ASTM E2851/E2851M-13(2021)

(Specification)Standard Specification for Ruggedness Requirements for HAZMAT Instrumentation

Standard Specification for Ruggedness Requirements for HAZMAT Instrumentation

ABSTRACT

This specification establishes the ruggedness requirements for equipment used in Hazardous Material (HAZMAT) instrumentation, including devices used to detect or monitor for hazardous material. It defines for design and test purposes the environment in which HAZMAT equipment will likely be exposed during storage, transport, and field use. Passive personal protective equipment such as respirators and protective suits are not covered. The specification addresses materials and manufacture, physical and mechanical properties, performance and environmental requirements, dimensions, mass and permissible variations, workmanship, and finish and appearance. Definitions of terms specific to this standard are provided, including body-worn, hand-carried, mobile, portable, and transportable.

SCOPE

1.1 This specification describes the ruggedness requirements for equipment used during Hazardous Material (HAZMAT) operations. The conditions defined by this specification include those related to equipment storage, transport, and field use.

1.2 This specification does not address passive personal protective equipment (PPE) such as respirators and protective suits.

1.3 The equipment addressed by this specification includes devices used to detect or monitor for hazardous material.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. When using a HAZMAT instrument, follow the manufacturer’s guidance and appropriate safety practices for the threat expected or suspected in the environment where the instrument will be used.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E2851/E2851M −13 (Reapproved 2021)

Standard Specification for

Ruggedness Requirements for HAZMAT Instrumentation

ThisstandardisissuedunderthefixeddesignationE2851/E2851M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 NFPA Standard:

1.1 This specification describes the ruggedness require-

National Fire Protection Association (NFPA) 1994, 2007

ments for equipment used during Hazardous Material

Edition Cold Temperature: -25°C (-13°F)

(HAZMAT) operations. The conditions defined by this speci-

2.2 ANSI Standards:

fication include those related to equipment storage, transport,

NA42.32 American National Standard Performance Criteria

and field use.

for Alarming Personal Radiation Detectors for Homeland

1.2 This specification does not address passive personal

Security

protective equipment (PPE) such as respirators and protective

N42.33 American National Standard for Portable Radiation

suits.

Detection Instrument for Homeland Security

N42.34 American National Standard for Performance Crite-

1.3 The equipment addressed by this specification includes

ria for Hand-Held Instruments for the Detection and

devices used to detect or monitor for hazardous material.

Identification of Radionuclides

1.4 The values stated in either SI units or inch-pound units

N42.35 American National Standard for Evaluation and

are to be regarded separately as standard. The values stated in Performance of Radiation Detection Portal Monitors for

each system may not be exact equivalents; therefore, each Use in Homeland Security

2.3 IEC Standards:

system shall be used independently of the other. Combining

IEC 60068-1 Environmental Testing—Part 1: General and

values from the two systems may result in non-conformance

Guidance

with the standard.

IEC 60068-2-18 Environmental Testing—Part 2-18: Tests—

1.5 This standard does not purport to address all of the

Test R and Guidance: Water

safety concerns, if any, associated with its use. It is the

IEC 60068-2-75 Environmental Testing—Part 2-75: Tests—

responsibility of the user of this standard to establish appro-

Tests Eh: Hammer Tests.

priate safety, health, and environmental practices and deter-

IEC 60529 Degrees of Protection Provided by Enclosures

mine the applicability of regulatory limitations prior to use.

(International Protection Rating or IP Code)

When using a HAZMAT instrument, follow the manufacturer’s

IEC61000-4-1 ElectromagneticCompatibility(EMC)—Part

guidance and appropriate safety practices for the threat

4-1: Testing and Measurement Techniques—Overview of

expected or suspected in the environment where the instrument

IEC 61000-4 Series

will be used.

IEC61000-4-2 ElectromagneticCompatibility(EMC)—Part

1.6 This international standard was developed in accor- 4-2: Testing and Measurement Techniques—Electrostatic

dance with internationally recognized principles on standard- Discharge Immunity Test

ization established in the Decision on Principles for the IEC61000-4-3 ElectromagneticCompatibility(EMC)—Part

Development of International Standards, Guides and Recom- 4-3: Testing and Measurement Techniques—Radiated,

Radio-Frequency, Electromagnetic Field Immunity Test

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 2.4 Underwriters Laboratories:

UL 2075 Gas and Vapor Detectors and Sensors

Available from National Fire Protection Association (NFPA), 1 Batterymarch

Park, Quincy, MA 02169-7471, http://www.nfpa.org.

