ASTM D4549-11

(Specification)Standard Classification System and Basis for Specification for Polystyrene and Rubber-Modified Polystyrene Molding and Extrusion Materials (PS)

Standard Classification System and Basis for Specification for Polystyrene and Rubber-Modified Polystyrene Molding and Extrusion Materials (PS)

ABSTRACT

This specification, which covers polystyrene materials, both crystal and rubber modified suitable for molding and extrusion, is intended to be a means of calling out plastic materials used in the fabrication of end items or parts. Polystyrene materials are classified according to classes after being grouped as crystal, rubber modified, and others. The materials are further classified according to grades after being grouped as general-purpose, other medium impact, high impact, super-high-impact, and others. The materials shall conform to the prescribed injection molded properties and natural colors.

SCOPE

1.1 This classification system covers polystyrene materials, both crystal and rubber modified, suitable for molding and extrusion.

1.2 This classification system and subsequent line callout (specification) are intended to be a means of calling out plastic materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection can be made by those having expertise in the plastics field after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the fabrication process to be employed, the inherent properties of the material other than those covered by this specification, and the economics.

1.3 The properties included in this specification are those required to identify the compositions covered. Other requirements necessary to identify particular characteristics important to specialized applications are to be specified using the suffixes as given in Section 5.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Note 1—This standard combines elements from ISO 1622-1-2 and ISO 2897-1-2, but is not equivalent to either ISO standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4549 −11

StandardClassification System and Basis for Specification for

Polystyrene and Rubber-Modified Polystyrene Molding and

1

Extrusion Materials (PS)

This standard is issued under the fixed designation D4549; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

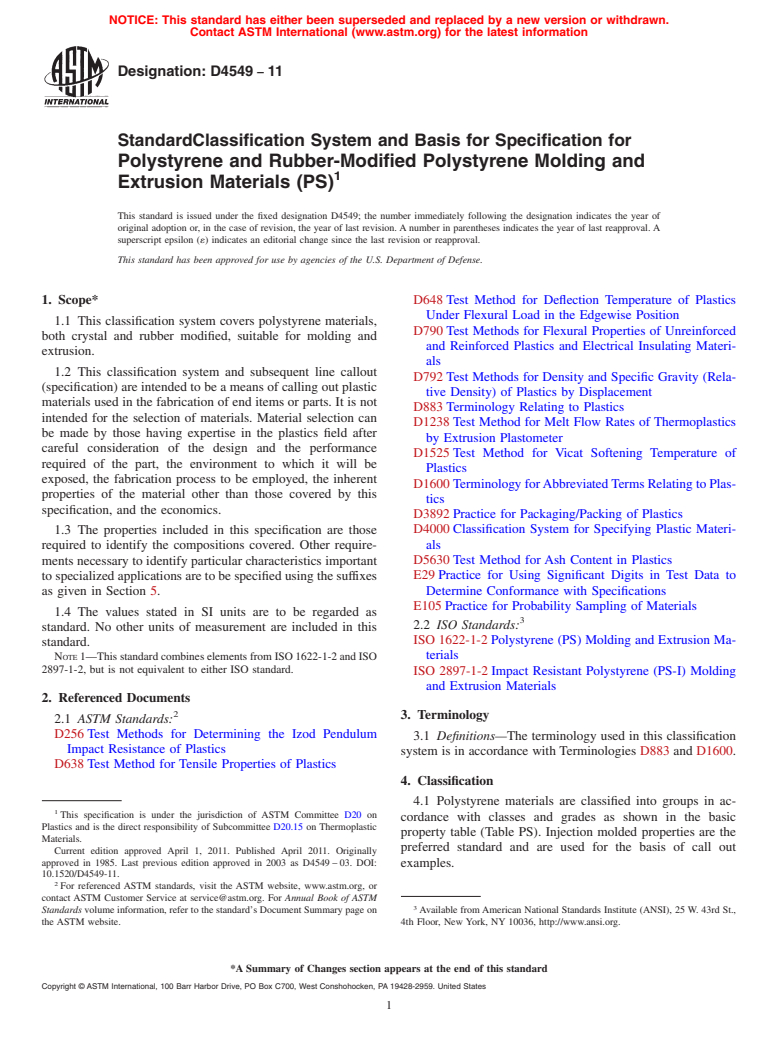

1. Scope* D648 Test Method for Deflection Temperature of Plastics

Under Flexural Load in the Edgewise Position

1.1 This classification system covers polystyrene materials,

D790 Test Methods for Flexural Properties of Unreinforced

both crystal and rubber modified, suitable for molding and

and Reinforced Plastics and Electrical Insulating Materi-

extrusion.

