ASTM F2468-05(2011)

(Classification)Standard Classification for Specifying Silicone Adhesives and Sealants for Transportation Applications

Standard Classification for Specifying Silicone Adhesives and Sealants for Transportation Applications

SIGNIFICANCE AND USE

The purpose of this classification system is to provide a method of adequately identifying silicone adhesives and sealants through the use of a line call-out designation.

This classification system was designed to permit the addition of property values for future silicone adhesives and sealants.

SCOPE

1.1 This classification covers silicone adhesives and sealants intended for but not limited to sealing and retaining metallic and nonmetallic component assemblies in transportation applications. The materials cure to an elastomeric state by their specified cure system and mechanism.

Note 1—The classification system may serve many of the needs of industries using silicone materials. This classification is subject to revision, as the need requires; therefore, the latest revision should always be used.

1.2 This classification is intended to be a means of classifying silicone materials. It is not intended for engineering design purposes.

1.3 It is not the intent of this classification to include pressure-sensitive or hot-melt adhesives.

1.4 In all cases in which the provisions of this classification system would conflict with the referenced ASTM standard for a particular method, the latter shall take precedence.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this classification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2468 −05 (Reapproved 2011)

Standard Classification for

Specifying Silicone Adhesives and Sealants for

Transportation Applications

This standard is issued under the fixed designation F2468; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D149 Test Method for Dielectric Breakdown Voltage and

DielectricStrengthofSolidElectricalInsulatingMaterials

1.1 This classification covers silicone adhesives and seal-

at Commercial Power Frequencies

ants intended for but not limited to sealing and retaining

D150 Test Methods forAC Loss Characteristics and Permit-

metallic and nonmetallic component assemblies in transporta-

tivity (Dielectric Constant) of Solid Electrical Insulation

tion applications. The materials cure to an elastomeric state by

D257 Test Methods for DC Resistance or Conductance of

their specified cure system and mechanism.

Insulating Materials

NOTE 1—The classification system may serve many of the needs of

D412 Test Methods forVulcanized Rubber andThermoplas-

industries using silicone materials. This classification is subject to

tic Elastomers—Tension

revision, as the need requires; therefore, the latest revision should always

D471 Test Method for Rubber Property—Effect of Liquids

be used.

D573 Test Method for Rubber—Deterioration in an Air

1.2 This classification is intended to be a means of classi-

Oven

fying silicone materials. It is not intended for engineering

D618 Practice for Conditioning Plastics for Testing

design purposes.

D624 Test Method for Tear Strength of Conventional Vul-

1.3 It is not the intent of this classification to include

canized Rubber and Thermoplastic Elastomers

pressure-sensitive or hot-melt adhesives.

D792 Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

1.4 In all cases in which the provisions of this classification

D907 Terminology of Adhesives

system would conflict with the referenced ASTM standard for

D1002 Test Method for Apparent Shear Strength of Single-

a particular method, the latter shall take precedence.

Lap-Joint Adhesively Bonded Metal Specimens by Ten-

1.5 The values stated in SI units are to be regarded as

sion Loading (Metal-to-Metal)

standard. No other units of measurement are included in this

D1053 Test Methods for Rubber Property—Stiffening at

standard.

LowTemperatures: Flexible Polymers and Coated Fabrics

1.6 The following safety hazards caveat pertains only to the

D1084 Test Methods for Viscosity of Adhesives

test methods portion, Section 7, of this classification. This

D1349 Practice for Rubber—Standard Temperatures for

standard does not purport to address all of the safety concerns,

Testing

if any, associated with its use. It is the responsibility of the user

D1415 Test Method for Rubber Property—International

of this standard to establish appropriate safety and health

Hardness

practices and determine the applicability of regulatory limita-

D1566 Terminology Relating to Rubber

tions prior to use.

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

D2240 Test Method for Rubber Property—Durometer Hard-

2. Referenced Documents

ness

2.1 ASTM Standards:

D3182 PracticeforRubber—Materials,Equipment,andPro-

C679 Test Method for Tack-Free Time of Elastomeric Seal-

cedures for Mixing Standard Compounds and Preparing

ants

Standard Vulcanized Sheets

D4800 Guide for Classifying and Specifying Adhesives

This classification is under the jurisdiction of ASTM Committee F03 on

2.2 SAE Standard:

Gaskets and is the direct responsibility of Subcommittee F03.30 on Classification.

