ASTM A1007-00

(Specification)Standard Specification for Carbon Steel Wire for Wire Rope

Standard Specification for Carbon Steel Wire for Wire Rope

SCOPE

1.1 This specification covers uncoated and four classes of round, metallic coated, cold-drawn, carbon steel wire for wire rope in five strength levels. This specification specifies:

1.1.1 Dimensional tolerances,

1.1.2 Mechanical characteristics,

1.1.3 Chemical composition requirements,

1.1.4 Coating requirements (if applicable), and

1.1.5 Packaging requirements.

1.2 The values stated for metric equivalents are provided for informational purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 1007 – 00

Standard Specification for

Carbon Steel Wire for Wire Rope

This standard is issued under the fixed designation A 1007; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope EN 10264-1.2 Steel Wire and Wire Products—Steel Wire

for Wire Rope

1.1 This specification covers uncoated and four classes of

2.4 Industry Standard:

round, metallic coated, cold-drawn, carbon steel wire for wire

API 9A Specification for Wire Rope

rope in five strength levels. This specification specifies:

2.5 Industry References:

1.1.1 Dimensional tolerances,

AIME/ISS Carbon Steel, Wire and Rods

1.1.2 Mechanical characteristics,

AIAG 02.00 Primary Metals Identification Tag Application

1.1.3 Chemical composition requirements,

2.6 Non-Referenced Industry Applicable Standards:

1.1.4 Coating requirements (if applicable), and

ISO Std. 2232 Drawn Wire for General Purpose Non-Alloy

1.1.5 Packaging requirements.

Steel Wire Ropes

1.2 The values stated for metric equivalents are provided for

informational purposes only.

3. Terminology

2. Referenced Documents 3.1 Definitions:

3.1.1 actual diameter—the arithmetic mean of the mini-

2.1 This specification incorporates, by dated or undated

mum and maximum diameter measurements in one location on

reference, provisions from other publications. These normative

the wire.

references are cited at their appropriate place in the text and the

3.1.2 breaking force level (Levels 1,2,3,4 or 5)—a wire

publications are listed. For dated references, subsequent

strength based on the minimum load carrying capability of a

amendments to or revisions of any of these publications apply

designated wire.

to this specification only when incorporated in it by amend-

3.1.3 drawn-galvanized—a zinc coating that is applied to

ment or revision. For undated references, the latest edition of

the wire prior to the final cold drawing operation by either an

the publication referred to would apply.

electro-deposition or hot-galvanizing process.

2.2 ASTM Standards:

3.1.4 drawn-Zn5 Al-MM—a zinc-aluminum alloy (mis-

A 90/A 90M Test Method for Weight (Mass) of Coating on

chmetal) coating that is applied to the wire prior to the final

Iron or Steel Articles with Zinc or Zinc-Alloy Coatings

cold drawing operation by a molten coating process.

A 510 Specification for General Requirements for Wire

3.1.5 final-coated Zn5 Al-MM—a zinc-aluminum alloy

Rods and Coarse Round Wire, Carbon Steel-Coated

(mischmetal) coating that is applied to the wire after the final

A 938 Test Method for Torsion Testing of Wire

cold drawing operation by a molten coating process.

B 6 Specification for Zinc (Slab Zinc)

3.1.6 final-galvanized—a zinc coating that is applied to the

B 750 Specification for Zinc-5 % Aluminum Mischmetal

4 wire after the final cold drawing operation by either an

Alloy (UNS Z38510) in Ingot Form for Hot-Dip Coatings

electro-deposition or hot-galvanizing process.

E 8 Test Methods of Tension Testing of Metallic Materials

3.1.7 nominal diameter—the diameter of the wire expressed

E 380 Practice for Use of International System of Units (SI)

in inches (millimetres) and specified by the user to designate

(the Modernization Metric System)

the wire size. It is the basis for the determination of the values

2.3 ISO/EN Standards:

of all characteristics of the wire for acceptance purposes.

3.1.8 ovality—the arithmetic difference between the maxi-

mum diameter and the minimum diameter in one location on

This specification is under the jurisdiction of ASTM Committee A-1 on Steel, the wire; it shall not be greater than half the tolerance specified

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

in the respective tables referred to in the following parts of this

A01.03 on Steel Rod and Wire.

specification.

Current edition approved April 10, 2000. Published June 2000.

Annual Book of ASTM Standards, Vol 01.06.

Annual Book of ASTM Standards, Vol 01.03.

Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 02.04.

Floor, New York, NY 10036.

Annual Book of ASTM Standards, Vol 03.01.

