ASTM D1403-97

(Test Method)Standard Test Methods for Cone Penetration of Lubricating Grease Using One-Quarter and One-Half Scale Cone Equipment

Standard Test Methods for Cone Penetration of Lubricating Grease Using One-Quarter and One-Half Scale Cone Equipment

SCOPE

1.1 These test methods cover two procedures for measuring the consistency of small samples of lubricating greases by penetration of a 1/4-scale cone or a 1/2-scale cone. These test methods include procedures for the measurement of unworked and worked penetrations.

1.2 Unworked penetrations do not generally represent the consistency of greases in use as effectively as do worked penetrations. The latter are usually preferred for inspecting lubricating greases.

1.3 The values in SI units are to be regarded as the standard. The values given in parentheses are for information only. In the United States, the equipment dimensions stated in inches are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 1403 – 97

Designation: 310/84 (92)

Standard Test Methods for

Cone Penetration of Lubricating Grease Using One-Quarter

and One-Half Scale Cone Equipment

This standard is issued under the fixed designation D 1403; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method has been approved by the sponsoring committee and accepted by the cooperating societies in accordance with

established procedures.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope IP 50 Method of Testing for Cone Penetration of Lubricat-

ing Grease

1.1 These test methods cover two procedures for measuring

the consistency of small samples of lubricating greases by

3. Terminology

1 1

penetration of a ⁄4-scale cone or a ⁄2-scale cone. These test

3.1 Definitions:

methods include procedures for the measurement of unworked

3.1.1 lubricating grease, n—a semi-fluid to solid product of

and worked penetrations.

a dispersion of a thickener in a liquid lubricant.

1.2 Unworked penetrations do not generally represent the

3.1.1.1 Discussion—The dispersion of the thickener forms a

consistency of greases in use as effectively as do worked

two-phase system and immobilizes the liquid lubricant by

penetrations. The latter are usually preferred for inspecting

surface tension and other physical forces. Other ingredients

lubricating greases.

imparting special properties are often included. D 217

1.3 The values in SI units are to be regarded as the standard.

3.1.2 lubricant, n—any material interposed between two

The values given in parentheses are for information only. In the

surfaces that reduces the friction or wear between them.

United States, the equipment dimensions stated in inches are to

D 4175

be regarded as the standard.

3.1.3 penetrometer, n—an instrument that measures the

1.4 This standard does not purport to address all of the

consistency or hardness of semiliquid to semisolid materials by

safety concerns, if any, associated with its use. It is the

measuring the depth to which a specified cone or needle under

responsibility of the user of this standard to establish appro-

a given force falls into the material.

priate safety and health practices and determine the applica-

3.1.3.1 Discussion—In these test methods, either a one-

bility of regulatory limitations prior to use.

quarter scale cone (A1.1) or a one-half scale cone (A1.3) can

2. Referenced Documents be used to determine the consistency of lubricating greases.

The penetration forces are determined by the respective masses

2.1 ASTM Standards:

of the cones and shafts.

D 217 Test Methods for Cone Penetration of Lubricating

3.1.4 thickener, n—in lubricating grease, a substance com-

Grease

posed of finely divided particles dispersed in a liquid lubricant

D 4175 Terminology Relating to Petroleum, Petroleum

to form the product’s structure.

Products, and Lubricants

3.1.4.1 Discussion—The thickener can be fibers (such as

2.2 IP Standard:

various metallic soaps) or plates or spheres (such as certain

non-soap thickeners) which are insoluble or, at the most, only

very slightly soluble in the liquid lubricant. The general

This test method is under the jurisdiction of ASTM Committee D-2 on requirements are that the solid particles be extremely small,

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

uniformly dispersed, and capable of forming a relatively stable,

D02.G on Lubricating Grease. In the IP, this test method is under the jurisdiction of

gel-like structure with the liquid lubricant. D 217

the Standardization Committee.

3.1.5 consistency, n—of lubricating grease, the degree of

Current edition approved Nov. 10, 1997. Published June 1998. Originally

published as D 1403 – 56 T. Last previous edition D 1403 – 96.

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 05.02.

