ASTM F1717-96

(Test Method)Standard Test Methods for Spinal Implant Constructs in a Vertebrectomy Model

Standard Test Methods for Spinal Implant Constructs in a Vertebrectomy Model

SCOPE

1.1 These test methods cover the materials and methods for the static and fatigue testing of spinal implant assemblies in a vertebrectomy model. The test materials for most combinations of spinal implant components can be specific depending on the intended spinal location and intended method of application to the spine.

1.2 These test methods are intended to provide a basis for the mechanical comparison among past, present, and future spinal implant assemblies. They allow comparison of spinal implant constructs with different intended spinal locations and methods of application to the spine. These test methods are not intended to define levels of performance, since sufficient knowledge is not available to predict the consequences of the use of a particular device.

1.3 These test methods set out guidelines for load types and methods of applying loads. Methods for three static load types and one fatigue test are defined for the comparative evaluation of spinal implant assemblies.

1.4 These test methods establish guidelines for measuring displacements, determining the yield load, and evaluating the stiffness and strength of the spinal implant assembly.

1.5 Some spinal constructs may not be testable in all test configurations.

1.6 Values stated in SI units are to be regarded as standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1717 – 96

Standard Test Methods for

Static and Fatigue for Spinal Implant Constructs in a

Corpectomy Model

This standard is issued under the fixed designation F 1717; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ized Stress-Life (S-N) and Strain-Life (e-N) Fatigue Data

E 1150 Definitions of Terms Relating to Fatigue

1.1 This standard covers the materials and methods for the

F 1582 Terminology Relating to Spinal Implants

static and fatigue testing of spinal implant assemblies in a

corpectomy model. The test materials for most combinations of

3. Terminology

spinal implant components can be specific depending on the

3.1 Definitions:

intended spinal location and intended method of application to

3.1.1 For definitions of terms relating to the test method, see

the spine.

Terminology E 6, Terminology F 1582 and Definitions E 1150.

1.2 This standard is intended to provide a basis for the

3.2 Definitions of Terms Specific to This Standard:

mechanical comparison among past, present and future spinal

3.2.1 active length of the longitudinal element—the straight

implant assemblies. It allows comparison of spinal implant

line distance between the center of attachment of the superior

constructs with different intended spinal locations and methods

anchor and the center of attachment of the inferior anchor.

of application to the spine. These test methods are not intended

3.2.2 angular displacement at 2 % offset yield (degrees)—

to define levels of performance, since sufficient knowledge is

the angular displacement of a construct measured via the

not available to predict the consequences of the use of a

actuator that produces a permanent angular displacement in the

particular device.

X-Y plane equal to 0.020 times the torsional aspect ratio (see

1.3 The standard sets out guidelines for load types and

Point A in Fig. 1).

methods of applying loads. Methods for three static load types

3.2.3 block moment arm—the perpendicular to the applied

and one fatigue test are defined for the comparative evaluation

load between the insertion point of an anchor and the axis of

of spinal implant assemblies.

the hidge pin.

1.4 This standard establishes guidelines for measuring dis-

3.2.4 compressive or tensile bending stiffness (N/mm)—the

placements, determining the yield load, evaluating the stiffness

compressive or tensile bending yield force divided by elastic

and strength of the spinal implant assembly.

displacement (see the initial slope of line BC in Fig. 1).

1.5 Some spinal constructs may not be testable in all test

3.2.5 compressive or tensile bending ultimate load (N)—the

configurations.

maximum compressive or tensile force in X-Z plane applied to

1.6 Values stated in SI units are to be regarded as standard.

a spinal implant assembly (see the force at Point E in Fig. 1).

1.7 This standard does not purport to address all of the

The ultimate load should be a function of the device and not of

safety concerns, if any, associated with its use. It is the

the load cell or testing machine.

responsibility of the user of this standard to establish appro-

3.2.6 compressive or tensile bending yield load (N)—the

priate safety and health practices and determine the applica-

compressive or tensile bending force in X-Z plane necessary to

bility of regulatory limitations prior to use.

produce a permanent deformation equal to 0.020 times the

2. Referenced Documents active length of the longitudinal element (see the force at Point

D in Fig. 1).