Available from American Petroleum Institute, 1801 K Street, N.W., Washing-

Annual Book of ASTM Standards, Vol 14.02.

ton, DC 20226.

Available from Automotive Industry Action Group (AIAG), 26200 Lahser

Road, Suite 200, Southfield, MI 48034–7100.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 1007

3.1.9 uncoated wire—the surface of a wire furnished with a limits specified in Specification B 750.

residual lube film as a result of cold-drawing said wire.

6. Chemical Composition

4. Ordering Information

6.1 Upon agreement with the purchaser, the wire manufac-

4.1 It is the responsibility of the purchaser to specify all

turer shall apply a steel of suitable chemical composition that

requirements that are necessary for material ordered under this

will satisfy the properties of the material ordered.

specification. Such requirements shall include, but are not

6.2 A quantitative analysis of each cast or heat shall be

limited to the following:

made by the steel producer or his representative to determine

4.1.1 Quantity (mass),

the percentage of the elements specified. The analysis shall be

4.1.2 Name of material (drawn steel wire for wire rope),

made from a test sample preferably taken during the pouring of

4.1.3 Wire type (uncoated, drawn- or final-galvanized/Zn5

the cast or heat. The chemical composition thus determined

Al-mm coated),

shall be reported, if required, to the purchaser or his represen-

4.1.4 Wire diameter,

tative.

4.1.5 Wire strength grade (Level 1 through 5),

6.3 An analysis may be made by the purchaser from the

4.1.6 Packaging (Section 14),

finished wire. The chemical composition thus determined as to

4.1.7 Cast or heat analysis; if requested,

the elements required shall conform to the product analysis

4.1.8 Certification or test report; if requested, and

requirements specified in Table 3 of Specification A 510 or as

4.1.9 ASTM designation and date of issue.

agreed upon between the purchaser and the manufacturer.

5. Materials and Manufacture

7. Wire Diameter

5.1 The base metal rod used in the manufacture of rope wire

7.1 The wire shall be measured using a micrometer with an

shall be rolled from good commercial quality steel. The steel

minimum accuracy of 0.0001 in. (0.002 mm) for all diameters.

may be either ingot cast or strand cast.

7.2 All diameter values measured in one location along the

5.2 A sufficient discard shall be made to ensure freedom

wire shall be within the tolerance limits given in Table 1 for

from detrimental piping and undue segregation.

uncoated and drawn-galvanized or drawn-Zn5 Al-MM rope

5.3 The wire shall be cold-drawn to produce the desired

wire or Table 2 for final-galvanized or final-coated Zn5 Al-MM

properties.

rope wire.

5.4 The wire shall be furnished in one of five types, as

8. Tensile Properties

specified:

5.4.1 Uncoated, 8.1 Tensile Test Procedure:

5.4.2 Drawn-galvanized, 8.1.1 Standard Testing Method—The tensile test shall be

5.4.3 Final-galvanized, carried out in accordance with Test Methods E 8. The distance

5.4.4 Drawn Zn5/Al-MM, and between the grips of the testing machine shall not be less than

5.4.5 Final coated Zn5/Al-MM. 8 in. (203 mm). The speed of the movable head of the testing

5.5 Uncoated, drawn-galvanized and drawn-Zn5 Al-MM machine, under no load, shall not exceed 1 in./min (0.4 mm/s).

wire can be furnished in Levels 1 through 5. Final-galvanized Any specimen breaking within 1 in. (25.4 mm) of the jaws may

and final-coated Zn5 Al-MM wire is usually furnished in be disregarded and a retest performed.

Levels 1 through 4. 8.1.2 Alternate Testing Method—The tensile test shall be

5.6 The method utilized in the production of either drawn- carried out in accordance with Test Methods E 8. The loading

or final-galvanized wire types may be by an electro-deposition rate may be greater than that specified, depending on the

or hot-dip galvanizing process at the option of the producer. number of tests to be carried out for the batch inspection.