1 3

This specification is under the jurisdiction of ASTM Committee E54 on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Homeland Security Applications and is the direct responsibility of Subcommittee 4th Floor, New York, NY 10036, http://www.ansi.org.

E54.01 on CBRNE Detection and Decontamination. Available from International Electrotechnical Commission (IEC), 3, rue de

Current edition approved Dec. 15, 2021. Published December 2021. Originally Varembé, P.O. Box 131, CH-1211 Geneva 20, Switzerland, http://www.iec.ch.

approved in 2013. Last previous edition approved in 2013 as E2851/E2851M – 13. Available from Underwriters Laboratories (UL), 2600 N.W. Lake Rd., Camas,

DOI: 10.1520/E2851_E2851M-13R21. WA 98607-8542, http://www.ul.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2851/E2851M−13 (2021)

2.5 Federal Standard: 5. Materials and Manufacture

MIL-Standard 810 Department of Defense Test Method

5.1 Materials resistant to extremes of temperature should be

Standard for Environmental Engineering Considerations

used in the manufacture of HAZMAT instrumentation.

and Laboratory Tests

7 5.2 Materials used in the manufacture of body-worn and

2.6 Code of Federal Regulations:

hand-carried equipment must not support combustion. They

CFR Telecommunications Chapter 1, Rule 15 Unintentional

should be self extinguishing if they do get hot enough to

Radiators

combust.

3. Terminology

5.3 Materials used in the manufacture of body-worn and

hand-carried equipment must not flow when melted.

3.1 Definitions:

3.1.1 body-worn—a HAZMAT instrument that typically

6. Physical Properties

weighs no more than 5.4 kg [12 lb] and is no larger than 65 cm

6.1 HAZMAT instrumentation should be built from strong,

(sum of the sides).

inert, weather-resistant materials with rugged finishes to with-

3.1.2 hand-carried—a HAZMAT instrument that typically

stand prolonged use in very harsh environments.

weighs no more than 2.3 kg [5 lb] and is no larger than 40 cm

6.2 HAZMATinstrumentation should resist the effects from

(sum of the sides).

and remain operational when exposed to the following:

3.1.3 installed—a HAZMAT instrument that is permanently

6.2.1 Saltwater, when used in coastal environments.

mounted at a location.

6.2.2 Temperatures as stated in Table 2 and Table 3, both

3.1.4 mobile—a HAZMAT instrument that is larger than a

natural and man-made.

man-portable, which is mounted to a mobile device to permit

6.2.3 Acidic chemicals found during fires and accidents.

relocation of the instrument as necessary for monitoring of

6.2.4 Caustic chemicals found during fires and accidents.

HAZMAT; the instrument may be operational while in motion.

7. Mechanical Properties

3.1.5 portable—a HAZMAT instrument that physically

weighsnomorethan16kg[35lb]andisnolargerthan120cm

7.1 Mechanical components of HAZMAT instrumentation

(sum of the sides).

shall be constructed so that they remain operational in their

3.1.6 transportable—a HAZMAT instrument that typically intended environment of use.

weighs no more than 22.7 kg [50 lb] and is no larger than

7.2 HAZMAT instrumentation shall be constructed so that

200 cm (sum of the sides).

they remain operational when exposed to the following condi-

tions:

3.2 A summary of the above can be found in Table 1.

7.2.1 Impacts from use and transport.

4. Purpose

7.2.2 Transport vibration.

7.2.3 Expansion or contraction due to hot or cold tempera-

4.1 The purpose of this specification is to define for design

tures.