IP Methods for Analysis and Testing available from 61 New Cavendish St.,

London, England WIM 8AR.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 1403

resistance to movement under stress. 6.2 ⁄4-Scale Cone and Shaft, as specified in Annex A1.1.

3.1.5.1 Discussion—The term consistency is used some- 6.3 ⁄4-Scale Grease Worker, as specified in Annex A1.2.

what synonymously with penetration. Generally, consistency 6.4 ⁄2-Scale Cone and Shaft, as specified in Annex A1.3.

refers to the worked penetration of a grease. D 217 6.5 ⁄2-Scale Grease Worker, as specified in Annex A1.4.

3.2 Definitions of Terms Specific to This Standard: 6.6 Temperature Bath, either a water bath or an airbath,

3.2.1 penetration, n—of lubricating grease, the depth in capable of regulating to 25 6 0.5°C (77 6 1°F) and designed

1 1

units of 0.1 mm that a ⁄4-scale cone or ⁄2-scale cone penetrates to bring the assembled grease worker to test temperature

the sample when released to fall under its own weight for 5 s. conveniently. If a water bath is to be used for specimens for

3.2.1.1 Discussion—The term penetration used in these test unworked penetration, means should be provided for protect-

methods is similar to that found in Test Methods D 217. Due to ing the grease surface from water and for maintaining the air

the differences in scale, the terms are not synonymous and above the specimen at test temperature.

should not be confused.

NOTE 2—A constant-temperature test room can also be used instead of

3.2.2 working, v—the subjection of a lubricating grease to

the water or air bath.

1 1

the shearing action of the ⁄4-scale or ⁄8-scale grease worker.

6.7 Spatula, corrosion-resistant, having a stiff blade 13 mm

3.2.3 unworked penetration, n—the penetration at 25°C

(0.5 in.) wide and convenient in length.

(77°F) of a sample of lubricating grease that has received only

1 1

minimum disturbance in transfer to a ⁄4-scale or ⁄8-scale

7. Procedure for Unworked Penetration

grease worker cup or dimensionally equivalent rigid container.

7.1 Sample—Sufficient sample to overfill the cup of the

3.2.4 worked penetration, n—the penetration of a sample of

grease worker is required. If the penetration by ⁄4 scale is

lubricating grease that has been brought to 25°C (77°F),

greater than 47 units or by ⁄2 scale greater than 97 units, at

1 1

subjected to 60 double strokes in a ⁄4-scale or ⁄8-scale grease

least three times the amount needed to fill the cup is required

worker, and penetrated without delay.

as only one result can be obtained from one filling of the grease

3.2.5 penetrometer, n—an instrument similar to that shown

cup.

in Fig. 1 of Test Methods D 217, designed to measure the depth

7.2 Preparing Sample for Measurement—Place the empty

1 1

to which the ⁄4-scale or the ⁄2-scale cone falls into grease.

grease worker cup and an appropriate amount of the sample in

a container in the temperature bath maintained at 25°C (77°F)

4. Summary of Test Method

for sufficient time to bring the temperature of the sample and

4.1 The penetration is determined at 25°C (77°F) by releas-

the worker cup to 25 6 0.5°C (77 6 1°F). Transfer the sample,

1 1

ing the ⁄4-scale or ⁄8-scale cone assembly from the penetrom-

preferably in one lump, to overfill the cup of the grease worker.

eter and allowing the cone to drop freely into the grease for 5

Make this transfer in such a manner that the grease will be

s.

worked as little as possible. Jar the cup to drive out trapped air

and pack the grease with the spatula, with as little manipulation

5. Significance and Use

as possible to fill the cup without air pockets. Scrape off the

5.1 These test methods are applicable to greases of National

excess grease extending above the rim by moving the blade of

Lubricating Grease Institute (NLGI) consistency numbers 0 to

the spatula, held inclined toward the direction of motion at an

4 and is intended for use only where the size of the sample

angle of 45°, across the rim of the cup. Do not perform any

prevents the use of Test Methods D 217.

further leveling or smoothing of the surface throughout the

5.2 Actual reduced-scale penetration values are not used or

determination of unworked penetration and determine the

reported. They are converted to full-scale penetration values

measurement immediately.

