ASTM D6464-02

(Specification)Standard Specification for Expandable Foam Adhesives for Fastening Gypsum Wallboard to Wood Framing

Standard Specification for Expandable Foam Adhesives for Fastening Gypsum Wallboard to Wood Framing

SCOPE

1.1 This specification establishes minimum performance requirements for determining strength, aging, and working properties of expandable foam adhesives intended for bonding back surfaces of gypsum wallboards of all thicknesses to wood framing. Minimum physical and performance requirements are specified for all measured properties of adhesives and adhesive bonds.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6464 – 02

Standard Specification for

Expandable Foam Adhesives for Fastening Gypsum

1

Wallboard to Wood Framing

This standard is issued under the fixed designation D 6464; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This specification establishes minimum performance 4.1 This specification applies to expandable foam adhesives

requirements for determining strength, aging, and working used to bond the back surface of gypsum wallboard to

properties of expandable foam adhesives intended for bonding Douglas-fir dimensional lumber or other lumber species of

back surfaces of gypsum wallboards of all thicknesses to wood equivalent bonding qualities capable of meeting the test

framing. Minimum physical and performance requirements are requirements.

specified for all measured properties of adhesives and adhesive 4.2 The specification establishes the minimum strength

bonds. requirements of the bond for the selected assembly materials.

1.2 The values stated in inch-pound units are to be regarded 4.3 The adhesive is not considered a substitute for mechani-

as the standard. The SI units given in parentheses are for cal fasteners. Fasteners will be required to restrict expansion of

information only. the foam adhesive while it cures. The recommended fastening

1.3 This standard does not purport to address all of the schedule must appear in the manufacturer’s application instruc-

safety concerns, if any, associated with its use. It is the tions.

responsibility of the user of this standard to establish appro-

5. Adhesive Physical Property Requirements

priate safety and health practices and determine the applica-

5.1 Open Assembly Time—These adhesives have a distinct

bility of regulatory limitations prior to use.

open assembly time and this time must be agreed upon by the

2. Referenced Documents

user and the manufacturer.

2.1 ASTM Standards: 5.2 Storage Life—The adhesive shall remain serviceable

2

C 1396/C 1396M Specification for Gypsum Board and meet all the requirements of this specification for not less

D 905 Test Method for Strength Properties of Adhesive than six months after delivery, when stored in original un-

3

Bonds in Shear by Compression Loading opened containers at temperatures ranging from 40 to 85°F (4

3

D 907 Terminology of Adhesives to 30°C).

4

E 4 Practice for Force Verification of Testing Machines

6. Adhesive Properties and Performance

3. Terminology

6.1 The adhesives shall conform to the requirements sum-

3.1 Definitions—Many terms in this specification are de- marized in Table 1.

fined in Terminology D 907.

7. Materials for Conducting Tests

3.2 Definitions of Terms Specific to This Standard:

3.2.1 expandable foam adhesive, n—any polymer that ex- 7.1 Adhesives—The adhesive shall be an expandable foam

adhesive.

pands during delivery or cure to fill the space between

1

substrates. 7.2 Gypsum Wallboard— ⁄2 in. (12.7 mm) thick, complying

with Specification C 1396/C 1396M; the dimensions are speci-

fied in each test.

1

This specification is under the jurisdiction of ASTM Committee D14 on

3 23

7.3 Plywood— ⁄4 or ⁄32 in. (19.0 or 18.3 mm)-thick U.S.

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

Product Standard PS-1-95 grade marked stamped, commercial

Adhesives.

plywood, Exterior, Group 1 Species, A-A or A-B grade face

Current edition approved April 10, 2002. Published June 2002. Originally

published as D 6464 - 99. Last previous edition D 6464 - 99.

and back veneers. The test specimen dimensions are specified

2

Annual Book of ASTM Standards, Vol 04.01.

in each test.

3

Annual Book of ASTM Standards, Vol 15.06.

