IEC 62841-3-5:2022

(Main)Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 3-5: Particular requirements for transportable band saws

Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 3-5: Particular requirements for transportable band saws

IEC 62841-3-5:2022 applies to band saws intended for cutting wood and analogous materials, plastics and metals, except magnesium. This document does not apply to transportable scroll saws and jig saws with a reciprocating blade. This document does not apply to

hand-held band saws;

non-vertical saws; and

wire saws.

NOTE 101 It is planned that a document on transportable scroll saws and jig saws will be published.

NOTE 102 Hand-held band saws will be covered by a future part of IEC 62841-2.

NOTE 103 In Europe (EN IEC 62841-3-5), the following conditions apply:

This document does not apply to stationary band saws intended to cut wood and similar materials. Stationary band saws that are intended to cut wood and similar materials are covered by EN 1807-1.

This document applies to band saws having a mass of:

- maximum 25 kg for tools capable of being lifted by hand by one person;

- maximum 50 kg for tools capable of being lifted by hand by two persons.

Outils électroportatifs à moteur, outils portables et machines pour jardins et pelouses - Sécurité - Partie 3-5: Exigences particulières pour les scies à ruban transportables

IEC 62841-3-5:2022 applique aux scies à ruban destinées à la coupe du bois et des matériaux analogues, des plastiques et des métaux, à l’exception du magnésium.

Le présent document ne s'applique pas aux scies à découper et aux scies sauteuses transportables avec une lame à va-et-vient.

Le présent document ne s'applique pas aux

scies à ruban portatives;

scies non verticales; et

scies à fil.

NOTE 101 Il est prévu qu'un document relatif aux scies à découper et aux scies sauteuses transportables soit publié.

NOTE 102 Les scies à ruban portatives seront couvertes par une future partie de l’IEC 62841-2.

NOTE 103 En Europe (EN IEC 62841-3-5), les conditions suivantes s'appliquent:

Le présent document ne s'applique pas aux scies à ruban fixes destinées à la coupe du bois et des matériaux similaires. Les scies à ruban fixes destinées à la coupe du bois et des matériaux similaires sont couvertes par l’EN 1807-1.

Le présent document s'applique aux scies à ruban dont la masse est:

– de 25 kg au plus pour les outils qui peuvent être soulevés à la main par une personne;

– de 50 kg au plus pour les outils qui peuvent être soulevés à la main par deux personnes.

General Information

- Status

- Published

- Publication Date

- 26-Apr-2022

- Technical Committee

- TC 116 - Safety of motor-operated electric tools

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Apr-2022

- Completion Date

- 06-May-2022

Overview

IEC 62841-3-5:2022 is an international standard published by the International Electrotechnical Commission (IEC) that specifies particular safety requirements for transportable band saws. This standard applies specifically to electric motor-operated band saws designed for cutting wood, plastics, analogous materials, and metals (excluding magnesium). It is part of the broader IEC 62841 series focused on safety aspects of electric motor-operated hand-held tools, transportable tools, and lawn and garden machinery.

Notably, IEC 62841-3-5:2022 excludes certain types of saws from its scope, such as transportable scroll saws, jig saws with reciprocating blades, hand-held band saws, non-vertical saws, wire saws, and stationary band saws. The standard also stipulates mass limits for applicable band saws, capping at 25 kilograms for tools lifted by one person, and 50 kilograms for tools lifted by two persons.

This standard supplements the general safety requirements defined in IEC 62841-1:2014, adding specific guidelines and test conditions relevant to transportable band saws to ensure operational safety and reduce mechanical and electrical hazards.

Key Topics

Scope and Applicability

Defines the specific band saw types covered-transportable, typically vertical, and used for cutting wood, plastics, and metals except magnesium. Clear exclusions help manufacturers identify relevant safety requirements.Safety Requirements

Includes mechanical hazard protections, alarm systems, protection against electrical shock, and control of hazardous emissions such as radiation or toxic substances.Testing and Endurance

Outlines testing protocols, including general test conditions, abnormal operation, endurance testing, and noise and vibration emission measurements.Mechanical Strength and Construction

Specifies criteria for mechanical robustness, safe construction practices, access restrictions to dangerous parts, and structural integrity under operational stresses.Marking and Instructions

Requires clear marking of safety warnings and provide detailed user manuals with operational guidance to mitigate misuse.Classification and Performance Levels

Guidance on classification based on tool features and performance thresholds to meet safety goals under IEC conformity assessments.

