ASTM E1752-95(2000)e1

(Guide)Standard Guide for Collection of Multi-Media Field Emission and Discharge Data Associated with Glycol Dehydration Units (Withdrawn 2009)

Standard Guide for Collection of Multi-Media Field Emission and Discharge Data Associated with Glycol Dehydration Units (Withdrawn 2009)

SIGNIFICANCE AND USE

This guide on the proper collection of emission and discharge wastes from glycol dehydrators is applicable to any natural gas industry and supplier that operates glycol dehydration units and that needs to identify which glycol units may have emissions above regulatory levels.

The emission and discharge sampling methods discussed in this guide are not regulatory standards. Standard protocols have been developed by the Gas Research Institute (3) and other gas associations (4) and some state regulatory agencies such as the Louisiana Department of Environmental Quality (LDEQ) (5) and the Texas Natural Resource Conservation Commission (TNRCC) (6) are accepting these data. This guide is not intended to instruct the user on how to perform the sampling using these protocols, but to make the user aware of certain practical considerations generally associated with sampling these waste streams.

SCOPE

1.1 Purpose This guide covers the proper collection of field emission and discharge data associated with glycol dehydration units used in the natural gas production, processing, transmission, storage, and distribution industries.

1.2 Background:

1.2.1 Increasing regulatory pressure has made emissions of benzene, toluene, ethylbenzene, and xylene isomers (collectively known as BTEX) and volatile organic compounds (VOCs) from the still vent of glycol dehydration units a major concern of the natural gas industry. The Clean Air Act Amendments (CAAA) of 1990 have been the impetus for air toxics regulations, and several states are regulating or are considering regulating emissions from glycol units (1). Liquid and solid waste discharges are exempt from Subtitle C (hazardous waste) regulation under the Resource Conservation and Recovery Act (RCRA), but may be regulated in the future (2).

1.2.2 Measurement of the waste streams from dehydrators is important to determine which units may have emissions above levels of regulatory concern. Measurements of air emissions from glycol dehydration units have been made from a variety of sampling points using different sampling protocols and analytical techniques since no standard methods have been developed by the United States Environmental Protection Agency (USEPA) or state regulatory agencies. Standard sampling methods do not exist for the liquid and solid waste streams since they are exempt from RCRA Subtitle C. The lack of standard protocols has meant that variations of this approach can result in very different emissions measurements (3).

1.2.3 Providing guidance on the collection of field emission and discharge data will allow the natural gas industry to quantify emissions and apply appropriate controls to comply with regulations.

1.3 Summary--This guide has several parts and an annex. Section 1 is Scope. Section 2 is Terminology that has definitions of terms commonly used with relation to glycol dehydration units in the natural gas industry. Section 3 is Significance and Use of this guide. Section 4 is a process description of glycol dehydration units. Section 5 is a discussion of the waste streams associated with glycol dehydrators. Section 6 presents the Approaches for Collecting Air Emission Data, while Sections 7 and 8 present the approaches for collecting liquid and solid waste discharge data, respectively. The annex includes a standard operating procedure (SOP) for the rich/lean glycol sampling method discussed in this guide.

1.4 The values stated in either inch-pound or SI units are to be regarded separately as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This guide covers the proper collection of field emission and di...

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:E1752–95 (Reapproved 2000)

Standard Guide for

Collection of Multi-Media Field Emission and Discharge

Data Associated with Glycol Dehydration Units

This standard is issued under the fixed designation E 1752; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Subsections 6.3.4 and 7.2.5 were corrected editorially in November 2000.

1. Scope 1.3 Summary—This guide has several parts and an annex.

Section 1 is Scope. Section 2 is Terminology that has defini-

1.1 Purpose—This guide covers the proper collection of

tions of terms commonly used with relation to glycol dehydra-

field emission and discharge data associated with glycol

tion units in the natural gas industry. Section 3 is Significance

dehydration units used in the natural gas production, process-

and Use of this guide. Section 4 is a process description of

ing, transmission, storage, and distribution industries.

glycol dehydration units. Section 5 is a discussion of the waste

1.2 Background:

streams associated with glycol dehydrators. Section 6 presents

1.2.1 Increasing regulatory pressure has made emissions of

the Approaches for Collecting Air Emission Data, while

benzene, toluene, ethylbenzene, and xylene isomers (collec-

Sections 7 and 8 present the approaches for collecting liquid

tively known as BTEX) and volatile organic compounds

and solid waste discharge data, respectively. The annex in-

(VOCs) from the still vent of glycol dehydration units a major

cludes a standard operating procedure (SOP) for the rich/lean

concern of the natural gas industry. The Clean Air Act

glycol sampling method discussed in this guide.

