EN 17613:2022

(Main)LPG equipment and accessories - Composite piping for use with LPG in liquid phase and vapour pressure phase - Design and manufacture

LPG equipment and accessories - Composite piping for use with LPG in liquid phase and vapour pressure phase - Design and manufacture

This document specifies requirements for the design, manufacture and testing of composite pipe for use with LPG in liquid phase and vapour pressure phase.

This document is applicable to LPG composite pipe having a maximum allowable pressure of less than or equal to 25 bar.

This document applies to pipe made from thermoplastics, which can include some degree of reinforcement.

It does not apply to fibre reinforced thermosets, commonly referred to as glass fibre reinforced plastic (GRP), nor rigid metals or corrugated metal pipe or hoses to EN ISO 10380 [6].

For the purpose of this document, composite pipe refers to the design requirements below:

a) Design 1: PE-based thick-walled pipe with multi-layer design without additional reinforcement than the wall thickness of the PE;

b) Design 2: Nylon-based multi-layer design with a polyester or aramid braid for reinforcement.

NOTE For installation of composite pipework systems, see EN 16125.

Flüssiggas-Geräte und Ausrüstungsteile - Verrohrung aus Verbundwerkstoffen zum Einsatz mit LPG in der Flüssig- und Dampfdruck-Phase - Auslegung und Herstellung

Dieses Dokument legt Anforderungen an die Auslegung, Herstellung und Prüfung von Rohren aus Verbundwerkstoffen für die Verwendung mit Flüssiggas in der Flüssig- und in der Dampfdruck-Phase fest.

Dieses Dokument ist anwendbar für Rohre aus Verbundwerkstoffen für Flüssiggas mit einem höchsten zulässigen Druck kleiner oder gleich 25 bar.

Dieses Dokument gilt für Rohre aus thermoplastischem Material, das einen gewissen Verstärkungsgrad einschließen kann.

Es gilt weder für faserverstärkte duroplastische Kunststoffe, gewöhnlich als glasfaserverstärkte Kunststoffe (GFK) bezeichnet, noch für starre oder gewellte Metallrohre oder -schläuche nach EN ISO 10380 [6].

Für die Zwecke dieses Dokuments beziehen sich Verbundrohre auf die nachstehenden Auslegungsanforderungen:

a) Auslegung 1: dickwandiges Rohr auf PE-Basis mit mehrschichtigem Aufbau ohne zusätzliche Verstärkung außer der Wanddicke des PE;

b) Auslegung 2: Rohr auf Nylonbasis mit mehrschichtigem Aufbau und mit einem Polyester- oder Aramidgeflecht als Verstärkung.

ANMERKUNG Zur Verlegung von Rohrleitungssystemen aus Verbundwerkstoffen siehe EN 16125.

Équipements pour gaz de pétrole liquéfié et leurs accessoires - Canalisations composites pour GPL en phase liquide et phase vapeur - Conception et fabrication

Le présent document spécifie les exigences pour la conception, la fabrication et les essais des tuyaux composites destinés à être utilisés avec du GPL en phase liquide et phase vapeur.

Le présent document est applicable aux tuyaux composites pour GPL ayant une pression maximale admissible inférieure ou égale à 25 bar.

Le présent document s'applique aux tuyaux fabriqués en thermoplastiques, qui peuvent inclure un certain degré de renforcement.

Il ne s'applique pas aux matériaux thermodurcissables renforcés de fibres, communément appelés plastique renforcé de verre (GRP), ni aux tuyaux métalliques rigides ou onduleux conformément à l'EN ISO 10380 [6].

Pour les besoins du présent document, le terme « tuyau composite » fait référence aux exigences de conception ci-dessous :

a) Conception 1 : tuyau à paroi épaisse en PE avec conception multicouches, sans renfort supplémentaire en plus de l'épaisseur de la paroi en PE;

b) Conception 2 : conception multicouches en nylon avec une armature en polyester ou en aramide pour le renforcement.

NOTE Pour l'installation des systèmes de canalisations composites, voir l'EN 16125.

