EN 12007-2:2012

(Main)Gas infrastructure - Pipelines for maximum operating pressure up to and including 16 bar - Part 2: Specific functional requirements for polyethylene (MOP up to and including 10 bar)

Gas infrastructure - Pipelines for maximum operating pressure up to and including 16 bar - Part 2: Specific functional requirements for polyethylene (MOP up to and including 10 bar)

This European Standard describes the specific functional requirements for polyethylene (PE) pipelines in addition to the general functional requirements of EN 12007-1 for:

a) a maximum operating pressure (MOP) up to and including 10 bar;

b) an operating temperature between -20 °C and +40 °C.

This European Standard covers three types of pipe:

- PE pipes including any identification stripes;

- PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe;

- PE pipes with a peelable, contiguous thermoplastics additional layer on the outside of the pipe.

This European Standard specifies common basic principles for gas infrastructure. Users of this European Standard should be aware that more detailed national standards and/or code of practice may exist in the CEN member countries. This European Standard is intended to be applied in association with these national standards and/or codes of practice setting out the above-mentioned basic principles.

In the event of conflicts in terms of more restrictive requirements in national legislation/regulation with the requirements of this European Standard, the national legislation/regulation should take precedence as illustrated in FprCEN/TR 13737-1.

FprCEN/TR 13737-1 gives:

- clarification of all legislations/regulations applicable in a member state;

- if appropriate, more restrictive national requirements;

- a national contact point for the latest information.

Gasinfrastruktur - Rohrleitungen mit einem maximal zulässigen Betriebsdruck bis einschließlich 16 bar - Teil 2: Spezifische funktionale Anforderungen für Polyethylen (MOP bis einschließlich 10 bar)

Diese Europäische Norm beschreibt, in Ergänzung zu den allgemeinen funktionalen Anforderungen von EN 12007-1, die besonderen funktionalen Anforderungen an Rohrleitungen aus Polyethylen, einschließlich der Verbindungen zwischen PE und anderen Werkstoffen, für:

a) einen maximal zulässigen Betriebsdruck (MOP) bis zu 10 bar;

b) und einer Betriebstemperatur von 20 °C bis 40 °C.

Diese Europäische Norm gilt für die folgenden drei Rohrarten:

- PE-Rohre einschließlich etwaiger Identifikationskennzeichnung;

- PE-Rohre mit auf der Rohraußen- oder Innenseite oder außen und/oder innen aufgebrachten co-extrudierten Schichten; und

- PE-Rohre mit einer abziehbaren, thermoplastischen Zusatzschicht auf der Rohraußenseite.

Diese Europäische Norm enthält allgemeine Grundsätze der Gasinfrastruktur. Anwender dieser Europäischen Norm sollten sich dessen bewusst sein, dass detailliertere nationale Normen und/oder Technische Regeln in den CEN-Mitgliedsländern existieren können.

Diese Europäische Norm soll in Verbindung mit diesen, die oben erwähnten allgemeinen Grundsätze darlegenden nationalen Normen und/oder Technischen Regeln angewendet werden.

Für den Fall eines Konflikts zwischen strengeren nationalen gesetzlichen Anforderungen/Bestimmungen und den Anforderungen dieser Europäischen Norm ist den nationalen gesetzlichen Anforderungen/Bestimmungen wie in CEN/TR 13737 (alle Teile) ausgeführt Vorrang einzuräumen.

CEN/TR 13737 (alle Teile) enthält

- eine Klarstellung aller geltenden Rechtsvorschriften/Bestimmungen eines Mitgliedstaats;

- ggf. weitergehende strengere nationale Anforderungen;

- einen nationalen Ansprechpartner für die Weitergabe neuester Informationen.

