ASTM G91-11(2018)

(Practice)Standard Practice for Monitoring Atmospheric SO2 Deposition Rate for Atmospheric Corrosivity Evaluation

Standard Practice for Monitoring Atmospheric SO<inf>2</inf> Deposition Rate for Atmospheric Corrosivity Evaluation

SIGNIFICANCE AND USE

5.1 Atmospheric corrosion of metallic materials is a function of many weather and atmospheric variables. The effect of specific corrodants, such as sulfur dioxide, can accelerate the atmospheric corrosion of metals significantly. It is important to have information available for the level of atmospheric SO2 when many metals are exposed to the atmosphere in order to determine their susceptibility to corrosion damage during their life time in the atmosphere.

5.2 Volumetric analysis of atmospheric SO2 concentration carried out on a continuous basis is considered by some investigators as the most reliable method of estimating the effects caused by this gas. However, these methods require sophisticated monitoring devices together with power supplies and other equipment that make them unsuitable for many exposure sites. These methods are beyond the scope of this practice.

5.3 The sulfation plate method provides a simple technique to independently monitor the level of SO2 in the atmosphere to yield a weighted average result. The lead peroxide cylinder is similar technique that produces comparable results, and the results are more sensitive to low levels of SO2.

5.4 Sulfation plate or lead peroxide cylinder results may be used to characterize atmospheric corrosion test sites regarding the effective average level of SO2 in the atmosphere at these locations.

5.5 Either sulfation plate or lead peroxide cylinder testing is useful in determining microclimate, seasonal, and long term variations in the effective average level of SO2.

5.6 The results of these sulfur dioxide deposition rate tests may be used in correlations of atmospheric corrosion rates with atmospheric data to determine the sensitivity of the corrosion rate to SO2 level.

5.7 The sulfur dioxide monitoring methods may also be used with other methods, such as Practice G84 for measuring time of wetness and Test Method G140 for atmospheric chloride deposition, to characterize the atmosphere at sites w...

SCOPE

1.1 This practice covers two methods of monitoring atmospheric sulfur dioxide, SO2 deposition rates with specific application for estimating or evaluating atmospheric corrosivity as it applies to metals commonly used in buildings, structures, vehicles and devices used in outdoor locations.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G91 − 11 (Reapproved 2018)

Standard Practice for

Monitoring Atmospheric SO Deposition Rate for

Atmospheric Corrosivity Evaluation

This standard is issued under the fixed designation G91; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G140 Test Method for Determining Atmospheric Chloride

Deposition Rate by Wet Candle Method

1.1 This practice covers two methods of monitoring atmo-

G193 Terminology and Acronyms Relating to Corrosion

spheric sulfur dioxide, SO deposition rates with specific

2.2 ISO Standards:

application for estimating or evaluating atmospheric corrosiv-

ISO 9225 Corrosion of metals and alloys – Corrosivity of

ity as it applies to metals commonly used in buildings,

atmospheres – Measurement of environmental parameters

structures, vehicles and devices used in outdoor locations.

affecting corrosivity of atmospheres

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions—The terminology used herein shall be in

1.3 This standard does not purport to address all of the

accordance with Terminology and Acronyms G193.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Practice

priate safety, health, and environmental practices and deter-

4.1 Sulfation plates consisting of a lead peroxide reagent in

mine the applicability of regulatory limitations prior to use.

an inverted dish are exposed for 30-day intervals. The plates

1.4 This international standard was developed in accor-

arerecoveredandsulfateanalysesperformedonthecontentsto

dance with internationally recognized principles on standard-

determine the extent of sulfur capture. Lead peroxide cylinders

ization established in the Decision on Principles for the

are also used for monitoring atmospheric SO in a similar

Development of International Standards, Guides and Recom-

manner. The results are reported in terms of milligrams of SO

mendations issued by the World Trade Organization Technical

per square metre per day.

Barriers to Trade (TBT) Committee.

2. Referenced Documents 5. Significance and Use

2.1 ASTM Standards:

5.1 Atmospheric corrosion of metallic materials is a func-

D516 Test Method for Sulfate Ion in Water tion of many weather and atmospheric variables. The effect of

D1193 Specification for Reagent Water

specific corrodants, such as sulfur dioxide, can accelerate the

D2010/D2010M Test Methods for Evaluation of Total Sul- atmospheric corrosion of metals significantly. It is important to

fation Activity in the Atmosphere by the Lead Dioxide have information available for the level of atmospheric SO

Technique when many metals are exposed to the atmosphere in order to

G16 Guide for Applying Statistics to Analysis of Corrosion determine their susceptibility to corrosion damage during their

Data life time in the atmosphere.

