ASTM A931-18

(Test Method)Standard Test Method for Tension Testing of Wire Ropes and Strand

Standard Test Method for Tension Testing of Wire Ropes and Strand

SIGNIFICANCE AND USE

4.1 Tension tests are generally to be performed on new wire ropes. The use of wire rope in any application can reduce individual wire strengths due to abrasion and nicking that will result in the wire rope strength being reduced. Damage to the outer wires will also lower the maximum strength achieved during tension testing.

4.2 The modulus of elasticity of wire rope is not considered to be a standard requirement at this time. The determination of this material property requires specialized equipment and techniques.

4.3 Rope to be tested should be thoroughly examined to verify that no external wire damage is present. If present, it should be noted. When possible, a new undamaged sample should be obtained for testing.

4.4 End attachments and their installation can directly affect breaking force achieved during testing. Any attachment that can be used to directly achieve the required rope breaking force can be used. Standard testing with a poured socket, using zinc, white metal or thermoset resin, has been considered the most efficient. Proficiency in attachment of any fitting can have a direct effect on the final test results.

SCOPE

1.1 This test method covers the tension testing of wire ropes and strand at room temperature, specifically to determine the measured breaking force, yield strength, elongation, and modulus of elasticity. Methods described in this standard are not intended for other purposes.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 1 and Note 2.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A931 − 18

Standard Test Method for

1

Tension Testing of Wire Ropes and Strand

This standard is issued under the fixed designation A931; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E6 Terminology Relating to Methods of Mechanical Testing

E8 Test Methods for Tension Testing of Metallic Materials

1.1 This test method covers the tension testing of wire ropes

[Metric] E0008_E0008M

and strand at room temperature, specifically to determine the

3

measuredbreakingforce,yieldstrength,elongation,andmodu- 2.2 ISO Standard

lus of elasticity. Methods described in this standard are not ISO 17558 Specification for Steel Wire Ropes – Socketing

intended for other purposes. Procedures – Molten Metal and Resin Socketing

1.2 The values stated in inch-pound units are to be regarded

3. Terminology

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only 3.1 The terminology relating to tensile testing in Terminol-

and are not considered standard.

ogy E6 applies to this test method. In addition, the following

definitions for wire rope will apply:

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.2 Definitions:

responsibility of the user of this standard to establish appro-

3.2.1 abrasion, n—frictional surface wear on the wires of a

priate safety, health, and environmental practices and deter-

wire rope.

mine the applicability of regulatory limitations prior to use.

3.2.2 aggregate area, n—see area, metallic.

Specific precautionary statements are given in Note 1 and Note

3.2.3 aggregate strength, n—thestrengthderivedbytotaling

2.

the individual breaking strengths of the elements of the strand

1.4 This international standard was developed in accor-

or rope. This strength does not give recognition to the

dance with internationally recognized principles on standard-

reduction in strength resulting from the angularity of the

ization established in the Decision on Principles for the

elements in the rope, or other factors that may affect efficiency.

Development of International Standards, Guides and Recom-

3.2.4 area, metallic, n—sum of the cross-sectional areas of

mendations issued by the World Trade Organization Technical

all wires either in a wire rope or in a strand.

Barriers to Trade (TBT) Committee.

3.2.5 breaking force, n—the maximum load at which a

2. Referenced Documents

tensile failure occurs in the sample of wire rope being tested.

2

3.2.5.1 Discussion—The term breaking force is synony-

2.1 ASTM Standards:

mous with actual strength.

A586 Specification for Zinc-Coated Parallel and Helical

Steel Wire Structural Strand

3.2.6 cable, n—a term loosely applied to wire rope, wire

A603 Specification for Zinc-Coated Steel Structural Wire

strand, and electrical conductors.

Rope

3.2.7 center, n—the axial member of a strand about which

A1023/A1023M Specification for Stranded Carbon Steel

the wires are laid.

Wire Ropes for General Purposes

3.2.8 classification, n—group or family designation based

E4 Practices for Force Verification of Testing Machines

onwireropeconstructionswithcommonstrengthsandweights

listed under the broad designation.

1

3.2.9 construction, n—geometric design description of the

This test method is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

wire rope’s cross section. This includes the number of strands,

A01.03 on Steel Rod and Wire.

the number of wires per strand, and the pattern of wire

Current edition approved Sept. 1, 2018. Published September 2018. Originally

arrangement in each strand.

approved in 1994. Last previous edition approved in 2013 as A931 – 08 (2013).

DOI: 10.1520/A0931-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A931 − 18

3.2.10 c

...