Infrastructures gazières - Canalisations pour pression maximale de service inférieure ou égale à 16 bar - Partie 2: Exigences fonctionnelles spécifiques pour le polyéthylène (MOP inférieure ou égale à 10 bar)

La présente Norme européenne décrit, en complément des exigences fonctionnelles générales de l’EN 12007-1, les exigences fonctionnelles spécifiques applicables aux canalisations en polyéthylène (PE) pour :

a) une pression maximale de service (MOP) inférieure ou égale à 10 bar;

b) une température de service comprise entre – 20 °C et + 40 °C.

La présente Norme européenne couvre trois types de tubes :

- les tubes en PE, y compris toutes bandes d’identification éventuelles ;

- les tubes en PE comportant des couches co-extrudées soit sur leur surface externe ou interne, soit sur leurs deux surfaces

- les tubes en PE comportant une couche supplémentaire thermoplastique contiguë pelable sur leur surface externe.

La présente Norme européenne spécifie les principes de base communs pour les infrastructures gazières. Il convient que les utilisateurs de la présente Norme européenne gardent à l'esprit l'existence éventuelle, dans les pays membres du CEN, de codes de pratique et/ou de normes nationales plus détaillées. La présente Norme européenne est destinée à s'appliquer conjointement avec ces normes nationales et/ou codes de pratique, qui détaillent les principes de base précités.

En cas de conflits en termes d’exigences plus restrictives dans la réglementations/législation nationale vis-à-vis des exigences de cette Norme européenne, la réglementation/législation nationale l’emporte, comme illustré dans le CEN/TR 13737 (toutes parties).

Le CEN/TR 13737 (toutes parties) donne :

- la clarification de toutes les législations/règlements applicables dans un état membre ;

- si approprié, des exigences nationales plus restrictives ;

- un point de contact national pour une information ultérieure.

Infrastruktura za plin - Cevovodni sistemi za najvišji delovni tlak do vključno 16 bar - 2. del: Posebne funkcionalne zahteve za polietilen (najvišji delovni tlak do vključno 10 bar)

Ta dokument se v celoti ali v delih normativno sklicuje na naslednje dokumente, ki so nepogrešljivi pri njegovi uporabi. Pri datiranih sklicevanjih se uporablja samo navedena izdaja. Pri nedatiranih sklicevanjih se uporablja zadnja izdaja referenčnega dokumenta (vključno z morebitnimi dopolnili). EN 1555-1, Cevni sistemi iz polimernih materialov za oskrbo s plinastimi gorivi – Polietilen (PE) – 1. del: Splošno EN 1555-2, Cevni sistemi iz polimernih materialov za oskrbo s plinastimi gorivi – Polietilen (PE) – 2. del: Cevi EN 1555-3, Cevni sistemi iz polimernih materialov za oskrbo s plinastimi gorivi – Polietilen (PE) – 3. del: Fitingi EN 1555-4, Cevni sistemi iz polimernih materialov za oskrbo s plinastimi gorivi – Polietilen (PE) – 4. del: Ventili EN 1555-5, Cevni sistemi iz polimernih materialov za oskrbo s plinastimi gorivi – Polietilen (PE) – 5. del: Ustreznost sistema namenu EN 12327, Infrastruktura za plin – Tlačni preskus, postopki za začetek in prenehanje obratovanja – Funkcionalne zahteve.

General Information

- Status

- Published

- Publication Date

- 31-Jul-2012

- Withdrawal Date

- 27-Feb-2013

- Technical Committee

- CEN/TC 234 - Gas infrastructure

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 04-Mar-2018

- Completion Date

- 04-Mar-2018

Relations

- Effective Date

- 08-Aug-2012

Overview

EN 12007-2:2012 - Gas infrastructure: specific functional requirements for polyethylene (PE) pipelines - covers PE pipelines used for gaseous fuel distribution with a maximum operating pressure (MOP) up to and including 10 bar and an operating temperature range of −20 °C to +40 °C. It complements the general principles of EN 12007-1 and applies to three PE pipe types: standard PE pipes (with identification stripes), co-extruded PE pipes, and PE pipes with a peelable external thermoplastic layer.