Applications

IEC 62841-3-5:2022 is essential for manufacturers, testing laboratories, and regulatory bodies involved with transportable band saws, particularly those intended for taxing cutting tasks in the woodworking, plastics, and metalworking industries. Its practical applications include:

Product Development and Manufacturing

Ensures that transportable band saws meet internationally recognized safety benchmarks during design and production phases.Safety Compliance and Certification

Facilitates certification processes by providing standard test methods and safety performance requirements for conformity assessments.Risk Management for End Users

Helps reduce risks of injury or equipment damage through mandated safety features and use instructions tailored to transportable band saw designs.Market Access and Regulatory Approval

Supports global market acceptance by harmonizing safety requirements across national and regional jurisdictions such as Europe through EN IEC 62841-3-5.Workplace Safety Programs

Assists occupational health and safety managers in enforcing tool safety standards that protect operators in construction and agriculture sectors.

Related Standards

IEC 62841-1:2014 – General safety requirements for electric motor-operated hand-held tools, transportable tools, and lawn and garden machinery, establishing baseline safety measures applicable to all tools in the series.

EN 1807-1 – Covers stationary band saws specifically intended for cutting wood and similar materials, complementing IEC 62841-3-5 exclusions.

Future Standards for Hand-Held Band Saws and Scroll/Jig Saws

Upcoming parts of IEC 62841 will address hand-held band saws (IEC 62841-2) and transportable scroll and jig saws, extending safety coverage in this tool category.IEC 62841 Series – A comprehensive framework for safety in electric motor-operated tools, ensuring a harmonized approach for manufacturers and users worldwide.

By adhering to IEC 62841-3-5:2022, stakeholders ensure that transportable band saws deliver high safety standards tailored to their specific operational risks. This promotes safer use, minimizes hazards, and supports global trade in power tools with confidence in product safety and compliance.

Frequently Asked Questions

IEC 62841-3-5:2022 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 3-5: Particular requirements for transportable band saws". This standard covers: IEC 62841-3-5:2022 applies to band saws intended for cutting wood and analogous materials, plastics and metals, except magnesium. This document does not apply to transportable scroll saws and jig saws with a reciprocating blade. This document does not apply to hand-held band saws; non-vertical saws; and wire saws. NOTE 101 It is planned that a document on transportable scroll saws and jig saws will be published. NOTE 102 Hand-held band saws will be covered by a future part of IEC 62841-2. NOTE 103 In Europe (EN IEC 62841-3-5), the following conditions apply: This document does not apply to stationary band saws intended to cut wood and similar materials. Stationary band saws that are intended to cut wood and similar materials are covered by EN 1807-1. This document applies to band saws having a mass of: - maximum 25 kg for tools capable of being lifted by hand by one person; - maximum 50 kg for tools capable of being lifted by hand by two persons.

IEC 62841-3-5:2022 applies to band saws intended for cutting wood and analogous materials, plastics and metals, except magnesium. This document does not apply to transportable scroll saws and jig saws with a reciprocating blade. This document does not apply to hand-held band saws; non-vertical saws; and wire saws. NOTE 101 It is planned that a document on transportable scroll saws and jig saws will be published. NOTE 102 Hand-held band saws will be covered by a future part of IEC 62841-2. NOTE 103 In Europe (EN IEC 62841-3-5), the following conditions apply: This document does not apply to stationary band saws intended to cut wood and similar materials. Stationary band saws that are intended to cut wood and similar materials are covered by EN 1807-1. This document applies to band saws having a mass of: - maximum 25 kg for tools capable of being lifted by hand by one person; - maximum 50 kg for tools capable of being lifted by hand by two persons.

IEC 62841-3-5:2022 is classified under the following ICS (International Classification for Standards) categories: 25.140.20 - Electric tools. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase IEC 62841-3-5:2022 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of IEC standards.

Standards Content (Sample)

IEC 62841-3-5 ®

Edition 1.0 2022-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety –

Part 3-5: Particular requirements for transportable band saws

Outils électroportatifs à moteur, outils portables et machines pour jardins et

pelouses – Sécurité –

Partie 3-5: Exigences particulières pour les scies à ruban transportables

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications. Avec un

La recherche avancée permet de trouver des publications IEC abonnement, vous aurez toujours accès à un contenu à jour

en utilisant différents critères (numéro de référence, texte, adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 300 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 19 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC Products & Services Portal - products.iec.ch

IEC 62841-3-5 ®

Edition 1.0 2022-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety –

Part 3-5: Particular requirements for transportable band saws

Outils électroportatifs à moteur, outils portables et machines pour jardins et

pelouses – Sécurité –

Partie 3-5: Exigences particulières pour les scies à ruban transportables

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 25.140.20 ISBN 978-2-8322-1097-6

