ASTM F2378-05(2016)

(Test Method)Standard Test Method for Sealability of Sheet, Composite, and Solid Form-in-Place Gasket Materials

Standard Test Method for Sealability of Sheet, Composite, and Solid Form-in-Place Gasket Materials

SIGNIFICANCE AND USE

5.1 This test method is designed to compare sealing characteristics of gasket materials under controlled conditions by providing a precise measure of leakage rate at different press loads up to 32 MPa (4640 psi).

5.2 This test method is suitable for measuring leakage rates from 0.1 mL/min to as high as 5 L/min for gases.

5.3 This test method evaluates leak rates after time periods (typically 30 min) that result in a steady state leakage rate condition. Holding gasket materials under load and internal fluid pressure until steady state is achieved is required to obtain reproducible results.

5.4 If the fluid being used in the test causes changes, such as swelling, in the gasket material, it may affect results and diminish repeatability.

SCOPE

1.1 This test method covers a means of evaluating the sealing properties of sheet, composite, and solid form-in-place gasket materials (see Classification F104 or F868) at room temperature, and may be used for fluid (gas or liquid) leak rate measurements. It utilizes relatively short hold times and is not intended to predict long-term performance in application.

1.2 This test method is suitable for evaluating the sealing characteristics of a gasket material under different press loads by measuring the leakage rate. This test method may be used as an acceptance test when the producer and user have agreed to specific test conditions for the following parameters: (1) test medium, (2) internal pressure of the medium, (3) press load on the gasket specimen, and (4) the surface finish of the platens.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2378 − 05 (Reapproved 2016)

Standard Test Method for

Sealability of Sheet, Composite, and Solid Form-in-Place

1

Gasket Materials

This standard is issued under the fixed designation F2378; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 ANSI Standard:

B57.1 Compressed Gas Cylinder Valve Outlet and Inlet

1.1 This test method covers a means of evaluating the

Connections

sealing properties of sheet, composite, and solid form-in-place

gasket materials (see Classification F104 or F868) at room

3. Terminology

temperature, and may be used for fluid (gas or liquid) leak rate

3.1 Definitions:

measurements. It utilizes relatively short hold times and is not

3.1.1 press load—the load applied by the hydraulic press to

intended to predict long-term performance in application.

the test assembly divided by the gasket area. The press load is

1.2 This test method is suitable for evaluating the sealing

not compensated for as the internal pressure is increased, so the

characteristics of a gasket material under different press loads

gasket stress is reduced for the test conditions.

by measuring the leakage rate. This test method may be used as

3.1.2 solid form-in-place gasket—a solid length of gasket-

an acceptance test when the producer and user have agreed to

ing material generally in a ribbon or rope form that can be laid

specific test conditions for the following parameters: (1) test

out on the platen surface and overlapped at the ends to form a

medium, (2) internal pressure of the medium, (3) press load on

continuous sealing surface.

the gasket specimen, and (4) the surface finish of the platens.

1.3 The values stated in SI units are to be regarded as the

4. Summary of Test Method

standard. The values given in parentheses are for information

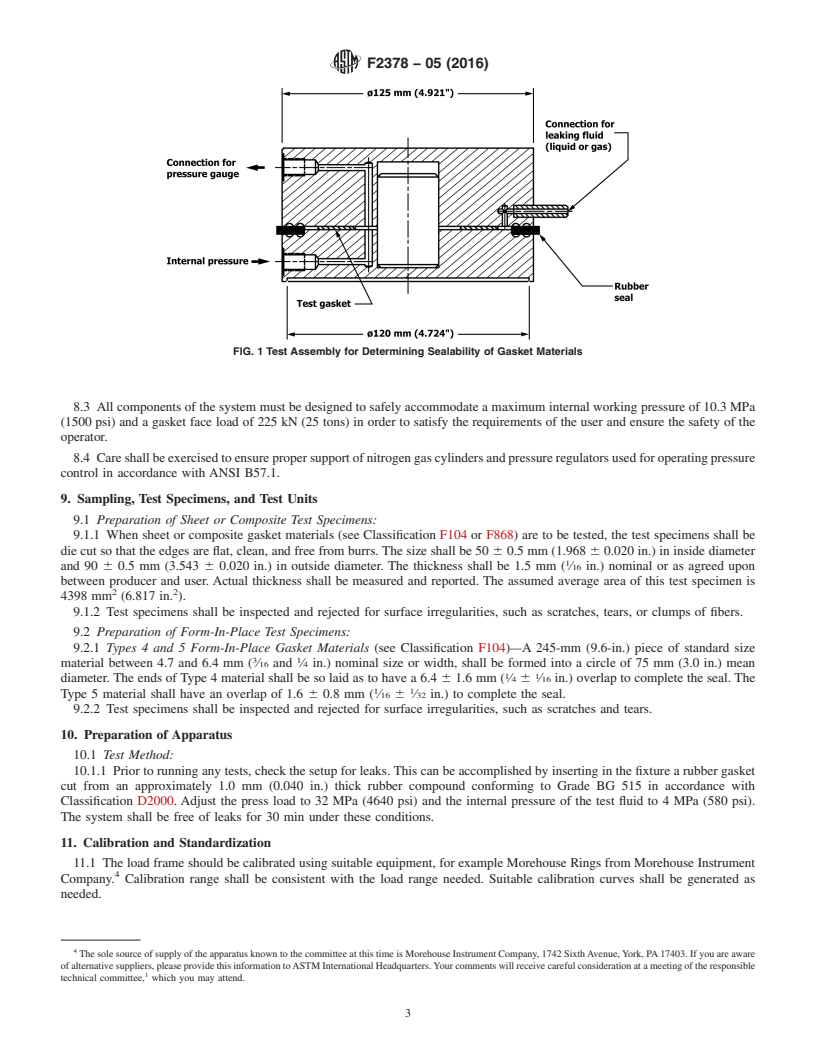

4.1 This test method utilizes a test specimen compressed in

only.

increasing stages between the surfaces of two flat steel platens.