Key topics and technical requirements

- Scope & applicability

- PE pipelines for gas distribution (MOP ≤ 10 bar; −20 °C to +40 °C).

- Intended to be used alongside national standards/codes of practice; national legislation takes precedence (see CEN/TR 13737).

- Materials & compatibility

- PE materials and components shall comply with EN 1555 (Parts 1–5) for pipes, fittings, valves and fitness-for-purpose.

- Design parameters

- Requirements for selecting SDR, nominal diameters, wall thickness and MRS / LCL concepts.

- Verification of overall design coefficients and RCP (rapid crack propagation) - including the PRCP criterion.

- Jointing & assembly

- Approved techniques: butt fusion, electrofusion, and mechanical joints; guidance on visual inspection and fusion integrity.

- Procedures for squeeze-off (flow stopping) and handling pipework inside buildings.

- Construction & handling

- Storage, handling and transportation rules for straight, coiled and drummed pipes (informative Annex A).

- Laying, connection to existing systems, static electricity considerations and quality control during installation.

- Testing & commissioning

- Pressure testing and commissioning functional requirements (linked to EN 12327) and inspection regimes (pre-installation, during laying, joint integrity).

- Informative annexes

- Fusion joint inspection guidance (Annex B) and technical changes from the 2000 edition (Annex C).

Applications and users

Who uses EN 12007-2:2012:

- Pipeline designers and system engineers for gas distribution networks

- PE pipe and fittings manufacturers ensuring standards compliance

- Installation contractors and fusion jointing technicians

- Network operators, asset owners and maintenance teams (including renovation/trenchless projects)

- Regulators and certification/inspection bodies

Practical uses:

- Specifying PE gas mains and service lines up to 10 bar

- Defining jointing, storage, handling and pressure-testing procedures

- Ensuring material selection and design consider RCP and long-term hydrostatic strength

Related standards (select)

- EN 12007-1 - General functional requirements

- EN 1555 (Parts 1–5) - PE piping systems for gaseous fuels

- EN 12327 - Pressure testing and commissioning procedures

- ISO 12176-1 / -2 - Fusion equipment for PE systems

- CEN/TR 13737 - National legislation/requirements and contact points

Keywords: EN 12007-2:2012, gas infrastructure, polyethylene pipelines, MOP up to 10 bar, fusion jointing, pressure testing, EN 1555, RCP, squeeze-off.

Frequently Asked Questions

EN 12007-2:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Gas infrastructure - Pipelines for maximum operating pressure up to and including 16 bar - Part 2: Specific functional requirements for polyethylene (MOP up to and including 10 bar)". This standard covers: This European Standard describes the specific functional requirements for polyethylene (PE) pipelines in addition to the general functional requirements of EN 12007-1 for: a) a maximum operating pressure (MOP) up to and including 10 bar; b) an operating temperature between -20 °C and +40 °C. This European Standard covers three types of pipe: - PE pipes including any identification stripes; - PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe; - PE pipes with a peelable, contiguous thermoplastics additional layer on the outside of the pipe. This European Standard specifies common basic principles for gas infrastructure. Users of this European Standard should be aware that more detailed national standards and/or code of practice may exist in the CEN member countries. This European Standard is intended to be applied in association with these national standards and/or codes of practice setting out the above-mentioned basic principles. In the event of conflicts in terms of more restrictive requirements in national legislation/regulation with the requirements of this European Standard, the national legislation/regulation should take precedence as illustrated in FprCEN/TR 13737-1. FprCEN/TR 13737-1 gives: - clarification of all legislations/regulations applicable in a member state; - if appropriate, more restrictive national requirements; - a national contact point for the latest information.

