ASTM F1864-98

(Test Method)Standard Test Method for Dust Erosion Resistance of Optical and Infrared Transparent Materials and Coatings

Standard Test Method for Dust Erosion Resistance of Optical and Infrared Transparent Materials and Coatings

SCOPE

1.1 This test method covers the resistance of transparent plastics and coatings used in aerospace windscreens, canopies, and viewports to surface erosion as a result of dust impingement. This test method simulates flight through a defined particle cloud environment via independent control of particle size, velocity, impact angle, mass loading, and test duration.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1864 – 98

Standard Test Method for

Dust Erosion Resistance of Optical and Infrared Transparent

Materials and Coatings

This standard is issued under the fixed designation F 1864; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 sweep time, n—the time required for one translation

pass.

1.1 This test method covers the resistance of transparent

3.1.4 translation pass, n—the translation of the specimen

plastics and coatings used in aerospace windscreens, canopies,

platformfromtheverticalorhorizontallimittothecorrespond-

and viewports to surface erosion as a result of dust impinge-

ing vertical or horizontal limit.

ment. This test method simulates flight through a defined

3.1.5 translation cycle, n—the translation of the specimen

particle cloud environment via independent control of particle

platformfromtheverticalorhorizontallimittothecorrespond-

size, velocity, impact angle, mass loading, and test duration.

ing vertical or horizontal limit and back to the initial vertical or

1.2 This standard does not purport to address all of the

horizontal limit. Two translation passes are equivalent to one

safety concerns, if any, associated with its use. It is the

translation cycle.

responsibility of the user of this standard to establish appro-

3.2 Symbols:

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

A 5 reference surface area of specimen platform (cm ),

s

2. Referenced Documents

C 5 simulated cloud concentration (g/m ),

c

2.1 ASTM Standards:

h 5 percent haze before exposure,

o

D 618 Practice for Conditioning Plastics and Electrical

h 5 percent haze after exposure,

e

Insulating Materials for Testing

m˙ 5 rate of particle mass impacting the reference surface

p

D 1003 Test Method for Haze and Luminous Transmittance

area (g/min),

of Transparent Plastics

m˙ 5 incremental mass loading (g/cm ),

i

3 2

D 1193 Specification for Reagent Water

m 5 total mass loading (g/cm ),

T

N 5 number of increments,

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

V 5 particle impact velocity (m/s),

poses

p

t 5 sweep time(s),

E 168 Practices for General Techniques of Infrared Quanti- s

T 5 optical or mean infrared (IR) transmission after

tative Analysis e

exposure (%),

3. Terminology T 5 opticalormeanIRtransmissionbeforeexposure(%),

o

a5 impact angle (normal incidence 5 90°),

3.1 Definitions of Terms Specific to This Standard:

Dt 5 exposure time (min) for loading increment i,

i

3.1.1 mass loading, n—the mass of dust per unit of total

f 5 incremental dust load (g/cm ) for loading increment

i

exposed surface area (including the sample holder) that im-

i,

pinges on the specimens.

F5 total dust load (g/cm ),

3.1.2 mean IR transmission, n—for the purposes of this

Dh 5 change in percent haze, and

standard, the average percentage of light transmitted by a

DT 5 change in optical or IR transmission.

material in the 8- to 12-µm bandwidth.

4. Summary of Test Method

4.1 This test method consists of: (1) measuring and record-

This test method is under the jurisdiction of ASTM Committee F-7 on

ing the light transmission properties, at visual or infrared

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on

Transparent Materials and Enclosures.

wavelengths, of test coupons; (2) mounting the coupons in a

Current edition approved April 10, 1998. Published July 1998.

test fixture; (3) exposing the coupons to a dust particle stream;

Annual Book of ASTM Standards, Vol 08.01.

