ISO 16781:2013

(Main)Space systems — Simulation requirements for control system

Space systems — Simulation requirements for control system

ISO 16781:2013 provides guidance to control system engineers on what to simulate and how to use simulation to support their system engineering tasks. ISO 16781:2013 provides simulation requirements of control system for different phases in the process of designing a control system. Control system engineers can carry out various types of simulation experiments during various phases, according to ISO 16781:2013. ISO 16781:2013 establishes a minimum set of requirements for simulation of control system. The requirements are generic in nature because of their broad applicability to all types of simulations.

Systèmes spatiaux — Exigences de simulation pour le système de contrôle

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16781

First edition

2013-11-15

Space systems — Simulation

requirements for control system

Systèmes spatiaux — Exigences de simulation pour le système de

contrôle

Reference number

ISO 16781:2013(E)

©

ISO 2013

---------------------- Page: 1 ----------------------

ISO 16781:2013(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 16781:2013(E)

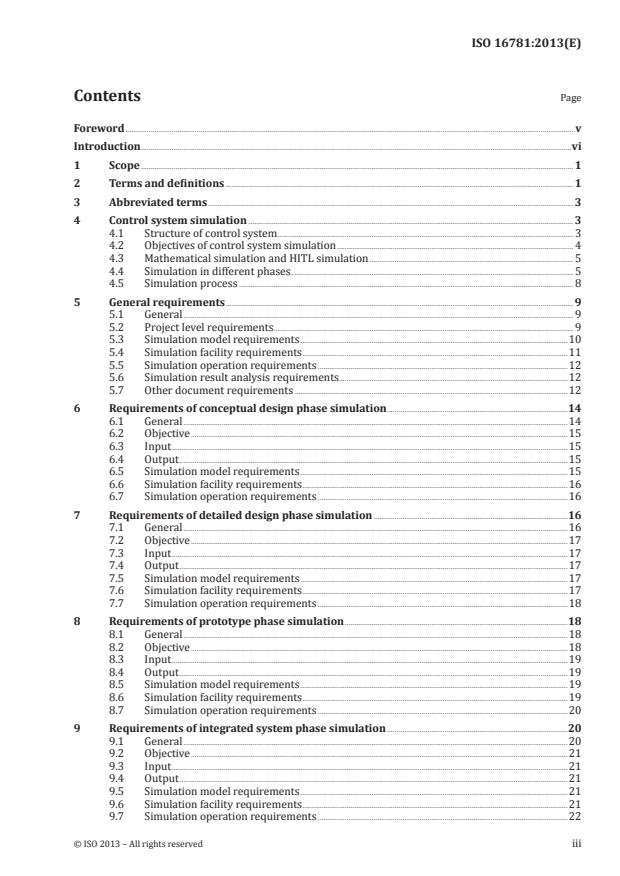

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Terms and definitions . 1

3 Abbreviated terms . 3

4 Control system simulation . 3

4.1 Structure of control system . 3

4.2 Objectives of control system simulation . 4

4.3 Mathematical simulation and HITL simulation . 5

4.4 Simulation in different phases . 5

4.5 Simulation process . 8

5 General requirements . 9

5.1 General . 9

5.2 Project level requirements . 9

5.3 Simulation model requirements .10

5.4 Simulation facility requirements .11

5.5 Simulation operation requirements .12

5.6 Simulation result analysis requirements.12

5.7 Other document requirements .12

6 Requirements of conceptual design phase simulation .14

6.1 General .14

6.2 Objective .15

6.3 Input .15

6.4 Output .15

6.5 Simulation model requirements .15

6.6 Simulation facility requirements .16

6.7 Simulation operation requirements .16

7 Requirements of detailed design phase simulation .16

7.1 General .16

7.2 Objective .17

7.3 Input .17

7.4 Output .17

7.5 Simulation model requirements .17

7.6 Simulation facility requirements .17

7.7 Simulation operation requirements .18

8 Requirements of prototype phase simulation .18

8.1 General .18

8.2 Objective .18

8.3 Input .19

8.4 Output .19

8.5 Simulation model requirements .19

8.6 Simulation facility requirements .19

8.7 Simulation operation requirements .20

9 Requirements of integrated system phase simulation .20

9.1 General .20

9.2 Objective .21

9.3 Input .21

9.4 Output .21

9.5 Simulation model requirements .21

9.6 Simulation facility requirements .21

9.7 Simulation operation requirements .22

© ISO 2013 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 16781:2013(E)

Annex A (normative) Phase comparison between ISO 14300 and ISO 16781 .23

Annex B (normative) Relationship between simulation phases and tables .24

iv © ISO 2013 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 16781:2013(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 14, SC14 Space Systems and Operations.

© ISO 2013 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 16781:2013(E)

Introduction

This International Standard provides space system control system engineers, simulation engineers and

customers with guidance of use simulation to support their system engineering tasks. This International

Standard is intended to help reduce the develop time and cost of space system control system design

and also enhance its quality and reliability. This International Standard focuses on requirements and

recommendations for what should be done during simulation. It does not prescribe how the requirements

are to be met.

vi © ISO 2013 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 16781:2013(E)

Space systems — Simulation requirements for control system

1 Scope

This International Standard provides guidance to control system engineers on what to simulate and

how to use simulation to support their system engineering tasks. Ground testing limitations typically

preclude a comprehensive “test as you fly” approach to most space system control systems. Likewise,

flight tests are prohibitively expensive. Therefore, high-fidelity simulation models of the control system

components must be validated. Wherever, possible ground test results should be compared to simulation

model outputs. Validated models are then used in various simulation environments to predict flight

performance. As an important means of design, analysis and validation, simulation of the control system

is widely used in each phase of the control system development, including conceptual design, detailed

design, prototype validation, and integrated system verification. This International Standard provides

simulation requirements of control system for different phases in the process of designing a control

system. Control system engineers can carry out various types of simulation experiments during various

phases, according to this International Standard. This International Standard establishes a minimum

set of requirements for simulation of control system. The requirements are generic in nature because of

their broad applicability to all types of simulations. Implementation details of the requirements should

be addressed in project-specific standards, requirements, handbooks, etc.