This European Standard describes the specific functional requirements for polyethylene (PE) pipelines in addition to the general functional requirements of EN 12007-1 for: a) a maximum operating pressure (MOP) up to and including 10 bar; b) an operating temperature between -20 °C and +40 °C. This European Standard covers three types of pipe: - PE pipes including any identification stripes; - PE pipes with co-extruded layers on either or both the outside and/or inside of the pipe; - PE pipes with a peelable, contiguous thermoplastics additional layer on the outside of the pipe. This European Standard specifies common basic principles for gas infrastructure. Users of this European Standard should be aware that more detailed national standards and/or code of practice may exist in the CEN member countries. This European Standard is intended to be applied in association with these national standards and/or codes of practice setting out the above-mentioned basic principles. In the event of conflicts in terms of more restrictive requirements in national legislation/regulation with the requirements of this European Standard, the national legislation/regulation should take precedence as illustrated in FprCEN/TR 13737-1. FprCEN/TR 13737-1 gives: - clarification of all legislations/regulations applicable in a member state; - if appropriate, more restrictive national requirements; - a national contact point for the latest information.

EN 12007-2:2012 is classified under the following ICS (International Classification for Standards) categories: 23.040.20 - Plastics pipes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12007-2:2012 has the following relationships with other standards: It is inter standard links to EN 12007-2:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12007-2:2012 is associated with the following European legislation: Standardization Mandates: M/017. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 12007-2:2012 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gasinfrastruktur - Rohrleitungen mit einem maximal zulässigen Betriebsdruck bis einschließlich 16 bar - Teil 2: Besondere funktionale Anforderungen für Polyethylen (MOP bis einschließlich 10 bar)Infrastructures gazières - Canalisations pour pression maximale de service inférieure ou égale à 16 bar - Partie 2: Recommandations fonctionnelles spécifiques pour polyéthylène (MOP inférieure ou égale à 10 bar)Gas infrastructure - Pipelines for maximum operating pressure up to and including 16 bar - Part 2: Specific functional requirements for polyethylene (MOP up to and including 10 bar)91.140.40Sistemi za oskrbo s plinomGas supply systemsICS:Ta slovenski standard je istoveten z:EN 12007-2:2012SIST EN 12007-2:2013en,fr,de01-januar-2013SIST EN 12007-2:2013SLOVENSKI

STANDARDSIST EN 12007-2:20001DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12007-2

August 2012 ICS 23.040.20 Supersedes EN 12007-2:2000English Version

Gas infrastructure - Pipelines for maximum operating pressure up to and including 16 bar - Part 2: Specific functional requirements for polyethylene (MOP up to and including 10 bar) Infrastructures gazières - Canalisations pour pression maximale de service inférieure ou égale à 16 bar - Partie 2: Exigences fonctionnelles spécifiques pour le polyéthylène (MOP inférieure ou égale à 10 bar)

Gasinfrastruktur - Rohrleitungen mit einem maximal zulässigen Betriebsdruck bis einschließlich 16 bar - Teil 2: Spezifische funktionale Anforderungen für Polyethylen (MOP bis einschließlich 10 bar) This European Standard was approved by CEN on 24 May 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12007-2:2012: ESIST EN 12007-2:2013