Oprema in pribor za utekočinjeni naftni plin (UNP) - Cevni sistemi iz kompozitnih materialov za UNP v tekoči in plinski fazi - Konstruiranje in izdelava

Ta evropski standard določa zahteve za konstruiranje, izdelavo in preskušanje cevnih sistemov iz kompozitnih materialov za UNP v tekoči in plinski fazi.

Ta dokument se uporablja za cevne sisteme iz kompozitnih materialov za UNP z največjim dovoljenim tlakom, manjšim ali enakim 25 barov.

General Information

- Status

- Published

- Publication Date

- 02-Aug-2022

- Technical Committee

- CEN/TC 286 - Liquefied petroleum gas equipment and accessories

- Drafting Committee

- CEN/TC 286/WG 8 - LPG pipework

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 03-Aug-2022

- Due Date

- 20-Jul-2022

- Completion Date

- 03-Aug-2022

Overview

EN 17613:2022 is a European standard from CEN that specifies design, manufacture and testing requirements for composite piping used with LPG (liquid phase and vapour pressure phase). It applies to thermoplastic-based composite pipe with a maximum allowable pressure of ≤ 25 bar, covering common composite constructions used in LPG systems while excluding GRP (glass‑fibre reinforced thermosets), rigid metal or corrugated metal pipe and hoses to EN ISO 10380.

Key design forms covered:

- Design 1: PE‑based, thick‑walled multi‑layer pipe without added braid reinforcement

- Design 2: Nylon‑based multi‑layer pipe with polyester or aramid braid reinforcement

For installation guidance, EN 16125 is referenced.

Key topics and requirements

- Materials: All materials in contact with LPG must be chemically and physically compatible with LPG; applicable referenced standards include EN 1555 series, ISO 11922‑1, EN 10088‑1, EN 549.

- Design conditions:

- Minimum operating temperature: −20 °C (shorter excursions below may occur)

- Maximum working temperature: +40 °C (above and underground)

- Estimated working life: at least 25 years

- Pressure rating: Intended for composite pipe with maximum allowable pressure up to 25 bar; design pressure for pressurised parts is at least 25 bar.

- Testing requirements: Specified test programme includes (but is not limited to):

- Internal burst pressure test

- Hydrostatic strength test (internal pressure resistance)

- Fatigue (cyclic) test

- Fitting pull‑out test

- Puncture test

- Permeation test and LPG compatibility test

- Static electricity considerations and classification

Typical sampling: three samples per test (assemblies with couplings); retest rules defined for failures.

- Documentation and marking: Requirements for product and installation manuals, marking of pipe and connectors, and record keeping are included.

- Environmental considerations: Manufacturers are encouraged to adopt environmental management practices (see EN ISO 14004 and related guidance).

Applications and who uses it

EN 17613:2022 is intended for:

- Manufacturers and designers of composite LPG pipe systems (PE and nylon constructions)

- Test laboratories and quality assurance teams verifying conformity to CEN requirements

- System integrators and installers referencing design limits and compatibility prior to installation (installation rules in EN 16125)

- Regulators and procurement teams specifying compliant components for LPG distribution, vehicle refuelling, retail forecourts and fixed installations

Related standards

- EN 16125 (installation of composite pipework systems)

- EN 1555 series (PE piping for gaseous fuels)

- EN 14427 (composite cylinders for LPG)

- EN ISO 1167 series (resistance to internal pressure)

- CEN/TS 16769 (LPG terminology)

Keywords: EN 17613:2022, LPG composite pipe, composite piping, thermoplastic LPG piping, PE-based pipe, nylon-based pipe, permeation test, hydrostatic strength, LPG equipment and accessories.

