ASTM D351-97(2008)e1

(Classification)Standard Classification for Natural Muscovite Block Mica and Thins Based on Visual Quality

Standard Classification for Natural Muscovite Block Mica and Thins Based on Visual Quality

SIGNIFICANCE AND USE

The properties included in this standard are those required to control the visual quality, usable area, thickness, hardness, and stiffness.

SCOPE

1.1 This classification covers the determination of commercially available natural muscovite block mica and is intended to be independent of the basic color of the mica or its source.

1.2 Muscovite mica is characterized by having an optical axial angle between 50 and 75° (see Appendix X1); and has a weight loss when heated for 5 min at 600°C not exceeding 0.2 % (based on the weight after drying at 120°C).

1.3 The visual system of classifying the quality of natural muscovite mica covered by this specification is based upon relative amounts of visible foreign inclusions such as air bubbles, stains, and spots in combination with relative amounts and types of waviness, as well as other physical properties. In this system, a perfectly clear, transparent, flat specimen of mica is the visual standard of perfection. Increasing amounts of visual defects lower the visual quality, and a total of 13 levels of visual quality are covered by this standard. This method of classification, generally known as the Bengal India System, is purely qualitative and is entirely dependent on personal opinion and judgment.

1.4 The standards for visual quality classification that are covered in this classification are the best commercially available concept of the various qualities and their relative positions. Variations in the methods of using and applying these standards from those herein defined may be specified by the purchaser, or defined by agreement between the supplier and the purchaser.

1.5 Standard size classifications are defined, based upon available usable rectangular areas and the minimum dimensions of the rectangles that the pieces will yield. Precautions to be taken in making thickness measurements are also described.

1.6 This standard covers the following two definite forms of commercial preparation:

1.6.1 Form 1—Full-trimmed natural block mica, 0.007 in. (0.178 mm) minimum thickness.

1.6.2 Form 2—Partially-trimmed natural block mica, 0.007 in. minimum thickness.

1.7 The basic color of mica, such as white, ruby, light green, dark green, brownish green, and rum, as well as other colors, and the method of controlling the color and other problems associated with the basic color, are not a part of this classification.

1.8 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.9 Section 5 is technically identical to procedures specified in ISO 67-1981.

1.10 Section 6 differs somewhat in procedure from ISO 5972-1978, but data obtained by either should be identical.

1.11 Section 7 is technically identical to procedures specified in ISO 2185-1972.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D351 −97(Reapproved 2008)

Standard Classification for

Natural Muscovite Block Mica and Thins Based on Visual

Quality

This standard is issued under the fixed designation D351; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

ε NOTE—The units statement in subsection 1.8 was corrected editorially in July 2008.

1. Scope 1.6 This standard covers the following two definite forms of

commercial preparation:

1.1 This classification covers the determination of commer-

1.6.1 Form 1—Full-trimmed natural block mica, 0.007 in.

ciallyavailablenaturalmuscoviteblockmicaandisintendedto

(0.178 mm) minimum thickness.

be independent of the basic color of the mica or its source.

1.6.2 Form 2—Partially-trimmed natural block mica, 0.007

1.2 Muscovite mica is characterized by having an optical

in. minimum thickness.

axial angle between 50 and 75° (see Appendix X1); and has a

1.7 Thebasiccolorofmica,suchaswhite,ruby,lightgreen,

weight loss when heated for 5 min at 600°C not exceeding

dark green, brownish green, and rum, as well as other colors,

0.2 % (based on the weight after drying at 120°C).

and the method of controlling the color and other problems

1.3 The visual system of classifying the quality of natural

associated with the basic color, are not a part of this classifi-

muscovite mica covered by this specification is based upon

cation.

relative amounts of visible foreign inclusions such as air

1.8 The values stated in inch-pound units are to be regarded

bubbles,stains,andspotsincombinationwithrelativeamounts

as standard. The values given in parentheses are mathematical

and types of waviness, as well as other physical properties. In

conversions to SI units that are provided for information only

thissystem,aperfectlyclear,transparent,flatspecimenofmica

and are not considered standard.

is the visual standard of perfection. Increasing amounts of

visual defects lower the visual quality, and a total of 13 levels 1.9 Section 5 is technically identical to procedures specified

of visual quality are covered by this standard. This method of in ISO 67-1981.

classification, generally known as the Bengal India System, is

1.10 Section 6 differs somewhat in procedure from ISO

purely qualitative and is entirely dependent on personal opin-

5972-1978, but data obtained by either should be identical.

ion and judgment.

1.11 Section 7 is technically identical to procedures speci-

1.4 The standards for visual quality classification that are

fied in ISO 2185-1972.

covered in this classification are the best commercially avail-

able concept of the various qualities and their relative posi-

2. Referenced Documents

tions. Variations in the methods of using and applying these

2.1 ASTM Standards:

standards from those herein defined may be specified by the

D374 Test Methods for Thickness of Solid Electrical Insu-

purchaser, or defined by agreement between the supplier and

lation (Withdrawn 2013)

the purchaser.

