ASTM D6158-05

(Specification)Standard Specification for Mineral Hydraulic Oils

Standard Specification for Mineral Hydraulic Oils

ABSTRACT

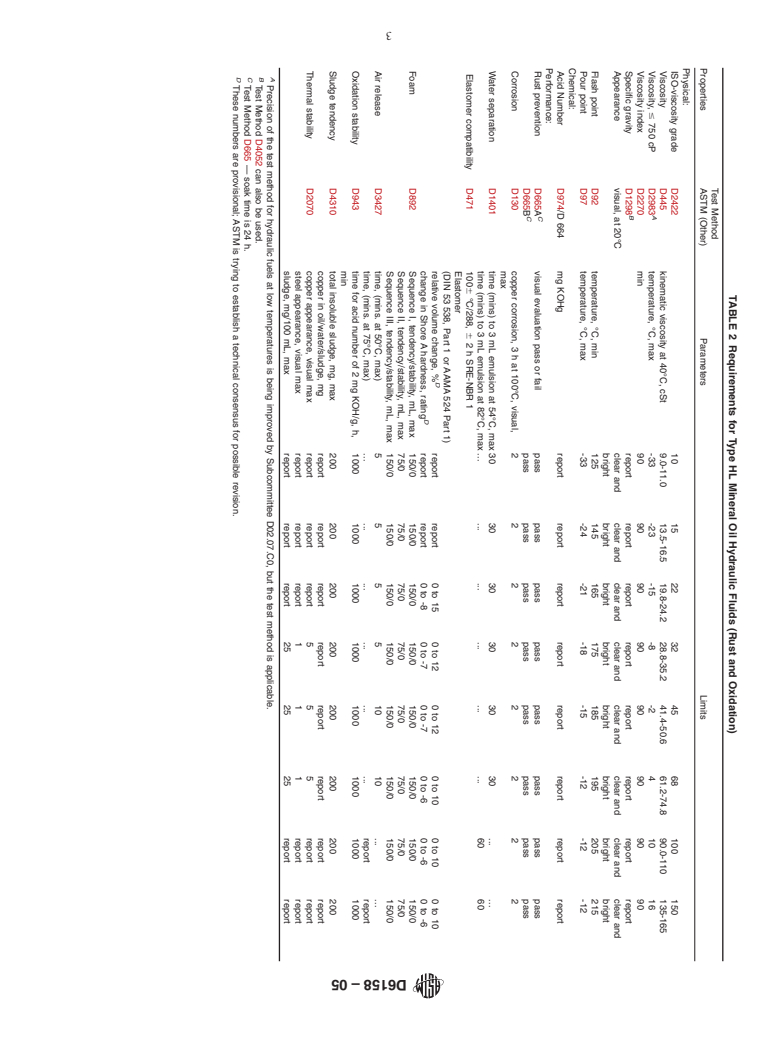

This specification covers the standard for mineral oils used in hydraulic systems which require refined base oil (Class HH), refined mineral base oil with rust and oxidation inhibitors (Class HL) or refined mineral base oil with rust and oxidation inhibitors plus antiwear characteristics (Class HM). This specification only covers lubricating oils before they are installed in the hydraulic system and does not include all hydraulic oils. Requirements for the mineral oils shall include, but not limited to, viscosity, specific gravity, appearance, flash point, chemical acid number, corrosion, water separation, elastomer compatibility, air release, and thermal stability.

SCOPE

1.1 This specification covers mineral oils used in hydraulic systems, where the performance requirements demand fluids with one of the following characteristics:

1.1.1 A refined base oil (Class HH),

1.1.2 A refined mineral base oil with rust and oxidation inhibitors (Class HL), and

1.1.3 A refined mineral base oil with rust and oxidation inhibitors plus antiwear characteristics (Class HM).

1.2 This specification defines the requirements of mineral oil-based hydraulic fluids that are compatible with most existing machinery components when there is adequate maintenance.

1.3 This specification defines only new lubricating oils before they are installed in the hydraulic system.

1.4 This specification defines specific types of hydraulic oils. It does not include all hydraulic oils. Some oils that are not included may be satisfactory for certain hydraulic applications. Certain equipment or conditions of use may permit or require a wider or narrower range of characteristics than those described herein.