Amendments (CAAA) of 1990 have been the impetus for air

1.4 The values stated in either inch-pound or SI units are to

toxics regulations, and several states are regulating or are

be regarded separately as the standard. The values given in

considering regulating emissions from glycol units(1). Liquid

parentheses are for information only.

and solid waste discharges are exempt from Subtitle C (haz-

1.5 This standard does not purport to address all of the

ardous waste) regulation under the Resource Conservation and

safety concerns, if any, associated with its use. It is the

RecoveryAct (RCRA), but may be regulated in the future (2).

responsibility of the user of this standard to establish appro-

1.2.2 Measurementofthewastestreamsfromdehydratorsis

priate safety and health practices and determine the applica-

important to determine which units may have emissions above

bility of regulatory limitations prior to use.

levels of regulatory concern. Measurements of air emissions

from glycol dehydration units have been made from a variety

2. Terminology

of sampling points using different sampling protocols and

2.1 Definitions of Terms Specific to This Standard:

analytical techniques since no standard methods have been

2.1.1 BTEX—the compounds benzene, toluene, ethylben-

developed by the United States Environmental Protection

zene, and xylene isomers.

Agency (USEPA) or state regulatory agencies. Standard sam-

2.1.2 Clean Air Act Amendments (CAAA)—the 1990 federal

pling methods do not exist for the liquid and solid waste

amendments to the Clean Air Act. These amendments address

streamssincetheyareexemptfromRCRASubtitleC.Thelack

nonattainment areas, hazardous air pollutants, permitting, and

ofstandardprotocolshasmeantthatvariationsofthisapproach

enforcement.

can result in very different emissions measurements (3).

2.1.3 condensate—water or light hydrocarbons that have

1.2.3 Providing guidance on the collection of field emission

changed from a vapor to a condensed liquid state.

and discharge data will allow the natural gas industry to

2.1.4 contactor (or absorber)—a vertical pressure vessel

quantify emissions and apply appropriate controls to comply

where gas and glycol are intermingled countercurrently to

with regulations.

remove water vapor from the gas.

2.1.5 dehdyration—removal of water vapor from natural

ThisguideisunderthejurisdictionofASTMCommitteeE50onEnvironmental

gas. Maximum water content of the dehydrated gas is normally

Assessment and is the direct responsibility of Subcommittee E50.05 on Wetland

7 lbs (3175 g) H O/MMSCF.

Ecosystems.

Current edition approved Oct. 10, 1995. Published December 1995.

The boldface numbers in parentheses refer to the list of references at the end of

the text.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1752

2.1.6 flashtank—atwo-orthree-phaseseparatorthatisused tion units and that needs to identify which glycol units may

in the rich glycol stream to remove entrained gas and hydro- have emissions above regulatory levels.

carbon liquid. 3.2 The emission and discharge sampling methods dis-

2.1.7 gas absorption—an operation in which a gas mixture cussed in this guide are not regulatory standards. Standard

is contacted with a liquid for the purposes of preferentially protocols have been developed by the Gas Research Institute

dissolving one or more components of the gas and to provide (3) and other gas associations (4) and some state regulatory

a solution of these in the liquid. agencies such as the Louisiana Department of Environmental

2.1.8 gas/glycol heat exchanger—a shell-and-tube, pipe-in- Quality (LDEQ) (5) and the Texas Natural Resource Conser-

pipe, or other type heat exchanger employed to cool the lean vation Commission (TNRCC) (6) are accepting these data.

glycol with the gas leaving the contactor before the glycol This guide is not intended to instruct the user on how to

enters the contactor. perform the sampling using these protocols, but to make the

2.1.9 glycol—a liquid desiccant used to absorb water vapor user aware of certain practical considerations generally asso-

from the gas. Triethylene glycol is the most common glycol ciated with sampling these waste streams.

used in natural gas dehydration.

2.1.10 lean glycol—glycol that has been regenerated and is 4. Process Description

essentially free of water.

4.1 Introduction— Glycol dehydration units are commonly

2.1.11 rich glycol—glycol that has absorbed water.

used in the natural gas industry to remove water from natural

2.1.12 reboiler—the vessel where water is boiled out of the

gas streams to prevent corrosion and hydrate formation in

glycol.

pipelines. Up to 40 000 glycol dehydration units may be in

2.1.13 resource conservation and recovery act (RCRA)—a

operation in the United States (7). TEG is commonly used as

federal regulatory measure for monitoring liquid and solid

the dehydrant since it is more stable than other glycols (for

waste discharges. Subtitle C of the RCRA, as amended by the

example, ethylene glycol) at high temperatures. A brief de-

1984 Hazardous and Solid Waste Amendments (HSWA) regu-

scription of a typical glycol dehydration unit is presented as

lations, provides EPA the statutory authority to adopt a

follows.