D1711 Terminology Relating to Electrical Insulation

1.5 Standard size classifications are defined, based upon

2.2 ISO Publications:

available usable rectangular areas and the minimum dimen-

ISO 67-1981 Muscovite Mica Blocks, Thins, and Films—

sions of the rectangles that the pieces will yield. Precautions to

Grading by Size

be taken in making thickness measurements are also described.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This classification is under the jurisdiction of ASTM Committee D09 on Standards volume information, refer to the standard’s Document Summary page on

Electrical and Electronic Insulating Materials and is the direct responsibility of the ASTM website.

Subcommittee D09.19 on Dielectric Sheet and Roll Products. The last approved version of this historical standard is referenced on

CurrenteditionapprovedMay1,2008.PublishedJuly2008.Originallyapproved www.astm.org.

in 1932. Last previous edition approved in 2003 as D351 – 97(2003) DOI: Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D0351-97R08E01. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D351−97 (2008)

ISO 2185-1972 Muscovite Mica Blocks,Thins, and Films— cross-grainsaccordingtothequalitydesired.Asfaraspossible,

Visual Classification all marginal cracks should be removed by recutting. The

ISO 5972-1978 Mica Blocks, Thins, Films, and Splittings— average area of the pieces for Grade 4 and larger shall be not

Measurement of Thickness more than 1.54 times the average area of the largest usable

rectangles. This would constitute a minimum yield of 65 %.

3. Terminology

For Grades 5 and smaller, the average area of the pieces shall

3.1 For definitions of terms relating to mica refer to Termi- be not more than two times the average area of the largest

nology D1711, Part III. usable rectangles. This would constitute a yield of 50 %.

3.2 Definitions of Terms Specific to This Standard: 5.2 Half-Trimmed—Forhalf-trimmedmica,followthegrad-

3.2.1 “A”—a series of rulings or striations intersecting at an ingdescribedin5.1fortrimmedsideswithnocracksextending

angle of about 60°. from the trimmed sides, except for sizes 6 and 5 ⁄2 on which

only side must be trimmed free of cracks. On the untrimmed

3.2.2 blocks—mica thickness of 0.007 in. (0.178 mm) mini-

sides,nodefectsofthedesignatedqualityareacceptablewithin

mum thickness, full-trimmed, unless otherwise designated.

the minimum rectangle of the designated grade.

3.2.3 buckle—one or more large depression(s) and eleva-

5.3 Natural Block and Thins—Natural block and thins,

tion(s).

muscovite mica shall be graded for size according to the area

3.2.4 cracks—irregular fractures within the crystal that may

of the rectangle (maximum rectangle for full-trimmed, maxi-

be natural or may arise from blasting, rough handling, etc.

mum rectangle of designated quality for half-trimmed) having

3.2.5 full-trimmed mica—mica trimmed on all sides with all

at least the minimum dimension of one side for the specified

cracks, reeves, and cross-grains removed.

grade. The area within such a rectangle shall meet the

3.2.6 haircracks or hairline cracks—minute, irregular

requirements of the quality specified by the purchaser as listed

cracks that are barely noticeable until mica is split into films, in Table 1.

resulting in production of torn films.