G84 Practice for Measurement of Time-of-Wetness on Sur-

5.2 Volumetric analysis of atmospheric SO concentration

faces Exposed to Wetting Conditions as in Atmospheric

carried out on a continuous basis is considered by some

Corrosion Testing

investigators as the most reliable method of estimating the

effects caused by this gas. However, these methods require

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

sophisticated monitoring devices together with power supplies

of Metals and is the direct responsibility of Subcommittee G01.04 on Corrosion of

and other equipment that make them unsuitable for many

Metals in Natural Atmospheric and Aqueous Environments.

Current edition approved May 1, 2018. Published June 2018. Originally exposure sites. These methods are beyond the scope of this

approved in 1986. Last previous edition approved in 2011 as G91 – 11. DOI:

practice.

10.1520/G0091-11R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from International Organization for Standardization (ISO), 1, ch. de

the ASTM website. la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G91 − 11 (2018)

5.3 The sulfation plate method provides a simple technique within 120 days of their preparation, and if stored they should

to independently monitor the level of SO in the atmosphere to be kept in a cool dry location.

yield a weighted average result. The lead peroxide cylinder is

8. Exposure of SO Monitoring Devices

similar technique that produces comparable results, and the

results are more sensitive to low levels of SO . 8.1 In general, the level of atmospheric sulfur dioxide varies

seasonally during the year so that a minimal exposure program

5.4 Sulfation plate or lead peroxide cylinder results may be

requires four 30-day exposures each year at roughly equal

used to characterize atmospheric corrosion test sites regarding

intervals. In order to establish the atmospheric SO level at an

the effective average level of SO in the atmosphere at these

atmospheric corrosion test site which has not been monitored

locations.

previously, a program in which six 30-day exposures per year

5.5 Either sulfation plate or lead peroxide cylinder testing is

for a period of 3 years is recommended. More extensive testing

useful in determining microclimate, seasonal, and long term

may be desirable if large variability is encountered in the

variations in the effective average level of SO .

results. Thereafter, the location should be monitored with at

least four tests in a 1-year period every 3 years. If the

5.6 The results of these sulfur dioxide deposition rate tests

maybeusedincorrelationsofatmosphericcorrosionrateswith subsequent tests are not consistent with the initial testing, then

another 3-year program of six tests per year is required. Also,

atmospheric data to determine the sensitivity of the corrosion

rate to SO level. if a major change in the general area occurs in terms of

industrial or urban development, then six tests per year for 3

5.7 The sulfur dioxide monitoring methods may also be

years should again be carried out.

used with other methods, such as Practice G84 for measuring

8.2 In monitoring exposure sites, a minimum of four plates

time of wetness and Test Method G140 for atmospheric

chloride deposition, to characterize the atmosphere at sites or two cylinders shall be used for each exposure period.

8.2.1 Sites which have a significant grade or elevation

where buildings or other construction is planned in order to

determine the extent of protective measures required for variation should be monitored with at least two plates or one

cylinder at the highest elevation and two plates or one cylinder

metallic materials.

at the lowest elevation.

6. Interferences

8.2.2 Plates and cylinders should be exposed, if possible, at

both the highest and lowest level above the ground at which

6.1 The lead peroxide reagent used in the sulfation plates or

corrosion test specimens are exposed.

lead peroxide cylinders may convert other sulfur containing

8.2.3 Sites larger than 10 000 m shall have at least eight

compounds such as mercaptans, hydrogen sulfide, and carbo-

plates or four cylinders exposed for each period. In rectangular

nyl sulfide into sulfate.

sites on level ground, it is desirable to expose two plates or one

NOTE 1—Hydrogen sulfide and mercaptans, at concentrations which

cylinder at each corner.

affect the corrosion of structural metals significantly, are relatively rare in

most atmospheric environments, but their effects regarding the corrosion

NOTE 2—Some investigators have reported significantly higher sulfa-

of metals are not equivalent to sulfur dioxide. Therefore, if H S, COS, or

tion results at locations closest to the ground.

