ASTM F816-83(2003)

(Test Method)Standard Test Method for Combined Fine and Gross Leaks for Large Hybrid Microcircuit Packages (Withdrawn 2009)

Standard Test Method for Combined Fine and Gross Leaks for Large Hybrid Microcircuit Packages (Withdrawn 2009)

SIGNIFICANCE AND USE

This test method provides an evaluation of the quality of an in-line sealing process on a real time basis for sealed packages. It eliminates the need to expose the specimen to long exposures of high pressure to drive the helium gas into the package to later be detected by the same method herein used. Previously, separate test methods were required to detect large or small leaks. This method provides only one test to accomplish all test levels without potential for specimens with leaks to escape detection within the range of detection being employed (see Practices F 98).

Both development and research, along with manufacturing control, may be served by using this test method. Current gross leak test methods and fine leak test methods may be combined into one using this method. No exposure to high pressure processing hazards is involved and safety of operation in production environment is enhanced.

SCOPE

1.1 This test method applies to hermetic package leak testing to detect leaks of a broad spectrum in size with a minimum detection level equal to the sensitivity of the helium mass spectrometer equipment used in the test.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method applies to hermetic package leak testing to detect leaks of a broad spectrum in size with a minimum detection level equal to the sensitivity of the helium mass spectrometer equipment used in the test.

Formerly under the jurisdiction of Committee F01 on Electronics and Subcommittee F01.03 on Metallic Materials, this practice was withdrawn in May 2009 with no replacement because the committee is not aware of the need to maintain the standard. Reference to the standard will remain available, but at this time, the committee does not wish to actively maintain the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 816–83(Reapproved2003)

Standard Test Method for

Combined Fine and Gross Leaks for Large Hybrid

Microcircuit Packages

This standard is issued under the fixed designation F 816; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope into the lid of the package.After sealing the lid on the package,

the vent hole in the lid is presented to a port in the inlet of the

1.1 This test method applies to hermetic package leak

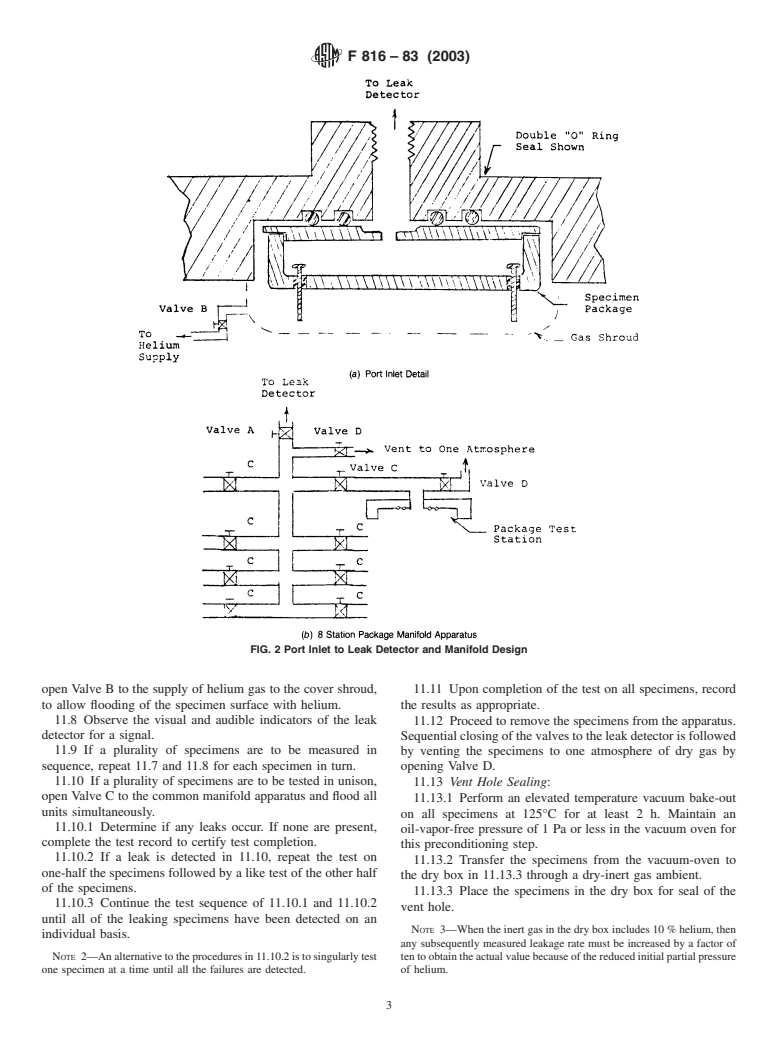

helium leak detector using an interface seal (See Fig. 2).After

testing to detect leaks of a broad spectrum in size with a

the internal volume is evacuated, a cloud of helium gas is

minimum detection level equal to the sensitivity of the helium

brought into close proximity to the entire outer surface of the

mass spectrometer equipment used in the test.