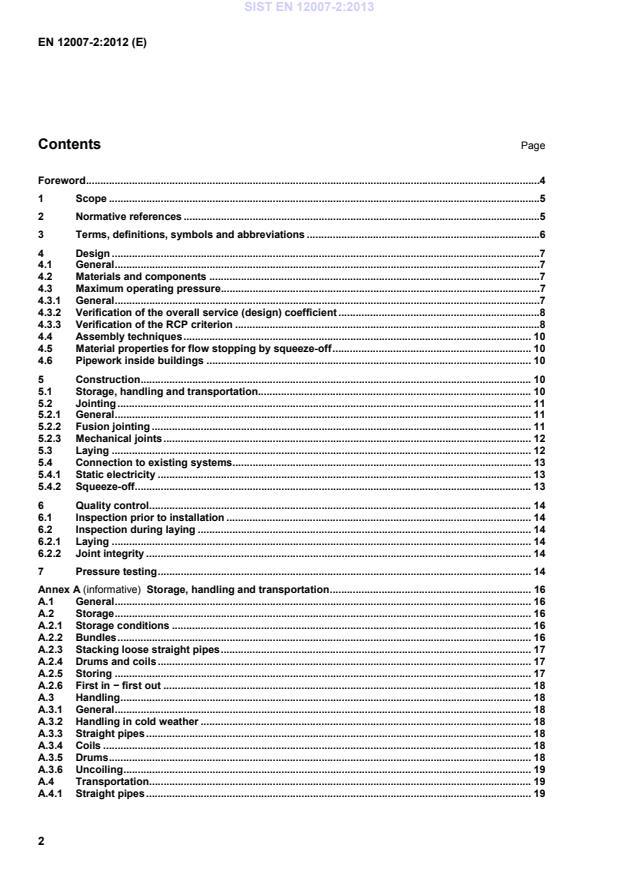

Storage, handling and transportation . 16A.1 General . 16A.2 Storage . 16A.2.1 Storage conditions . 16A.2.2 Bundles . 16A.2.3 Stacking loose straight pipes . 17A.2.4 Drums and coils . 17A.2.5 Storing . 17A.2.6 First in − first out . 18A.3 Handling . 18A.3.1 General . 18A.3.2 Handling in cold weather . 18A.3.3 Straight pipes . 18A.3.4 Coils . 18A.3.5 Drums . 18A.3.6 Uncoiling . 19A.4 Transportation . 19A.4.1 Straight pipes . 19SIST EN 12007-2:2013

Fusion joint integrity . 20B.1 General . 20B.2 Visual inspection criteria . 20B.2.1 General . 20B.2.2 Butt fusion guidelines for the visual examination of butt fusion joints . 20B.2.3 Electrofusion . 23B.2.4 Ancillary tooling . 26Annex C (informative) Technical changes between this European Standard and EN 12007-2:2000 . 27Bibliography . 28 SIST EN 12007-2:2013

Pipelines for maximum operating pressure up to and including 16 bar consists of the following parts: Part 1: General functional requirements Part 2: Specific functional requirements for polyethylene (MOP up to and including 10 bar)Part 3: Specific functional requirements for steel Part 4: Specific functional requirements for renovation Part 5: Specific functional recommendations of new service lines1 According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

1 To be published. SIST EN 12007-2:2013

Polyethylene (PE)

Part 1: General EN 1555-2, Plastics piping systems for the supply of gaseous fuels

Polyethylene (PE)

Part 2: Pipes EN 1555-3, Plastics piping systems for the supply of gaseous fuels

Polyethylene (PE)

Part 3: Fittings EN 1555-4, Plastics piping systems for the supply of gaseous fuels

Polyethylene (PE)

Part 4: Valves EN 1555-5, Plastics piping systems for the supply of gaseous fuels

Polyethylene (PE)

Part 5: Fitness for purpose of the system EN 12327, Gas infrastructure

Pressure testing, commissioning and decommissioning procedures — Functional requirements SIST EN 12007-2:2013

Equipment for fusion jointing polyethylene systems

Part 1: Butt fusion ISO 12176-2, Plastics pipes and fittings

Equipment for fusion jointing polyethylene systems — Part 2: Electrofusion 3 Terms, definitions, symbols and abbreviations For the purposes of this document, the following terms, definitions, symbols and abbreviations apply. 3.1

nominal outside diameter dn specified outside diameter

3.2

nominal wall thickness en

numerical designation of the wall thickness of a component, which is a convenient round number, approximately equal to the manufacturing dimension in millimetres 3.3

standard dimension ratio SDR number approximately equal to the quotient of the nominal outside diameter and the nominal wall thickness 3.4

maximum operating pressure MOP

maximum pressure at which a system can be operated continuously under normal operating conditions Note 1 to entry: Normal operating conditions are: no fault in any device or stream. 3.5

