ASTM F2759-09

(Guide)Standard Guide for Assessment of the Ultra High Molecular Weight Polyethylene (UHMWPE) Used in Orthopedic and Spinal Devices

Standard Guide for Assessment of the Ultra High Molecular Weight Polyethylene (UHMWPE) Used in Orthopedic and Spinal Devices

SIGNIFICANCE AND USE

This guide aims to provide guidance for a range of various assessments and evaluations to aid in preclinical research and device development of various UHMWPE components in orthopedic and spinal devices used for the repair of musculoskeletal disorders.

This guide includes brief descriptions of various assessments, representative data, processing conditions, and intended use or uses, as well as the qualitative and quantitative analyses of the UHMWPE powder to a finished product component.

The user is encouraged to use appropriate ASTM International and other standards to conduct the physical, chemical, mechanical, biocompatibility, and preclinical tests on UHMWPE materials, device components, or devices before assessment of an in vivo model.

Assessments of UHMWPE should be performed in accordance with the provisions of 21 CFR 58 where feasible.

Studies to support investigational device exemption (IDE), premarket approval (PMA), or 510K submissions should conform to appropriate Food and Drug Administration (FDA) guidelines for the development of medical devices.

Assessments with physical, chemical, mechanical, biocompatibility, and preclinical tests on UHMWPE components are not necessarily predictive of human results and should be, therefore, interpreted cautiously with respect to potential applicability to human conditions. Referenced UHMWPE publications can be found in the References section at the end of this guide for further review.

SCOPE

1.1 This guide covers general guidelines for the physical, chemical, biocompatibility, mechanical, and preclinical assessments of ultra-high molecular weight polyethylene (UHMWPE) in implantable orthopedic and spinal devices intended to replace a musculoskeletal joint. The UHMWPE components may include knee, hip, shoulder, elbow, ankle, total disc replacement, toe, finger, and wrist joint implant devices. This guide does not cover UHMWPE in fiber or tape forms.

1.2 This guide includes a description and rationale of assessments for the various UHMWPE types and processing conditions. Assessment testing based on physical, chemical, biocompatibility, mechanical, and preclinical analyses are briefly described and referenced. The user should refer to specific test methods for additional details.

1.3 This guide does not attempt to define all of the assessment methods associated with UHMWPE components in orthopedic and spinal devices.

1.4 Units—The values given in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2759–09

Standard Guide for

Assessment of the Ultra High Molecular Weight

Polyethylene (UHMWPE) Used in Orthopedic and Spinal

Devices

This standard is issued under the fixed designation F2759; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1621 Test Method for Compressive Properties of Rigid

Cellular Plastics

1.1 This guide covers general guidelines for the physical,

D2765 Test Methods for Determination of Gel Content and

chemical, biocompatibility, mechanical, and preclinical assess-

Swell Ratio of Crosslinked Ethylene Plastics

ments of ultra-high molecular weight polyethylene (UHM-

D4020 Specification for Ultra-High-Molecular-Weight

WPE) in implantable orthopedic and spinal devices intended to

Polyethylene Molding and Extrusion Materials

replace a musculoskeletal joint. The UHMWPE components

E132 Test Method for Poisson’s Ratio at Room Tempera-

may include knee, hip, shoulder, elbow, ankle, total disc

ture

replacement, toe, finger, and wrist joint implant devices. This

E647 Test Method for Measurement of Fatigue Crack

guide does not cover UHMWPE in fiber or tape forms.

Growth Rates

1.2 This guide includes a description and rationale of

F619 Practice for Extraction of Medical Plastics

assessments for the various UHMWPE types and processing

F648 Specification for Ultra-High-Molecular-Weight Poly-

conditions. Assessment testing based on physical, chemical,

ethylene Powder and Fabricated Form for Surgical Im-

biocompatibility, mechanical, and preclinical analyses are

plants

briefly described and referenced. The user should refer to

F732 Test Method for Wear Testing of Polymeric Materials

specific test methods for additional details.

Used in Total Joint Prostheses

1.3 This guide does not attempt to define all of the assess-

F748 Practice for Selecting Generic Biological Test Meth-

ment methods associated with UHMWPE components in

ods for Materials and Devices

orthopedic and spinal devices.

F749 Practice for Evaluating Material Extracts by Intracu-

1.4 Units—The values given in SI units are to be regarded

taneous Injection in the Rabbit

as the standard. No other units of measurement are included in

F756 Practice for Assessment of Hemolytic Properties of

this standard.

Materials

1.5 This standard does not purport to address all of the

F763 Practice for Short-Term Screening of Implant Materi-

safety concerns, if any, associated with its use. It is the

als

responsibility of the user of this standard to establish appro-

F813 Practice for Direct Contact Cell Culture Evaluation of

priate safety and health practices and determine the applica-

Materials for Medical Devices

bility of regulatory limitations prior to use.

