CEN/TS 17482:2020

(Main)Bitumen and bituminous binders - Determination of acid number of bitumen - Potentiometric method

Bitumen and bituminous binders - Determination of acid number of bitumen - Potentiometric method

This document describes a method for the determination of the free acidic constituents present in bitumen, conventionally known as acid number.

WARNING - The use of this document may involve hazardous materials, operations and equipment. This document does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this document to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

Bitumen und bitumenhaltige Bindemittel - Bestimmung der Säurezahl von Bitumen - Potentiometrisches Verfahren

Dieses Dokument beschreibt ein Verfahren zur Bestimmung der in Bitumen enthaltenen freien sauren Bestandteile, gemeinhin als Säurezahl bekannt.

WARNUNG - Die Anwendung dieses Dokuments kann gefährliche Substanzen, Arbeitsgänge und Ausrüstung einschließen. Dieses Dokument erhebt nicht den Anspruch, auf alle Sicherheitsprobleme hinzuweisen, die mit seiner Anwendung verbunden sind. Es liegt in der Verantwortung des Anwenders dieses Dokuments, geeignete Sicherheits und Gesundheitsschutzmaßnahmen vorzusehen und im Vorfeld die Anwendbarkeit von einschränkenden Vorschriften zu klären.

Bitumes et liants bitumineux - Détermination de l'indice d'acide d’un bitume - Méthode potentiométrique

Le présent document spécifie une méthode de détermination des constituants acides libres présents dans un bitume, conventionnellement désignés sous le terme « indice d’acide ».

AVERTISSEMENT - L'utilisation de ce document implique l'intervention de produits, d'opérations et d'équipements à caractère dangereux. Le présent document n'est pas censé aborder tous les problèmes de sécurité concernés par son usage. Il est de la responsabilité de l'utilisateur de ce document de consulter et d'établir des règles de sécurité et d'hygiène appropriées et de déterminer l'applicabilité des restrictions réglementaires avant utilisation.

Bitumen in bitumenska veziva - Določevanje kislinskega števila bitumna - Potenciometrijska metoda

General Information

- Status

- Published

- Publication Date

- 14-Jul-2020

- Technical Committee

- CEN/TC 336 - Bituminous binders

- Drafting Committee

- CEN/TC 336/WG 2 - Emulsions and fluxed bitumens

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 30-May-2024

- Completion Date

- 14-Apr-2025

Overview

CEN/TS 17482:2020 - Bitumen and bituminous binders - Determination of acid number of bitumen - Potentiometric method - specifies a laboratory potentiometric titration procedure to measure the acid number (mg KOH/g) of bitumen and bituminous binders. The method quantifies the free acidic constituents by dissolving bitumen in a solvent/alcohol mixture and titrating with an alcoholic potassium hydroxide solution while monitoring the potential change (potentiometry).

Safety note: the procedure involves hazardous chemicals and equipment. Users must follow appropriate health, safety and regulatory requirements.

Key topics and technical requirements

- Principle: Dissolve bitumen in a 1:1 mix of solvent (xylene or toluene) and isopropanol (propan-2-ol) and titrate with 0.1 mol/L alcoholic KOH; determine equivalence point by the inflection of the potential curve.

- Reagents: Analytical-grade potassium hydroxide (KOH), propan-2-ol, solvent (xylene or toluene), benzoic acid (for standardization). A 0.1 mol/L alcoholic KOH solution can be prepared (≈6.0 ± 0.2 g KOH per 1 L propan-2-ol) or used as a certified ready-to-use solution.

- Apparatus: Automatic or manual potentiometric titration system with sensitivity ≥2 mV, Ag/AgCl reference and non-aqueous pH glass electrode (or combined electrode), magnetic stirrer, precision balance (±1 mg).

- Sampling & sample prep: Follow EN 58 for sampling and EN 12594 for preparation. Typical test uses ~5 g bitumen dissolved in 50 mL solvent + 50 mL propan-2-ol (ratios adjustable while maintaining 1:1 solvent/alcohol and minimum bitumen-to-solvent ratio).

- Standardization & blanks: Standardize alcoholic KOH by titrating benzoic acid and perform a daily blank on the solvent/alcohol mix. Titrations should be continued until potential slope stabilizes; multiple equivalence points may occur and must be reported.

- Results & precision: Calculation and reporting procedures are specified; users should follow the document for expression of results, repeatability and reproducibility requirements.

Applications and who uses it

- Quality control and laboratory testing in bitumen production and paving material supply chains.

- Asphalt technologists, bitumen suppliers, materials testing laboratories, road authorities and research institutes who need reliable measurement of acidic constituents that can affect binder performance, adhesion and compatibility with additives.