Frequently Asked Questions

EN 17613:2022 is a standard published by the European Committee for Standardization (CEN). Its full title is "LPG equipment and accessories - Composite piping for use with LPG in liquid phase and vapour pressure phase - Design and manufacture". This standard covers: This document specifies requirements for the design, manufacture and testing of composite pipe for use with LPG in liquid phase and vapour pressure phase. This document is applicable to LPG composite pipe having a maximum allowable pressure of less than or equal to 25 bar. This document applies to pipe made from thermoplastics, which can include some degree of reinforcement. It does not apply to fibre reinforced thermosets, commonly referred to as glass fibre reinforced plastic (GRP), nor rigid metals or corrugated metal pipe or hoses to EN ISO 10380 [6]. For the purpose of this document, composite pipe refers to the design requirements below: a) Design 1: PE-based thick-walled pipe with multi-layer design without additional reinforcement than the wall thickness of the PE; b) Design 2: Nylon-based multi-layer design with a polyester or aramid braid for reinforcement. NOTE For installation of composite pipework systems, see EN 16125.

This document specifies requirements for the design, manufacture and testing of composite pipe for use with LPG in liquid phase and vapour pressure phase. This document is applicable to LPG composite pipe having a maximum allowable pressure of less than or equal to 25 bar. This document applies to pipe made from thermoplastics, which can include some degree of reinforcement. It does not apply to fibre reinforced thermosets, commonly referred to as glass fibre reinforced plastic (GRP), nor rigid metals or corrugated metal pipe or hoses to EN ISO 10380 [6]. For the purpose of this document, composite pipe refers to the design requirements below: a) Design 1: PE-based thick-walled pipe with multi-layer design without additional reinforcement than the wall thickness of the PE; b) Design 2: Nylon-based multi-layer design with a polyester or aramid braid for reinforcement. NOTE For installation of composite pipework systems, see EN 16125.

EN 17613:2022 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase EN 17613:2022 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2022

Oprema in pribor za utekočinjeni naftni plin (UNP) - Cevni sistemi iz kompozitnih

materialov za UNP v tekoči in plinski fazi - Konstruiranje in izdelava

LPG equipment and accessories - Composite piping for use with LPG in liquid phase and

vapour pressure phase - Design and manufacture

Flüssiggas-Geräte und Ausrüstungsteile - Verrohrung aus Verbundwerkstoffen zum

Einsatz mit LPG in der Flüssig- und Gasdruck-Phase - Auslegung und Herstellung

Équipements pour gaz de pétrole liquéfié et leurs accessoires - Canalisations

composites pour GPL en phase liquide et phase vapeur - Conception et fabrication

Ta slovenski standard je istoveten z: EN 17613:2022

ICS:

23.040.01 Deli cevovodov in cevovodi Pipeline components and

na splošno pipelines in general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17613

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2022

EUROPÄISCHE NORM

ICS 23.040.01

English Version

LPG equipment and accessories - Composite piping for use

with LPG in liquid phase and vapour pressure phase -

Design and manufacture

Équipements pour gaz de pétrole liquéfié et leurs Flüssiggas-Geräte und Ausrüstungsteile - Verrohrung

accessoires - Canalisations composites pour GPL en aus Verbundwerkstoffen zum Einsatz mit LPG in der

phase liquide et phase vapeur - Conception et Flüssig- und Gasdruck-Phase - Auslegung und

fabrication Herstellung

This European Standard was approved by CEN on 22 May 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17613:2022 E

worldwide for CEN national Members.