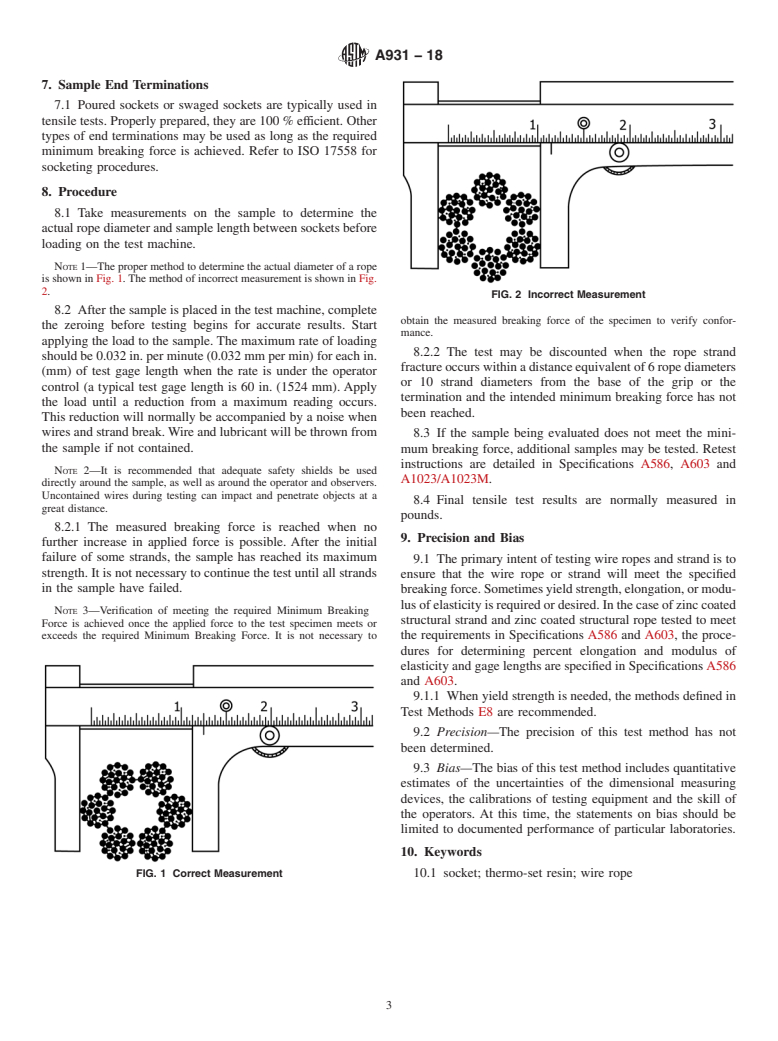

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A931 − 08 (Reapproved 2013) A931 − 18

Standard Test Method for

1

Tension Testing of Wire Ropes and Strand

This standard is issued under the fixed designation A931; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the tension testing of wire ropes and strand at room temperature, specifically to determine the

measured breaking force, yield strength, elongation, and modulus of elasticity. Methods described in this standard are not intended

for other purposes.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

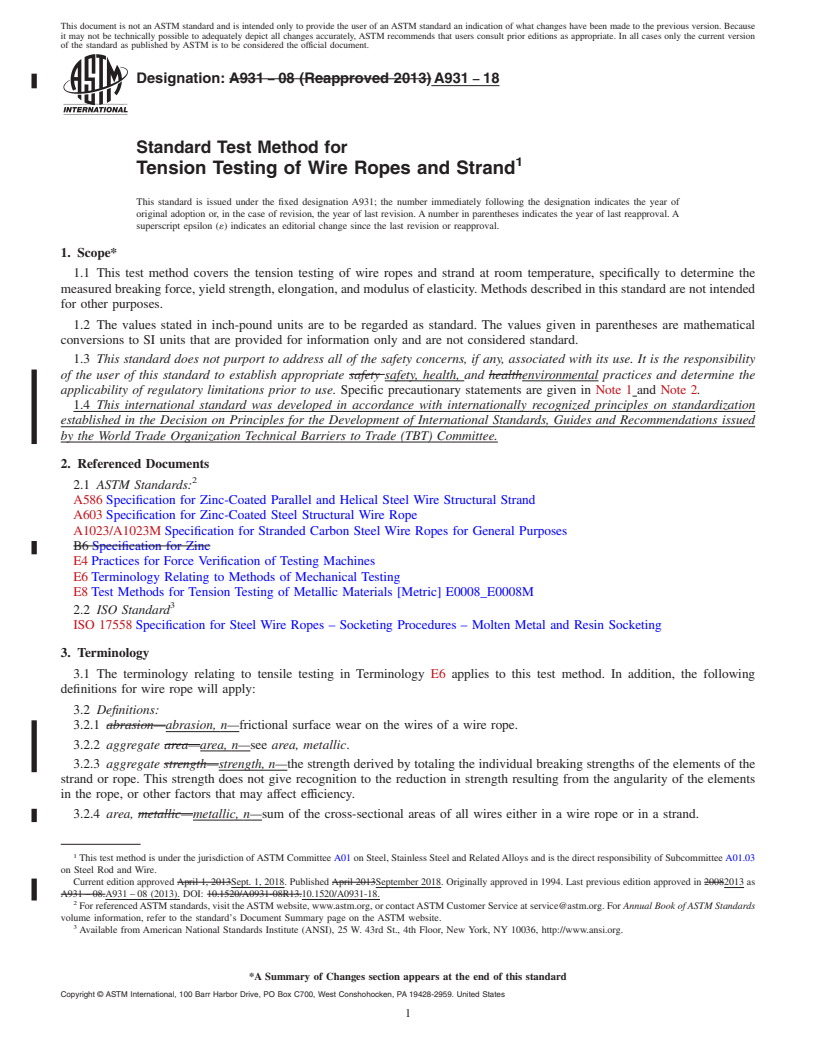

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 1 and Note 2.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A586 Specification for Zinc-Coated Parallel and Helical Steel Wire Structural Strand