and test purposes the environment in which HAZMAT equip-

7.2.4 Corrosion from harsh environments, that is, salt mist.

ment will likely be exposed during storage, transportation, and

use. The environments addressed by this specification are

8. Performance Requirements

related to equipment that are typically man-portable, body-

8.1 There is a broad spectrum between the different envi-

worn, hand-carried, transportable, mobile, or installed. This

ronmental conditions equipment are exposed to during storage

could include extremes that range from mid-winter Alaska to

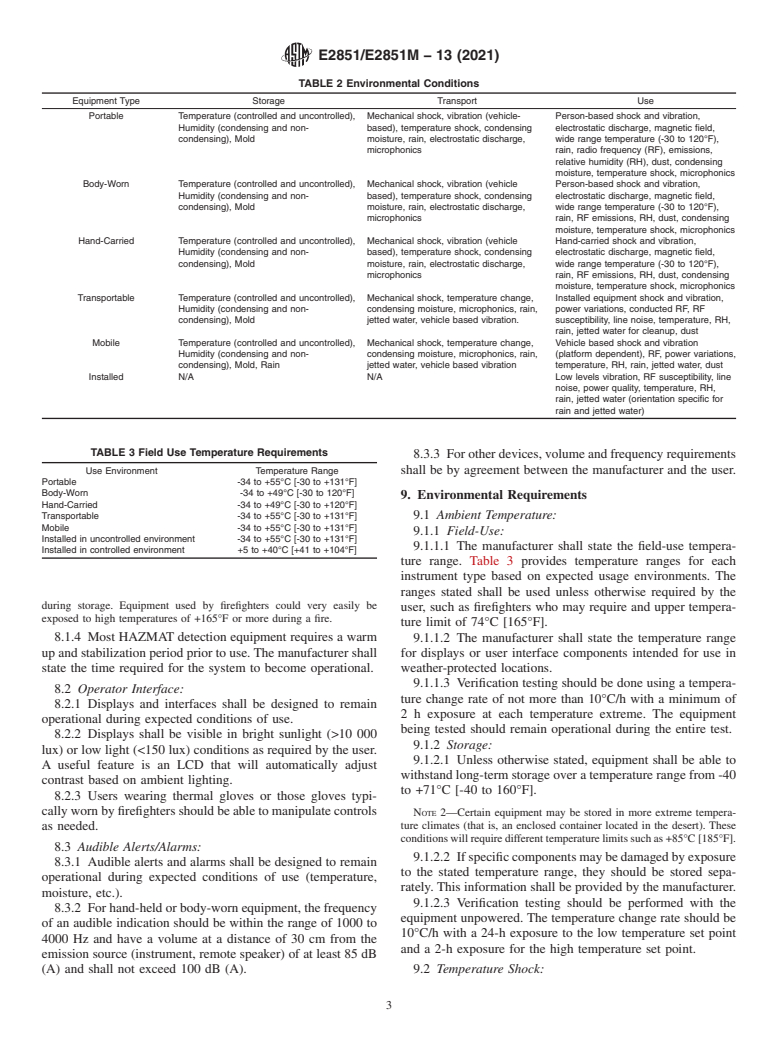

and use. Refer to Table 2 for specific environmental conditions

mid-summer Death Valley environments.

for each category of HAZMAT instrumentation.

8.1.1 HAZMAT equipment shall be operable in rain,

humidity, heat, and cold at the levels defined in this specifica-

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

tion. Environments could also include smoke, toxic chemicals

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

(for example, chlorine, ammonia), caustic chemicals, and

www.dodssp.daps.mil.

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

extreme heat. Meeting these requirements shall be by agree-

732 N. Capitol st., NW, Mail Stop: SDE, Washington, DC 20401, http://

ment between the manufacturer and the user.

www.access.gpo.gov.

8.1.2 Body-worn HAZMAT equipment should endure fire-

fighter environments (heat, water, smoke, cold) on a regular

TABLE 1 HAZMAT Instrumentation Size and Weight

basis.

A

Instrument Type Maximum Weight Maximum Size

8.1.3 Storage of HAZMAT equipment varies widely. Some

Sum of Sides in cm

in kg/lb

agencies store their HAZMAT equipment inside a temperature

Portable 16/35 120

controlled area while others use trucks or containers located in

Body-Worn 5.4/12 65

Hand-Carried 2.3/5 40

uncontrolled environments.

Transportable 22.7/50 200

Mobile No Limit No Limit

NOTE 1—Agencies surveyed regarding temperature and temperature

Installed No Limit No Limit

shock to HAZMAT equipment almost all agree that -30 to 120°F is an

A

appropriate operating range. This temperature range also encompasses

Not including attachments such as handles, nipples, filter cartridges, and hoses.

most of the extreme temperatures the equipment would be exposed to

E2851/E2851M−13 (2021)

TABLE 2 Environmental Conditions

Equipment Type Storage Transport Use

Portable Temperature (controlled and uncontrolled), Mechanical shock, vibration (vehicle- Person-based shock and vibration,

Humidity (condensing and non- based), temperature shock, condensing electrostatic discharge, magnetic field,

condensing), Mold moisture, rain, electrostatic discharge, wide range temperature (-30 to 120°F),

microphonics rain, radio frequency (RF), emissions,

relative humidity (RH), dust, condensing

moisture, temperature shock, microphonics

Body-Worn Temperature (controlled and uncontrolled), Mechanical shock, vibration (vehicle Person-based shock and vibration,