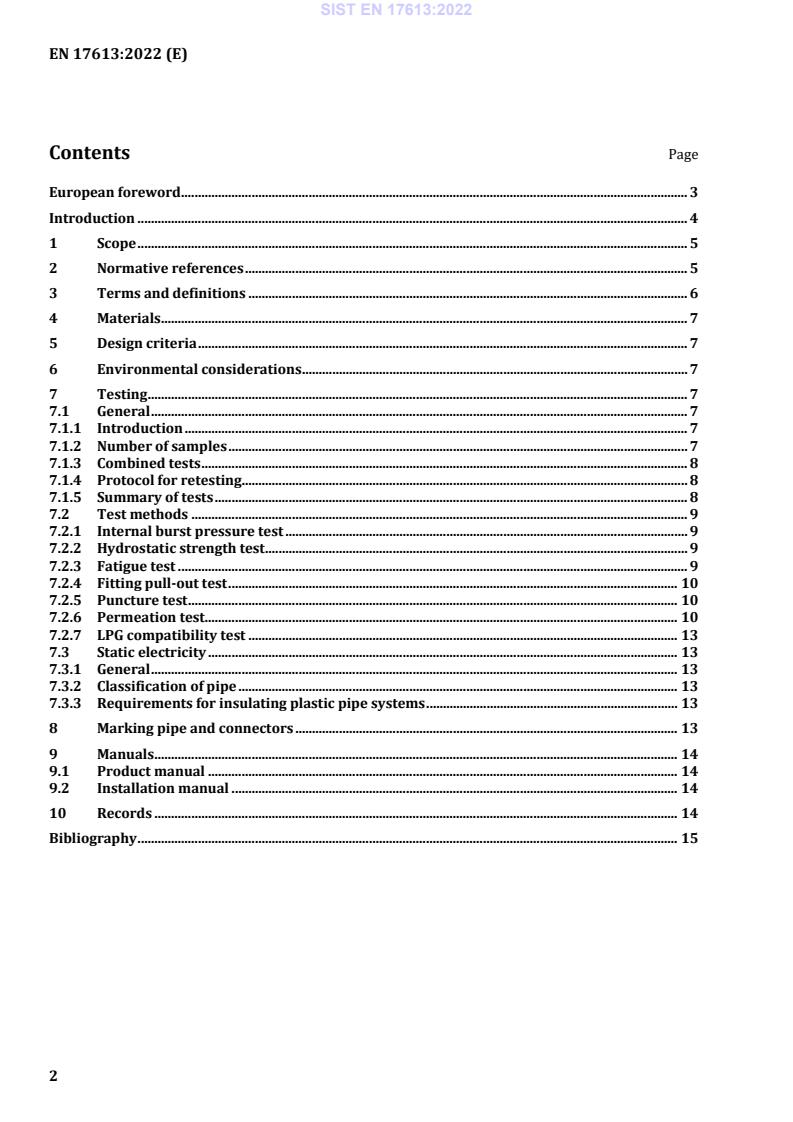

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Materials . 7

5 Design criteria . 7

6 Environmental considerations . 7

7 Testing . 7

7.1 General . 7

7.1.1 Introduction . 7

7.1.2 Number of samples . 7

7.1.3 Combined tests . 8

7.1.4 Protocol for retesting. 8

7.1.5 Summary of tests . 8

7.2 Test methods . 9

7.2.1 Internal burst pressure test . 9

7.2.2 Hydrostatic strength test . 9

7.2.3 Fatigue test . 9

7.2.4 Fitting pull-out test . 10

7.2.5 Puncture test . 10

7.2.6 Permeation test. 10

7.2.7 LPG compatibility test . 13

7.3 Static electricity . 13

7.3.1 General . 13

7.3.2 Classification of pipe . 13

7.3.3 Requirements for insulating plastic pipe systems . 13

8 Marking pipe and connectors . 13

9 Manuals . 14

9.1 Product manual . 14

9.2 Installation manual . 14

10 Records . 14

Bibliography . 15

European foreword

This document (EN 17613:2022) has been prepared by Technical Committee CEN/TC 286 “LPG

equipment and accessories”, the secretariat of which is held by NSAI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2023, and conflicting national standards shall

be withdrawn at the latest by February 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document calls for the use of substances and procedures that may be injurious to health and/or the

environment if adequate precautions are not taken. It refers only to technical suitability and does not

absolve the user from legal obligations at any stage.

This document is intended for users who take on the responsibility for the manufacturing of composite

pipe.

Protection of the environment is a key political issue in Europe and elsewhere. For CEN/TC 286 this is

covered in CEN/TS 16765 [1] and this Technical Specification should be read in conjunction with this

document. This document provides guidance on the environmental aspects to be considered regarding

equipment and accessories produced for the LPG industry and the following is addressed:

a) design;

b) manufacture;

c) packaging;

d) use and operation; and

e) disposal.

It is recommended that manufacturers develop an environmental management policy. For guidance see

EN ISO 14004 [2]. It has been assumed in the drafting of this document that the execution of its provisions

is entrusted to appropriately qualified and experienced people.