(see Sections 9 and 10). This test method is not intended to

7.3 Cleaning Cone and Shaft—Clean the penetrometer cone

replace the full-scale penetration as described in Test Methods

carefully before each test. Bending of the cone shaft can be

D 217. Precision is better in the full-scale penetration method.

avoided by holding it securely in its raised position while

5.3 Worked penetration results, after conversion to full-

cleaning. Do not permit grease or oil on the penetrometer shaft,

scale values, may be used to establish the consistency of

as they can cause drag on the shaft assembly. Do not rotate the

lubricating greases within the above NLGI consistency num-

cone, as this can cause wear on the release mechanism.

bers. The results obtained from these test methods are widely

7.4 Penetration Measurement—Place the cup on the pen-

used for specification purposes, however, no correlation with

etrometer table, making certain that it cannot teeter. Set the

field performance has been established.

mechanism to hold the cone in the zero position of the indicator

5.4 Unworked penetration results provide a means of evalu-

dial, and adjust the apparatus carefully so that the tip of the

ating the effect of storage conditions on grease consistency.

cone just touches the surface at the center of the test sample.

6. Apparatus Watching the shadow of the cone tip is an aid to accurate

setting. Release the cone shaft rapidly, and allow it to drop for

6.1 Penetrometer—An instrument similar to that shown in

1 5.0 6 0.1 s. The release mechanism should not drag on the

Fig. 1 of Test Methods D 217, adapted for use with the ⁄4-scale

shaft. Gently depress the indicator shaft until stopped by the

or ⁄8-scale cone.

cone shaft and read the penetration to the nearest full unit (0.1

NOTE 1—Any slight binding in the instrument may produce a signifi-

mm) from the indicator.

cant error in penetration values. Periodic check of the release mechanism,

cone dimensions, and weights of cone and its movable attachments is NOTE 3—If the indicator shaft is depressed with force, the penetration

recommended. measurement may vary considerably.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 1403

7.4.1 If the specimen has a penetration over 47 units by ⁄4 in succession on the same specimen. Return to the cup the

scale or over 97 units by ⁄2 scale, this specimen can then be portion previously removed with the spatula, then repeat the

used for only one test. If the specimen has a penetration of 47 operations described in 8.3 and 8.4. Report the average of the

1 1 1 1

units or less by ⁄4 scale or 97 units or less by ⁄2 scale, perform three tests, to the nearest 0.1 mm, as the ⁄4-scale or ⁄2-scale

three tests in a single cup spacing these tests on three radii 120° worked penetration of the sample.