maximum incidental pressure MIP maximum pressure which a system can experience during a short time limited by the safety devices 3.6

butt fusion joint

method of jointing PE pipes and fittings where the two pipe ends are heated and brought together to be fused without the use of a separate fitting or filler material 3.7

electrofusion joint method of jointing PE pipes, using fittings which have an integrated electric heating element 3.8

squeeze-off act of squeezing a pipe to prevent the flow of gas 3.9

minimum required strength MRS value of the lower confidence limit rounded down to the next lower value of the R10 series when the lower confidence limit is below 10 MPa, or to the next lower value of the R20 series when the lower confidence limit is 10 MPa or greater SIST EN 12007-2:2013

Key P

pressure levels; PRCP

critical rapid crack propagation pressure; STPmax maximum strength test pressure; STPmin minimum strength test pressure; MIP

maximum incidental pressure; MOP maximum operating pressure. System design F120DSDRCMRSMOP×−××≤)( 1,5RCPPMOP≤ Pressure testing 1201,5−≤≤×SDRMRSSTPMOP RCP0,9PSTPMIP≤< NOTE For RCP conditions see EN 1555-2 and EN 1555-5. Figure 1 — Pressure conditions in a PE-system SIST EN 12007-2:2013

Figure 2 — Isobaric curves of global radiation in gigajoules per square metre per year in Europe

Pipes shall not be used where it is considered that they have exceeded the maximum UV exposure limit, unless they have been tested to demonstrate acceptable performance in accordance with existing standards. Further guidance on storage, handling and

...

SIST EN 12007-2:2013は、ポリエチレン(PE)パイプラインに関する特定の機能要件を定めており、ガスインフラストラクチャの一部として重要な役割を果たします。この標準は、最大運転圧力(MOP)が10バールまでの範囲を対象としており、-20 °Cから+40 °Cの間の運転温度を考慮しています。 この標準の強みは、PEパイプの多様性をカバーしている点です。具体的には、識別ストライプを含むPEパイプ、外側または内側に共押出層を持つPEパイプ、外側に剥がし可能な連続熱可塑性追加層を持つPEパイプを扱います。このように、異なるタイプのパイプに対する具体的な要件を設定することで、利用者は特定の用途に応じた適切な選択を行うことができます。 さらに、EN 12007-2:2012は、ガスインフラストラクチャに関連する基本的な原則を定めており、CEN加盟国における国別標準や実施基準との相互適用性を考慮しているため、実務上の柔軟性も持っています。国の法律や規制がより厳しい要件を提示している場合、国の法律が優先されることも明確にされており、現場での適応が容易です。 この文書は、ガスインフラストラクチャの安全性と効率性を向上させるための基盤を提供しているため、業界関係者にとって非常に関連性の高い標準です。すべての利害関係者がこれらの特定の要件を理解し、遵守することで、ガス供給の安全性が確保されることが期待されます。