CurrenteditionapprovedMay1,2011.PublishedJuly2011.Originallyapproved

in 2005. Last previous edition approved in 2005 as F2468 – 05. DOI: 10.1520/

F2468-05R11.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

the ASTM website. PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2468−05 (2011)

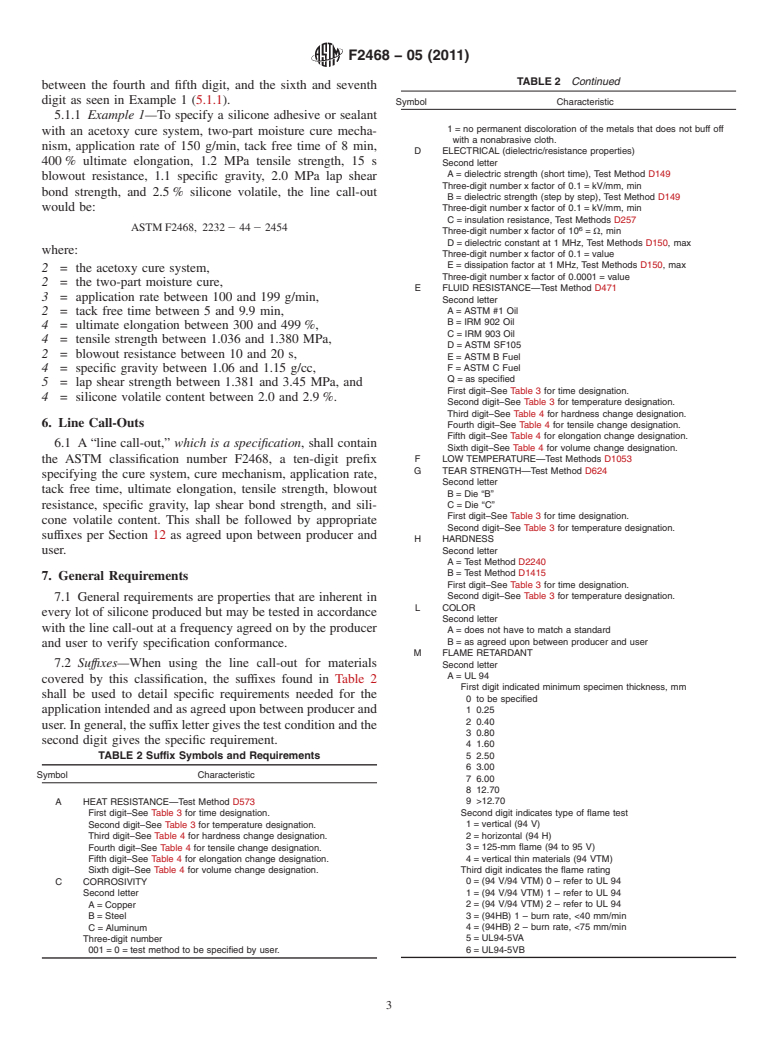

TABLE 1 Minimum Classification Requirements

Selection Property Designation

Order

Sequence

1 23456 7 8 9

st

1 Digit Cure system Addition Acetoxy Alkoxy Amine Enoxy Oxime Free . As

(Cure by-product) (no by- (acetic (methanol, (cyclo- (acetone) (methyl ethyl radical specified

product) acid) ethanol) hexylamine) ketoxime)

nd

2 Digit Cure mechanism One-part Two-part One-part One-part One-part Two-part Radiation . As

moisture moisture radiation radiation- thermal thermal specified

A

cure cure cure moisture cure cure

cure

rd

3 Digit Application rate, g/min <50 50-99 100-199 200-299 300-499 500-749 750-999 >999 As

specified

th

4 Digit Test Method C679, <5 5-9.9 10-19.9 20-29.9 30-39.9 40-49.9 50-60 >60 As

Tack free time, min specified

th

5 Digit Test Methods D412 (Die <100 100-199 200-299 300-499 500-699 700-999 >999 . As

C) specified

Ultimate elongation, %

th

6 Digit Test Methods D412, <0.345 0.345-0.690 0.691-1.035 1.036-1.380 1.381-3.450 3.451-6.899 6.90-14.0 >14 As

Tensile strength, MPa specified

th B

7 Digit Blowout resistance, s <10 10-20 21-30 31-40 41-50 51-60 >60 . As

specified

th

8 Digit Test Methods D792, <0.85 0.86-0.95 0.96-1.05 1.06-1.15 1.16-1.25 1.26-1.35 1.36-1.50 >1.5 As

Specific gravity, g/cc specified

th C

9 Digit Test Method D1002, <0.345 0.345-0.690 0.691-1.035 1.036-1.380 1.381-3.450 3.451-6.899 6.90-14.0 >14 As

Lap shear bond

specified

strength, MPa

th

10 Digit Silicone volatile <0.6 0.6-1.0 1.1-1.9 2.0-2.9 3.0-4.9 5.0-6.9 7-10 >10 As

Content, % specified

A

Ultraviolet light (UV), microwave, or visible light cure.

B

Resistance to blowout refers to the time to failure at a standardized internal pressure using a fixture as agreed upon between producer and user.