3 and (4) remeasuring the light transmission properties to deter-

Annual Book of ASTM Standards, Vol 09.01.

mine changes in these properties.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1864

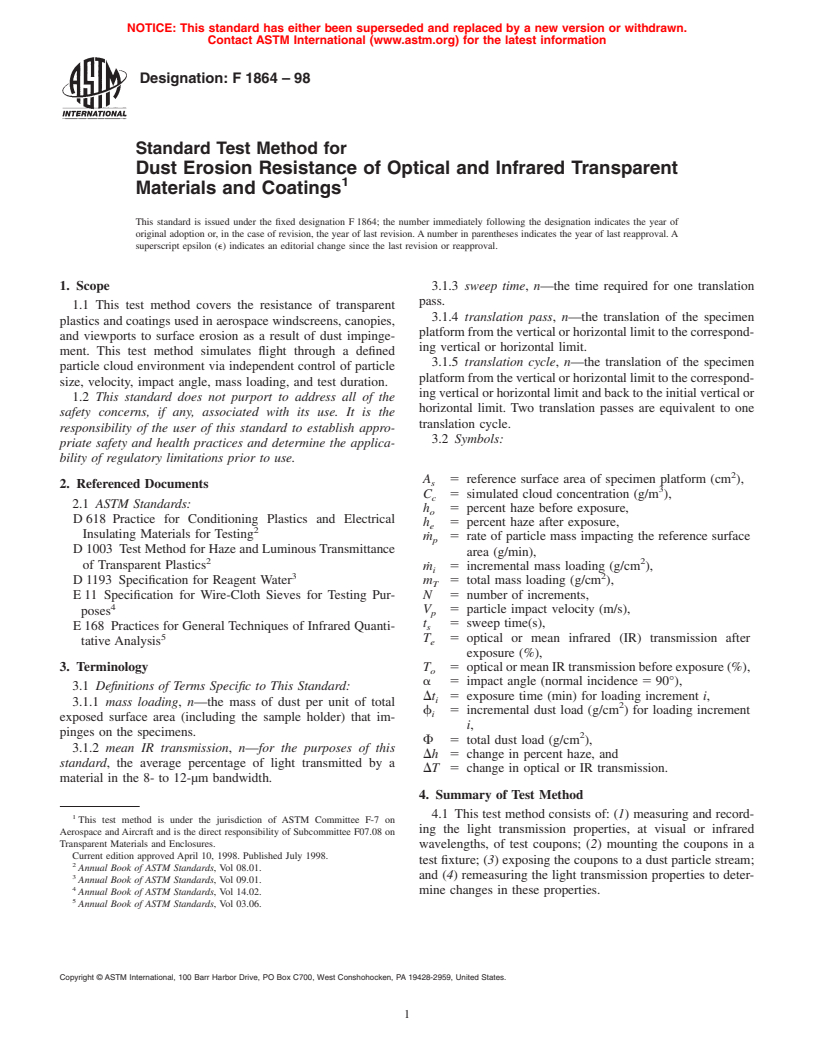

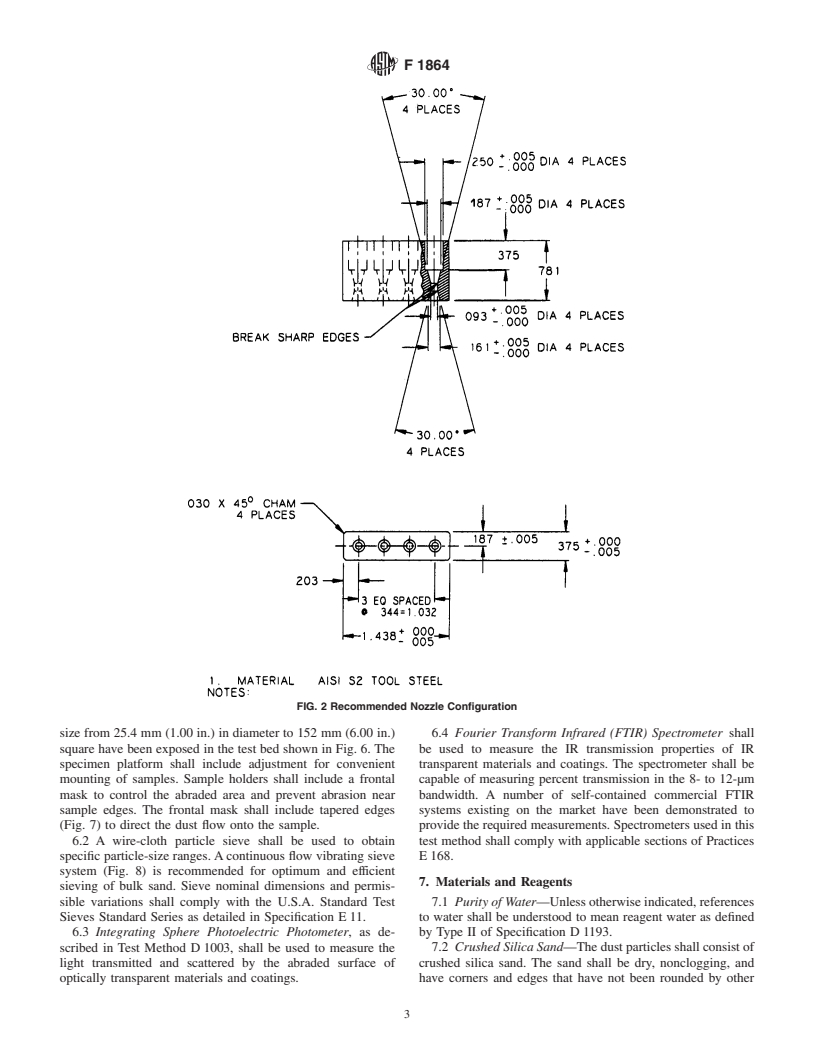

4.2 The dust particle stream simulates flight at a specified subsystems: transport gas system, dust particle delivery sys-

velocitythroughadustcloudofspecifieddensity.Simulationis tem, dust velocity calibration system, and specimen platform.

accomplished through control of particle size distribution,

6.1.1 The transport gas system carries the dust particles at

mean particle velocity, particle mass flow rate, and angle of

specified velocity. The transport gas for the particles may be

impact.

dry air or nitrogen. The transport gas shall be controlled by a

4.3 The degree of abrasion is measured by the amount of

system of precision regulators and pressure transducers and

change in haze and luminous transmittance for materials

routed through a nozzle which produces stable flow for the

transparent in the visual wavelengths and by the amount of

particle sizes and velocities of interest. Dust particles are

change in IR spectral transmission for materials transparent in

accelerated to target velocities in a circular jet formed by the

the infrared wavelengths.

expansion of compressed gas in the nozzle. The nozzles

conforming to Fig. 2 have been shown to produce stable flow

5. Significance and Use

for inlet pressures in the range 5.50 to 620 kPa (0.800 to 90.0

5.1 All materials on exterior aircraft surfaces are subject to psi). The nozzle consists of converging-diverging sections,

abrasion from airborne particles of various sizes and shapes. which accelerate the gas phase to supersonic speeds, and a

Transparent materials are particularly vulnerable to abrasion, constant diameter extension which provides sufficient resident

since their performance is based on their ability to transmit time for particle acceleration. Fig. 3 shows typical stable

light with a minimal amount of scatter. Scratches, pitting, and velocities that can be achieved using the nozzle in Fig. 2. The

coating removal and delamination as a result of abrasion may nozzle mount shall include adjustments for convenient access

increase scatter, reduce transmission, and degrade the perfor-

to the specimen platform during mounting of the specimen

mance of transparent materials. Visually transparent materials holder and for positioning the nozzle a distance of 25.4 mm

arerequiredforpilotandaircrewenclosures,suchascanopies,

(1.00 in.) from the specimen after mounting.