Humidity (condensing and non- based), temperature shock, condensing electrostatic discharge, magnetic field,

condensing), Mold moisture, rain, electrostatic discharge, wide range temperature (-30 to 120°F),

microphonics rain, RF emissions, RH, dust, condensing

moisture, temperature shock, microphonics

Hand-Carried Temperature (controlled and uncontrolled), Mechanical shock, vibration (vehicle Hand-carried shock and vibration,

Humidity (condensing and non- based), temperature shock, condensing electrostatic discharge, magnetic field,

condensing), Mold moisture, rain, electrostatic discharge, wide range temperature (-30 to 120°F),

microphonics rain, RF emissions, RH, dust, condensing

moisture, temperature shock, microphonics

Transportable Temperature (controlled and uncontrolled), Mechanical shock, temperature change, Installed equipment shock and vibration,

Humidity (condensing and non- condensing moisture, microphonics, rain, power variations, conducted RF, RF

condensing), Mold jetted water, vehicle based vibration. susceptibility, line noise, temperature, RH,

rain, jetted water for cleanup, dust

Mobile Temperature (controlled and uncontrolled), Mechanical shock, temperature change, Vehicle based shock and vibration

Humidity (condensing and non- condensing moisture, microphonics, rain, (platform dependent), RF, power variations,

condensing), Mold, Rain jetted water, vehicle based vibration temperature, RH, rain, jetted water, dust

Installed N/A N/A Low levels vibration, RF susceptibility, line

noise, power quality, temperature, RH,

rain, jetted water (orientation specific for

rain and jetted water)

TABLE 3 Field Use Temperature Requirements

8.3.3 Forotherdevices,volumeandfrequencyrequirements

Use Environment Temperature Range shall be by agreement between the manufacturer and the user.

Portable -34 to +55°C [-30 to +131°F]

Body-Worn -34 to +49°C [-30 to 120°F]

9. Environmental Requirements

Hand-Carried -34 to +49°C [-30 to +120°F]

Transportable -34 to +55°C [-30 to +131°F] 9.1 Ambient Temperature:

Mobile -34 to +55°C [-30 to +131°F]

9.1.1 Field-Use:

Installed in uncontrolled environment -34 to +55°C [-30 to +131°F]

9.1.1.1 The manufacturer shall state the field-use tempera-

Installed in controlled environment +5 to +40°C [+41 to +104°F]

ture range. Table 3 provides temperature ranges for each

instrument type based on expected usage environments. The

ranges stated shall be used unless otherwise required by the

during storage. Equipment used by firefighters could very easily be

user, such as firefighters who may require and upper tempera-

exposed to high temperatures of +165°F or more during a fire.

ture limit of 74°C [165°F].

8.1.4 Most HAZMAT detection equipment requires a warm 9.1.1.2 The manufacturer shall state the temperature range

up and stabilization period prior to use.The manufacturer shall for displays or user interface components intended for use in

state the time required for the system to become operational. weather-protected locations.

9.1.1.3 Verification testing should be done using a tempera-

8.2 Operator Interface:

ture change rate of not more than 10°C/h with a minimum of

8.2.1 Displays and interfaces shall be designed to remain

2 h exposure at each temperature extreme. The equipment

operational during expected conditions of use.

being tested should remain operational during the entire test.

8.2.2 Displays shall be visible in bright sunlight (>10 000

9.1.2 Storage:

lux) or low light (<150 lux) conditions as required by the user.

9.1.2.1 Unless otherwise stated, equipment shall be able to

A useful feature is an LCD that will automatically adjust

withstand long-term storage over a temperature range from -40

contrast based on ambient lighting.

to +71°C [-40 to 160°F].

8.2.3 Users wearing thermal gloves or those gloves typi-

cally worn by firefighters should be able to manipulate controls

NOTE 2—Certain equipment may be stored in more extreme tempera-

ture climates (that is, an enclosed container located in the desert). These

as needed.

conditionswillrequiredifferenttemperaturelimitssuchas+85°C[185°F].

8.3 Audible Alerts/Alarms:

9.1.2.2 Ifspecificcomponentsmaybedamagedbyexposure

8.3.1 Audible alerts and alarms shall be designed to remain

to the stated temperature range, they should be stored sepa-

operational du

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.