Die europäische Norm EN 12007-2:2012 behandelt die spezifischen funktionalen Anforderungen für Polyethylen (PE) Pipelines, die für einen maximalen Betriebsdruck (MOP) von bis zu und einschließlich 10 bar ausgelegt sind. Sie ergänzt die allgemeinen funktionalen Anforderungen der EN 12007-1 und fokussiert sich auf wichtige Aspekte wie die Betriebstemperatur, die zwischen -20 °C und +40 °C liegen darf. Eine der herausragenden Stärken der EN 12007-2:2012 ist die klare Abgrenzung der verschiedenen Typen von PE-Rohren, die in der Norm berücksichtigt werden. Diese beinhalten nicht nur herkömmliche PE-Rohre mit Kennzeichnungsstreifen, sondern auch solche mit co-extrudierten Schichten sowie Rohre mit abziehbaren thermoplastischen Zusatzschichten. Diese Differenzierung ermöglicht eine gezielte Anwendung der Norm in verschiedenen Szenarien der Gasinfrastruktur und trägt dazu bei, dass die spezifischen funktionalen Anforderungen optimal erfüllt werden können. Ein weiteres wesentliches Merkmal dieser Norm ist die Festlegung gemeinsamer Grundprinzipien für die Gasinfrastruktur. Dies ist besonders relevant, da sie die Basis für die Anwendung in Verbindung mit nationalen Standards und/oder Praktiken in den CEN-Mitgliedsländern bildet. Die Norm hebt die Wichtigkeit hervor, dass Nutzer sich der bestehenden nationalen Standards bewusst sind, um die örtlichen rechtlichen Rahmenbedingungen und spezifischen Anforderungen zu berücksichtigen. Dies fördert nicht nur die Einhaltung, sondern auch die Sicherheit und Effizienz in der Anwendung der PE-Pipelines. Ein zusätzliches starkes Element der EN 12007-2:2012 ist der Hinweis, dass im Falle von Konflikten zwischen nationalen Regelungen und den Anforderungen dieser europäischen Norm die nationalen Vorschriften Vorrang haben sollten. Dies zeigt deutlich, dass die Norm flexibel und anpassungsfähig ist, um den unterschiedlichen gesetzlichen Anforderungen der Mitgliedstaaten gerecht zu werden. Zusammenfassend lässt sich sagen, dass die EN 12007-2:2012 nicht nur einen klaren Rahmen für die spezifischen funktionalen Anforderungen an Polyethylen Pipelines bietet, sondern auch relevante Aspekte für die Umsetzung in der Praxis thematisiert. Ihre Relevanz in der Gasinfrastruktur ist unbestreitbar, da sie auf die modernen Anforderungen und die unterschiedlichen technischen Gegebenheiten reagiert und somit einen entscheidenden Beitrag zur Sicherheit und Zuverlässigkeit von Gasversorgungssystemen leistet.

EN 12007-2:2012 표준은 최대 운영 압력이 10 바까지 정치화공(PE) 파이프라인의 특정 기능 요구 사항을 설명하는 중요한 문서입니다. 이 표준의 범위는 -20°C에서 +40°C 사이의 운영 온도를 포함하여, 일반 기능 요구 사항을 제정한 EN 12007-1의 내용을 보완합니다. 이 표준은 세 가지 유형의 PE 파이프를 다루고 있습니다. 첫째, 식별 스트라이프가 포함된 PE 파이프; 둘째, 내부 또는 외부 또는 둘 다에 공동 압출층이 있는 PE 파이프; 셋째, 표면에 부착 가능한 연속 열가소성 추가 층이 있는 PE 파이프입니다. 이러한 유형의 구분은 사용자가 다양한 적용 분야에 맞춰 적합한 리소스를 선택하는 데 도움을 줍니다. EN 12007-2:2012의 강점 중 하나는 가스 인프라의 공통 기본 원칙을 명확히 하고 있다는 점입니다. 이는 사용자들이 자신의 국가에서 더 세부적인 표준이나 실천 강령이 존재할 수 있음을 알고, 이를 참고하여 더욱 안전하고 효과적으로 PE 파이프를 설계하고 설치할 수 있도록 합니다. 이 표준은 CEN 회원국의 국가 표준 및 실천 강령과 함께 적용될 것을 권장하며, 국가별 법령 및 규정이 EN 12007-2:2012의 요구 사항보다 더 엄격한 경우 국가 법령이 우선 적용됨을 명시하고 있습니다. 이러한 사항은 FprCEN/TR 13737-1에서 구체적으로 설명되어 있으며, 다양한 국가 법령의 적용 가능성에 대한 명확한 정보를 제공합니다. 결론적으로, EN 12007-2:2012 표준은 PE 파이프라인의 설계 및 운영에 있어 필수적인 기준을 제시하며, 그 범위와 강점을 통해 가스 인프라의 안전성과 신뢰성을 높이는 데 기여하고 있습니다.