– 2 – IEC 62841-3-5:2022 © IEC 2022

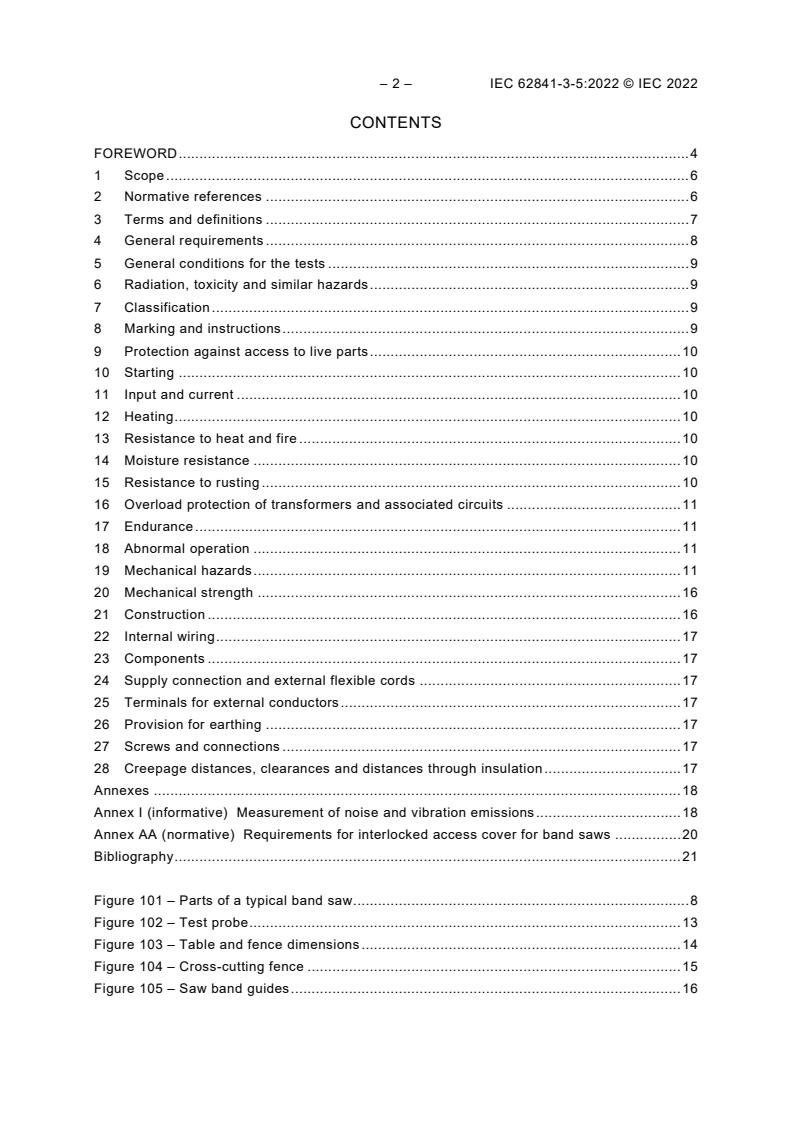

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 General requirements . 8

5 General conditions for the tests . 9

6 Radiation, toxicity and similar hazards . 9

7 Classification . 9

8 Marking and instructions . 9

9 Protection against access to live parts . 10

10 Starting . 10

11 Input and current . 10

12 Heating . 10

13 Resistance to heat and fire . 10

14 Moisture resistance . 10

15 Resistance to rusting . 10

16 Overload protection of transformers and associated circuits . 11

17 Endurance . 11

18 Abnormal operation . 11

19 Mechanical hazards . 11

20 Mechanical strength . 16

21 Construction . 16

22 Internal wiring . 17

23 Components . 17

24 Supply connection and external flexible cords . 17

25 Terminals for external conductors . 17

26 Provision for earthing . 17

27 Screws and connections . 17

28 Creepage distances, clearances and distances through insulation . 17

Annexes . 18

Annex I (informative) Measurement of noise and vibration emissions . 18

Annex AA (normative) Requirements for interlocked access cover for band saws . 20

Bibliography . 21

Figure 101 – Parts of a typical band saw. 8

Figure 102 – Test probe . 13

Figure 103 – Table and fence dimensions . 14

Figure 104 – Cross-cutting fence . 15

Figure 105 – Saw band guides . 16

Table 4 – Required performance levels . 11

Table I.101 – Noise test conditions for band saws that are not intended for cutting

metal . 18

Table I.102 – Test conditions for band saws that are intended for cutting metal . 19

