ASTM G91-11

(Practice)Standard Practice for Monitoring Atmospheric SO2 Deposition Rate for Atmospheric Corrosivity Evaluation

Standard Practice for Monitoring Atmospheric SO<sub>2</sub> Deposition Rate for Atmospheric Corrosivity Evaluation

SIGNIFICANCE AND USE

Atmospheric corrosion of metallic materials is a function of many weather and atmospheric variables. The effect of specific corrodants, such as sulfur dioxide, can accelerate the atmospheric corrosion of metals significantly. The sulfation plate method provides a simple technique to independently monitor the level of SO2 in the atmosphere to yield a weighted average result.

Sulfation plate results may be used to characterize atmospheric corrosion test sites regarding the effective average level of SO2 in the atmosphere at these locations.

Sulfation plate testing is useful in determining microclimate, seasonal, and long term variations in the effective average level of SO2.

The results of sulfation plate tests may be used in correlations of atmospheric corrosion rates with atmospheric data to determine the sensitivity of the corrosion rate to SO2 level.

The sulfation plate method may also be used with other methods to characterize the atmosphere at sites where buildings or other construction is planned in order to determine the extent of protective measures required for metallic materials.

SCOPE

1.1 This practice covers a weighted average effective SO2 level for a 30-day interval through the use of the sulfation plate method, a technique for estimating the effective SO2 content of the atmosphere, and especially with regard to the atmospheric corrosion of stationary structures or panels. This practice is aimed at determining SO2 levels rather than sulfuric acid aerosol or acid precipitation.

1.2 The results of this practice correlate approximately with volumetric SO2 concentrations, although the presence of dew or condensed moisture tends to enhance the capture of SO2 into the plate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G91 − 11

Standard Practice for

Monitoring Atmospheric SO Deposition Rate for

2

1

Atmospheric Corrosivity Evaluation

This standard is issued under the fixed designation G91; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 ISO Standards:

ISO 9225 Corrosion of metals and alloys- Corrosivity of

1.1 This practice covers two methods of monitoring atmo-

atmospheres – Measurement of environmental parameters

spheric sulfur dioxide, SO deposition rates with specific

2

affecting corrosivity of atmospheres

application for estimating or evaluating atmospheric corrosiv-

ity as it applies to metals commonly used in buildings,

3. Terminology

structures, vehicles and devices used in outdoor locations.

3.1 Definitions—The terminology used herein shall be in

1.2 The values stated in SI units are to be regarded as

accordance with Terminology and Acronyms G193.

standard. No other units of measurement are included in this

standard.