La norme EN 12007-2:2012 définit les exigences fonctionnelles spécifiques pour les pipelines en polyéthylène (PE) spécifiquement pour une pression de fonctionnement maximale (MOP) allant jusqu'à 10 bar. Son domaine d'application est essentiel pour assurer que ces infrastructures gasifiantes soient non seulement conformes aux exigences techniques, mais également adaptées aux conditions environnementales avec une température de fonctionnement allant de -20 °C à +40 °C. L'une des forces majeures de cette norme réside dans son approche exhaustive, qui couvre trois types de tuyaux en PE : les tuyaux en PE avec des bandes d'identification, ceux présentant des couches co-extrudées, et ceux dotés d'une couche supplémentaire de thermoplastique peelable. Cette diversité permet une grande flexibilité dans l'application et le choix des matériaux, garantissant ainsi une adaptation aux besoins spécifiques de l'infrastructure gazière. De plus, la norme EN 12007-2:2012 souligne l'importance d'intégrer les exigences de la norme EN 12007-1, établissant un cadre solide de principes de base pour l'infrastructure gazière. Il est crucial de noter que bien que cette norme européenne offre une direction claire, elle n’opère pas en vase clos et indique que des normes nationales plus détaillées peuvent exister. Cette synergie assure que les utilisateurs soient bien informés des législations et régulations en vigueur dans leur pays, garantissant ainsi la conformité avec toute exigence nationale plus stricte. En outre, son alinéa sur la prépondérance de la législation nationale en cas de conflit souligne la pertinence de cette norme dans le contexte de la régulation locale. Ce point est essentiel pour les acteurs du secteur, car il leur permet de naviguer efficacement dans le paysage complexe des réglementations tout en répondant aux spécificités de l'application des pipelines en PE. En conclusion, la norme EN 12007-2:2012 se révèle être un document fondamental pour toute entreprise impliquée dans l'infrastructure gazière, assurant que les exigences fonctionnelles sont respectées tout en tenant compte des divers égards réglementaires nationaux. Sa formalisation des exigences fonctionnelles spécifiques pour les pipelines en polyéthylène ajoute une valeur significative à la sécurité et à l'efficacité des systèmes gaziers.

The EN 12007-2:2012 standard provides a comprehensive framework for the specific functional requirements of polyethylene (PE) pipelines intended for gas infrastructure with a maximum operating pressure (MOP) up to and including 10 bar. Its well-defined scope includes detailed specifications for operating temperatures ranging from -20 °C to +40 °C, ensuring optimal performance and safety within these conditions. One of the notable strengths of this standard is its coverage of three distinct types of PE pipes, which enhances its applicability across various gas transportation scenarios. The inclusion of PE pipes with identification stripes, co-extruded layers, and peelable thermoplastics additional layers ensures that the standard addresses diverse technical requirements and enhances the versatility of PE pipelines in gas infrastructure projects. Furthermore, the standard emphasizes the importance of integration with pre-existing national standards and codes of practice, promoting a harmonized approach to gas pipeline design and installation across CEN member countries. This collaborative aspect ensures that while EN 12007-2:2012 provides a robust baseline, stakeholders are encouraged to adhere to potentially more restrictive national regulations, prioritizing local legislative requirements where applicable. The relevance of EN 12007-2:2012 cannot be understated in the context of safety and efficiency in gas infrastructure. By specifying common basic principles, the standard aids manufacturers, engineers, and regulatory bodies in understanding and implementing the essential safety measures necessary for reliable gas transport. Additionally, its alignment with the guidelines set forth in FprCEN/TR 13737-1 offers clarity in navigating national legislations, further enhancing its applicability and effectiveness. Overall, the EN 12007-2:2012 standard serves as a critical reference for the gas infrastructure sector, ensuring that PE pipelines are designed, manufactured, and maintained in accordance with stringent functional requirements, thereby fostering reliability and safety in gas distribution operations.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...