– 4 – IEC 62841-3-5:2022 © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC MOTOR-OPERATED HAND-HELD TOOLS, TRANSPORTABLE

TOOLS AND LAWN AND GARDEN MACHINERY – SAFETY –

Part 3-5: Particular requirements for transportable band saws

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of

IEC Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other

IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 62841-3-5 has been prepared by IEC technical committee 116: Safety of motor-operated

electric tools. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

116/574/FDIS 116/585/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

This Part 3-5 is to be used in conjunction with the first edition of IEC 62841-1:2014.

This Part 3-5 supplements or modifies the corresponding clauses in IEC 62841-1:2014, so as

to convert it into the IEC Standard: Particular requirements for transportable band saws.

Where a particular subclause of IEC 62841-1:2014 is not mentioned in this Part 3-5, that

subclause applies as far as relevant. Where this standard states "addition", "modification" or

"replacement", the relevant text in IEC 62841-1:2014 is to be adapted accordingly.

The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

notes: in small roman type.

–

The terms defined in Clause 3 are printed in bold typeface.

Subclauses, notes, tables and figures which are additional to those in IEC 62841-1:2014 are

numbered starting from 101.

A list of all parts of the IEC 62841 series, under the general title: Electric motor-operated hand-

held tools, transportable tools and lawn and garden machinery – Safety, can be found on the

IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

NOTE The attention of National Committees is drawn to the fact that equipment manufacturers and testing

organizations may need a transitional period following publication of a new, amended or revised IEC publication in

which to make products in accordance with the new requirements and to equip themselves for conducting new or

revised tests.

It is the recommendation of the committee that the content of this publication be adopted for implementation nationally

not earlier than 36 months from the date of publication.

– 6 – IEC 62841-3-5:2022 © IEC 2022

ELECTRIC MOTOR-OPERATED HAND-HELD TOOLS, TRANSPORTABLE

TOOLS AND LAWN AND GARDEN MACHINERY – SAFETY –

Part 3-5: Particular requirements for transportable band saws

1 Scope

IEC 62841-1:2014, Clause 1 is applicable, except as follows.

Addition:

This document applies to band saws intended for cutting wood and analogous materials,

plastics and metals, except magnesium.

This document does not apply to transportable scroll saws and jig saws with a reciprocating

blade.

This document does not apply to

– hand-held band saws;

– non-vertical saws; and

– wire saws.

NOTE 101 It is planned that a document on transportable scroll saws and jig saws will be published.

NOTE 102 Hand-held band saws will be covered by a future part of IEC 62841-2.

NOTE 103 In Europe (EN IEC 62841-3-5), the following conditions apply:

This document does not apply to stationary band saws intended to cut wood and similar materials. Stationary band

saws that are intended to cut wood and similar materials are covered by EN 1807-1.

This document applies to band saws having a mass of:

– maximum 25 kg for tools capable of being lifted by hand by one person;

– maximum 50 kg for tools capable of being lifted by hand by two persons.

2 Normative references

IEC 62841-1:2014, Clause 2 is applicable, except as follows.

Addition:

IEC 62841-1:2014, Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety – Part 1: General requirements

3 Terms and definitions

IEC 62841-1:2014, Clause 3 is applicable, except as follows.

Addition:

3.101

band saw

tool designed to cut materials by means of a vertical revolving endless saw band which is

carried on two or more band wheels

Note 101 to entry: Band saws have a table to support and position the workpiece that is fed by hand against the

saw band. See Figure 101.

3.102

cross-cutting fence

device to guide or position the workpiece during the cutting process that is designed to move

parallel with the plane of the saw band

Note 101 to entry: The cross-cutting fence may have provisions to adjust the workpiece guiding face laterally and

may have mitre angle capability.

3.103

parallel fence

fence that has the workpiece guiding face parallel with the plane of the saw band and can be

set to a desired distance from the saw band

3.104

saw band

flexible closed loop metal band with cutting elements such as teeth or abrasive material

– 8 – IEC 62841-3-5:2022 © IEC 2022

Key

1 access cover

2 saw band tensioner

3 band wheel

4 adjustable guard for the cutting area

5 saw band guide

6 saw band

7 driving band wheel

8 parallel fence

9 power switch

10 table

Figure 101 – Parts of a typical band saw

4 General requirements

IEC 62841-1:2014, Clause 4 is applicable.