als

1.2 This classification system and subsequent line callout

D792 Test Methods for Density and Specific Gravity (Rela-

(specification) are intended to be a means of calling out plastic

tive Density) of Plastics by Displacement

materials used in the fabrication of end items or parts. It is not

D883 Terminology Relating to Plastics

intended for the selection of materials. Material selection can

D1238 Test Method for Melt Flow Rates of Thermoplastics

be made by those having expertise in the plastics field after

by Extrusion Plastometer

careful consideration of the design and the performance

D1525 Test Method for Vicat Softening Temperature of

required of the part, the environment to which it will be

Plastics

exposed, the fabrication process to be employed, the inherent

D1600 Terminology forAbbreviatedTerms Relating to Plas-

properties of the material other than those covered by this

tics

specification, and the economics.

D3892 Practice for Packaging/Packing of Plastics

D4000 Classification System for Specifying Plastic Materi-

1.3 The properties included in this specification are those

required to identify the compositions covered. Other require- als

D5630 Test Method for Ash Content in Plastics

ments necessary to identify particular characteristics important

to specialized applications are to be specified using the suffixes E29 Practice for Using Significant Digits in Test Data to

5. Determine Conformance with Specifications

as given in Section

E105 Practice for Probability Sampling of Materials

1.4 The values stated in SI units are to be regarded as

3

2.2 ISO Standards:

standard. No other units of measurement are included in this

ISO 1622-1-2 Polystyrene (PS) Molding and Extrusion Ma-

standard.

NOTE 1—This standard combines elements from ISO 1622-1-2 and ISO terials

2897-1-2, but is not equivalent to either ISO standard.

ISO 2897-1-2 Impact Resistant Polystyrene (PS-I) Molding

and Extrusion Materials

2. Referenced Documents

2

3. Terminology

2.1 ASTM Standards:

D256 Test Methods for Determining the Izod Pendulum

3.1 Definitions—The terminology used in this classification

Impact Resistance of Plastics

system is in accordance with Terminologies D883 and D1600.

D638 Test Method for Tensile Properties of Plastics

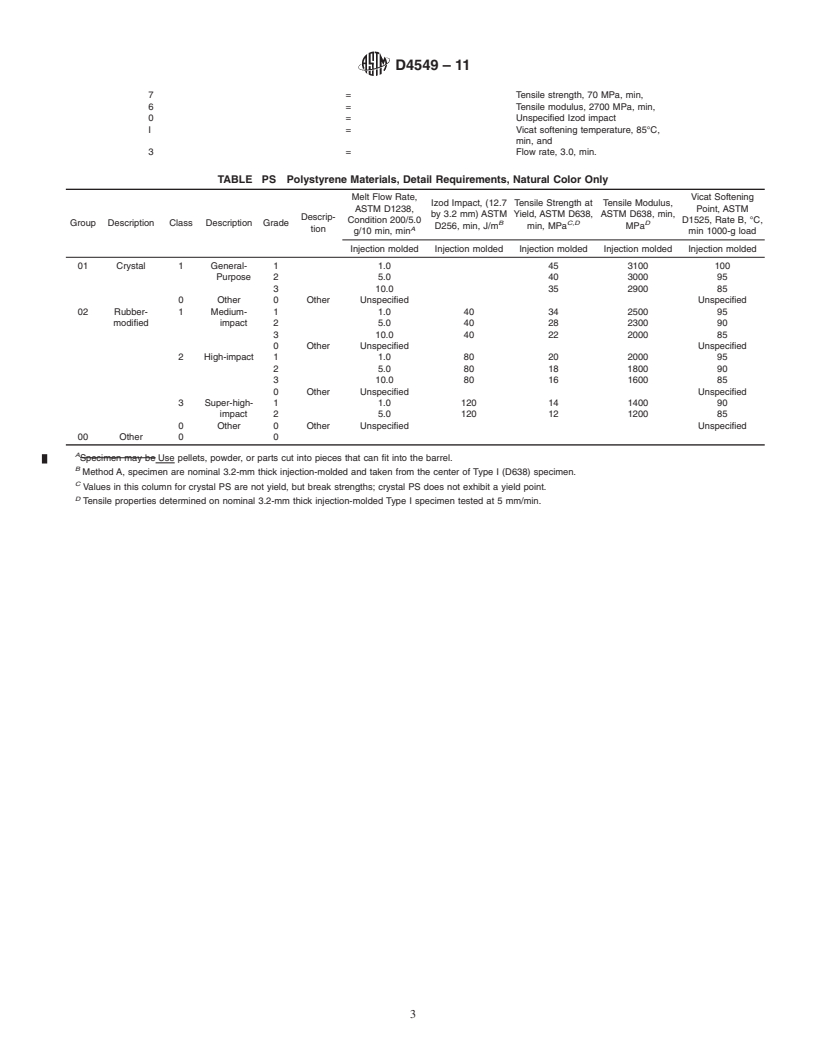

4. Classification

4.1 Polystyrene materials are classified into groups in ac-

1

This specification is under the jurisdiction of ASTM Committee D20 on

cordance with classes and grades as shown in the basic

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

property table (Table PS). Injection molded properties are the

Materials.