Related standards

- EN 58 - Sampling of bituminous binders

- EN 12594 - Preparation of test samples for bituminous binders

Keywords: CEN/TS 17482:2020, acid number, bitumen, potentiometric method, alcoholic potassium hydroxide, potentiometry, bituminous binders, titration, Ag/AgCl electrode.

Frequently Asked Questions

CEN/TS 17482:2020 is a technical specification published by the European Committee for Standardization (CEN). Its full title is "Bitumen and bituminous binders - Determination of acid number of bitumen - Potentiometric method". This standard covers: This document describes a method for the determination of the free acidic constituents present in bitumen, conventionally known as acid number. WARNING - The use of this document may involve hazardous materials, operations and equipment. This document does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this document to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

This document describes a method for the determination of the free acidic constituents present in bitumen, conventionally known as acid number. WARNING - The use of this document may involve hazardous materials, operations and equipment. This document does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this document to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

CEN/TS 17482:2020 is classified under the following ICS (International Classification for Standards) categories: 75.140 - Waxes, bituminous materials and other petroleum products; 91.100.50 - Binders. Sealing materials. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase CEN/TS 17482:2020 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2020

Bitumen in bitumenska veziva - Določevanje kislinskega števila bitumna -

Potenciometrijska metoda

Bitumen and bituminous binders - Determination of acid number of bitumen -

Potentiometric method

Bitumen und bitumenhaltige Bindemittel - Bestimmung der Säurezahl von Bitumen -

Potentiometrisches Verfahren

Bitumes et liants bitumineux - Détermination de l'indice d'acide d’un bitume - Méthode

potentiométrique

Ta slovenski standard je istoveten z: CEN/TS 17482:2020

ICS:

75.140 Voski, bitumni in drugi naftni Waxes, bituminous materials

proizvodi and other petroleum products

91.100.50 Veziva. Tesnilni materiali Binders. Sealing materials

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TS 17482

TECHNICAL SPECIFICATION

SPÉCIFICATION TECHNIQUE

July 2020

TECHNISCHE SPEZIFIKATION

ICS 75.140; 91.100.50

English Version

Bitumen and bituminous binders - Determination of acid

number of bitumen - Potentiometric method

Bitumes et liants bitumineux - Détermination de Bitumen und bitumenhaltige Bindemittel -

l'indice d'acide d'un bitume - Méthode Bestimmung der Säurezahl von Bitumen -

potentiométrique Potentiometrisches Verfahren

This Technical Specification (CEN/TS) was approved by CEN on 1 June 2020 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to

submit their comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS

available promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in

parallel to the CEN/TS) until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 17482:2020 E

worldwide for CEN national Members.