5 General conditions for the tests

IEC 62841-1:2014, Clause 5 is applicable, except as follows.

5.17 Addition:

The mass of the tool includes the guard and fence(s), if any.

Any additional parts such as leg sets or carrying means that are required in accordance with

the user instructions are included in the mass.

6 Radiation, toxicity and similar hazards

IEC 62841-1:2014, Clause 6 is applicable.

7 Classification

IEC 62841-1:2014, Clause 7 is applicable.

8 Marking and instructions

IEC 62841-1:2014, Clause 8 is applicable, except as follows.

8.3 Addition:

Band saws shall be marked with:

– direction of rotation of the driven band wheel which shall be indicated on the tool by an

arrow raised or sunk, or by any other means not less visible and indelible;

In addition, where a tool is designed to operate at more than one cutting speed, the following

requirements apply:

– on tools where a speed change is achieved by changing the position of the drive belts on

the drive pulleys, the selected speed shall be indicated on the same side of the tool as the

start control by a diagram showing the relevant speed selected for each combination of

pulleys;

– on tools where a speed change is achieved by an electronic control circuit, the selected

speed shall be indicated on the tool at the selecting device (e.g. variable speed control dial

provided with numerical speed settings).

8.14.1 Addition:

The additional safety instructions as specified in 8.14.1.101 shall be given. This part may be

printed separately from the "General power tool safety warnings".

8.14.1.101 Safety instructions for band saws

a) Always use saw bands that are not damaged or deformed. Damaged or deformed saw

bands could split and/or snap.

b) Do not use liquid coolants. Using water or other liquid coolants may result in electrocution

or shock.

NOTE 101 The warning in item b) above is omitted for tools equipped with a liquid system.

– 10 – IEC 62841-3-5:2022 © IEC 2022

c) Operate the band saw at the proper speed for recommended applications and

materials. Using a speed inappropriate for the material being cut may lead to breakage of

the saw band and personal injury.

d) Do not operate the tool when the band saw blade access cover is open. Contact with

the moving parts may result in personal injury.

NOTE 102 At the manufacturer’s discretion, the term "band saw blade" is replaced by "saw band".

8.14.2 a) Addition:

101) Information about specified saw band dimensions (e.g. length and width);

102) Instruction on how to adjust the saw band guides and thrust wheel;

103) Instructions for the saw band changing procedure including proper saw band direction

installation and how to mount and tension saw bands.

8.14.2 b) Addition:

101) Instruction to adjust the guard as close to the workpiece as practicable;

102) Instruction on how to adjust the saw band guide for the cutting area;

103) Instruction on how to set a bevel angle;

104) Instructions on how to properly feed the workpiece, including the application of auxiliary

materials that may be used as an aid to feed the workpiece;

105) Instruction to wear gloves when handling saw bands.

9 Protection against access to live parts

IEC 62841-1:2014, Clause 9 is applicable.

10 Starting

IEC 62841-1:2014, Clause 10 is applicable.

11 Input and current

IEC 62841-1:2014, Clause 11 is applicable.

12 Heating

IEC 62841-1:2014, Clause 12 is applicable.

13 Resistance to heat and fire

IEC 62841-1:2014, Clause 13 is applicable.

14 Moisture resistance

IEC 62841-1:2014, Clause 14 is applicable.

15 Resistance to rusting

IEC 62841-1:2014, Clause 15 is applicable.

16 Overload protection of transformers and associated circuits

IEC 62841-1:2014, Clause 16 is applicable.

17 Endurance

IEC 62841-1:2014, Clause 17 is applicable.

18 Abnormal operation

IEC 62841-1:2014, Clause 18 is applicable, except as follows.

18.8 Replacement of Table 4:

Table 4 – Required performance levels

Type and purpose of SCF Minimum Performance

Level (PL)

Power switch – prevent unwanted switch-on b

Power switch – provide desired switch-off b

Provide desired direction of rotation Not an SCF

Any electronic control to pass the test of 18.3 a

Prevent exceeding thermal limits as in 18.4 and 18.5.3 a

Provide function to de-energize or disengage drive to

a

the saw band as required in 19.101.1 d)

Provide run-down time as required by 19.105 a

Prevent self-resetting as required in 23.3 b

NOTE In Europe (EN IEC 62841-3-5), the following additional requirement applies:

Restart prevention as required by 21.18.2.1 a

19 Mechanical hazards

IEC 62841-1:2014, Clause 19 is applicable, except as follows.

19.1 Addition:

The requirements of 19.1, except for mechanical strength requirements, do not apply to the

access cover specified in 19.101 and the adjustable guard in the cutting area specified in

19.102.