2.1 ASTM Standards:

3.2.7 coordinate system/axes—three orthogonal axes are

D 638 Test Method for Tensile Properties of Plastic

3 defined in Fig. 2 and Fig. 3. The anterior-posterior axis is X

E 4 Practices for Force Verification of Testing Machines

with positive being anterior. The medial-lateral axis is Y with

E 6 Terminology Relating to Methods of Mechanical Test-

3 left being positive when viewed posteriorly. The superior-

ing

inferior axis is Z with superior being positive.

E 739 Practice for Statistical Analysis of Linear or Linear-

3.2.8 displacement at 2 % offset yield (mm)—the displace-

ment of a construct measured via the actuator that produces a

These test methods are under the jurisdiction of ASTM Committee F-4 on

permanent deformation equal to 0.020 times the active length

Medical and Surgical Materials and Devices and are the direct responsibility of

of the longitudinal element (see Point A in Fig. 1).

Subcommittee F04.25on Spinal Devices.

Current edition approved June 10, 1996. Published December 1996.

Annual Book of ASTM Standards, Vol 08.01.

3 4

Annual Book of ASTM Standards, Vol 03.01. Annual Book of ASTM Standards, Vol 13.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1717

FIG. 2 A Standard Bilateral Construct Containing Screw, Rod and

Screw

FIG. 1 Typical Load Displacement Curve or Torque Angulation

Curve

3.2.9 elastic angular displacement (degrees)—the angular

displacement at 2 % offset yield (see Point A in Fig. 1) minus

the 2 % offset angular displacement (see Point B in Fig. 1).

(The distance between Point A and Point B in Fig. 1.)

3.2.10 elastic displacement (mm)—the displacement at 2 %

offset yield (see Point A in Fig. 1) minus the 2 % offset

displacement (see Point B in Fig. 1). (The distance between

Point A and Point B in Fig. 1.)

3.2.11 failure—permanent deformation resulting from frac-

ture, plastic deformation or loosening beyond the ultimate

displacement or loosening that renders the spinal implant

assembly ineffective or unable to adequately resist load.

3.2.12 fatigue life—the number of loading cycle, N,ofa

specified character that the spinal implant assembly sustains

before failure of a specified nature occurs (see Definitions

E 1150).

3.2.13 insertion point of an anchor—the location where the

anchor is attached to the test block. The insertion points shown

in Figs. 2-15 are to be adhered to if possible. In situations

FIG. 3 A Bilateral Hook, Rod, Screw, and Transverse Element

where the design of the spinal implant assembly or the

Construct

manufacturer’s surgical instructions for installation dictate

otherwise, the attachment points may deviate from these

dimensions. spine intended for the application of the spinal implant

3.2.14 intended method of application—spinal implant as- assembly. Spinal implant assemblies are developed for specific

semblies contain different types of anchors. Each type of spinal locations such as the anterior cervical spine or the

anchor has an intended method of application to the spine. posterior thoracolumbar, lumbar and lumbosacral spine.

3.2.15 intended spinal location—the anatomic region of the 3.2.16 hinge pin—the cylindrical rod connecting a test