apart and midway between the center and side of the cup so

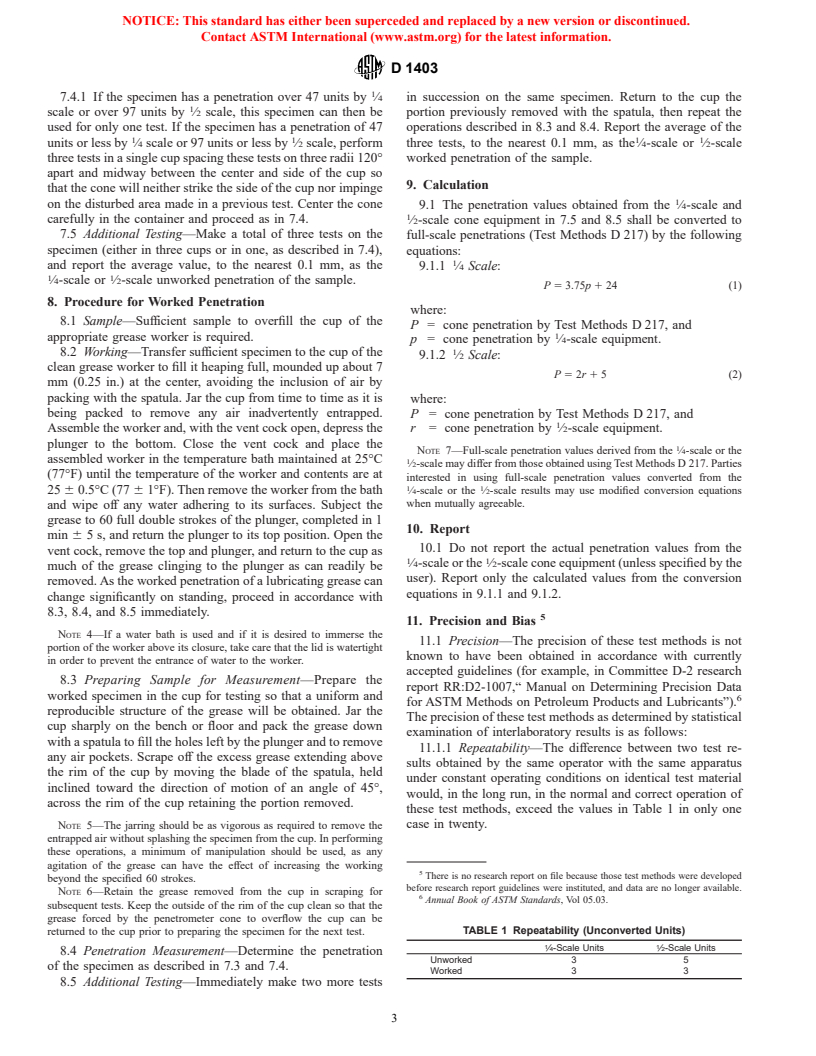

9. Calculation

that the cone will neither strike the side of the cup nor impinge

on the disturbed area made in a previous test. Center the cone

9.1 The penetration values obtained from the ⁄4-scale and

carefully in the container and proceed as in 7.4. ⁄2-scale cone equipment in 7.5 and 8.5 shall be converted to

7.5 Additional Testing—Make a total of three tests on the

full-scale penetrations (Test Methods D 217) by the following

specimen (either in three cups or in one, as described in 7.4), equations:

and report the average value, to the nearest 0.1 mm, as the

9.1.1 ⁄4 Scale:

1 1

⁄4-scale or ⁄2-scale unworked penetration of the sample.

P 5 3.75p 1 24 (1)

8. Procedure for Worked Penetration

where:

8.1 Sample—Sufficient sample to overfill the cup of the

P = cone penetration by Test Methods D 217, and

appropriate grease worker is required.

p = cone penetration by ⁄4-scale equipment.

8.2 Working—Transfer sufficient specimen to the cup of the 1

9.1.2 ⁄2 Scale:

clean grease worker to fill it heaping full, mounded up about 7

P 5 2r 1 5 (2)

mm (0.25 in.) at the center, avoiding the inclusion of air by

packing with the spatula. Jar the cup from time to time as it is

where:

being packed to remove any air inadvertently entrapped.

P = cone penetration by Test Methods D 217, and

r = cone penetration by ⁄2-scale equipment.

Assemble the worker and, with the vent cock open, depress the

plunger to the bottom. Close the vent cock and place the

NOTE 7—Full-scale penetration values derived from the ⁄4-scale or the

assembled worker in the temperature bath maintained at 25°C

⁄2-scale may differ from those obtained using Test Methods D 217. Parties

(77°F) until the temperature of the worker and contents are at

interested in using full-scale penetration values converted from the

1 1

25 6 0.5°C (77 6 1°F). Then remove the worker from the bath ⁄4-scale or the ⁄2-scale results may use modified conversion equations

when mutually agreeable.

and wipe off any water adhering to its surfaces. Subject the

grease to 60 full double strokes of the plunger, completed in 1

10. Report

min 6 5 s, and return the plunger to its top position. Open the

10.1 Do not report the actual penetration values from the

vent cock, remove the top and plunger, and return to the cup as

1 1

⁄4-scale or the ⁄2-scale cone equipment (unless specified by the

much of the grease clinging to the plunger as can readily be

user). Report only the calculated values from the conversion

removed. As the worked penetration of a lubricating grease can

equations in 9.1.1 and 9.1.2.

change significantly on standing, proceed in accordance with

8.3, 8.4, and 8.5 immediately.

11. Precision and Bias

NOTE 4—If a water bath is used and if it is desired to immerse the

11.1 Precision—The precision of these test methods is not

portion of the worker above its closure, take care that the lid is watertight

known to have been obtained in accordance with currently

in order to prevent the entrance of water to the worker.

accepted guidelines (for example, in Committee D-2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.