F895 Test Method for Agar Diffusion Cell Culture Screen-

2. Referenced Documents

ing for Cytotoxicity

F981 Practice forAssessment of Compatibility of Biomate-

2.1 ASTM Standards:

rials for Surgical Implants with Respect to Effect of

D256 Test Methods for Determining the Izod Pendulum

Materials on Muscle and Bone

Impact Resistance of Plastics

F1714 Guide for Gravimetric Wear Assessment of Pros-

D638 Test Method for Tensile Properties of Plastics

thetic Hip Designs in Simulator Devices

D883 Terminology Relating to Plastics

F1715 Guide for Wear Assessment of Prosthetic Knee

Designs in Simulator Devices

F2003 Practice for Accelerated Aging of Ultra-High Mo-

This guide is under the jurisdiction of ASTM Committee F04 on Medical and

Surgical Materials and Devices and is the direct responsibility of Subcommittee

lecularWeightPolyethyleneafterGammaIrradiationinAir

F04.11 on Polymeric Materials.

F2025 Practice for Gravimetric Measurement of Polymeric

Current edition approved Feb. 1, 2009. Published February 2009. DOI: 10.1520/

Components for Wear Assessment

F2759-09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

Withdrawn. The last approved version of this historical standard is referenced

the ASTM website.

on www.astm.org.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

F2759–09

F2102 Guide for Evaluating the Extent of Oxidation in 2.3 Federal Standard:

Ultra-High-Molecular-Weight Polyethylene Fabricated 21 CFR 58 Good Laboratory Practices Regulations

Forms Intended for Surgical Implants

3. Terminology

F2183 Test Method for Small Punch Testing of Ultra-High

3.1 Definitions—Additional terminology related to ultra

Molecular Weight Polyethylene Used in Surgical Implants

high molecular weight polyethylene (UHMWPE) and plastics

F2214 Test Method for In Situ Determination of Network

can be found in Terminology D883 and Specifications D4020

Parameters of Crosslinked Ultra High Molecular Weight

and F648 and referenced publications (1-7).

Polyethylene (UHMWPE)

3.2 Definition of Term Specific to This Standard:

F2381 Test Method for Evaluating Trans-Vinylene Yield in

3.2.1 fabricated form, n—any bulk shape of UHMWPE

IrradiatedUltra-High-Molecular-WeightPolyethyleneFab-

fabricated from the virgin polymer powder with or without

ricated Forms Intended for Surgical Implants by Infrared

additives or prior irradiation and used during the process of

Spectroscopy

fabricating surgical implants before packaging and steriliza-

F2423 Guide for Functional, Kinematic, and Wear Assess-

tion.

ment of Total Disc Prostheses

3.2.1.1 Discussion—This form results from the application

F2625 Test Method for Measurement of Enthalpy of Fu-

of heat and pressure to the virgin polymer powder, and the

sion, Percent Crystallinity, and Melting Point of Ultra-

material characteristics of this form are subject to the appli-

High-Molecular Weight Polyethylene by Means of Differ-

cable requirements of this guide. In present practice, this

ential Scanning Calorimetry

includes ram-extruded bars, compression-molded sheets, and

F2695 Specification for Ultra-High MolecularWeight Poly-

direct-molded shapes that are subsequently trimmed.

ethylenePowderBlendedWithAlpha-Tocopherol(Vitamin

E) and Fabricated Forms for Surgical ImplantApplications

4. Significance and Use

2.2 ISO Standards:

4.1 This guide aims to provide guidance for a range of

ISO 527 Plastics: Determination of Tensile Properties

various assessments and evaluations to aid in preclinical

ISO 3451–1 Plastics: Determination of Ash Part 1: General

research and device development of various UHMWPE com-

Methods

ponents in orthopedic and spinal devices used for the repair of

ISO 5834–1 Implants for Surgery—Ultra High Molecular

musculoskeletal disorders.

Weight Polyethylene. Part 1: Powder Form

4.2 This guide includes brief descriptions of various assess-

ISO 5834–2 Implants for Surgery—Ultra High Molecular

ments, representative data, processing conditions, and intended

Weight Polyethylene. Part 2: Molded Forms

use or uses, as well as the qualitative and quantitative analyses

ISO 11542–2 Plastics—Ultra-High-Molecular-Weight-

of the UHMWPE powder to a finished product component.

Polyethylene (PE-UHMWPE) Molding and Extrusion

4.3 The user is encouraged to use appropriate ASTM

Materials. Part 2: Preparation of Test Specimens and

International and other standards to conduct the physical,

Determination of Properties

chemical, mechanical, biocompatibility, and preclinical tests

ISO 10993 Biological Evaluation of Medical Devices

on UHMWPE materials, device components, or devices before

ISO 14242–1 Implants for Surgery—Wear of Total Hip-

assessment of an in vivo model.

Joint Prostheses. Part 1: Loading and Displacement Pa-

4.4 Assessments of UHMWPE should be performed in

rameters for Wear-Testing Machines and Corresponding

accordance with the provisions of 21 CFR 58 where feasible.