5.6.1 The slab zinc used in galvanized zinc coatings shall be However, it shall not exceed the rate corresponding to a 25 %

as specified in Specification B 6. elongation between anchorages in 1 min. The minimum

5.7 The method utilized in the production of Zn5 Al-MM distance between the clamping jaws of the test machine is 4 in.

wire types may be either a continuous hot-dip alloy coating or (100 mm). In the event of a dispute, the tensile test shall be

two step coating where the first coating is zinc followed by a carried out strictly in accordance with Test Methods E 8, in

final bath having an aluminum content up to 7.2 % to prevent particular with regard to the loading rate.

depletion of the aluminum content of the bath. 8.1.3 The minimum breaking forces are specified in Table 3

5.7.1 The bath metal used in continuous hot-dip Zn-5 of this specification, for wire grade Levels 1 through 5. The

Al-MM alloy coating shall meet the chemical composition range in breaking force for a given grade level is based on the

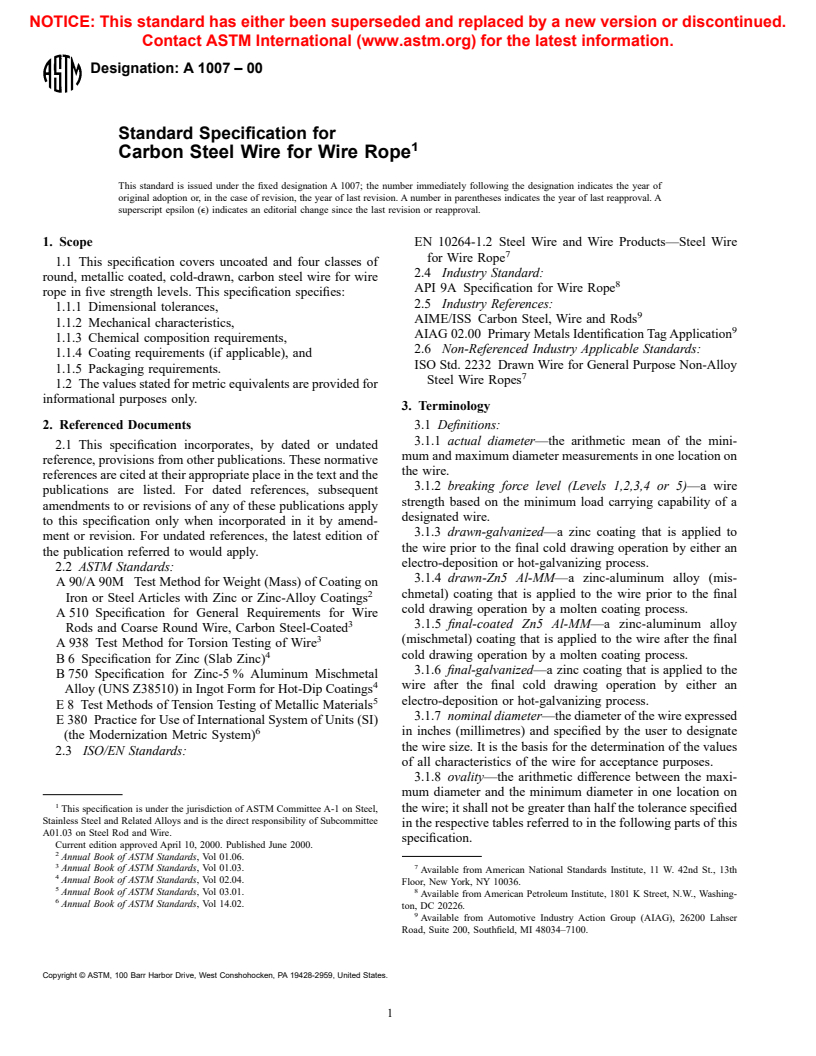

TABLE 1 Wire Diameter Tolerances Uncoated and Drawn-Galvanized or Zn5 Al-MM Rope Wire

Diameter Range, in. Diameter Range, mm Tolerance, in. Tolerance, mm

Minus Plus Minus Plus

0.010 to 0.025 incl. 0.25 to 0.64 incl. 0.0003 0.0007 0.01 0.02

Over 0.025 to 0.060 incl. Over 0.64 to 1.50 incl. 0.0005 0.001 0.01 0.03

Over 0.060 to 0.093 incl. Over 1.50 to 2.36 incl. 0.001 0.001 0.03 0.03

Over 0.093 to 0.142 incl. Over 2.36 to 3.61 incl. 0.001 0.0015 0.03 0.04

Over 0.142 to 0.200 incl. Over 3.61 to 5.08 incl. 0.0015 0.002 0.04 0.05

Over 0.200 to .250 incl. Over 5.08 to 6.35 incl. 0.002 0.002 0.05 0.05

A 1007

TABLE 2 Wire Diameter Tolerances Final-Galvanized or Final-Coated Zn5 Al-MM Rope Wire

