI units given in parentheses are for information only.

1.4 The following precautionary statement pertains to the test method portions only, Sections 11 and 12, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: F 1292 – 99

Standard Specification for

Impact Attenuation of Surface Systems Under and Around

Playground Equipment

This standard is issued under the fixed designation F 1292; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The need for a systematic means of evaluating surfacing materials for use on playgrounds has been

amply demonstrated by the current difficulty in assessing the relative merits of such surfaces amid a

diversity of testing methods, agencies, and terminology. Consequently, the goal of this specification

is to establish a uniform means for measure to compare characteristics of the materials in order to

provide the potential buyer with a useful yardstick by which to measure available materials as a

surface under and around playground equipment.

1. Scope F 355 Test Method for Shock-Absorbing Properties of Play-

ing Surface Systems and Materials

1.1 This specification covers minimum impact attenuation

F 429 Test Method for Shock-Attenuation Characteristics of

requirements, when tested in accordance with Test Method

Protective Headgear for Football

F 355, for surface systems to be used under and around any

2.2 SAE Standard:

piece of playground equipment from which a person may fall.

SAE J 211 Recommended Practice for Instrumentation for

This specification applies to all types of material that can be

Impact Tests

used under playground equipment.

1.2 This specification does not imply that an injury cannot

3. Terminology

be incurred if the surface system complies with this specifica-

3.1 Definitions of Terms Specific to This Standard:

tion.

3.1.1 acceleration—the time rate of change of velocity.

1.3 The values stated in inch-pound units are to be regarded

3.1.2 around playground equipment—the area under and

as standard. The SI units given in parentheses are for informa-

surrounding playground equipment established as protection

tion only.

from falls from equipment.

1.4 The following precautionary statement pertains to the

3.1.3 deceleration—the time rate of reduction of velocity.

test method portions only, Sections 12 and 13, of this specifi-

3.1.4 g—acceleration into gravity at the earth’s surface at

cation: This standard does not purport to address all of the

sea level (32 ft/s (9.8 m/s)).

safety concerns, if any, associated with its use. It is the

3.1.5 g-max—the multiple of g that represents a maximum

responsibility of the user of this standard to establish appro-

deceleration experienced during an initial impact.

priate safety and health practices and determine the applica-

3.1.6 headform—the striking part of a testing apparatus.

bility of regulatory limitations prior to use.

3.1.7 head injury criteria (HIC)—a measure of impact

2. Referenced Documents severity that considers the duration over which the most critical

section of the deceleration pulse persists as well as the peak

2.1 ASTM Standards:

level of that deceleration.

E 691 Practice for Conducting an Interlaboratory Study to

2 3.1.8 impact attenuation—the ability of a surface system to

Determine the Precision of a Test Method

reduce and dissipate the energy of an impacting body.

3.1.9 impact velocity—the velocity of a falling body at the

time of impact.

This test method is under the jurisdiction of ASTM Committee F08 on Sports

Equipment and Facilities and is the direct responsibility of Subcommittee F08.63 on

Playground Surfacing Systems.

Current edition approved Aug. 10, 1999. Published August 1999. Originally Annual Book of ASTM Standards, Vol 15.07.

published as F 1292 – 91. Last previous edition F 1292 – 96. Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Annual Book of ASTM Standards, Vol 14.02. Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

F1292–99

3.1.10 loose fill system—a surface system consisting of ground surface system and can be used only for comparisons

small independent, movable components; that is, sand, gravel, and for establishing minimum requirements.

wood chips, and so forth.

7. Operator Qualifications

3.1.11 non-loose fill system—a surface system consisting of

one or more components bound together; that is, foam com-

7.1 If not an employee of an accredited or recognized

posites, urethane/rubber blocks, asphalt, and so forth.

laboratory, the operator shall be trained and certified by the

3.1.12 surface system—all materials that contribute to the

equipment supplier, including written and performance testing,

impact absorbing unit.

to establish competency in performing appropriate Specifica-

3.1.13 theoretical drop height—equates the measured ve-

tion F 1292 testing.

locity of the headform at the moment of impact to a height that

8. Test Apparatus

would generate the same velocity if the test were performed at

sea level and there was no friction to retard the headform

8.1 The signal from the acceleration transducer shall be

during a drop from that height.

