ASTM F957-91(2006)

(Specification)Standard Specification for Gong, Sound Signaling

Standard Specification for Gong, Sound Signaling

ABSTRACT

This specification covers gongs for use on ships of certain length, as required by International Regulations. The gong cylinder, brackets, clapper rod, "U" bracket, washers, and clapper support pin shall be made of stainless steel. The clapper mass shall be made of cast alloy steel. In addition, the support bolt, nut, flat washer, and cotter pins shall be made of stainless steel compatible with the other materials. The general arrangement of the assembled gong, as well as details of the gong cylinder, brackets, clapper, and miscellaneous fittings are presented. The sound characteristics of these gongs shall be determined by an acoustic test. These gongs shall be free from cracks, burrs, sharp cutting edges, and other defects affecting their life, appearance, and serviceability.

SCOPE

1.1 This specification covers gongs for use on ships 100 m or more in length, as required by International Regulations (see Appendix X1).

1.2 For consistency with International Regulations, all measurements are in SI units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F957 – 91 (Reapproved 2006)

Standard Specification for

1

Gong, Sound Signaling

ThisstandardisissuedunderthefixeddesignationF957;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.3 Packaging and marking, if other than commercial.

1.1 This specification covers gongs for use on ships 100 m

4. Materials and Manufacture

ormoreinlength,asrequiredbyInternationalRegulations(see

4.1 Materials:

Appendix X1).

4.1.1 The gong cylinder, brackets, clapper rod, “U” bracket,

1.2 For consistency with International Regulations, all mea-

washers, and clapper support pin shall be of stainless steel, in

surements are in SI units.

accordance with Specification A167, UNS number S31600.

2. Referenced Documents 4.1.2 The clapper mass shall be of cast alloy steel in

2 accordance with Specification A276, UNS S31600.

2.1 ASTM Standards:

4.1.3 The support bolt, nut, flat washer, and cotter pins shall

A167 Specification for Stainless and Heat-Resisting

be of stainless steel compatible with the other materials.