4

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D6464–02

TABLE 1 Adhesive Properties and Performance Requirements

Test Method Section Property Condition Requirements

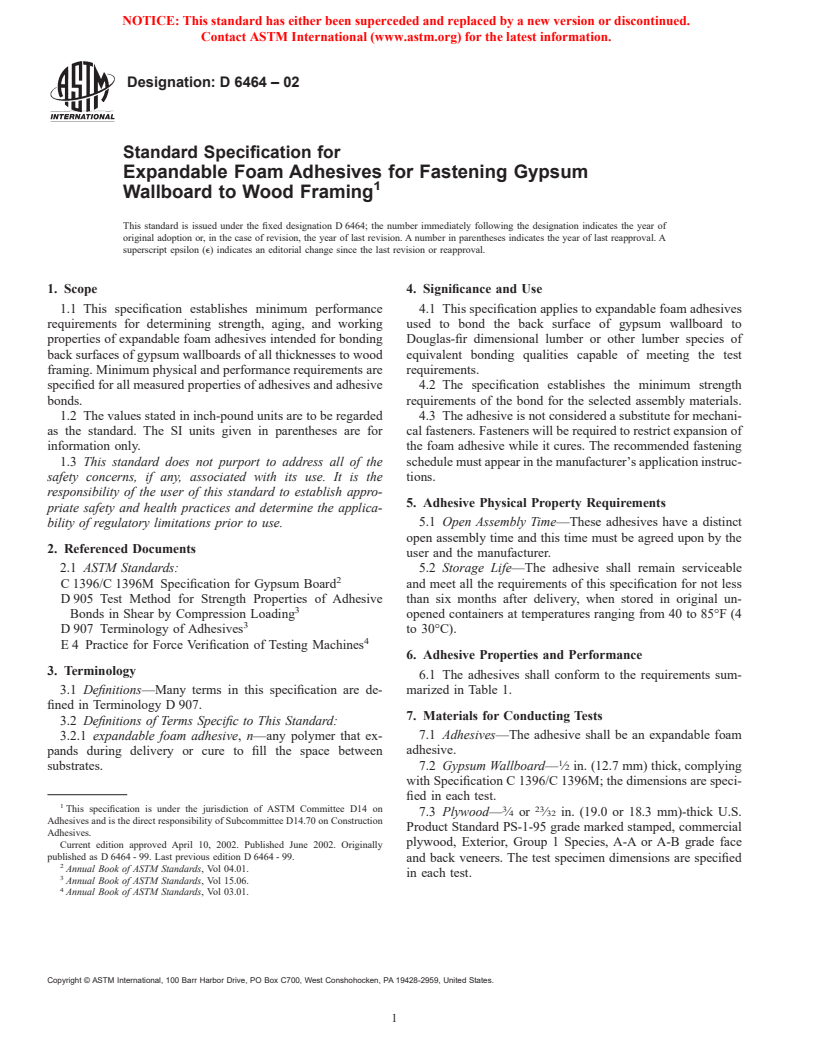

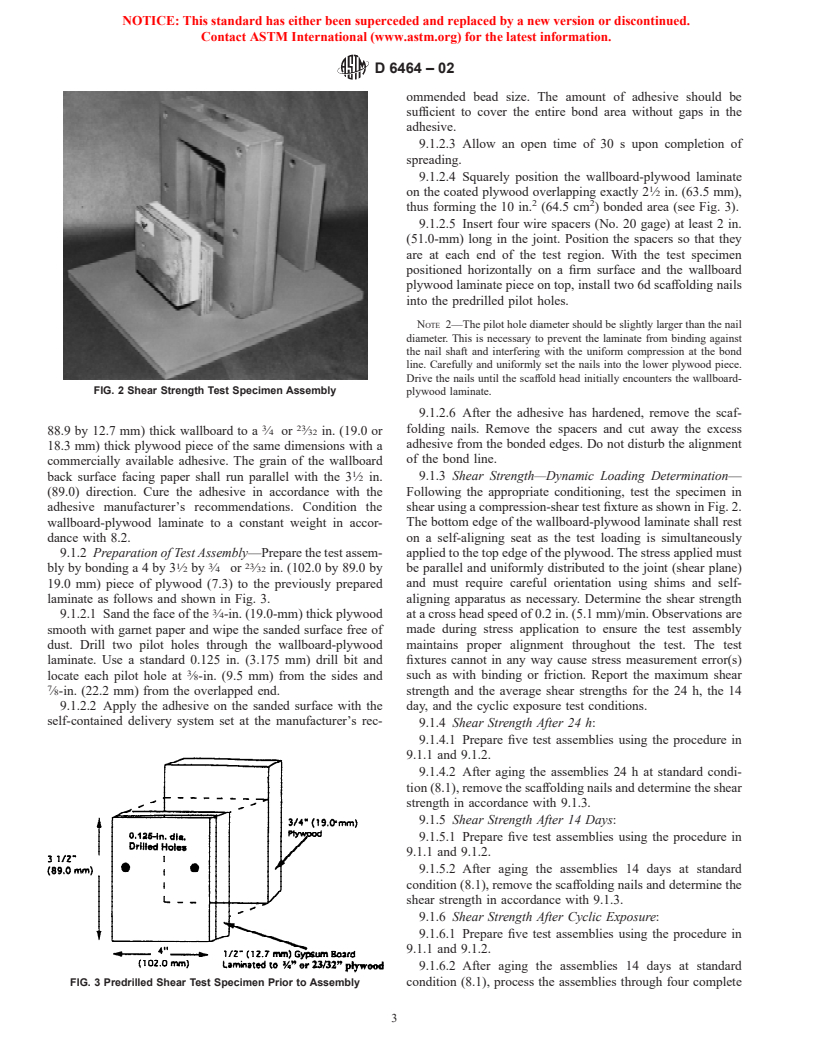

Rate of shear strength 9.1.4 shear strength 24 h at RT 10 psi (69 kPa) min

9.1.5 shear strength 14 days at RT 40 psi (276 kPa) min

9.1.6 shear strength 14 days at RT, + cyclic 32 psi (220 kPa) min

lab exposure, + 2 days at RT

9.1.7 resistance to static load in shear (a) 40 lb (178 N) for 24 h at RT no bond separation

(b) 20 lb (89 N) for 24 h at 100°F no bond separation

Rate of strength development 9.2.2 tensile strength 24 h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.