preferred standard and are used for the basis of call out

Current edition approved April 1, 2011. Published April 2011. Originally

approved in 1985. Last previous edition approved in 2003 as D4549 – 03. DOI:

examples.

10.1520/D4549-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

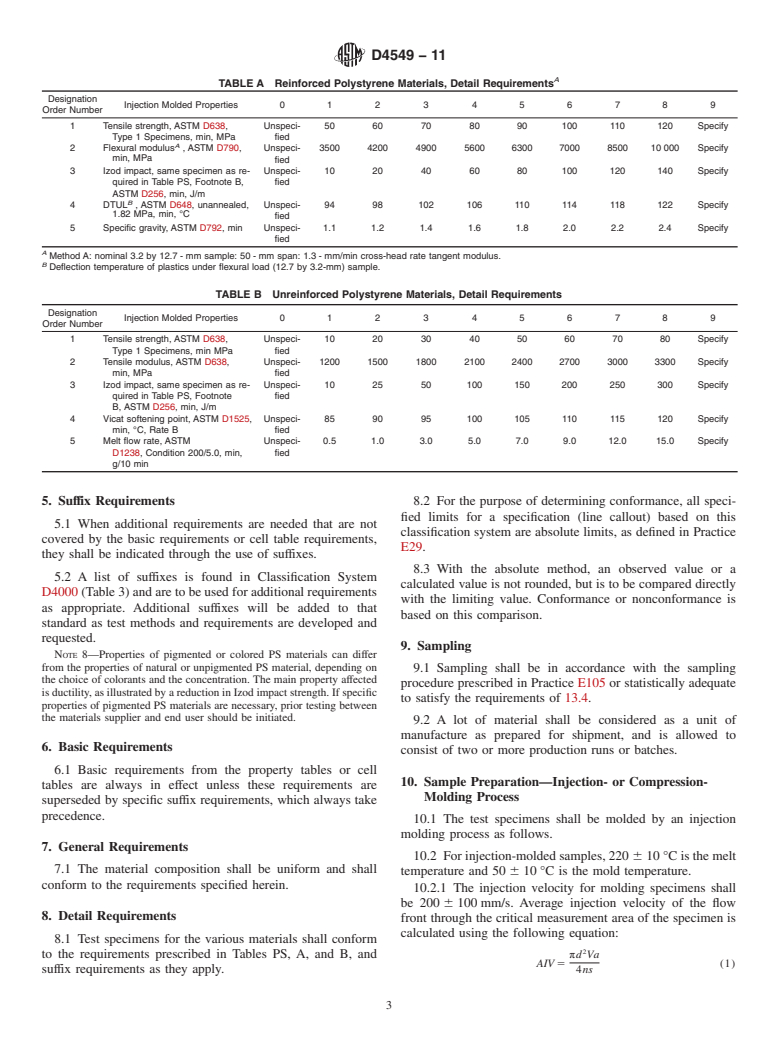

D4549−11

NOTE 2—Since compression molded properties have been removed Test Method D5630 where applicable.

from the standard with this publication, refer to previous publications of

4.2.2 Table A, Detail Requirements—An identifying number

this standard, if interested in these properties.

is made up of the letter A and five digits comprising the cell

NOTE 3—An example of this classification system for PS0111 is as

follow

...