Environmental Conditions for Test

4.5 Studies to support investigational device exemption

ISO 14242–2 Implants for Surgery—Wear of Total Hip-

(IDE), premarket approval (PMA), or 510K submissions

Joint Prostheses. Part 2: Methods of Measurement

should conform to appropriate Food and Drug Administration

ISO 14243–1 Implants for Surgery—Wear of Total Knee-

(FDA) guidelines for the development of medical devices.

Joint Prostheses. Part 1: Load and Displacement Param-

4.6 Assessments with physical, chemical, mechanical, bio-

eters for Wear-Testing Machines with Load Control and

compatibility, and preclinical tests on UHMWPE components

Corresponding Environmental Conditions for Test

are not necessarily predictive of human results and should be,

ISO 14243–2 Implants for Surgery—Wear of Total Knee-

therefore, interpreted cautiously with respect to potential ap-

Joint Prostheses. Part 2: Methods of Measurement

plicability to human conditions. Referenced UHMWPE publi-

ISO 14243–3 Implants for Surgery—Wear of Total Knee-

cationscanbefoundintheReferencessectionattheendofthis

Joint Prostheses. Part 3: Loading and Displacement Pa-

guide for further review.

rameters for Wear-Testing Machines with Displacement

Control and Corresponding Environmental Conditions for

5. UHMWPE Fabricated Forms and Conditions

Test

5.1 Conventional UHMWPE is manufactured by compres-

ISO18192–1 ImplantsforSurgery—WearofTotalInterver-

sion molding or ram extrusion and has not been intentionally

tebral Disc Prostheses. Part 1: Loading and Displacement

cross-linked before terminal sterilization.

Parameters for Wear Testing and Corresponding Environ-

mental Conditions for Test

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

4 6

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., The boldface numbers in parentheses refer to the list of references at the end of

4th Floor, New York, NY 10036, http://www.ansi.org. this standard.

F2759–09

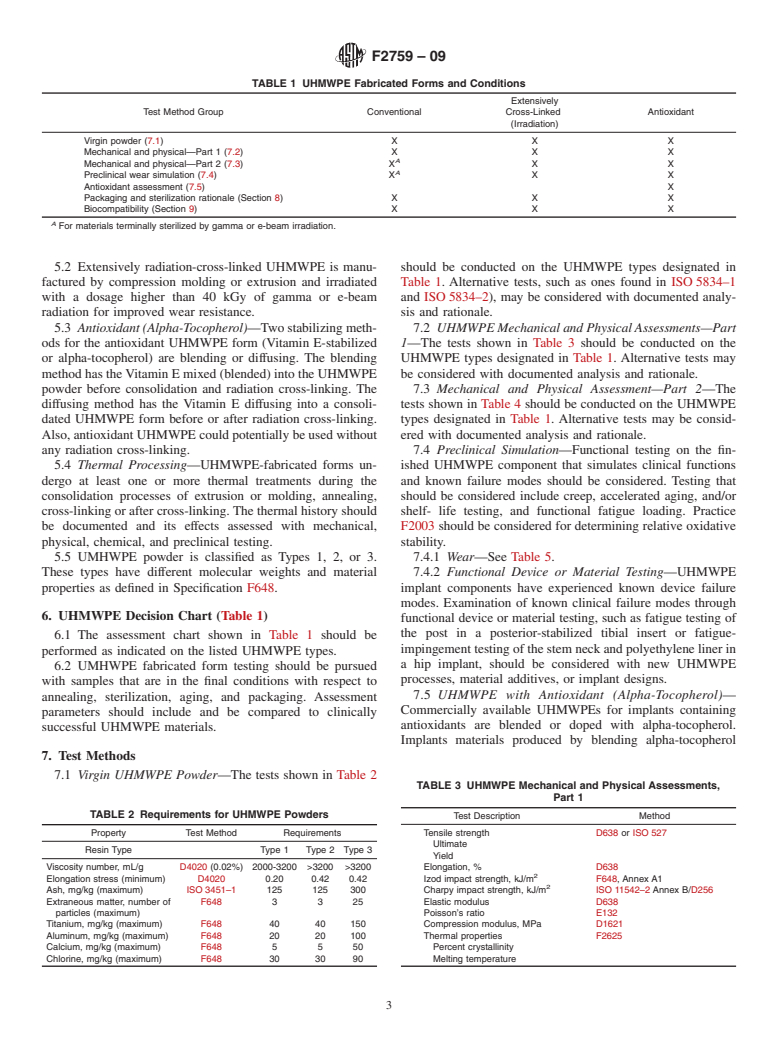

TABLE 1 UHMWPE Fabricated Forms and Conditions

Extensively

Test Method Group Conventional Cross-Linked Antioxidant

(Irradiation)

Virgin powder (7.1)X X X

Mechanical and physical—Part 1 (7.2)X X X

A

Mechanical and physical—Part 2 (7.3)X XX

A

Preclinical wear simulation (7.4)X XX

Antioxidant assessment (7.5) X

Packaging and sterilization rationale (Section 8)X X X

Biocompatibility (Section 9)X X X

A

For materials terminally sterilized by gamma or e-beam irradiation.

5.2 Extensively radiation-cross-linked UHMWPE is manu- should be conducted on the UHMWPE types d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.