All pressures are gauge unless otherwise stated.

NOTE This document uses measurement of material properties, dimensions and pressures. All such

measurements are subject to a degree of uncertainty due to tolerances in measuring equipment, etc. It could be

beneficial to refer to the leaflet “measurement uncertainty leaflet (SP INFO 2000 27 uncertainty.pdf)” [9].

1 Scope

This document specifies requirements for the design, manufacture and testing of composite pipe for use

with LPG in liquid phase and vapour pressure phase.

This document is applicable to LPG composite pipe having a maximum allowable pressure of less than or

equal to 25 bar.

This document applies to pipe made from thermoplastics, which can include some degree of

reinforcement.

It does not apply to fibre reinforced thermosets, commonly referred to as glass fibre reinforced plastic

(GRP), nor rigid metals or corrugated metal pipe or hoses to EN ISO 10380 [6].

For the purpose of this document, composite pipe refers to the design requirements below:

a) Design 1: PE-based thick-walled pipe with multi-layer design without additional reinforcement than

the wall thickness of the PE;

b) Design 2: Nylon-based multi-layer design with a polyester or aramid braid for reinforcement.

NOTE For installation of composite pipework systems, see EN 16125.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 549, Rubber materials for seals and diaphragms for gas appliances and gas equipment

EN 1555-1, Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 1: General

EN 1555-2, Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 2: Pipes

EN 1555-3, Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 3: Fittings

EN 1555-4, Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 4: Valves

EN 1555-5, Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 5: Fitness for

purpose of the system

EN 10088-1, Stainless steels - Part 1: List of stainless steels

EN 14125:2013, Thermoplastic and flexible metal pipework for underground installation at petrol filling

stations

EN 14427:2022, LPG equipment and accessories - Transportable refillable fully wrapped composite

cylinders for LPG - Design and construction

CEN/TS 16769, LPG equipment and accessories - Terminology

EN 60243-2, Electric strength of insulating materials - Test methods - Part 2: Additional requirements for

tests using direct voltage

CLC/TR 60079-32-1, Explosive atmospheres - Part 32-1: Electrostatic hazards, guidance

EN ISO 8031, Rubber and plastics hoses and hose assemblies - Determination of electrical resistance and

conductivity (ISO 8031)

EN ISO 1167-1, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids - Determination

of the resistance to internal pressure - Part 1: General method (ISO 1167-1)

EN ISO 1167-2, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids - Determination

of the resistance to internal pressure - Part 2: Preparation of pipe test pieces (ISO 1167-2)

EN ISO 1167-3, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids - Determination

of the resistance to internal pressure - Part 3: Preparation of components (ISO 1167-3)

EN ISO 1167-4, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids - Determination

of the resistance to internal pressure - Part 4: Preparation of assemblies (ISO 1167-4)

ISO 11922-1, Thermoplastics pipes for the conveyance of fluids — Dimensions and tolerances — Part 1:

Metric series

ISO 15105-2, Plastics — Film and sheeting — Determination of gas-transmission rate — Part 2: Equal-

pressure method

3 Terms and definitions

For the purposes of this document, the terms and definitions given in CEN/TS 16769 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

design temperature

T

des

for each design condition, maximum fluid temperature that can be reached during service

[SOURCE: ISO 14692-1:2017, 3.2.18 [8]]

3.2

fitting

pressure containing component fitted to an LPG pressure system

3.3

liquefied petroleum gas

LPG

low pressure liquefied gas composed of one or more light hydrocarbons which are assigned to UN 1011,

UN 1075, UN 1965, UN 1969 or UN 1978 only and which consists mainly of propane, propene, butane,

butane isomers, butene with traces of other hydrocarbon gases

3.4

maximum allowable pressure

maximum pressure for which the equipment is designed

Note 1 to entry: All pressures are gauge pressures unless otherwise stated.

4 Materials

All materials in contact with LPG shall be physically and chemically compatible with LPG under all

operating conditions for which the pipe is designed.

Materials for pipe shall be selected to g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...