A603 Specification for Zinc-Coated Steel Structural Wire Rope

A1023/A1023M Specification for Stranded Carbon Steel Wire Ropes for General Purposes

B6 Specification for Zinc

E4 Practices for Force Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing

E8 Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

3

2.2 ISO Standard

ISO 17558 Specification for Steel Wire Ropes – Socketing Procedures – Molten Metal and Resin Socketing

3. Terminology

3.1 The terminology relating to tensile testing in Terminology E6 applies to this test method. In addition, the following

definitions for wire rope will apply:

3.2 Definitions:

3.2.1 abrasion—abrasion, n—frictional surface wear on the wires of a wire rope.

3.2.2 aggregate area—area, n—see area, metallic.

3.2.3 aggregate strength—strength, n—the strength derived by totaling the individual breaking strengths of the elements of the

strand or rope. This strength does not give recognition to the reduction in strength resulting from the angularity of the elements

in the rope, or other factors that may affect efficiency.

3.2.4 area, metallic—metallic, n—sum of the cross-sectional areas of all wires either in a wire rope or in a strand.

1

This test method is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.03

on Steel Rod and Wire.

Current edition approved April 1, 2013Sept. 1, 2018. Published April 2013September 2018. Originally approved in 1994. Last previous edition approved in 20082013 as

A931 – 08.A931 – 08 (2013). DOI: 10.1520/A0931-08R13.10.1520/A0931-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

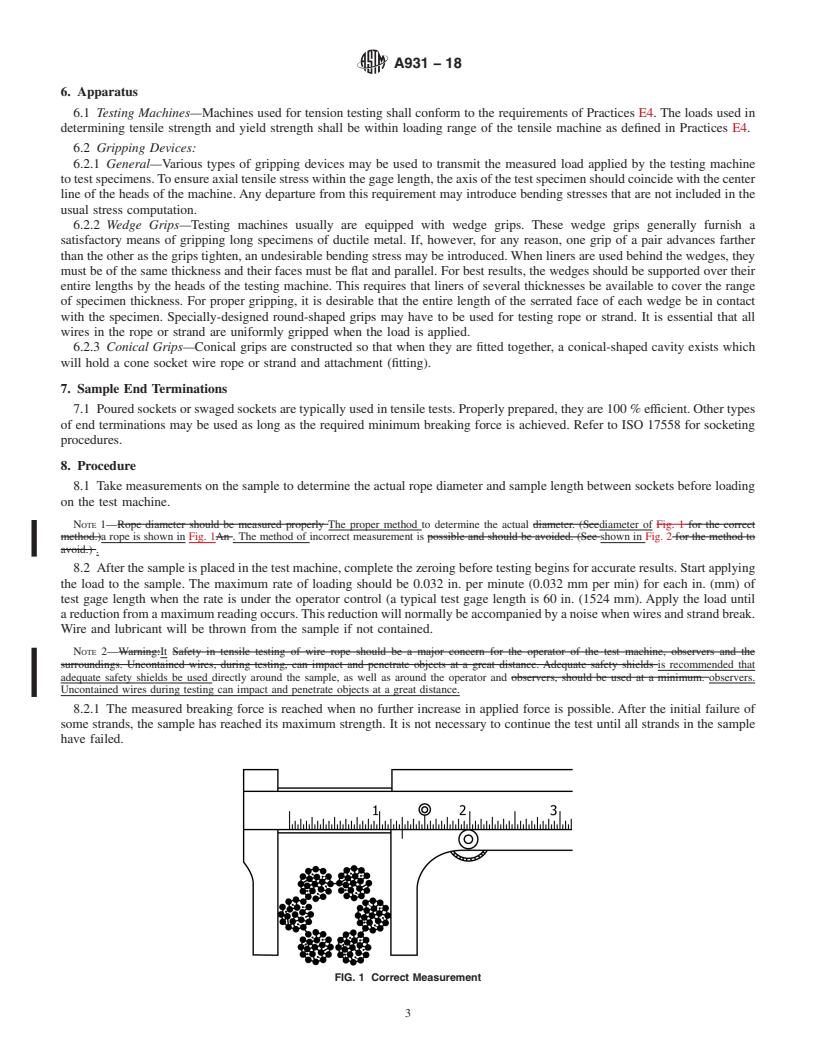

A931 − 18

3.2.5 breaking force—force, n—the maximum load at which a tensile failure occurs in the sample of wire rope being tested.

3.2.5.1 Discussion—

The term breaking force is synonymous with actual strength.

3.2.6 cable—cable, n—a term loosely applied to wire rope, wire strand, and electrical conductors.

3.2.7 center—center, n—the axial member of a strand about which the wires are laid.

3.2.8 classification—classification, n—group or family designation bas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.