4. Summary of Practice

1.3 This standard does not purport to address all of the

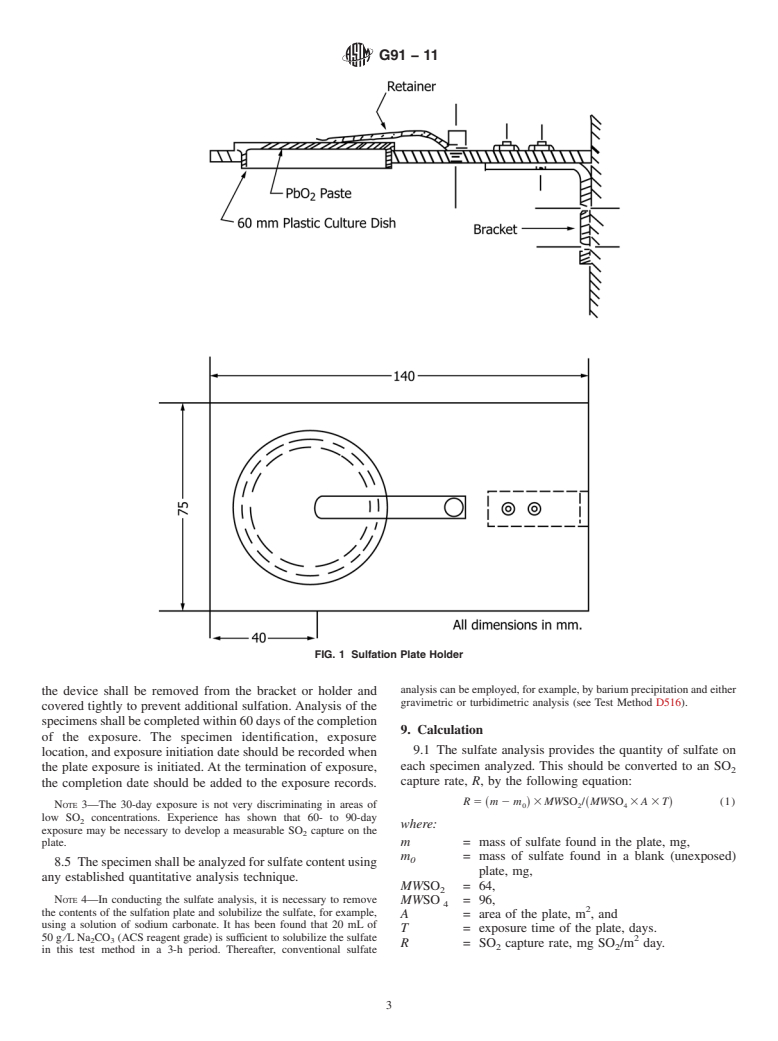

4.1 Sulfation plates consisting of a lead peroxide reagent in

safety concerns, if any, associated with its use. It is the

an inverted dish are exposed for 30-day intervals. The plates

responsibility of the user of this standard to establish appro-

arerecoveredandsulfateanalysesperformedonthecontentsto

priate safety and health practices and determine the applica-

determine the extent of sulfur capture. Lead peroxide cylinders

bility of regulatory limitations prior to use.

are also used for monitoring atmospheric SO in a similar

2

manner. The results are reported in terms of milligrams of SO

2

2. Referenced Documents

per square metre per day.

2

2.1 ASTM Standards:

D516 Test Method for Sulfate Ion in Water

5. Significance and Use

D1193 Specification for Reagent Water

5.1 Atmospheric corrosion of metallic materials is a func-

D2010/D2010M Test Methods for Evaluation of Total Sul-

tion of many weather and atmospheric variables. The effect of

fation Activity in the Atmosphere by the Lead Dioxide

specific corrodants, such as sulfur dioxide, can accelerate the

Technique

atmospheric corrosion of metals significantly. It is important to

G16 Guide for Applying Statistics to Analysis of Corrosion

have information available for the level of atmospheric SO

2

Data

when many metals are exposed to the atmosphere in order to

G84 Practice for Measurement of Time-of-Wetness on Sur-

determine their susceptibility to corrosion damage during their

faces Exposed to Wetting Conditions as in Atmospheric

life time in the atmosphere.

Corrosion Testing

5.2 Volumetric analysis of atmospheric SO concentration

2

G140 Test Method for Determining Atmospheric Chloride

carried out on a continuous basis is considered by some

Deposition Rate by Wet Candle Method

investigators as the most reliable method of estimating the

G193 Terminology and Acronyms Relating to Corrosion

effects caused by this gas. However, these methods require

sophisticated monitoring devices together with power supplies

and other equipment that make them unsuitable for many

exposure sites. These methods are beyond the scope of this

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

practice.

of Metals and is the direct responsibility of Subcommittee G01.04 on Atmospheric

5.3 The sulfation plate method provides a simple technique

Corrosion.

Current edition approved Nov. 1, 2011. Published December 2011. Originally

to independently monitor the level of SO in the atmosphere to

2

approved in 1986. Last previous edition approved in 2010 as G91–97(2010). DOI:

yield a weighted average result. The lead peroxide cylinder is

10.1520/G0091-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from International Organization for Standardization (ISO), 1, ch. de

the ASTM website. la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G91−11

similar technique that produces comparable results, and the 8. Exposure of SO Monitoring Devices

2

results are more sensitive to low levels of SO .

2

8.1 In general, the level of atmospheric sulfur dioxide varies

5.4 Sulfation plate or lead peroxide cylinder results may be

seasonally during the year so that a minimal exposure program

u

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G91 – 11

Standard Practice for

Monitoring Atmospheric SO Deposition Rate for

2

1

Atmospheric Corrosivity Evaluation

This standard is issued under the fixed designation G91; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers two methods of monitoring atmospheric sulfur dioxide, SO deposition rates with specific application

2

for estimating or evaluating atmospheric corrosivity as it applies to metals commonly used in buildings, structures, vehicles and

devices used in outdoor locations.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D516 Test Method for Sulfate Ion in Water

D1193 Specification for Reagent Water

D2010/D2010M Test Methods for Evaluation of Total Sulfation Activity in the Atmosphere by the Lead Dioxide Technique

G16 Guide for Applying Statistics to Analysis of Corrosion Data

G84 Practice for Measurement of Time-of-Wetness on Surfaces Exposed to Wetting Conditions as in Atmospheric Corrosion

Testing

G140 Test Method for Determining Atmospheric Chloride Deposition Rate by Wet Candle Method