F 1717

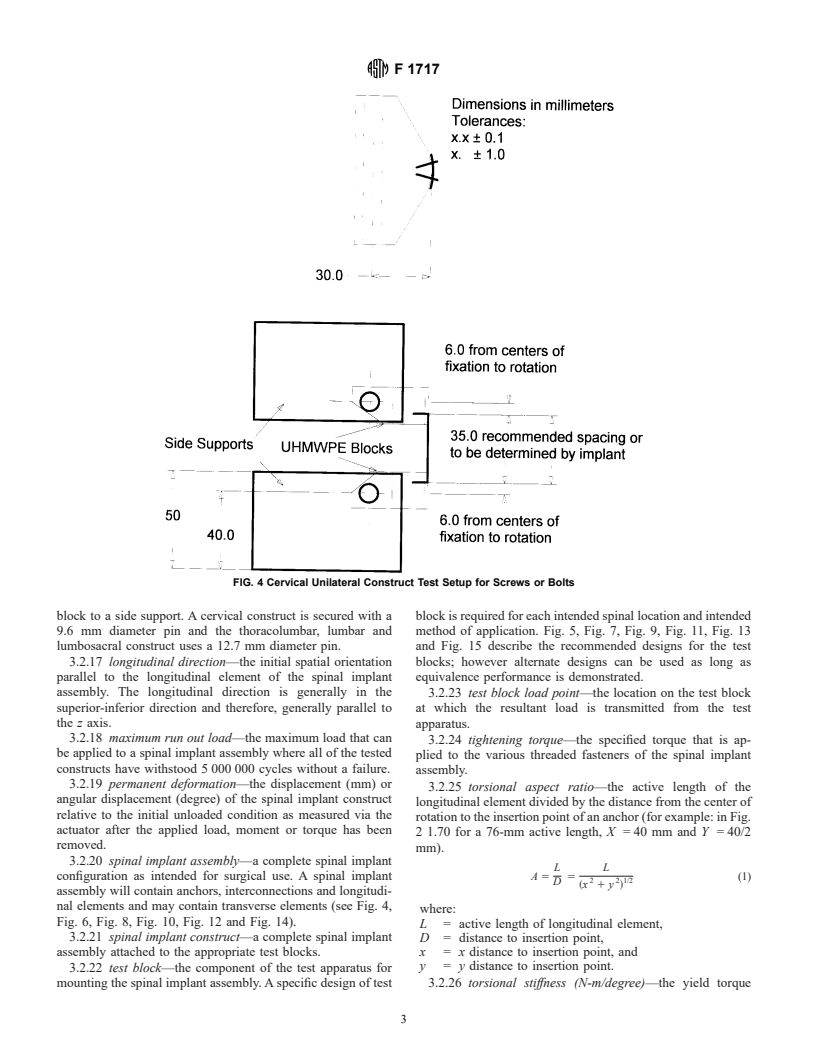

FIG. 4 Cervical Unilateral Construct Test Setup for Screws or Bolts

block to a side support. A cervical construct is secured with a block is required for each intended spinal location and intended

9.6 mm diameter pin and the thoracolumbar, lumbar and method of application. Fig. 5, Fig. 7, Fig. 9, Fig. 11, Fig. 13

lumbosacral construct uses a 12.7 mm diameter pin. and Fig. 15 describe the recommended designs for the test

3.2.17 longitudinal direction—the initial spatial orientation blocks; however alternate designs can be used as long as

parallel to the longitudinal element of the spinal implant equivalence performance is demonstrated.

assembly. The longitudinal direction is generally in the 3.2.23 test block load point—the location on the test block

superior-inferior direction and therefore, generally parallel to

at which the resultant load is transmitted from the test

the z axis. apparatus.

3.2.18 maximum run out load—the maximum load that can

3.2.24 tightening torque—the specified torque that is ap-

be applied to a spinal implant assembly where all of the tested

plied to the various threaded fasteners of the spinal implant

constructs have withstood 5 000 000 cycles without a failure.

assembly.

3.2.19 permanent deformation—the displacement (mm) or

3.2.25 torsional aspect ratio—the active length of the

angular displacement (degree) of the spinal implant construct

longitudinal element divided by the distance from the center of

relative to the initial unloaded condition as measured via the

rotation to the insertion point of an anchor (for example: in Fig.

actuator after the applied load, moment or torque has been

2 1.70 for a 76-mm active length, X =40mmand Y = 40/2

removed.

mm).

3.2.20 spinal implant assembly—a complete spinal implant

L L

configuration as intended for surgical use. A spinal implant A 5 5 (1)

2 2 1/2

D

x 1 y !

~

assembly will contain anchors, interconnections and longitudi-

nal elements and may contain transverse elements (see Fig. 4,

where:

Fig. 6, Fig. 8, Fig. 10, Fig. 12 and Fig. 14).

L = active length of longitudinal element,

3.2.21 spinal implant construct—a complete spinal implant

D = distance to insertion point,

assembly attached to the appropriate test blocks. x = x distance to insertion point, and

y = y distance to insertion point.

3.2.22 test block—the component of the test apparatus for

mounting the spinal implant assembly. A specific design of test 3.2.26 torsional stiffness (N-m/degree)—the yield torque

F 1717

FIG. 5 Cervical Unilateral UHWMPE Block for Screws or Bolts

(N-m) divided by elastic angular displacement (degrees) (the 3.2.30 ultimate displacement (mm)—the displacement asso-

initial slope of line BC in Fig. 1). ciated with the ultimate load, ultimate bending load or ultimate

3.2.27 torsional ultimate load (N-m)—the maximum torque torque (the displacement at Point F in Fig. 1).

in X-Y plane applied to a spinal implant assembly (the torque 3.2.31 yield torque (N-m)—the torque in X-Y plane required

at Point E in Fig. 1). The ultimate torque should be a function to produce a permanent displacement of 0.020 times the

of the device and not of the load cell or testing machine. torsional aspect ratio (the torque at Point D in Fig. 1).