19.3 Replacement:

It shall not be possible to reach hazardous moving parts through dust collection openings with

the detachable parts or provisions for dust collection removed, if any.

Compliance is checked by the following test.

For dust collection openings, the test probe B of IEC 61032:1997 is used. The test probe is

inserted with a force not exceeding 5 N into the dust collection opening until the probe’s stop

face reaches the plane of the dust collection opening and shall not touch hazardous moving

parts.

– 12 – IEC 62841-3-5:2022 © IEC 2022

19.6 This subclause of IEC 62841-1:2014 is not applicable.

19.7 This subclause of IEC 62841-1:2014 is not applicable for tools intended to be fixed to a

bench or the floor in accordance with 8.14.2 a) 1).

19.7.101 Band saws not intended to be fixed to a bench or the floor in accordance with

8.14.2 a) 1) shall have adequate stability.

Compliance is checked by the following tests.

The tests are conducted with the band saw placed on a horizontal surface of medium density

3 3

fibreboard (MDF) having a density of 650 kg/m to 850 kg/m . If the tool is provided with a

stand, the tool is tested with or without the stand in the most unfavourable configuration(s).

When a push force of 100 N is applied to the front edge of the band saw table in the plane of

the saw band and in the direction of the workpiece feed, the tool shall not move.

The push force is then increased to 300 N or until the tool begins to move horizontally,

whichever is achieved first. During this test, the tool shall not tip over.

19.8 This subclause of IEC 62841-1:2014 is applicable.

19.101 Band wheel, driving mechanism and saw band guarding

19.101.1 The band wheels, the drive mechanism and the whole saw band in the non-cutting

area shall be guarded.

Access cover(s) that have to be opened to change the saw band in accordance with

8.14.2 a) 103) shall remain attached to the band saw and at least one of the following

requirements a) to d) shall be met:

a) The access cover(s) is a fixed guard; or

b) The access cover(s) do not permit access to hazardous moving parts other than the saw

band when open; or

c) The power switch is located on the same side as the access cover(s); or

d) The access cover(s) comply with the requirements of Annex AA.

For options a) and c), compliance is checked by inspection. For option b), compliance is

checked by manual test using test probe B of IEC 61032:1997 with a force not exceeding 5 N.

For option d), compliance is checked by the requirements of Annex AA.

NOTE 101 In Europe (EN IEC 62841-3-5), the following requirement applies:

19.101.1 The band wheels, the drive mechanism and the whole saw band in the non-cutting area shall be guarded.

Access cover(s) that have to be opened to change the saw band in accordance with 8.14.2 a) 103) shall remain

attached to the band saw and comply with the requirements of Annex AA.

Compliance is checked by the requirements of Annex AA.

19.101.2 An access cover in accordance with 19.101.1 c), if any, shall prevent access to

hazardous moving parts behind the access cover while the access cover is being opened and

before the drive to the saw band is de-energized or disengaged.

Compliance is checked by the following test.

The access cover is opened to the point where the drive to the saw band is just de-energized

or disengaged. It shall not be possible to touch hazardous moving parts with the test probe

specified in Figure 102 with a force not exceeding 5 N.

Dimensions in millimetres

Key

1 handle section

2 test section

3 probe’s flange

Figure 102 – Test probe

19.102 Adjustable guard in the cutting area

All sides of the saw band above the table, except that part necessary to process the workpiece

or to change the saw band, shall be covered by a guard. The guard shall be adjustable from

the maximum height of cut down to a height of maximum 8 mm above the table surface when

the table is in the horizontal position. The adjustable guard shall be capable of being fixed in

every position within this range without the aid of a tool and shall be so designed that it does

not have to be removed from the tool during a saw band change. See Figure 101.

The guard shall be so designed and constructed that it does not prevent the movement of the

workpiece and does not impair the visibility at the point of operation when sawing. It shall be

capable of being adjusted only in combination with the saw band guide above the table.

Compliance is checked by inspection, measurement and by applying the test probe according

to Figure 102 with a force not exceeding 5 N. Except in the area between table surface and

guard, it shall not be possible to contact the teeth of the saw band.

19.103 Band saws shall be equipped with a table (see Figure 101). The dimensions of the

table for supporting the workpiece shall comply with the dimensions specified in Figure 103.

The slot in the table for the saw band shall be as small as practicable and the area surrounding

the saw band where it passes through the table shall be a replaceable insert of a material that

can easily be cut such as plastic, wood or light-alloy.