Diameter Range, in. Diameter Range, mm Tolerance, in. Tolerance, mm

Minus Plus Minus Plus

0.025 to 0.061 incl. 0.64 to 1.55 incl. 0.001 0.001 0.03 0.03

Over 0.061 to 0.079 incl. Over 1.55 to 2.01 incl. 0.002 0.002 0.05 0.05

Over 0.079 to 0.092 incl. Over 2.01 to 2.34 incl. 0.003 0.003 0.08 0.08

Over 0.092 to 0.103 incl. Over 2.34 to 2.62 incl. 0.003 0.003 0.08 0.08

Over 0.103 to 0.119 incl. Over 2.62 to 3.02 incl. 0.003 0.003 0.08 0.08

Over 0.119 to 0.142 incl. Over 3.02 to 3.61 incl. 0.003 0.003 0.08 0.08

Over 0.142 to 0.187 incl. Over 3.61 to 4.75 incl. 0.004 0.004 0.10 0.10

Over 0.187 Over 4.75 0.004 0.004 0.10 0.10

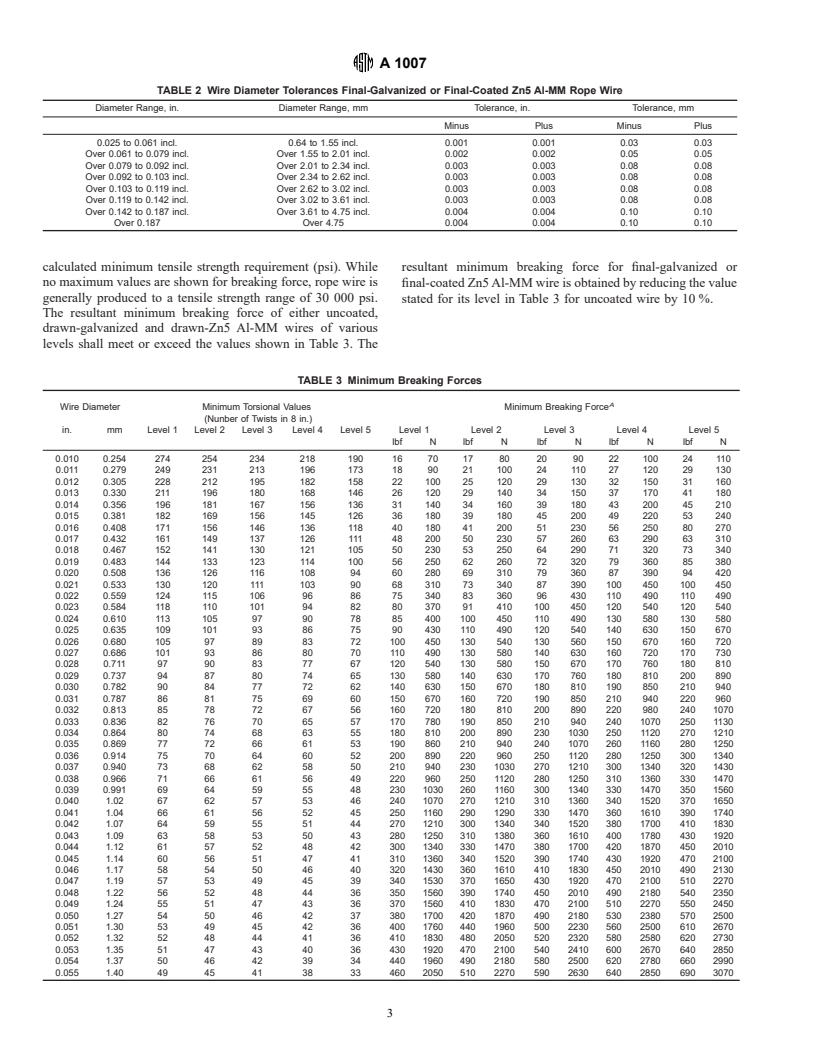

calculated minimum tensile strength requirement (psi). While resultant minimum breaking force for final-galvanized or

no maximum values are shown for breaking force, rope wire is

final-coated Zn5 Al-MM wire is obtained by reducing the value

generally produced to a tensile strength range of 30 000 psi.

stated for its level in Table 3 for uncoated wire by 10 %.