conditioned with a low pass filter, complying to Channel Class

3.2 For the definitions of other terms used in this specifica-

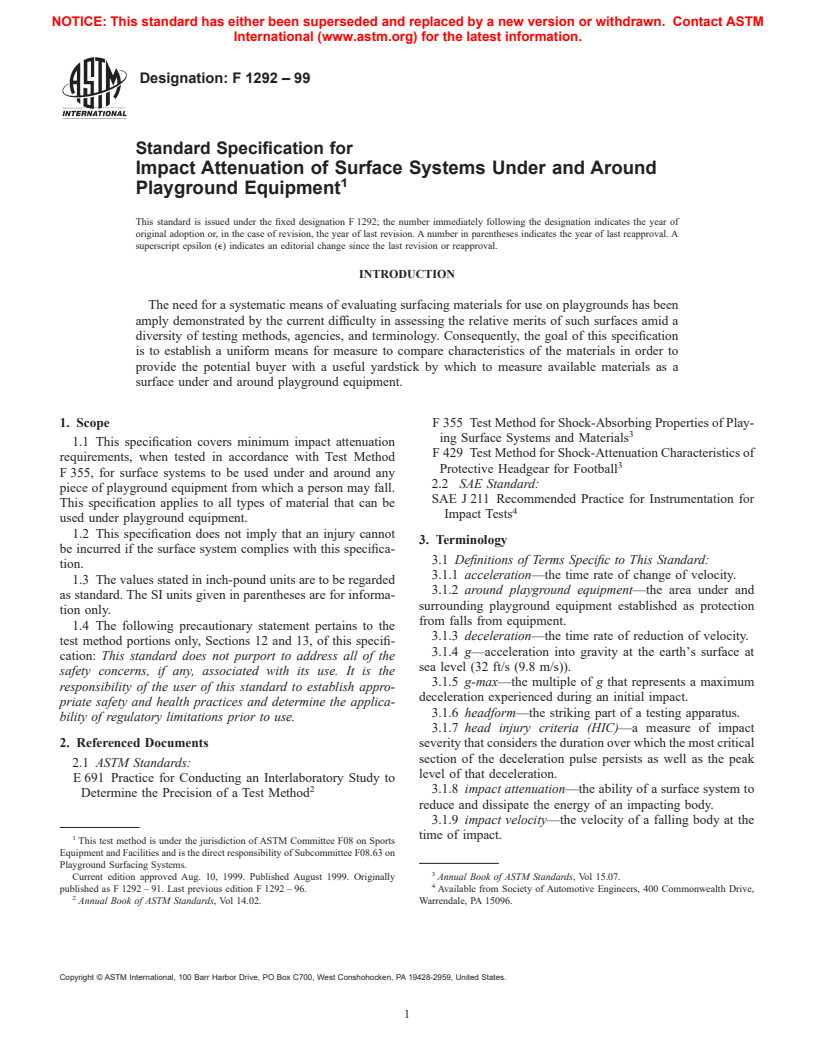

1000 of SAE J 211 (see Fig. 1).

tion, refer to Test Methods F 355 and F 429.

8.2 The acceleration recording system must be capable of

accurately resolving the deceleration to a minimum of 65 g

4. Performance Requirements

from 0 to 500 g.

4.1 All surface systems must be tested in accordance with

8.3 The acceleration transducer must be capable of with-

the performance requirements in 4.2. In addition, surfaces may

standing impacts of at least 1000 g without damage.

also be tested in accordance with 4.3. Testing in accordance

8.4 Use the ANSI metal Headform C from Test Method

with the performance requirements in 4.3 is optional.

F 355 or the hemispherical headform from the free fall test

4.2 When tested in accordance with Test Method F 355 or

method in Annex A1.

the free fall test method in Annex A1, using an average of the

8.4.1 The ANSI metal Headform C from Test Method

last two of three drops, no value shall exceed 200 g-max or

F 355, Procedure C, must be connected to guides (such as

1000 HIC for laboratory tests at temperatures of 30, 72, and

monorail, dual rail, or guide wires) using a follower or other

120°F (–1, 23, and 49°C), respectively.

mechanism. Alternatively, the hemispherical headform from

4.3 When tested in the field at ambient temperature in

the free fall test method in Annex A1 may be used if connected

accordance with Test Method F 355 or the free fall test method

to a system of guides. A uniaxial or triaxial accelerometer must

in Annex A1, using an average of the last two of three drops,

be used. The guidance system must allow the headform to be

no value shall exceed 200 g-max or 1000 HIC at the height

leveled prior to and during the drop tests in the crown position.

specified by the initial owner/operator prior to purchase of the

The vertical accelerometer must be aligned to within 5° of the

surface.

vertical axis. The accelerometer must be attached at the center

4.4 When the surface system, while in use, is tested in

of mass of the headform.

accordance with Test Method F 355 or the free fall test method

in Annex A1, using an average of the last two of three drops,

at each of three test sites, and exceeds 200 g-max or 1000 HIC

at ambient temperature, as determined by Section 13, at the

height specified by the initial owner/operator prior to the

purchase of the surface, the surface system should be made to

comply or the playground equipment on the surface should not

be used until the surface complies.

5. Summary of Test Method

5.1 Representative playground surface systems or surfacing

material samples, or both, are tested in accordance with Test

Method F 355 or the free fall test method described in Annex

A1. Conduct laboratory tests at various drop heights and test

temperatures. Conduct the field tests at the drop height speci-

fied and at the ambient temperature of the site within a

specified range. The laboratory test method will determine the

maximum drop height at which the g-max does not exceed 200

or the HIC does not exceed 1000. The field test method will

determine the g-max and the HIC from the drop height

specified by the initial owner/operator at the ambient tempera-

ture of the test.