The table may be inclinable perpendicular to the direction of the workpiece feed by not more

than 45°.

Compliance is checked by inspection and by measurement.

– 14 – IEC 62841-3-5:2022 © IEC 2022

Band wheel

diameter

Minimum dimensions of the saw table

d

mm mm

Length of parallel Height of parallel

c e

fence fence a

d ≤ 150

100 100 150 25

150 < d ≤ 315

150 150 250 50

315 < d ≤ 350

250 250 350 60

Figure 103 – Table and fence dimensions

19.104 Band saws may be equipped with a parallel fence (see Figure 101). If the table is

inclinable, the parallel fence, if any, shall be

– capable of being fitted on the lower side of the table when inclined; and

– prevented from falling down when the table is inclined.

In addition, band saws may be equipped with a cross-cutting fence. The fixing arrangement

shall ensure that the fence cannot rise or swing out of position.

A cross-cutting fence shall be adjustable to avoid contact with the saw band when set for any

angle of cut. The part of the fence adjacent to the saw band shall be made from material that

can easily be cut such as plastic, wood or light-alloy. See Figure 104.

Compliance is checked by inspection.

Key

1 cross-cutting fence

Figure 104 – Cross-cutting fence

19.105 Run-down time

The run-down time of the saw band shall not exceed 10 s after switching off the motor.

Device(s), if any, to achieve the 10 s run-down time shall not be applied directly to the saw

band.

Compliance is checked by inspection and by the following test, which is performed ten times.

The tool is operated for a minimum of 30 s, then the power switch is switched to the "off"

position. The run-down time is measured. For each test, the run-down time shall not exceed

10 s.

19.106 Guiding of the saw band

Band saws shall be equipped with saw band guides which guide the saw band above and

below the table. The guide above the table shall be adjustable. See Figure 105.

Compliance is checked by inspection.

– 16 – IEC 62841-3-5:2022 © IEC 2022

Key

1 upper saw band guides

2 thrust wheel

NOTE 101 Parts of the adjustable guard have been removed for clarity.

Figure 105 – Saw band guides

20 Mechanical strength

IEC 62841-1:2014, Clause 20 is applicable, except as follows.

20.5 This subclause of IEC 62841-1:2014 is not applicable.

21 Construction

IEC 62841-1:2014, Clause 21 is applicable, except as follows.

21.18.2.1 This subclause of IEC 62841-1:2014 is not applicable.

NOTE In Europe (EN IEC 62841-3-5), this subclause of Part 1 is applicable and the following requirement applies:

The tool shall not restart after an interruption of the mains supply without releasing and re-actuating the power

switch.

21.30 This subclause of IEC 62841-1:2014 is not applicable.

21.35 This subclause of IEC 62841-1:2014 is applicable.

22 Internal wiring

IEC 62841-1:2014, Clause 22 is applicable.

23 Components

IEC 62841-1:2014, Clause 23 is applicable, except as follows.

23.3 This subclause of IEC 62841-1:2014 is applicable.

24 Supply connection and external flexible cords

IEC 62841-1:2014, Clause 24 is applicable.

25 Terminals for external conductors

IEC 62841-1:2014, Clause 25 is applicable.

26 Provision for earthing

IEC 62841-1:2014, Clause 26 is applicable.

27 Screws and connections

IEC 62841-1:2014, Clause 27 is applicable.

28 Creepage distances, clearances and distances through insulation

IEC 62841-1:2014, Clause 28 is applicable.

– 18 – IEC 62841-3-5:2022 © IEC 2022

Annexes

The annexes of IEC 62841-1:2014 are applicable, except as follows.

Annex I

(informative)

Measurement of noise and vibration emissions

NOTE In Europe (EN IEC 62841-3-5), Annex I is normative.

I.2 Noise test code (grade 2)

IEC 62841-1:2014, Clause I.2 is applicable, except as follows.

I.2.4 Installation and mounting conditions of the power tools during noise tests

Addition:

Band saws supplied with a working stand are placed on this working stand standing on a

reflecting plane.

Other band saws are placed on a test bench as shown in Figure I.1 standing on a reflecting

plane.

I.2.5 Operating conditions

Addition:

Band saws are tested under load under the conditions shown in Table I.101 or Table I.102, as

applicable.

Table I.101 – Noise test conditions for band saws that are not intended for cutting metal

3 3

Material

Medium density fibreboard (MDF) having a density of 650 kg/m to 850 kg/m

(19 ± 1,5) mm × (400 ± 50) mm × width as required for five cuts

Feed force Just sufficient to cut at a brisk pace without overloading the tool

Width of cut-off 5 mm minimum at 90° as set by the guide fence, if any

Tool bit New saw band suitable for this material and work process, to be used for the entire series

of tests

Test cycle Five cuts quickly following each other constitutes one complete test cycle.