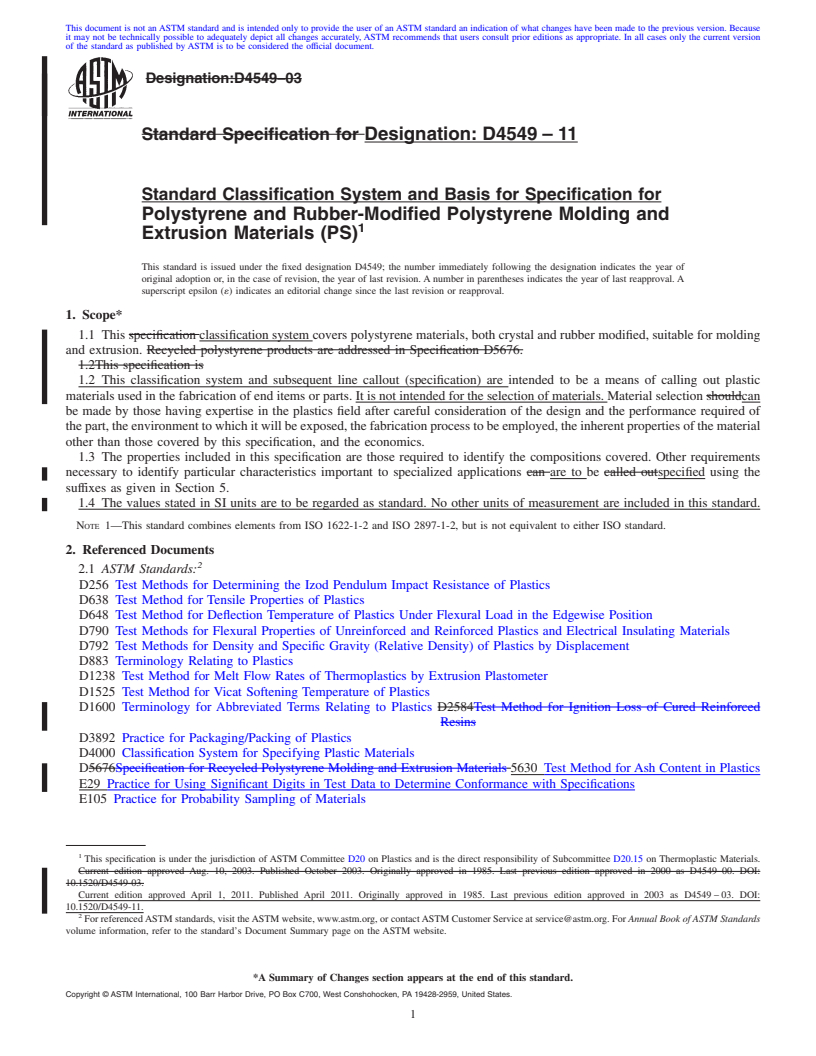

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4549–03

Standard Specification for Designation: D4549 – 11

Standard Classification System and Basis for Specification for

Polystyrene and Rubber-Modified Polystyrene Molding and

1

Extrusion Materials (PS)

This standard is issued under the fixed designation D4549; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification classification system covers polystyrene materials, both crystal and rubber modified, suitable for molding

and extrusion. Recycled polystyrene products are addressed in Specification D5676.

1.2This specification is

1.2 This classification system and subsequent line callout (specification) are intended to be a means of calling out plastic

materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection shouldcan

be made by those having expertise in the plastics field after careful consideration of the design and the performance required of

thepart,theenvironmenttowhichitwillbeexposed,thefabricationprocesstobeemployed,theinherentpropertiesofthematerial

other than those covered by this specification, and the economics.

1.3 The properties included in this specification are those required to identify the compositions covered. Other requirements

necessary to identify particular characteristics important to specialized applications can are to be called outspecified using the

suffixes as given in Section 5.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

NOTE 1—This standard combines elements from ISO 1622-1-2 and ISO 2897-1-2, but is not equivalent to either ISO standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D256 Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

D638 Test Method for Tensile Properties of Plastics

D648 Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D883 Terminology Relating to Plastics

D1238 Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

D1525 Test Method for Vicat Softening Temperature of Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics D2584Test Method for Ignition Loss of Cured Reinforced

Resins

D3892 Practice for Packaging/Packing of Plastics

D4000 Classification System for Specifying Plastic Materials

D5676Specification for Recycled Polystyrene Molding and Extrusion Materials 5630 Test Method forAsh Content in Plastics

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E105 Practice for Probability Sampling of Materials

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved Aug. 10, 2003. Published October 2003. Originally approved in 1985. Last previous edition approved in 2000 as D4549–00. DOI:

10.1520/D4549-03.

Current edition approved April 1, 2011. Published April 2011. Originally approved in 1985. Last previous edition approved in 2003 as D4549 – 03. DOI:

10.1520/D4549-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4549 – 11

3

2.2 ISO Standards:

ISO 1622-1-2 Polystyrene (PS) Molding and Extrusion Materials

ISO 2897-1-2 Impact Resistant Polystyrene (PS-I) Molding and Extrusion Materials

3. Terminology

3.1Definitions—For definitions of technical terms pertaining to plastics used in this specification, see Terminology

3.1 Definitions—The terminology used in this classification system is in accordance with Terminologies D883 and D1600.

4. Classification

4.1 Polystyrene materials are classi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.