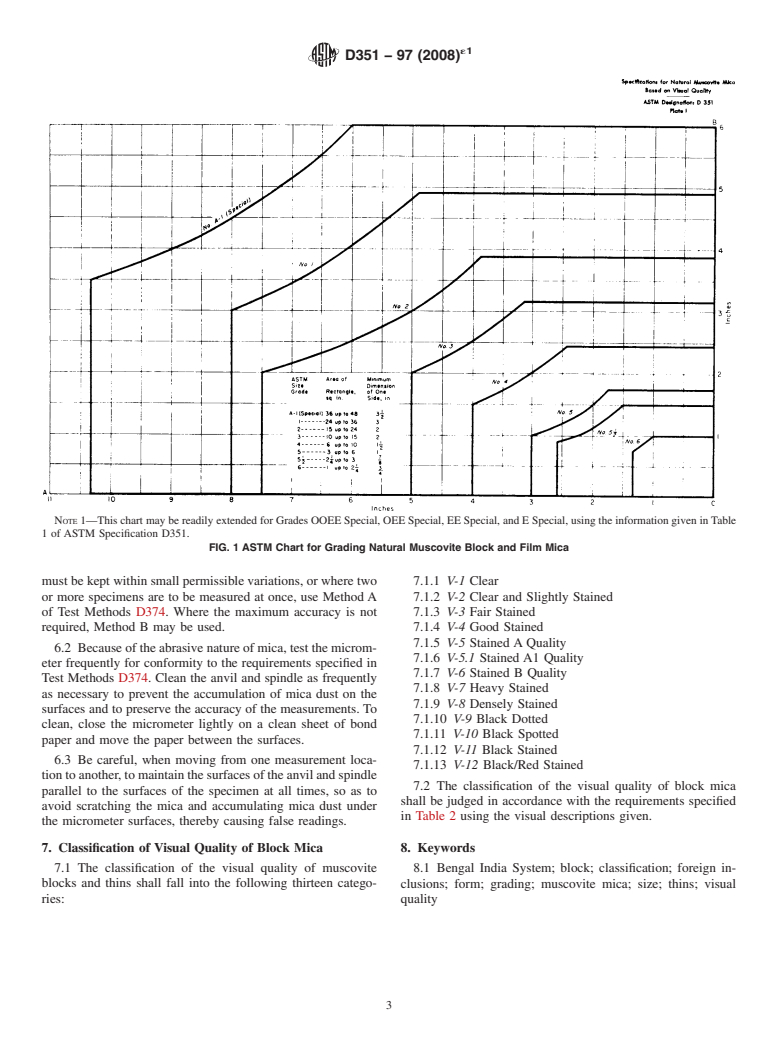

5.4 Method of Grading for Size—TheStandardASTMChart

3.2.7 reeves or cross grains—tangled laminations giving

shown in Fig. 1 shall be used for grading natural block and

imperfect cleavage, that results in tears or breaks during

thins, muscovite mica according to size. In grading natural

splitting.

block mica and thins for size, all dimensions apply to the

smaller surface measured from the foot of the bevel-trimmed

3.2.8 ribboned or rules mica—mica that breaks into narrow

edge.The specimen to be graded shall be laid upon the chart so

strips because of parallel fractures.

that it covers point O and has its maximum and minimum

3.2.9 ribs or ridges—crenulations in the form of steps.

dimensions extending along and covering lines OA and OB,

3.2.10 ripple—multiple short waves.

respectively.Thespecimenshallbeshifteduntiltheusablearea

3.2.11 stains—stains arise from foreign materials, resulting

completely covers the largest rectangle, determined by a

in a partial or total loss of transparency. They may be in the

diagonal extending from point O to or beyond a point on any

form of specks or patches of appreciable area for example,

of the curves. The number of the curve at the greatest distance

slight stain, “vegetable” stain, clay stain, black stain, red stain, from O cut by the diagonal of the rectangle designates the

blackspeckled,lightdotorspot,black,redorgreendotorspot,

grade of the specimen.

etc. (see “inclusions” in Terminology D1711).

6. Thickness of Block Mica

3.2.12 stones and stone holes—small embedded crystals or

6.1 Measure the thickness with a micrometer as specified in

holes resulting from them.

Test Methods D374. In determining thickness of mica that

3.2.13 thins—knife-dressed mica, 0.002 in. (0.05 mm) to

less than 0.007 in. (0.18 mm) in thickness. They may be

TABLE 1 ASTM Grade Sizes of Muscovite Uncut Mica Block and

classified as follows:

Thins

3.2.13.1 Thins, 0.002 to 0.004 in. (0.05 to 0.10 mm), and

Minimum

Area of

3.2.13.2 Thick-thins, 0.004 to 0.007 in. (0.10 to 0.18 mm).

Dimen-

Minimum

ASTM

sion of

3.2.14 unmanufactured mica—commercial form of mica

Rectangle

Grade

One Side

known as blocks, thins, films, and splittings, as described. Sizes

Equiva- Equiva-

in. in.

3.2.15 waves—alternate elevations and depressions that

lent, cm lent, mm

may be classified as slight, medium, or heavy. OOEE Special 100 650 4 100

OEE Special 80 520 4 100

EE Special 60 390 4 100

4. Significance and Use

E Special 48 310 4 100

4.1 The properties included in this standard are those A-1 (Special) 36 235 3 ⁄2 89

No. 1 24 155 3 76

required to control the visual quality, usable area, thickness,

No. 2 15 97 2 51

hardness, and stiffness.

No. 3 10 65 2 51

No. 4 6 40 1 ⁄2 38

5. Grading for Size

No. 5 3 20 1 25

1 1 7

No. 5 ⁄2 2 ⁄4 15 ⁄8 22

5.1 Full-Trimmed—All full-trimmed mica blocks and thins

No. 6 1 6.5 ⁄4 19

shall be fully trimmed to remove all cracks, holes, reeves, and

´1

D351−97 (2008)

NOTE 1—This chart may be readily extended for Grades OOEE Special, OEE Special, EE Special, and E Special, using the information given in Table

1 of ASTM Specification D351.

FIG. 1ASTM Chart for Grading Natural Muscovite Block and Film Mica

must be kept within small permissible variations, or where two 7.1.1 V-1 Clear

or more specimens are to be measured at once, use Method A 7.1.2 V-2 Clear and Slightly Stained

of Test Methods D374. Where the maximum accuracy is not 7.1.3 V-3 Fair Stained

required, Method B may be used. 7.1.4 V-4 Good Stained

7.1.5 V-5 Stained A Quality

6.2 Because of the abrasive nature of mica, test the microm-

7.1.6 V-5.1 Stained A1 Quality

eter frequently for conformity to the requirements specified in

7.1.7 V-6 Stained B Quality

Test Methods D374. Clean the anvil and spindle as frequently

7.1.8 V-7 Heavy Stained

as necessary to prevent the accumulation of mica dust on the

7.1.9 V-8 Densely Stained

surfaces and to preserve the accuracy of the measurements. To

7.1.10 V-9 Black Dotted

clean, close the micrometer lightly on a clean sheet of bond

7.1.11

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.