The following safety hazard caveat pertains to the test methods referenced in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitation prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6158 – 05

Standard Specification for

1

Mineral Hydraulic Oils

This standard is issued under the fixed designation D6158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D97 Test Method for Pour Point of Petroleum Products

D130 Test Method for Corrosiveness to Copper from Pe-

1.1 This specification covers mineral oils used in hydraulic

troleum Products by Copper Strip Test

systems, where the performance requirements demand fluids

D445 Test Method for Kinematic Viscosity of Transparent

with one of the following characteristics:

and Opaque Liquids (and Calculation of Dynamic Viscos-

1.1.1 A refined base oil (Class HH),

ity)

1.1.2 A refined mineral base oil with rust and oxidation

D471 Test Method for Rubber Property—Effect of Liquids

inhibitors (Class HL), and

D664 Test Method forAcid Number of Petroleum Products

1.1.3 A refined mineral base oil with rust and oxidation

by Potentiometric Titration

inhibitors plus antiwear characteristics (Class HM).

D665 Test Method for Rust-Preventing Characteristics of

1.2 This specification defines the requirements of mineral

Inhibited Mineral Oil in the Presence of Water

oil-based hydraulic fluids that are compatible with most

D892 Test Method for Foaming Characteristics of Lubricat-

existing machinery components when there is adequate main-

ing Oils

tenance.

D943 Test Method for Oxidation Characteristics of Inhib-

1.3 This specification defines only new lubricating oils

ited Mineral Oils

before they are installed in the hydraulic system.

D974 Test Method for Acid and Base Number by Color-

1.4 This specification defines specific types of hydraulic

Indicator Titration

oils.Itdoesnotincludeallhydraulicoils.Someoilsthatarenot

D1298 Test Method for Density, Relative Density (Specific

included may be satisfactory for certain hydraulic applications.

Gravity), or API Gravity of Crude Petroleum and Liquid

Certain equipment or conditions of use may permit or require

Petroleum Products by Hydrometer Method

a wider or narrower range of characteristics than those de-

D1401 Test Method for Water Separability of Petroleum

scribed herein.

Oils and Synthetic Fluids

1.5 The following safety hazard caveat pertains to the test

D2070 Test Method forThermal Stability of Hydraulic Oils

methods referenced in this specification. This standard does

D2270 Practice for Calculating Viscosity Index from Kine-

not purport to address all of the safety concerns, if any,

matic Viscosity at 40 and 100°C

associated with its use. It is the responsibility of the user of this

D2422 Classification of Industrial Fluid Lubricants by Vis-

standard to establish appropriate safety and health practices

cosity System

and determine the applicability of regulatory limitation prior

D2619 Test Method for Hydrolytic Stability of Hydraulic

to use.

Fluids (Beverage Bottle Method)

2. Referenced Documents

D2983 Test Method for Low-Temperature Viscosity of

2

Lubricants Measured by Brookfield Viscometer

2.1 ASTM Standards:

D3427 TestMethodforAirReleasePropertiesofPetroleum

D92 Test Method for Flash and Fire Points by Cleveland

Oils

Open Cup Tester

D4052 Test Method for Density and Relative Density of

Liquids by Digital Density Meter

1

This specification is under the jurisdiction of ASTM Committee D02 on

D4310 Test Method for Determination of Sludging and

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

Corrosion Tendencies of Inhibited Mineral Oils

D02.N0 on Hydraulic Fluids.

D6080 PracticeforDefiningtheViscosityCharacteristicsof

CurrenteditionapprovedJune1,2005.PublishedJuly2005.Originallyapproved

in 1997. Last previous edition approved in 1999 as D6158–99. DOI: 10.1520/

Hydraulic Fluids

D6158-05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6158 – 05

D7043 Test Method for Indicating Wear Characteristics of 4. Classification Requirements

Non-Petroleum and Petroleum Hydraulic Fluids in a Con-

4.1 Type HH—The requirements for this type of oil are

stant Volume Vane Pump

presented in Table 1 and include Viscosity Grades ISO VG

from 10 to 150, in accordance with Classification D2422.

3. Classification

4.2 Type HL—The requirements for this type of oil ar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.