package. Helium passing into the inner volume of the package

1.2 This standard does not purport to address all of the

through any leak orifice in an amount greater than the

safety concerns, if any, associated with its use. It is the

minimum sensitivity of the leak detector will be detected

responsibility of the user of this standard to establish appro-

within a few seconds. The successfully sealed product is then

priate safety and health practices and determine the applica-

placed into a controlled atmosphere dry box for vacuum

bility of regulatory limitations prior to use.

purging and back filling the internal volume of the package

2. Referenced Documents through the vent hole with an inert gas having some detectable

partial pressure level of helium gas. While under this latter

2.1 ASTM Standards:

condition, the vent hole is sealed off by a suitable manner. The

E691 Practice for Conducting an Interlaboratory Study to

specimen is then immediately retested by the above method to

Determine the Precision of a Test Method

detect successful sealing of the vent hole.

F78 Test Method for Calibration of Helium Leak Detectors

by Use of Secondary Standards

4. Significance and Use

F98 Practices for Determining Hermeticity of Electron

4.1 Thistestmethodprovidesanevaluationofthequalityof

Devices by a Bubble Test

an in-line sealing process on a real time basis for sealed

F134 Test Methods for Determining Hermeticity of Elec-

packages.Iteliminatestheneedtoexposethespecimentolong

tron Devices with a Helium Mass Spectrometer Leak

4 exposures of high pressure to drive the helium gas into the

Detector

package to later be detected by the same method herein used.

2.2 Federal Standard:

Previously, separate test methods were required to detect large

Federal Standard 209B Clean Room and Work Station Re-

or small leaks. This method provides only one test to accom-

quirements, Controlled Environment

plish all test levels without potential for specimens with leaks

3. Summary of Method

to escape detection within the range of detection being em-

ployed (see Practices F 98).