3.2.28 two percent (2 %) offset angular displacement 3.2.32 zero displacement intercept (mm)—the intersection

(degrees)—a permanent angular displacement in the X-Y plane of the straight line section of the load displacement curve and

measured via the actuator equal to 0.020 times the torsional the zero load axis (the zero displacement reference Point 0 in

aspect ratio (for example: 1.95° for 1.70 3 0.02 3 180°/pi) Fig. 1).

(see Point B in Fig. 1).

4. Summary of Test Methods

3.2.29 two percent (2 %) offset displacement (mm)—a per-

manent deformation measured via the actuator equal to 0.020 4.1 Similar test methods are proposed for the mechanical

times the active length of the longitudinal element (for ex- evaluation of cervical spinal implant assemblies (see Fig. 4,

ample: 1.52 mm for a 76 mm active length of the longitudinal Fig. 6 and Fig. 8) and thoracolumbar, lumbar and lumbosacral

element or 0.70 mm for 35 mm) (see Point B in Fig. 1). spinal implant assemblies (see Fig. 10, Fig. 12 and Fig. 14).

F 1717

FIG. 6 Cervical Bilateral Construct Test Setup for Screws or Bolts

4.2 Testing of the spinal implant assemblies will simulate a 4.5 The intended method of application of the spinal im-

corpectomy model via a large gap between two Ultra High plant assembly may vary for specific anatomic regions and

Molecular Weight Polyethylene (UHMWPE) test blocks. The clinical indications. Spinal implant assemblies contain different

UHMWPE used to manufacture the test blocks should have a types of anchors. Each type of anchor has an intended method

tensile breaking strength equal to 40 6 3 MPa (see Specifica- of application to the spine. For example, one assembly may

tion F 638). The UHMWPE test blocks (see Fig. 5, Fig. 7, Fig. include anterior vertebral body screws and rods (see Fig. 2),

9, Fig. 11, Fig. 13, and Fig. 15) will eliminate the effects of the while another assembly may contain posterior sacral screws,

variability of bone properties and morphometry. Alternate hooks, rods and transverse elements (see Fig. 3). The block

designs of test blocks may be used as long as equivalence moment arm of a test configuration will be independent of the

performance is demonstrated. intended method of application of a spinal implant assembly,

4.3 Three static mechanical tests and one dynamic test will therefore the test data for different intended method of appli-

evaluate the spinal implant assemblies. The three static me- cation may be compared.

chanical tests are compression bending, tensile bending and

5. Significance and Use

torsion. The dynamic test is a compression bending fatigue.

4.4 A specific clinical indication generally requires a spe- 5.1 Spinal implants are generally composed of several

cific spinal implant assembly. Spinal implant assemblies will components which, when connected together, form a spinal

be evaluated with test configurations which simulate the implant assembly. Spinal implant assemblies are designed to

clinical requirements for the intended spinal location. The provide some stability to the spine while arthrodesis takes

intended spinal locations are both anterior (see Fig. 4) and place. This standard outlines standard materials and methods

posterior (see Fig. 6 and Fig. 8) surfaces of the cervical spine for the evaluation of different spinal implant assemblies so that

or both anterior (see Fig. 10) and posterior (see Fig. 12 and Fig. comparison between different designs may be facilitated.

14) surfaces of the thoracolumbar, lumbar and lumbosacral 5.2 This standard is used to quantify the static and dynamic

spine. The block moment arm (see 6.6) for a test configuration mechanical characteristics of different designs of spinal im-

depends on the intended spinal location. The cervical spine plant assemblies. The mechanical tests are conducted in vitro

configuration (see Fig. 5, Fig. 7, and Fig. 9) specifies one block using simplified load schemes and do not attempt to mimic the

moment arm, while a larger block moment arm (see Fig. 11, complex loads of the spine.

Fig. 13, and Fig. 15) is specified for the thoracolumbar, lumbar 5.3 The loads applied to the spinal implant assemblies in

and lumbosacral spine. vivo will, in general, differ from the loading configurations

F 1717

FIG. 7 Cervical Bilateral UHMWPE Block for Screws or Bolts

used in this standard. The results obta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.