mercaptans are present in the atmosphere, that is, the odor of rotten eggs

8.3 Installation:

is present, the lead peroxide method must not be used to assess

8.3.1 Brackets shall be used to hold the sulfation plates

atmospheric corrosivity. It should also be noted that no actual measure-

ments have been made which would establish the correlation between securely in an inverted position so that the lead peroxide

atmospheric H S, COS, or mercaptan level and sulfation as measured by

mixture faces downward. The plate shall be horizontal and

this practice.

shall be placed so that it is not protected from normal winds

6.2 The inverted exposure position of the sulfation plate is

and air currents. The bracket design should include a retaining

intended to minimize capture of sulfuric acid aerosols and

clip or other provision to hold the plate in the event of strong

sulfur bearing species from precipitation. The lead peroxide

winds. The retainer clip may be made from stainless steel,

cylinder method may be more susceptible to capturing sulfuric

spring bronze, hard aluminum alloy (3003H19), or other alloys

acid aerosol particles. However, it should be noted that such

withsufficientstrengthandatmosphericcorrosionresistance.A

aerosols are rare in most natural environments.

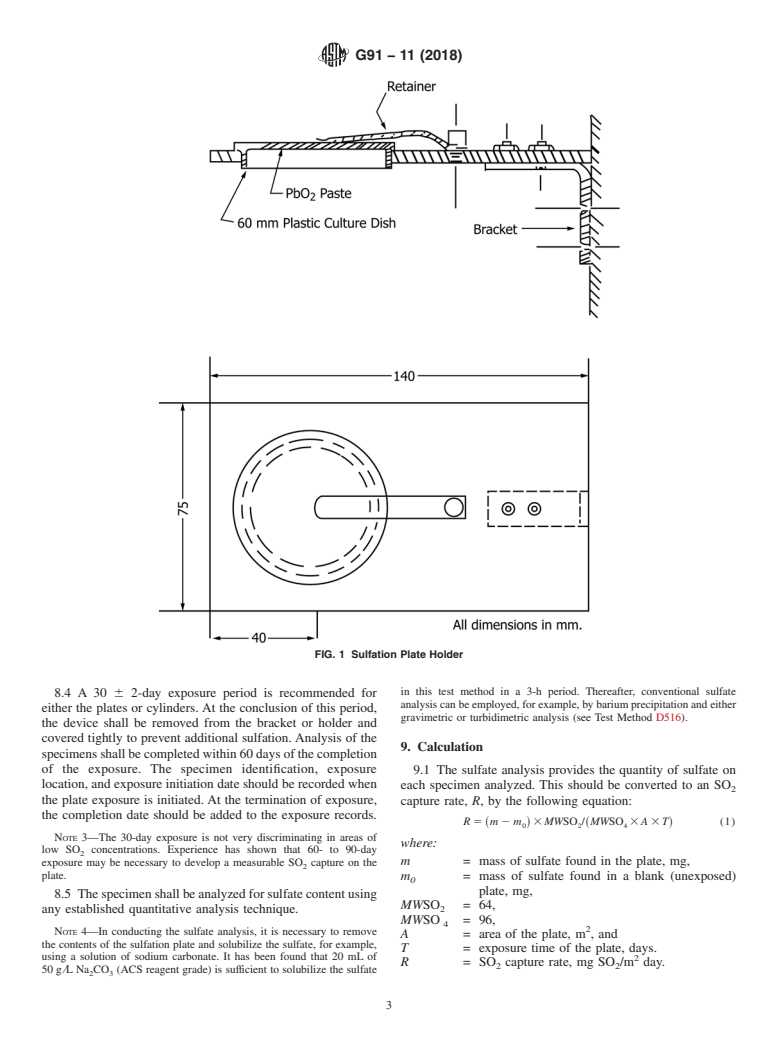

typical bracket design is shown in Fig. 1.