windshields, and viewpoints. Materials transparent in the IR

6.1.2 The dust particle delivery system directs particles into

region (8 to 12 µm) are required for tracking, targeting, and

the transport gas stream. The delivery system shall deliver

navigational instrumentation.

uniform and consistent mass flow over the range of 0.200 to

5.2 This test method is intended to provide a calibrated and

10.0 g/min. The system consists of a pressurized holding

repeatable means of determining the relative abrasion resis-

container for the dust and a mechanism for directing the dust

tance of materials and coatings for optical and IR transparent

into the transport gas stream.Ascrew feeder system housed in

materials and coatings.The test parameters for this test method

apressurizedplenum(Fig.4)hasbeendemonstratedtoprovide

can be directly related to dust cloud densities and velocities to

the required mass flow. The particle delivery system shall

which transparent materials are exposed in the field.

possess control instrumentation separate from the transport gas

control system so that mass flow rate of the dust can be

6. Apparatus

controlled independent of the transport gas velocity.

6.1 Dust Erosion Abrader, as illustrated in Fig. 1. The test

6.1.3 The dust velocity calibration system shall consist of a

apparatus simulates flight through dust environments by blow-

noninvasive velocity measurement system (VMS) such that

ing crushed silica particles, at a controlled mass flow rate and

particle velocity may be calibrated to transport gas pressure

velocity, onto samples that are stationary in the direction of

and dust mass flow rate. The laser doppler velocimeter (LDV)

particle flow. The dust erosion abrader consists of four distinct

shown in Fig. 5 has been demonstrated to provide the required

velocity measurements. In-situ monitoring of velocity during

dust exposure is recommended. However, if the size or

configuration of the noninvasive VMS prohibits in-situ moni-

toring,pre-andpost-exposurecalibrationshallbeconductedto

ensure that the velocity/pressure calibration has remained valid

through the test.

6.1.4 The specimen platform and test bed consists of stages

and fixtures onto which test specimens and the nozzle are

mounted. The test bed shall include adjustments such that dust

particle incidence angles range from normal to 70° off-normal.

Because the particle stream is substantially smaller than the

specimen holder, the specimen platform shall translate both

horizontallyandverticallythroughtheparticlestreamtoensure

uniform coverage of all specimens. Screw-type mechanisms or

stepper motors are recommended for platform translation.

Translation rates shall be adjustable from 0 to 30 translation

cycles per minute horizontally and 0 to 4 translation cycles per

minute vertically. The translation range shall be sufficient to

permittheoutermostspecimenstotranslatecompletelypastthe

dust jet in all directions. The specimen platform shall accom-

FIG. 1 Dust Erosion Abrader modateavarietyoftestsamplegeometries.Samplesrangingin

F 1864

FIG. 2 Recommended Nozzle Configuration

size from 25.4 mm (1.00 in.) in diameter to 152 mm (6.00 in.) 6.4 Fourier Transform Infrared (FTIR) Spectrometer shall

square have been exposed in the test bed shown in Fig. 6. The be used to measure the IR transmission properties of IR

specimen platform shall include adjustment for convenient transparent materials and coatings. The spectrometer shall be

mounting of samples. Sample holders shall include a frontal capable of measuring percent transmission in the 8- to 12-µm

mask to control the abraded area and prevent abrasion near bandwidth. A number of self-contained commercial FTIR

sample edges. The frontal mask shall include tapered edges systems existing on the market have been demonstrated to

(Fig. 7) to direct the dust flow onto the sample. provide the required measurements. Spectrometers used in this

6.2 A wire-cloth particle sieve shall be used to obtain test method shall comply with applicable sections of Practices

specific particle-size ranges.Acontinuous flow vibrating sieve E 168.