Chromium-Nickel Steel Plate, Sheet, and Strip

4.2 Welding:

A276 Specification for Stainless Steel Bars and Shapes

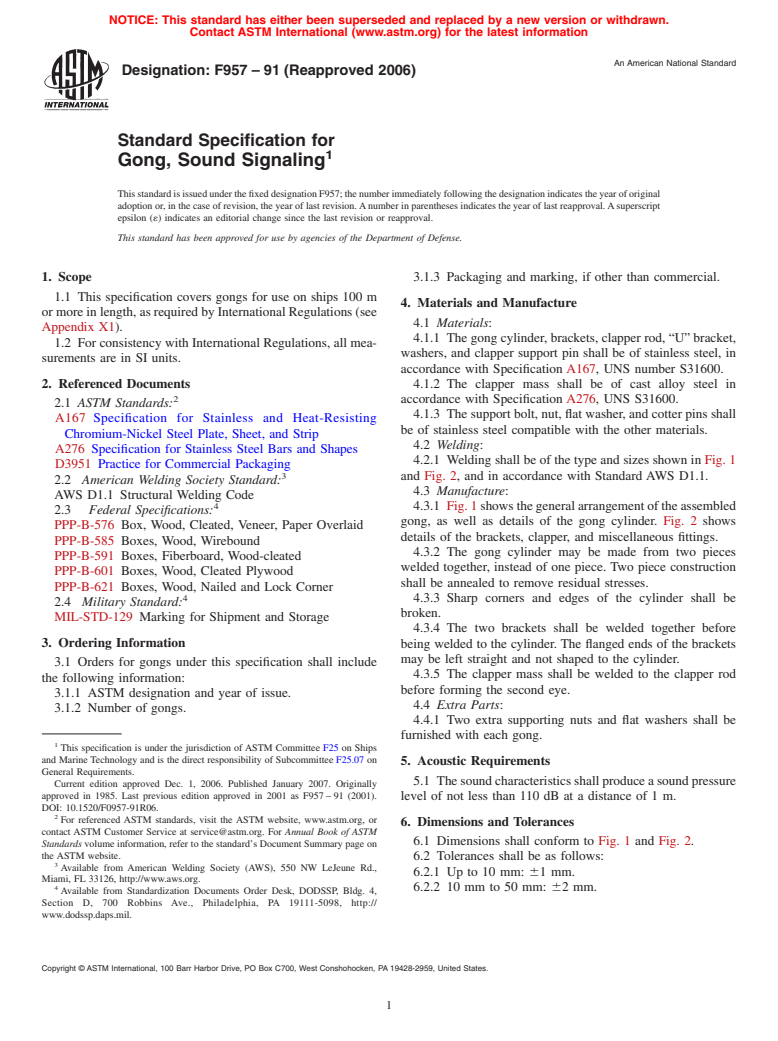

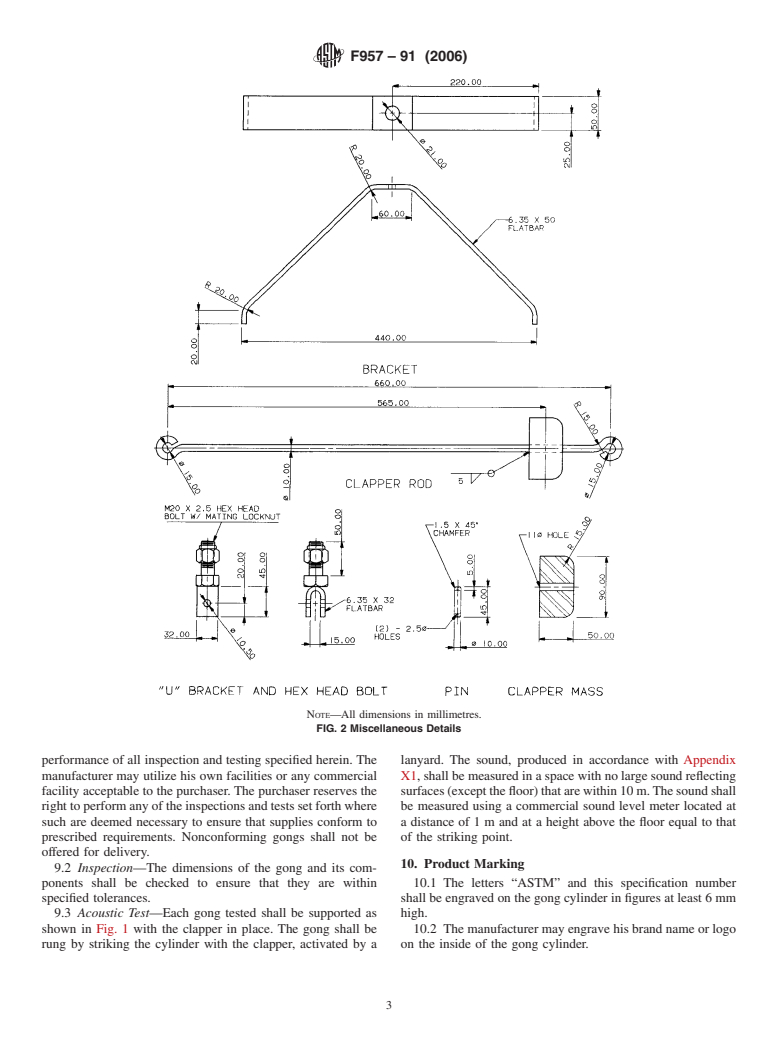

4.2.1 Welding shall be of the type and sizes shown in Fig. 1

D3951 Practice for Commercial Packaging

3

and Fig. 2, and in accordance with Standard AWS D1.1.

2.2 American Welding Society Standard:

4.3 Manufacture:

AWS D1.1 Structural Welding Code

4

4.3.1 Fig.1showsthegeneralarrangementoftheassembled

2.3 Federal Specifications:

gong, as well as details of the gong cylinder. Fig. 2 shows

PPP-B-576 Box, Wood, Cleated, Veneer, Paper Overlaid

details of the brackets, clapper, and miscellaneous fittings.

PPP-B-585 Boxes, Wood, Wirebound

4.3.2 The gong cylinder may be made from two pieces

PPP-B-591 Boxes, Fiberboard, Wood-cleated

welded together, instead of one piece. Two piece construction

PPP-B-601 Boxes, Wood, Cleated Plywood

shall be annealed to remove residual stresses.

PPP-B-621 Boxes, Wood, Nailed and Lock Corner

4 4.3.3 Sharp corners and edges of the cylinder shall be

2.4 Military Standard:

broken.

MIL-STD-129 Marking for Shipment and Storage

4.3.4 The two brackets shall be welded together before

3. Ordering Information

being welded to the cylinder. The flanged ends of the brackets

may be left straight and not shaped to the cylinder.

3.1 Orders for gongs under this specification shall include

4.3.5 The clapper mass shall be welded to the clapper rod

the following information:

before forming the second eye.

3.1.1 ASTM designation and year of issue.

4.4 Extra Parts:

3.1.2 Number of gongs.

4.4.1 Two extra supporting nuts and flat washers shall be

furnished with each gong.

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.07 on

5. Acoustic Requirements

General Requirements.

5.1 Thesoundcharacteristicsshallproduceasoundpressure

Current edition approved Dec. 1, 2006. Published January 2007. Originally

approved in 1985. Last previous edition approved in 2001 as F957 – 91 (2001).

level of not less than 110 dB at a distance of 1 m.

DOI: 10.1520/F0957-91R06.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6. Dimensions and Tolerances

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Dimensions shall conform to Fig. 1 and Fig. 2.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

6.2 Tolerances shall be as follows:

3

Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

6.2.1 Up to 10 mm: 61 mm.

Miami, FL 33126, http://www.aws.org.

4 6.2.2 10 mm to 50 mm: 62 mm.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F957 – 91 (2006)

NOTE—All dimensions in millimetres.

FIG. 1 Assembly of Gong

6.2.3 Over 50 mm: 63 mm. 8.2 For orders of 3 to 10 gongs, 2 gongs shall be selected at

random. If any one of them fails to meet requirements, then all

7. Workmanship, Finish, and Appearance

gongs in the order shall be inspected and tested.

7.1 Gongs shall be free from cracks, burrs, sharp cutting 8.3 For orders of more than 10 gongs, they shall be

edges, and other defects affecting their life, appearance, and

separated into groups of 10 (or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.