C

Standard test conditions: 5 cm (1.97 in.)/min cross head speed, 1 mm (0.039 in.) gap, 1.27 cm (0.50 in.) overlap, Q panel 20204T3 Aluminum (as received).

SAE J369 Flammability of Polymeric Interior Materials— 3.2.6 thixotropic—a rheological property of uncured seal-

Horizontal Test Method ants in which the sealant resists sagging or slumping unless

disturbed by an external force or pressure.

2.3 UL Standard:

UL 94 Flammability 3.2.7 transportation—any transportation venue involving

land, sea, or air, civilian or military, stationary and small

3. Terminology

engines.

3.1 Definitions—Some terms in this classification are de-

3.2.8 volatiles—low molecular weight components of an

fined in Terminiologies D907 and D1566. adhesive or sealant that can be extracted by the environment of

the application.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 cure mechanism—the method of initiating the cure for

4. Significance and Use

a silicone material.

4.1 The purpose of this classification system is to provide a

3.2.2 cure system—thecross-linkingmechanismthesilicone

method of adequately identifying silicone adhesives and seal-

material uses to transition to the elastomeric state.

ants through the use of a line call-out designation.

3.2.3 draw-down—a method of sample preparation of vis-

4.2 This classification system was designed to permit the

cous and sag-resistant sealants, in which the sealant is leveled

using a knife or tool to a specified thickness. addition of property values for future silicone adhesives and

sealants.

3.2.4 formed in place gasket, fipg—a one- or two-

component adhesive or sealant applied wet, uncured, to a joint

5. Classification

surface where the mating parts are assembled before the curing

process is complete. When fully cured it forms a barrier to

5.1 A ten-digit numbering system is used to classify a

media migration across the joint.

silicone adhesive and sealant cure system, cure mechanism,

application rate, tack free time; ultimate elongation, tensile

3.2.5 sag resistance—a property of some adhesives and

strength; blowout resistance, lap shear bond strength, specific

sealants that enables the applied or extruded material to retain

gravity, and silicone volatile content as defined in Table 1. The

its shape before curing or cross-linking.

firstcolumn(leftsideofthetable)indicatesthedigitnumberor

order sequence required while the designation numbers for

eachpropertyareindicatedonthetopofthetable.Theten-digit

Available from Underwriters Laboratories (UL), 333 Pfingsten Rd., North-

brook, IL 60062-2096, http://www.ul.com. classification number must also be separated with hyphens

F2468−05 (2011)

TABLE2 Continued

between the fourth and fifth digit, and the sixth and seventh

digit as seen in Example 1 (5.1.1). Symbol Characteristic

5.1.1 Example 1—To specify a silicone adhesive or sealant

1 = no permanent discoloration of the metals that does not buff off

with an acetoxy cure system, two-part moisture cure mecha-

with a nonabrasive cloth.

nism, application rate of 150 g/min, tack free time of 8 min,

D ELECTRICAL (dielectric/resistance properties)

400 % ultimate elongation, 1.2 MPa tensile strength, 15 s Second letter

A = dielectric strength (short time), Test Method D149

blowout resistance, 1.1 specific gravity, 2.0 MPa lap shear

Three-digit number x factor of 0.1 = kV/mm, min

bond strength, and 2.5 % silicone volatile, the line call-out

B = dielectric strength (step by step), Test Method D149

would be: Three-digit number x factor of 0.1 = kV/mm, min

C = insulation resistance, Test Methods D257

ASTM F2468, 2232 2 44 2 2454 6

Three-digit number x factor of 10 =Ω,min

D = dielectric constant at 1 MHz, Test Methods D150, max

where:

Three-digit number x factor of 0.1 = value

E = dissipation factor at 1 MHz, Test Methods D150, max

2 = the acetoxy cure system,

Three-digit number x factor of 0.0001 = value

2 = the two-part moisture cure,

E FLUID RESISTANCE—Test Method D471

3 = application rate between 100 and 199 g/min,

Second letter

A = ASTM #1 Oil

2 = tack free time between 5 and 9.9 min,

B = IRM 902 Oil

4 = ultimate elongation between 300 and 499 %,

C = IRM 903 Oil

4 = tensile strength between 1.036 and 1.380 MPa,

D = ASTM SF105

2 = blowout resistance between 10 and 20 s,

E = ASTM B Fuel

F = ASTM C Fuel

4 = specific gravity between 1.06 and 1.15 g/cc,

Q = as specified

5 = lap shear strength between 1.381 and 3.45 MPa, and

First digit–See Table 3 for time designation.

4 = silicone volatile content between 2.0 and 2.9 %.

Second digit–See Table 3 for temperature designation.

Third digit–See Table 4 for hardness change designati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.