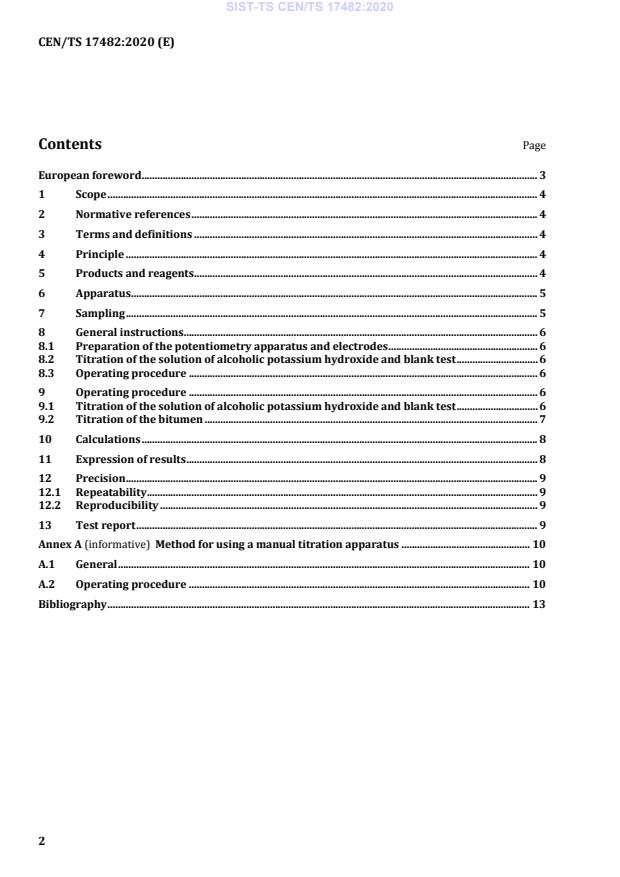

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 4

4 Principle . 4

5 Products and reagents . 4

6 Apparatus . 5

7 Sampling . 5

8 General instructions. 6

8.1 Preparation of the potentiometry apparatus and electrodes . 6

8.2 Titration of the solution of alcoholic potassium hydroxide and blank test . 6

8.3 Operating procedure . 6

9 Operating procedure . 6

9.1 Titration of the solution of alcoholic potassium hydroxide and blank test . 6

9.2 Titration of the bitumen . 7

10 Calculations . 8

11 Expression of results . 8

12 Precision . 9

12.1 Repeatability . 9

12.2 Reproducibility . 9

13 Test report . 9

Annex A (informative) Method for using a manual titration apparatus . 10

A.1 General . 10

A.2 Operating procedure . 10

Bibliography . 13

European foreword

This document (CEN/TS 17482:2020) has been prepared by Technical Committee CEN/TC 336

“Bituminous binders”, the secretariat of which is held by AFNOR.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to announce this Technical Specification: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document describes a method for the determination of the free acidic constituents present in

bitumen, conventionally known as acid number.

WARNING — The use of this document may involve hazardous materials, operations and equipment. This

document does not purport to address all of the safety problems associated with its use. It is the

responsibility of the user of this document to establish appropriate safety and health practices and to

determine the applicability of regulatory limitations prior to use.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 58, Bitumen and bituminous binders — Sampling bituminous binders

EN 12594, Bitumen and bituminous binders — Preparation of test samples

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

acid number

number of milligrams of potassium hydroxide necessary for the neutralization of the free acids contained

in one gram of bitumen

3.2

equivalence point

stage of the titration procedure at which the added volume (equivalent volume) of titration reagent has

allowed to neutralize the acid compounds of the test sample

Note 1 to entry: In potentiometric titrations, this point corresponds to the inflexion point of the potential curve.

4 Principle

The bitumen is dissolved in a solvent-alcohol mixture. The acidic constituents are titrated using a solution

of alcoholic potassium hydroxide. The titration is monitored by potentiometry.

5 Products and reagents

5.1 General

Only use reagents of a quality recognized for analysis.

5.2 Potassium hydroxide RP (analytical grade), in pellets.

5.3 Propan-2-ol (isopropanol) RP (analytical grade).

5.4 Solvent RP (analytical grade), xylene or methyl benzene (toluene).

5.5 Benzoic acid RP (analytical grade).

5.6 Solution of alcoholic potassium hydroxide, 0,1 mol/L.

Dissolve (6,0 ± 0,2) g of potassium hydroxide pellets (5.2) in 1 L of pure propan-2-ol (5.3).

A ready-for-use, off-the-shelf solution can also be used. Only a titration certificate coming from an

authorized supplier can avoid the titration procedure (9.1). The alcoholic potassium hydroxide solution

shall be kept in brown glass containers and stored in the dark.

6 Apparatus

6.1 General

Usual laboratory equipment, together with the following.

6.2 Balance of adequate capacity for weight with precision of ± 1 mg.

6.3 Potentiometry apparatus, for automatic or manual titration:

— apparatus for automatic titration, including a titration device with sensitivity of at least 2 mV,

equipped with an automatic dosage unit with a capacity of 5 mL to 20 mL. Most of these pieces of

equipment offer a program for potentiometric detection with dynamic equivalence point titration. It

means that increment is slowed down near the equivalence point;

— apparatus for manual titration, including a potentiometer with a sensitivity of at least 2 mV and a

burette with a pointed spout.

The equipment shall allow titration steps to be performed at an accuracy of at least ± 0,05 mL in volume.

6.4 Glass combination electrode – Ag/AgCl.

6.4.1 A pH glass electrode for non-aqueous media and a reference electrode of Ag/AgCl (kept in its

inner reference electrolyte).

6.4.2 Combined pH electrode for non-aqueous media instead of the two electrodes cell of 6.4.1.

6.5 Glass beakers, or any glass titration container, specific for the automatic potentiometric titration

device (6.3).

The volume of beakers shall be appropriate for immersing the membrane of electrodes into the tested

solution and shall allow increasing this volume during titration.

The level of solution in the beaker shall be below the filling hole of the electrodes but has to be high

enough to prevent the stirring bar (if it is necessary to use it) from hitting the membranes if the electrodes

have to be close to the bottom of the beaker.

6.6 Magnetic stirrer, with polytetrafluoroethylene (PTFE)-coated bar.

7 Sampling

Take the sample in accordance with EN 58. Prepare the test samples in accordance with EN 12594.

8 General instructions

8.1 Preparation of the potentiometry apparatus and electrodes

The titration device shall be prepared following manufacturer instructions.

Special attention shall be paid to the storing and maintenance of the electrodes:

— before using, the inner body shall be filled with the electrolyte. If necessary, refill and let the electrode

to rest for at least o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...