3.1 This test method for the hermeticity of packages used

4.2 Both development and research, along with manufactur-

for housing multichip and hybrid microcircuits is to be applied

2 2

ing control, may be served by using this test method. Current

generally to those equal to or greater than 1 in. (645 mm)in

gross leak test methods and fine leak test methods may be

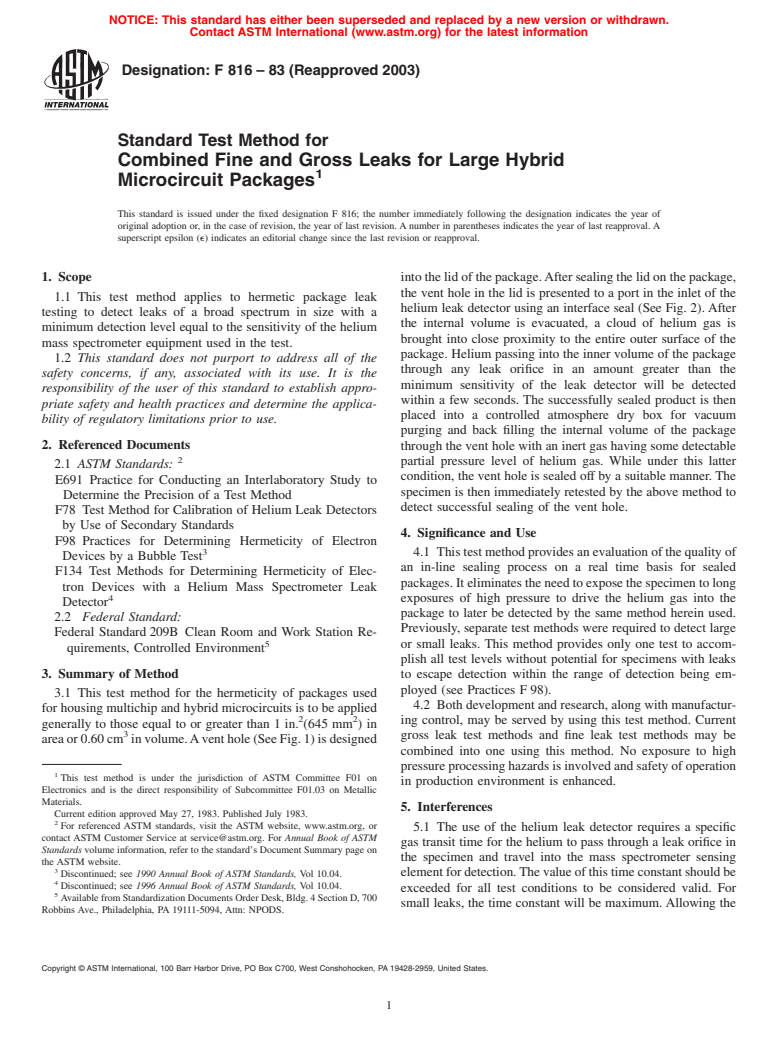

areaor0.60cm involume.Aventhole(SeeFig.1)isdesigned

combined into one using this method. No exposure to high

pressure processing hazards is involved and safety of operation

This test method is under the jurisdiction of ASTM Committee F01 on

in production environment is enhanced.

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

Materials.

5. Interferences

Current edition approved May 27, 1983. Published July 1983.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 The use of the helium leak detector requires a specific

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

gas transit time for the helium to pass through a leak orifice in

Standards volume information, refer to the standard’s Document Summary page on

the specimen and travel into the mass spectrometer sensing

the ASTM website.

elementfordetection.Thevalueofthistimeconstantshouldbe

Discontinued; see 1990 Annual Book of ASTM Standards, Vol 10.04.

Discontinued; see 1996 Annual Book of ASTM Standards, Vol 10.04.

exceeded for all test conditions to be considered valid. For

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

small leaks, the time constant will be maximum. Allowing the

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 816–83 (2003)

FIG. 1 Lid Vent Hole Design Option

helium gas to bathe the specimen for a time in excess of this 7.3 Cleaning Solutions/Solvents.

time constant will suffice. This time constant should normally 7.4 Soft Solder and Soldering Iron.

be no longer than 5 s.

8. Sampling

5.2 Any contaminating films or seal defects in the interface

8.1 No specific sampling plan is to be implied by the use of

between the apparatus port and the vent hole in the lid of the

this test method. The user is encouraged to adopt this method

package may indicate a false leak. Adequate handling, clean-

for 100 % testing of production product.

liness, and operator performance to ensure the integrity of this

interface seal is necessary.

9. Preparation of Apparatus

5.3 When a large leak is encountered that allows a large

9.1 Prepare apparatus in accordance with Test Methods

charge of helium gas to enter the mass spectrometer, it may be

F 134.

necessary to allow the system to regain a normal (unsaturated)

condition before proceeding.

10. Calibration of Apparatus

6. Apparatus 10.1 Calibrate apparatus in accordance with Test Method

F 78.

6.1 See Test Methods F 134 for helium leak detector test

apparatus.

11. Procedure

6.2 See Fed. Std. No. 209B.

11.1 Place each specimen to be tested on the test port (Note

6.3 See Fig. 2 for a sketch of manifold for specimen

1), one to each port for multiport manifold apparatus designs,

interface with leak detector and helium cup enclosure. The

with the vent hole centered on the interface seal surface

elastomersealmaterialmaybemadeofbutylrubber,neoprene,

location.

or fluorocarbon rubber (Viton) depending on the desired

compression force being used. The O-ring squeeze should be

NOTE 1—Abackground or tare reading may be taken for each package

about 0.2 mm to assure a tight seal on a dry surface. style (plating) by rotating it 180° so the seal surface location is covered by

aportionofthepackagelidthatdoesnothaveaventhole.Thisestablishes

6.4 The dry box in which the vent hole is sealed may either

a measurement threshold value for each package style and lid plating

be provided with a soldering iron or a spot welding head

material.

depending upon which method of seal is selected. The dry box

11.2 Vent the leak test apparatus to evacuation mode by

shall also be provided with an adequate flow of dry nitrogen or

opening Valve A (See Fig. 2).

some other inert gas to which can be added up to 10 % by

11.3 Place a helium cloud chamber shroud over the speci-

volume of helium gas. A tube connected to a vacuum source

men(s) (common or singular units

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.