system (Fig. 8) is recommended for optimum and efficient

7. Materials and Reagents

sieving of bulk sand. Sieve nominal dimensions and permis-

sible variations shall comply with the U.S.A. Standard Test 7.1 Purity of Water—Unless otherwise indicated, references

Sieves Standard Series as detailed in Specification E 11. to water shall be understood to mean reagent water as defined

6.3 Integrating Sphere Photoelectric Photometer,asde- by Type II of Specification D 1193.

scribed in Test Method D 1003, shall be used to measure the 7.2 Crushed Silica Sand—The dust particles shall consist of

light transmitted and scattered by the abraded surface of crushed silica sand. The sand shall be dry, nonclogging, and

optically transparent materials and coatings. have corners and edges that have not been rounded by other

F 1864

FIG. 3 Typical Velocity/Pressure Profile for Fig. 2 Nozzle

8. Test Specimens

8.1 Optically Transparent Materials—Test specimens shall

be clean flat samples of the material or substrate/coating

system to be evaluated. Sample dimensions, including thick-

ness, may be of any convenient dimension that can be

accommodated by the specimen platform and test bed, with a

2 2

minimum exposed surface area of 363 mm (0.750 in. ).

Samples ranging in size from 25.4 to 152 mm (1.00 to 6.00 in.)

square have been found to accommodate most test require-

ments. Sides of samples shall be substantially plane and

parallel. Edge chipping and coating delamination resulting

fromsamplefabricationorpreparationshallnotextendintothe

unmasked portion of the sample.

8.2 IR Transparent Materials—Test specimens shall be

cleanflatsamplesofthematerialorsubstrate/coatingsystemto

be evaluated. Sample dimensions, including thickness, may be

of any convenient dimension that can be accommodated by the

specimen platform and test bed, with a minimum exposed

2 2

surface area of 363 mm (0.750 in. ). Samples 25.4 mm (1.00

in.) in diameter have been found to be suitable for most test

requirements. Edge chipping and coating delamination result-

ingfromsamplefabricationorpreparationshallnotextendinto

the unmasked portion of the sample.

8.3 Apply specimen ID numbers to the edges of specimens

using a permanent marker suitable for the material being

exposed.

8.4 For each exposure condition, prepare and test a mini-

mum of three samples.

FIG. 4 Screw Feeder and Pressurized Plenum

8.5 For storage purposes, wrap samples in lint-free tissue or

other suitable materials to prevent scratching or marring of the

surface.

than the crushing process. Bulk dust particle sizes shall be

uniformly distributed in the range 10 to 250 µm.

9. Preparation of Apparatus

7.3 CompressedAir or Nitrogen—Thetransportgasshallbe

dry and pressurized to a minimum of 827 kPa (120 psi) at the

9.1 Identify the distribution of dust particles to be used in

source. theexposureandsievethebulksandtothedesireddistribution.

7.4 Isopropyl Alcohol Solution—Mix isopropyl alcohol Follow the operating directions of automated sieving equip-

(C H OH) with water in a volumetric ratio of 1:1. ment if used.

3 7

F 1864

FIG. 5 Laser Doppler Velocimeter for Pre- and Post-Calibration

FIG. 6 Dust Erosion Test Bed FIG. 7 Typical Frontal Mask

9.2 Fill the pressurized holding chamber with the dust

NOTE 1—Warning: Sieving of the bulk sand can create small airborne

required for the exposure run.

dust particles that can irritate the nose, throat, and lungs.Wear a breathing

9.2.1 If the holding container requires simple replenishment

mask appropriate for the particle size being sieved to minimize the hazard

of inhaling airborne dust particles. of dust, remove the chamber lid and add the required amount

F 1864

mass flow rate to the screw size, screw speed, and particle size

distribution by measuring the accumulated mass delivered by

the screw feeder over a number of selected time intervals.

10.3 Dust Velocity—If in-situ dust velocity measurement is

not performed, calibrate the dust velocity to the tra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.