ASTM D1186-93

(Test Method)Standard Test Methods for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to a Ferrous Base

Standard Test Methods for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to a Ferrous Base

SCOPE

1.1 These test methods cover the nondestructive measurement of the dry film thickness of nonmagnetic coatings applied over a ferrous base material using commercially available test instruments. The test methods cover the use of instruments based on magnetic measuring principles only. Test Method A provides for the measurement of films using magnetic pull-off gages and Test Method B provides for the measurement of films using magnetic flux gages.

1.2 These test methods are not applicable to coatings that will be readily deformable under the load of the measuring instruments, as the instrument probe must be placed directly on the coating surface to take a reading.

1.3 The values given in SI units of measurement are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1186 – 93

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Methods for

Nondestructive Measurement of Dry Film Thickness of

1

Nonmagnetic Coatings Applied to a Ferrous Base

This standard is issued under the fixed designation D 1186; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope SSPC-PA2 Measurement of Dry Paint Thickness with Mag-

3

netic Gages

1.1 These test methods cover the nondestructive measure-

ment of the dry film thickness of nonmagnetic coatings applied

TEST METHOD A—MAGNETIC PULL-OFF GAGES

over a ferrous base material using commercially available test

instruments. The test methods cover the use of instruments

3. Summary of Test Method

based on magnetic measuring principles only. Test Method A

3.1 Instruments complying with this test method measure

provides for the measurement of films using magnetic pull-off

thickness by using a spring calibrated to determine the force

gages and Test Method B provides for the measurement of

required to pull a permanent magnet from a ferrous base coated

films using magnetic flux gages.

with a nonmagnetic film. The instrument must be placed

1.2 These test methods are not applicable to coatings that

directly on the coating surface to take a reading.

will be readily deformable under the load of the measuring

3.2 The attractive force of the magnet to the substrate varies

instruments, as the instrument probe must be placed directly on

inversely with the thickness of the applied film. The spring

the coating surface to take a reading.

tension required to overcome the attraction of the magnet to the

1.3 This standard does not purport to address all of the

substrate is shown on the instrument scale as the distance (in

safety problems, if any, associated with its use. It is the

mils or micrometres) between the magnet and the substrate.

responsibility of the user of this standard to establish appro-

3.3 It should be recognized that the accuracy of the mea-

priate safety and health practices and determine the applica-

surements can be influenced when measurements are made

bility of regulatory limitations prior to use.

closer than 1 in. (25 mm) to an edge.

2. Referenced Documents

4. Significance and Use

2.1 ASTM Standards:

4.1 After calibrating the instrument using shims of known

D 609 Practice for Preparation of Cold-Rolled Steel Panels

thickness and either a bare part of the metal object or metal of

for Testing Paint, Varnish, Conversion Coatings, and

the same kind, the instrument magnet (or metal foot) is placed

2

Related Coating Products

in contact with the coated metal in the manner described in

D 823 Practices for Producing Films of Uniform Thickness

12.1. The results of many test methods applicable to coatings

2

of Paint, Varnish, and Related Products on Test Panels

are markedly affected by the film thickness of the dry film,

D 1005 Test Method for Measurement of Dry-Film Thick-

some examples being adhesion, flexibility, and hardness to

2

ness of Organic Coatings Using Micrometers

name a few. To be able to compare results obtained by different

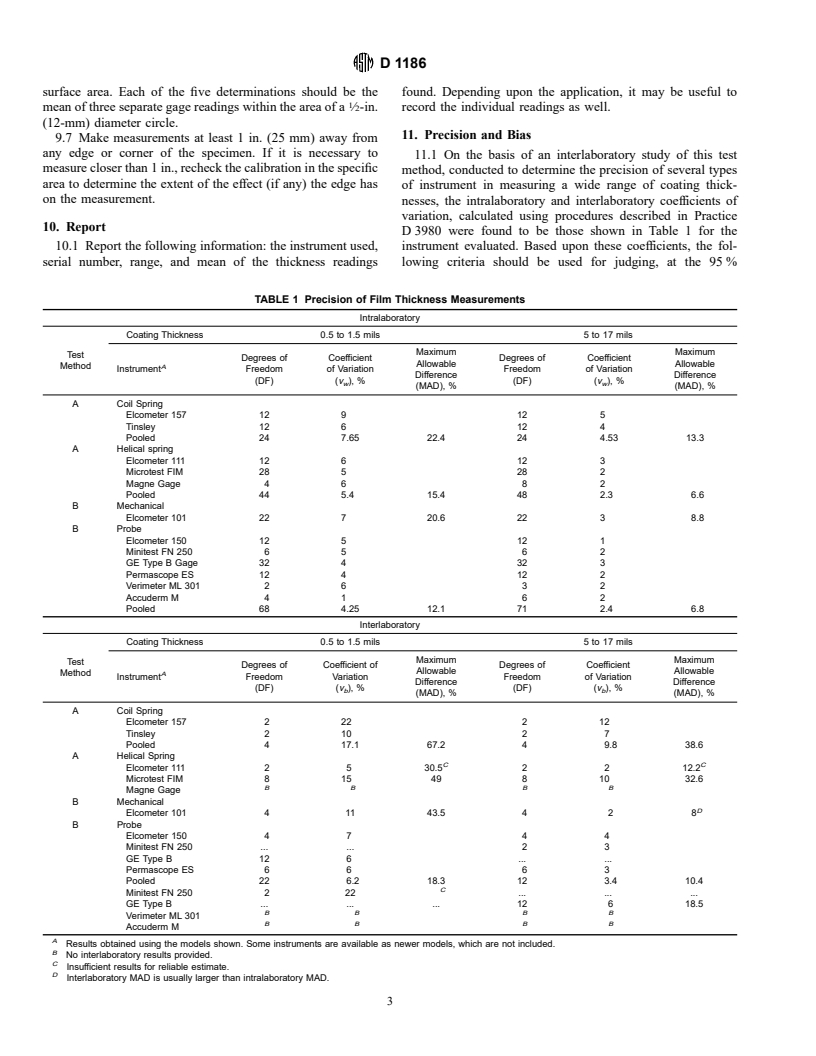

D 3980 Practice for Interlaboratory Testing of Paint and

operators, it is essential to measure film thickness closely.

2

Related Materials

4.2 Most protective and high performance coatings are

2.2 Steel Structures Painting Council Standard:

applied to meet a requirement or a specification for the dry-film

thickness of each coat, or for the complete system, or both.

Coatings must be applied within certain minimum and maxi-

mum thickness tolerances in order that they can fulfill their

intended function. In addition to potential performance defi-

1

These test methods are under the jurisdiction of ASTM Committee D-1 on Paint

ciencies, it is uneconomical to apply more material than

and Related Coatings, Materials, and Applications and are the direct responsibility

of Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved Oct. 15, 1993. Published December 1993. Originally

3

published as D 1186 – 51. Last previous edition D 1186 – 87. Available from Steel Structures Painting Council, 4516 Henry St., Pittsburgh,

2

Annual Book of ASTM Standards, Vol 06.01. PA 15213.

1

---------------------- Page: 1 ----------------------

D 1186

necessary when coating large areas such as metal structures 7.4 Lay a calibration shim on the bare, uncoated substrate

and coils. This test method is used

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.