1.4 This standard does not purport to address all of the After the specified press load is applied, fluid (typically

safety concerns, if any, associated with its use. It is the nitrogen) is introduced into the center of the annular gasket

responsibility of the user of this standard to establish appro- compressed between platens, and a pressure of 4 MPa (580 psi)

priate safety and health practices and to determine the is applied. The fluid leak rate is measured. The fluid pressure is

applicability of regulatory limitations prior to use. relieved and the press load is increased to the next level. The

fluid pressure is reapplied and the leak rate measured again.

2. Referenced Documents The cycle is repeated 5 times until a final press load of 32 MPa

(4640 psi) is achieved. Other press loads, internal pressures,

2

2.1 ASTM Standards:

pressurizing fluids, and number of cycles can be used as agreed

D2000 Classification System for Rubber Products in Auto-

upon between the producer and the user. All variations from the

motive Applications

standard requirements must be reported with the test results.

F104 Classification System for Nonmetallic Gasket Materi-

4.1.1 The fluid leak rate is measured by mass flow meters

als

located downstream from the gasket test fixture. Other means

F868 Classification for Laminated Composite Gasket Mate-

of leak measurement also may be used and would depend upon

rials

the test fluid, the leak rate, and the accuracy required as agreed

upon between the producer and the user.

4.2 This test method uses flat platens on which an external

1

This test method is under the jurisdiction of ASTM Committee F03 on Gaskets

load is applied to produce a compressive force on the gasket

and is the direct responsibility of Subcommittee F03.10 on Composite Gaskets.

test specimen. The uncompensated load applied is the press

Current edition approved Oct. 1, 2016. Published October 2016. Originally

approved in 2005. Last previous edition approved in 2011 as F2378 – 05 (2011).

load.

DOI: 10.1520/F2378-05R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2378 − 05 (2016)

4.3 Results of the sealability tests are typically expressed as from the ga

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2378 − 05 (Reapproved 2011) F2378 − 05 (Reapproved 2016)

Standard Test Method for

Sealability of Sheet, Composite, and Solid Form-in-Place

1

Gasket Materials

This standard is issued under the fixed designation F2378; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a means of evaluating the sealing properties of sheet, composite, and solid form-in-place gasket

materials (see Classification F104 or F868) at room temperature, and may be used for fluid (gas or liquid) leak rate measurements.

It utilizes relatively short hold times and is not intended to predict long-term performance in application.

1.2 This test method is suitable for evaluating the sealing characteristics of a gasket material under different press loads by

measuring the leakage rate. This test method may be used as an acceptance test when the producer and user have agreed to specific

test conditions for the following parameters: (1) test medium, (2) internal pressure of the medium, (3) press load on the gasket

specimen, and (4) the surface finish of the platens.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D2000 Classification System for Rubber Products in Automotive Applications

F104 Classification System for Nonmetallic Gasket Materials

F868 Classification for Laminated Composite Gasket Materials

3

2.2 ANSI Standard:

B57.1 Compressed Gas Cylinder Valve Outlet and Inlet Connections

3. Terminology

3.1 Definitions:

3.1.1 press load—the load applied by the hydraulic press to the test assembly divided by the gasket area. The press load is not

compensated for as the internal pressure is increased, so the gasket stress is reduced for the test conditions.

3.1.2 solid form-in-place gasket—a solid length of gasketing material generally in a ribbon or rope form that can be laid out

on the platen surface and overlapped at the ends to form a continuous sealing surface.

4. Summary of Test Method

4.1 This test method utilizes a test specimen compressed in increasing stages between the surfaces of two flat steel platens. After

the specified press load is applied, fluid (typically nitrogen) is introduced into the center of the annular gasket compressed between

platens, and a pressure of 4 MPa (580 psi) is applied. The fluid leak rate is measured. The fluid pressure is relieved and the press

load is increased to the next level. The fluid pressure is reapplied and the leak rate measured again. The cycle is repeated 5 times

until a final press load of 32 MPa (4640 psi) is achieved. Other press loads, internal pressures, pressurizing fluids, and number of

cycles can be used as agreed upon between the producer and the user. All variations from the standard requirements must be

reported with the test results.

1

This test method is under the jurisdiction of ASTM Committee F03 on Gaskets and is the direct responsibility of Subcommittee F03.10 on Composite Gaskets.

Current edition approved May 1, 2011Oct. 1, 2016. Published July 2011October 2016. Originally approved in 2005. Last previous edition approved in 20052011 as

F2378 – 05 (2011).F2378–05. DOI: 10.1520/F2378-05R11.10.1520/F2378-05R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2378 − 05 (2016)

4.1.1 The fluid leak rate is measured by mass flow meters located downstream from the gasket test fixture. Other means of leak

measurement also may be used and would depend upon the test fluid, the leak rate, and the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.