The resultant minimum breaking force of either uncoated,

drawn-galvanized and drawn-Zn5 Al-MM wires of various

levels shall meet or exceed the values shown in Table 3. The

TABLE 3 Minimum Breaking Forces

A

Wire Diameter Minimum Torsional Values Minimum Breaking Force

(Nunber of Twists in 8 in.)

in. mm Level 1 Level 2 Level 3 Level 4 Level 5 Level 1 Level 2 Level 3 Level 4 Level 5

lbf N lbf N lbf N lbf N lbf N

0.010 0.254 274 254 234 218 190 16 70 17 80 20 90 22 100 24 110

0.011 0.279 249 231 213 196 173 18 90 21 100 24 110 27 120 29 130

0.012 0.305 228 212 195 182 158 22 100 25 120 29 130 32 150 31 160

0.013 0.330 211 196 180 168 146 26 120 29 140 34 150 37 170 41 180

0.014 0.356 196 181 167 156 136 31 140 34 160 39 180 43 200 45 210

0.015 0.381 182 169 156 145 126 36 180 39 180 45 200 49 220 53 240

0.016 0.408 171 156 146 136 118 40 180 41 200 51 230 56 250 80 270

0.017 0.432 161 149 137 126 111 48 200 50 230 57 260 63 290 63 310

0.018 0.467 152 141 130 121 105 50 230 53 250 64 290 71 320 73 340

0.019 0.483 144 133 123 114 100 56 250 62 260 72 320 79 360 85 380

0.020 0.508 136 126 116 108 94 60 280 69 310 79 360 87 390 94 420

0.021 0.533 130 120 111 103 90 68 310 73 340 87 390 100 450 100 450

0.022 0.559 124 115 106 96 86 75 340 83 360 96 430 110 490 110 490

0.023 0.584 118 110 101 94 82 80 370 91 410 100 450 120 540 120 540

0.024 0.610 113 105 97 90 78 85 400 100 450 110 490 130 580 130 580

0.025 0.635 109 101 93 86 75 90 430 110 490 120 540 140 630 150 670

0.026 0.680 105 97 89 83 72 100 450 130 540 130 560 150 670 160 720

0.027 0.686 101 93 86 80 70 110 490 130 580 140 630 160 720 170 730

0.028 0.711 97 90 83 77 67 120 540 130 580 150 670 170 760 180 810

0.029 0.737 94 87 80 74 65 130 580 140 630 170 760 180 810 200 890

0.030 0.782 90 84 77 72 62 140 630 150 670 180 810 190 850 210 940

0.031 0.787 86 81 75 69 60 150 670 160 720 190 850 210 940 220 960

0.032 0.813 85 78 72 67 56 160 720 180 810 200 890 220 980 240 1070

0.033 0.836 82 76 70 65 57 170 780 190 850 210 940 240 1070 250 1130

0.034 0.864 80 74 68 63 55 180 810 200 890 230 1030 250 1120 270 1210

0.035 0.869 77 72 66 61 53 190 860 210 940 240 1070 260 1160 280 1250

0.036 0.914 75 70 64 60 52 200 890 220 960 250 1120 280 1250 300 1340

0.037 0.940 73 68 62 58 50 210 940 230 1030 270 1210 300 1340 320 1430

0.038 0.966 71 66 61 56 49 220 960 250 1120 280 1250 310 1360 330 1470

0.039 0.991 69 64 59 55 48 230 1030 260 1160 300 1340 330 1470 350 1560

0.040 1.02 67 62 57 53 46 240 1070 270 1210 310 1360 340 1520 370 1650

0.041 1.04 66 61 56 52 45 250 1160 290 1290 330 1470 360 1610 390 1740

0.042 1.07 64 59 55 51 44 270 1210 300 1340 340 1520 380 1700 410 1830

0.043 1.09 63 58 53 50 43 280 1250 310 1380 360 1610 400 1780 430 1920

0.044 1.12 61 57 52 48 42 300 1340 330 1470 380 1700 420 1870 450 2010

0.045 1.14 60 56 51 47 41 310 1360 340 1520 390 1740 430 1920 470 2100

0.046 1.17 58 54 50 46 40 320 1430 360 1610 410 1830 450 2010 490 2130

0.047 1.19 57 53 49 45 39 340 1530 370 1650 430 1920 470 2100 510 2270

0.048 1.22 56 52 48 44 36 350 1560 390 1740 450 2010 490 2180 540 2350

0.049 1.24 55 51 47 43 36 370 1560 410 1830 470 2100 510 2270 550 2450

0.050 1.27 54 50 46 42 37 380 1700 420 1870 490 2180 530 2380 570 2500

0.051 1.30 53 49 45 42 36 400 1760 440 1960 500 2230 560 2500 610 2670

0.052 1.32 52 48 44 41 36 410 1830 480 2050 520 2320 580 2580 620 2730

0.053 1.35 51 47 43 40 36 430 1920 470 2100 540 2410 600 2670 640 2850

0.054 1.37 50 46 42 39 34 440 1960 490 2180 580 2500 620 2780 660 2990

0.055 1.40 49 45 41 38 33 460 2050 510 2270 590 2630 640 2850 690 3070

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.