6. Significance and Use

6.1 Data obtained from this specification are indicative of

the relative impact attenuation characteristics of the play- FIG. 1 Data Channel Dynamic Accuracy

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

F1292–99

8.4.2 The hemispherical headform from the free fall test 12.2.1 Carry forth the impact test to a maximum drop height

method in Annex A1 must be used with a triaxial accelerom- in whole foot increments, that is, 1, 2, 3 . n, that gives both a

eter. The vertical accelerometer must be aligned to within 5° of deceleration force of 200-g max and an HIC of 1000 or less. It

the vertical axis. The accelerometer must be attached at the must also be measured at intervals of 1 ft over and under this

center of mass of the headform. maximum drop height.

8.5 The minimum system sampling rate required is 16 000 12.2.2 An impact test consists of three drops at the same

Hz or 16 000 samples/s. impact site, at each height. The impact site shall be at the

8.6 The HIC shall be calculated based on the following location that exhibits the least optimal impact characteristics

mathematical expression: (as described in 9.1). Calculate the average of the second and

third drops.

2.5

t

1 2

HIC 5 ~t 2 t ! adt , 1000 (1)

F 2 1 S * D G 12.2.3 The impact test uses a different sample at all heights

~t 2 t ! t

2 1 max

at the given temperatures.

The specified algorithm and verification calculations for HIC

12.2.4 The impact test samples are to be tested at the three

are included as Appendix X2.

specific temperatures of 30, 72, and 120°F (−1, 23, and 49°C,

respectively) after the required conditioning.

9. Test Sample

12.2.5 If for any reason during the test, the headform

9.1 Each sample of surfacing material shall represent the

holding fixture interferes with the test, note it in the report and

playground surface system as it is intended to be used in place,

discontinue the test. The information recorded shall be consid-

including seams, partitions, corners, and fasteners/anchors or

ered invalid.

other areas that may result in less than optimal impact

12.2.6 When using Test Method F 355, measure and record

characteristics.

the impact velocity for each drop. It cannot vary more than

9.2 In the case of non-loose fill playground surface systems,

60.5 ft/s from the theoretical free fall velocity at the drop

the minimum sample shall be 12 by 12 in. (300 by 300 mm).

height used.

9.3 In the case of loose fill playground surface systems, a

box with a minimum inside dimension of 18 by 18 in. (450 by

13. Field Test Procedure (Test Method)

450 mm) and side walls of sufficient height to hold the loose fill

13.1 Test at least three different impact sites of each surface

material at the thickness of intended use and to keep the loose

system in use in accordance with the selected test method,

fill materials in place should be constructed around the base of

either Test Method F 355 or the free fall test method in Annex

the test equipment. The loose fill materials shall be poured to

A1 with the headform in the crown position. The selected

an even depth and the surface leveled and left undisturbed for

impact sites shall include those areas that may exhibit less than

the entire test period.

optimal impact characteristics. These areas may be high traffic

or compressed areas as well as areas containing seams,

10. Number of Specimens

partitions, corners, and fasteners/anchors.

10.1 At least nine specimens of a specific playground

13.2 Conduct impact test in accordance with the following

surface system shall be submitted for laboratory testing.

criteria:

13.2.1 Carry forth the impact tests at the drop height, as

11. Sample Conditioning

specified by the initial owner/operator.

11.1 Laboratory samples shall be preconditioned at 506

13.2.2 The impact test shall have three drops at each of the

10 % relative humidity 72 6 5°F (23 6 3°C) for a minimum

impact sites, for a total of nine impacts. Report the average of

of 24 h prior to beginning testing.

the second and the third drops for both g-max and HIC values.

11.2 Samples tested at various temperatures, 30, 72, and

13.2.3 Insert a temperature measuring device into the sur-

120°F, (−1, 23, and 49 6 1°C, respectively) shall be condi-

face system (within 6 in. (152 mm) of the impact site) at the

tioned for 4 h minimum. Testing must be started within 1 min

time of the impact test, to measure the temperature of the

of taking each sample out of the environmental chamber with

surface system, at a ⁄2-in. (12.5-mm) depth or no more than

a time interval between drops of 3 6 0.25 min. If the test

half the depth of the surface system.

intervals are not met, an additional conditioning period of 4 h

13.2.4 Measure and record the impact velocity for each

will be necessary.

drop. The impact velocity cannot vary more than 60.5 ft./sec.

from the theoretical free fall velocity at the drop height used.

12. Laboratory Procedure (Test Method)

14. Report

12.1 Test all samples of the surface system in accordance

14.1 Report the following information:

with the selected test method, Test Method F 355, or the free

14.1.1 The sample identification, including type, source,

fall test method in Annex A1, with the headform impacting in

size, and thickness.

the crown position.

14.1.2 Test procedure used and missile description, includ-

12.2 Conduct impact tests considering the following crite-

ing mass, geometry, and orientation.

ria:

14.1.3 Testing conditions, including sample temperatures

and drop heights employed.

14.1.4 Individual drop values and the average of the second

Chou, C., and Nyquist, G., “Analytical Studies of the Head Injury Criterion,”

Society of Automotive Engineers, SAE Paper No. 740082, 1974. and third drop values for both g-max and HIC values.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.