complex set of regulations for identification and management

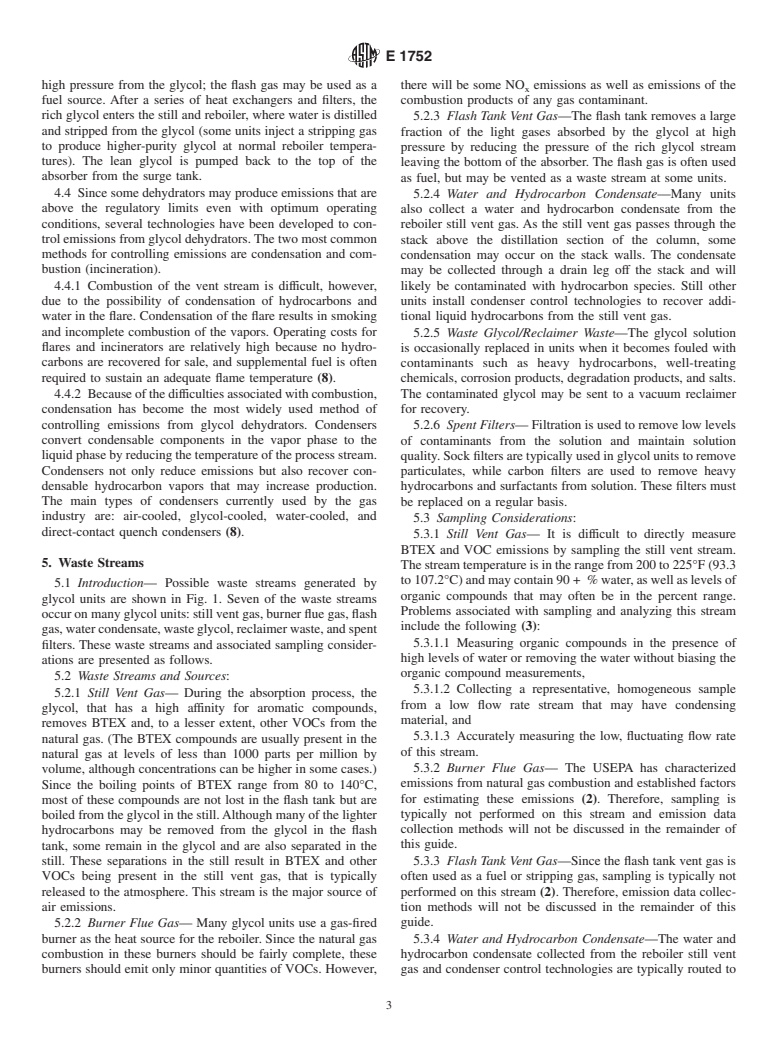

4.2 Fig. 1 is a simplified flow diagram for a glycol dehy-

of hazardous waste from “cradle to grave,” that is, from the

dration unit. A glycol dehydration unit usually consists of an

initialgenerationthroughthetreatment,transportation,storage,

absorber, a flash tank, heat exchanger(s), filter(s), a glycol

and disposal of wastes.

reboiler still, and associated pumping and piping equipment.

2.1.14 still column—vertically mounted fractionation col-

The moist natural gas enters the bottom of the absorber, where

umn on top of the reboiler.

it is contacted countercurrently with the cool, lean glycol that

absorbs the water. The dry gas exits the top of the absorber.

3. Significance and Use

4.3 The rich glycol (containing water) leaves the bottom of

3.1 This guide on the proper collection of emission and theabsorberandoftengoesthroughagas-drivenbalancepump

discharge wastes from glycol dehydrators is applicable to any to a flash tank, which is normally present only on larger units.

natural gas industry and supplier that operates glycol dehydra- Theflasktankseparatesmuchofthenaturalgascapturedunder

FIG. 1 Typical TEG Dehydrator Waste Streams

E1752

high pressure from the glycol; the flash gas may be used as a there will be some NO emissions as well as emissions of the

x

fuel source. After a series of heat exchangers and filters, the combustion products of any gas contaminant.

rich glycol enters the still and reboiler, where water is distilled

5.2.3 Flash Tank Vent Gas—The flash tank removes a large

and stripped from the glycol (some units inject a stripping gas

fraction of the light gases absorbed by the glycol at high

to produce higher-purity glycol at normal reboiler tempera-

pressure by reducing the pressure of the rich glycol stream

tures). The lean glycol is pumped back to the top of the

leaving the bottom of the absorber. The flash gas is often used

absorber from the surge tank.

as fuel, but may be vented as a waste stream at some units.