G193 Terminology and Acronyms Relating to Corrosion

3

2.2 ISO Standards:

ISO 9225 Corrosion of metals and alloys- Corrosivity of atmospheres – Measurement of environmental parameters affecting

corrosivity of atmospheres

3. Terminology

3.1 Definitions—The terminology used herein shall be in accordance with Terminology and Acronyms G193.

4. Summary of Practice

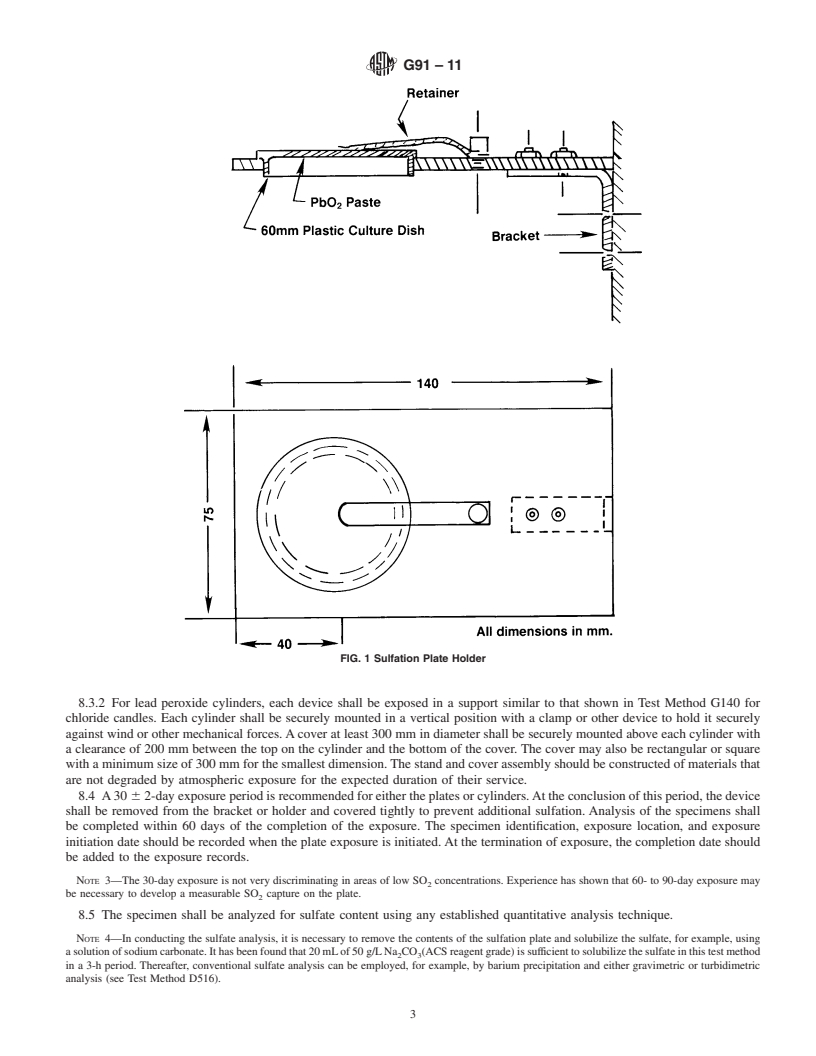

4.1 Sulfation plates consisting of a lead peroxide reagent in an inverted dish are exposed for 30-day intervals. The plates are

recovered and sulfate analyses performed on the contents to determine the extent of sulfur capture. Lead peroxide cylinders are

also used for monitoring atmospheric SO in a similar manner. The results are reported in terms of milligrams of SO per square

2 2

metre per day.

5. Significance and Use

5.1 Atmospheric corrosion of metallic materials is a function of many weather and atmospheric variables. The effect of specific

corrodants, such as sulfur dioxide, can accelerate the atmospheric corrosion of metals significantly. It is important to have

information available for the level of atmospheric SO when many metals are exposed to the atmosphere in order to determine their

2

susceptibility to corrosion damage during their life time in the atmosphere.

5.2 Volumetric analysis of atmospheric SO concentration carried out on a continuous basis is considered by some investigators

2

as the most reliable method of estimating the effects caused by this gas. However, these methods require sophisticated monitoring

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.04 on Atmospheric

Corrosion.

Current edition approved Nov. 1, 2011. Published December 2011. Originally approved in 1986. Last previous edition approved in 2010 as G91–97(2010). DOI:

10.1520/G0091-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

G91–11

devices together with power supplies and other equipment that make them unsuitable for many exposure sites. These methods are

beyond the scope of this practice.

5.3 The sulfation plate method provides a simple technique to independently monitor the level of SO in the atmosphere to yield

2

a weighted average result. The lead peroxide cylinder is similar technique that produces comparable results, and th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.