The measurement is conducted (averaged) over the complete test cycle.

Table I.102 – Test conditions for band saws that are intended for cutting metal

Material Sheet mild steel with a minimum length of 300 mm, a thickness of approximately 3 mm and

a width as required for five cuts

Feed force Just sufficient to cut at a brisk pace without overloading the tool

Width of cut-off 5 mm minimum at 90° as set by the guide fence, if any

Tool bit New saw band suitable for this material and work process, to be used for the entire series

of tests

Test cycle Five cuts quickly following each other constitutes one complete test cycle.

The measurement is conducted (averaged) over the complete test cycle.

I.3 Vibration

IEC 62841-1:2014, Clause I.3 is not applicable.

– 20 – IEC 62841-3-5:2022 © IEC 2022

Annex AA

(normative)

Requirements for interlocked access cover for band saws

The band wheels, the drive mechanism and the whole saw band in the non-cutting area shall

be enclosed by fixed guards and/or interlocked moveable guards, see Figure 101. It shall be

possible to change the saw band without the need to remove a fixed guard.

It shall not be possible to start the tool when an interlocked movable guard is open. The

interlock function may be achieved by means of a switch with a contact separation of less than

3 mm. As a protection against the easy defeating of a switch used for the interlock, it shall not

be possible to actuate the switch with test probe B of IEC 61032:1997, when the guard is open.

Compliance is checked by manual test using test probe B of IEC 61032:1997, with a force not

exceeding 5 N.

A movable guard shall prevent access to moving parts behind the movable guard whilst the

guard is being opened and before the interlocking switch actuates.

Compliance is checked by the following test.

The guard is opened to the point where the switch is just actuated. It shall not be possible to

get access to moving parts with the test probe specified in Figure 102. The test probe is applied

with a force not exceeding 5 N.

For a saw with an interlocked movable guard, either:

– the run-down time of the saw band shall be less than 2 s; or

– a locking means shall be provided such that the guard cannot be removed until the saw

band has come to a stop.

Compliance with the first dash is checked by the following test.

The saw band is adjusted in accordance with 8.14.2 a). The band saw shall be run in for 1 min

before starting the test. The test is made under no-load. The test sequence shall consist of a

total of 2 500 cycles. The time measurement starts when the interlocking switch has opened.

The run-down time of the saw band shall not exceed 2 s for the first six cycles and for the final

six cycles of the test sequence.

Compliance with the second dash is checked by inspection.

Bibliography

The bibliography of IEC 62841-1:2014 is applicable, except as follows.

Addition:

EN 1807-1, Safety of woodworking machines – Band sawing machines – Part 1: Table band

saws and band re-saws

___________

– 22 – IEC 62841-3-5:2022 © IEC 2022

SOMMAIRE

AVANT-PROPOS . 24

1 Domaine d’application . 26

2 Références normatives . 26

3 Termes et définitions . 27

4 Exigences générales . 28

5 Conditions générales d’essai . 29

6 Rayonnement, toxicité et dangers analogues . 29

7 Classification . 29

8 Marquage et indications . 29

9 Protection contre l'accès aux parties actives. 30

10 Démarrage . 30

11 Puissance et courant . 30

12 Échauffements. 30

13 Résistance à la chaleur et au feu . 30

14 Résistance à l’humidité . 30

15 Protection contre la rouille . 31

16 Protection contre la surcharge des transformateurs et des circuits associés . 31

17 Endurance . 31

18 Fonctionnement anormal . 31

19 Dangers mécaniques . 31

20 Résistance mécanique . 37

21 Construction . 37

22 Conducteurs internes. 38

23 Composants . 38

24 Raccordement au réseau et câbles souples extérieurs . 38

25 Bornes pour conducteurs externes . 38

26 Dispositions de mise à la terre . 38

27 Vis et connexions . 38

28 Lignes de fuite, distances d'isolement et distances à travers l’isolation . 38

Annexes . 39

Annexe I (informative) Mesure des émissions acoustique et de vibration . 39

Annexe AA (normative) Exigences relatives au capot d’accès verrouillé des scies à

ruban . 41

Bibliographie . 42

Figure 101 – Éléments d'une scie à ruban type . 28

Figure 102 – Sonde d’essai . 33

Figure 103 – Dimensions de la table et du guide .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...