8.3.2 For lead peroxide cylinders, each device shall be

7. Preparation of SO Deposition Monitoring Devices

exposed in a support similar to that shown in Test Method

G140 for chloride candles. Each cylinder shall be securely

7.1 Sulfation plates can be prepared according to the

method of Huey. The plate preparation method is given in mounted in a vertical position with a clamp or other device to

hold it securely against wind or other mechanical forces. A

Appendix X1. Laboratory prepared plates should be exposed

within 120 days of preparation. cover at least 300 mm in diameter shall be securely mounted

above each cylinder with a clearance of 200 mm between the

7.2 Lead peroxide cylinders can be prepared as shown in

top on the cylinder and the bottom of the cover.The cover may

ISO 9225. The cylinder preparation procedure is also shown in

also be rectangular or square with a minimum size of 300 mm

Appendix X2. Lead peroxide cylinders should be exposed

for the smallest dimension. The stand and cover assembly

should be constructed of materials that are not degraded by

atmospheric exposure for the expected duration of their ser-

Huey, N. A., “The Lead Dioxide Estimation of Sulfur Dioxide Pollution,”

Journal of the Air Pollution Control Association, Vol 18, No. 9, 1968, pp. 610–611. vice.

G91 − 11 (2018)

FIG. 1 Sulfation Plate Holder

in this test method in a 3-h period. Thereafter, conventional sulfate

8.4 A 30 6 2-day exposure period is recommended for

analysis can be employed, for example, by barium precipitation and either

either the plates or cylinders. At the conclusion of this period,

gravimetric or turbidimetric analysis (see Test Method D516).

the device shall be removed from the bracket or holder and

covered tightly to prevent additional sulfation. Analysis of the

9. Calculation

specimensshallbecompletedwithin60daysofthecompletion

of the exposure. The specimen identification, exposure

9.1 The sulfate analysis provides the quantity of sulfate on

location, and exposure initiation date should be recorded when

each specimen analyzed. This should be converted to an SO

the plate exposure is initiated. At the termination of exposure,

capture rate, R, by the following equation:

the completion date should be added to the exposure records.

R 5 ~m 2 m ! 3MWSO /~MWSO 3A 3T! (1)

0 2 4

NOTE 3—The 30-day exposure is not very discriminating in areas of

where:

low SO concentrations. Experience has shown that 60- to 90-day

m = mass of sulfate found in the plate, mg,

exposure may be necessary to develop a measurable SO capture on the

plate.

m = mass of sulfate found in a blank (unexposed)

plate, mg,

8.5 Thespecimenshallbeanalyzedforsulfatecontentusing

MWSO = 64,

any established quantitative analysis technique.

MWSO = 96,

NOTE 4—In conducting the sulfate analysis, it is necessary to remove

A = area of the plate, m , and

the contents of the sulfation plate and solubilize the sulfate, for example,

T = exposure time of the plate, days.

using a solution of sodium carbonate. It has been found that 20 mL of 2

R =SO capture rate, mg SO /m day.

2 2

50 g ⁄L Na CO (ACS reagent grade) is sufficient to solubilize the sulfate

2 3

G91 − 11 (2018)

9.2 The SO capture rate may be converted to equivalent lead peroxide cylinder and the sulfation plate technique. The

SO or SO values if desired, but for comparison purposes, standard deviation of the slope of the correlation line divided

3 4

SO rates shall be used. by the slope was assumed to be a reasonable maximum value

for the ratio of the coefficient of variation for the plates This is

9.3 The average value and standard deviation of the values

expressed by the relation shown in Eq 4.

should be calculated according to Guide G16.

σ 5 0.0577 m (4)

c c

NOTE 5—The maximum sulfur dioxide capture rate for sulfation plates

2 2

is 9000 mg/m day, and for cylinders it is 5000 mg/m day. r 5 0.162 m (5)

c c

where:

10. Report

σ = standard deviation of the cylinder average in mg

c

10.1 The report shall include the following information:

SO /m day

10.1.1 A description of the exposure site and the locations

m = average net SO capture measured by the cylinder

c 2

where the plates or cylinders were exposed, including the

devices in mg SO /m day,

bracket identity number or designation and the location on the

r = repeatability of the SO capture by the cylinder method

c 2

exposure stand,

in mg SO /m day.

10.1.2 The exposure initiation and termination dates of

However, the standard error of estimate of the regression

plates or cylinders,

equation derived from the results of this study was 0.0312 mg

10.1.3 The identification numbers and sources of the sulfa-

SO /m day,andthereforethisisthelowerlimitforσ whenthe

tion plates or cylinders if they were obtained from a commer- 2 c

m value is below 0.54 mg SO /m day.The repeatability in this

cial source,

c 2

case is 0.0847 mg SO /m day.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.