4.4 Since some dehydrators may produce emissions that are 5.2.4 Water and Hydrocarbon Condensate—Many units

above the regulatory limits even with optimum operating

also collect a water and hydrocarbon condensate from the

conditions, several technologies have been developed to con- reboiler still vent gas. As the still vent gas passes through the

trol emissions from glycol dehydrators.The two most common

stack above the distillation section of the column, some

methods for controlling emissions are condensation and com-

condensation may occur on the stack walls. The condensate

bustion (incineration).

may be collected through a drain leg off the stack and will

4.4.1 Combustion of the vent stream is difficult, however, likely be contaminated with hydrocarbon species. Still other

due to the possibility of condensation of hydrocarbons and units install condenser control technologies to recover addi-

water in the flare. Condensation of the flare results in smoking tional liquid hydrocarbons from the still vent gas.

and incomplete combustion of the vapors. Operating costs for 5.2.5 Waste Glycol/Reclaimer Waste—The glycol solution

flares and incinerators are relatively high because no hydro-

is occasionally replaced in units when it becomes fouled with

carbons are recovered for sale, and supplemental fuel is often contaminants such as heavy hydrocarbons, well-treating

required to sustain an adequate flame temperature (8).

chemicals, corrosion products, degradation products, and salts.

The contaminated glycol may be sent to a vacuum reclaimer

4.4.2 Becauseofthedifficultiesassociatedwithcombustion,

condensation has become the most widely used method of for recovery.

controlling emissions from glycol dehydrators. Condensers

5.2.6 Spent Filters— Filtration is used to remove low levels

convert condensable components in the vapor phase to the of contaminants from the solution and maintain solution

liquidphasebyreducingthetemperatureoftheprocessstream.

quality. Sock filters are typically used in glycol units to remove

Condensers not only reduce emissions but also recover con- particulates, while carbon filters are used to remove heavy

densable hydrocarbon vapors that may increase production.

hydrocarbons and surfactants from solution. These filters must

The main types of condensers currently used by the gas be replaced on a regular basis.

industry are: air-cooled, glycol-cooled, water-cooled, and

5.3 Sampling Considerations:

direct-contact quench condensers (8).

5.3.1 Still Vent Gas— It is difficult to directly measure

BTEX and VOC emissions by sampling the still vent stream.

5. Waste Streams

Thestreamtemperatureisintherangefrom200to225°F(93.3

to107.2°C)andmaycontain90 + %water,aswellaslevelsof

5.1 Introduction— Possible waste streams generated by

organic compounds that may often be in the percent range.

glycol units are shown in Fig. 1. Seven of the waste streams

Problems associated with sampling and analyzing this stream

occur on many glycol units: still vent gas, burner flue gas, flash

include the following (3):

gas,watercondensate,wasteglycol,reclaimerwaste,andspent

5.3.1.1 Measuring organic compounds in the presence of

filters. These waste streams and associated sampling consider-

high levels of water or removing the water without biasing the

ations are presented as follows.

organic compound measurements,

5.2 Waste Streams and Sources:

5.3.1.2 Collecting a representative, homogeneous sample

5.2.1 Still Vent Gas— During the absorption process, the

from a low flow rate stream that may have condensing

glycol, that has a high affinity for aromatic compounds,

material, and

removes BTEX and, to a lesser extent, other VOCs from the

5.3.1.3 Accurately measuring the low, fluctuating flow rate

natural gas. (The BTEX compounds are usually present in the

of this stream.

natural gas at levels of less than 1000 parts per million by

5.3.2 Burner Flue Gas— The USEPA has characterized

volume, although concentrations can be higher in some cases.)

emissions from natural gas combustion and established factors

Since the boiling points of BTEX range from 80 to 140°C,

for estimating these emissions (2). Therefore, sampling is

most of these compounds are not lost in the flash tank but are

boiled from the glycol in the still.Although many of the lighter typically not performed on this stream and emission data

collection methods will not be discussed in the remainder of

hydrocarbons may be removed from the glycol in the flash

tank, some remain in the glycol and are also separated in the this guide.

still. These separations in the still result in BTEX and other 5.3.3 Flash Tank Vent Gas—Since the flash tank vent gas is

VOCs being present in the still vent gas, that is typically often used as a fuel or stripping gas, sampling is typically not

released to the atmosphere. This stream is the major source of performed on this stream (2). Therefore, emission data collec-

air emissions. tion methods will not be discussed in the remainder of this

guide.

5.2.2 Burner Flue Gas— Many glycol units use a gas-fired

burner as the heat source for the reboiler. Since the natural gas 5.3.4 Water and Hydrocarbon Condensate—The water and

combustion in these burners should be fairly complete, these hydrocarbon condensate collected from the reboiler still vent

burners should emit only minor quantities of VOCs. However, gas and condenser control technologies are typically routed to

E1752

a three-phase separator (liquid hydrocarbon, water, and non- rol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.