In general, standards can focus on engineering/technical requirements, processes, procedures, practices,

or methods. This International Standard focuses on requirements and recommendations. Hence, this

International Standard specifies what must be done; it does not prescribe how the requirements are to

be met, nor does it specify who the responsible team is for complying with the requirements. Conflicts

between this International Standard and other requirements documents shall be resolved by the

responsible technical designer.

2 Terms and definitions

2.1

accuracy

measure of how close a value is to the “true” value

[SOURCE: ISO 14952-1:2003]

2.2

control system

closed-loop configuration of sensors, processors/algorithms, and actuators designed to manage the

dynamic behavior of space systems

2.3

emulator

prototype of the flight equipment, which has the identical input/output interfaces as the flight equipment

and has similar operating behaviour

2.4

fidelity

degree to which a model or simulation reproduces the state and behaviour of a real world object

or the perception of a real world object, feature, condition, or chosen standard in a measurable or

perceivable manner

2.5

hardware in the loop simulation

kind of simulation, in which some simulation models of control system are implemented by real equipment

© ISO 2013 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 16781:2013(E)

2.6

mathematical simulation

kind of simulation, in which all the simulation models of control system are implemented by software

2.7

real-time simulation

kind of simulation, in which the time scale of dynamic process in simulation model strictly equals to that

of the real system

2.8

reliability

ability of an item to perform a required function under given conditions for a given time interval

[SOURCE: ISO 10795:2011]

2.9

simulation

use of a similar or equivalent system to imitate a real system, so that it behaves like or appears to be

the real system

2.10

simulation of control system

complex progress of building simulation system based on the mathematical model of control system,

testing the model, solving the system dynamic equations, imitating dynamic behaviors of control system,

and taking qualitative and quantitative analysis and research about scheme, structure, parameters, and

performance of control system

2.11

simulation model

equivalent model in the simulation system, which is transformed from mathematical model of control

system by means of simulation software or hardware

2.12

simulation plan

document in which the content, operate steps, and implement method of all simulation items are specified

2.13

stability

ability of a system submitted to bound external disturbances to remain indefinitely in a bounded domain

around an equilibrium position or around an equilibrium trajectory

2.14

validation

confirmation, through the provision of objective evidence, that the requirements for a specific intended

use or application have been fulfilled

Note 1 to entry: The term “validated” is used to designate the corresponding status.

Note 2 to entry: The use conditions for validation can be real or simulated.

Note 3 to entry: Validation can be determined by a combination of test, analysis, demonstration, and inspection.

[SOURCE: ISO 10795:2011]

2.15

verification

confirmation through the provision of objective evidence that specified requirements have been fulfilled

Note 1 to entry: The term “verified” is used to designate the corresponding status.

Note 2 to entry: Confirmation can comprise activities such as

2 © ISO 2013 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 16781:2013(E)

—performing alternative calculations,

—comparing a new design specification with a similar proven design specification,

—undertaking tests and demonstrations, and

—reviewing documents prior to issue.

Note 3 to entry: Verification can be determined by a combination of test, analysis, demonstration, and inspection.

[SOURCE: ISO 10795:2011]

3 Abbreviated terms

Table 1 — Abbreviated terms

A/D Analog/ Digital Transform

CM Configuration Management

D/A Digital/Analog Transform

DI/DO Digital Input/Digital Output

HITL Hardware-in-the-Loop

M&S Modelling and Simulation

V&V Verification and Validation

4 Control system simulation

4.1 Structure of control system

Control system is one of the most important systems of launch vehicle, satellite, spaceship, etc.

Generally, the architecture of control system is illustrated in Figure 1.

© ISO 2013 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO 16781:2013(E)

Figure 1 — Control System Architecture

a) Flight environment includes atmosphere or space environment in which the spacecraft exists. In

terms of different kinds of spacecraft, control system shall consider mechanical, thermodynamic,

optical, and electromagnetic environment, etc.

b) Sensors are fixed on the spacecraft to measure the states, which are provided to flight control

computer for control algorithm calculation.

c) Flight control computer receives and deals with measured information from sensors, and then

control signals are gained by control algorithm and sent to servos as commands.

d) Servos receive commands from flight control computer and drive actuators, which produce forces

and moments and affect the flight states of spacecraft, so that a closed-loop is formed and the

objective of control is achieved.

e) Command input indicates control command and binding parameter.

f) Vehicle dynamics indicates the dynamic behaviour of a plant.

g) Logger records telemetry data and flight status.

4.2 Objectives of control system simulation

Control system design is an iterative process from design, test, and validation to modification, retest, and

revalidation. Analytical method is not enough for research and design of control system, so simulation

experiment is demanded.

The primary objectives of control system simulation are as follows:

a) verify and optimize the control system scheme;

b) verify and optimize the control system parameters;

c) analyse the stability and robustness of the control system;

d) emulate control system faults that can occur in flight;

e) predict the performance of control system;

f) comprehensively verify functions of control system components;

4 © ISO 2013 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 16781:2013(E)

g) minimize the scheme design iteration;

h) shorten the development time;

i) minimize the development budget.

4.3 Mathematical simulation and HITL simulation

Compared to mathematical simulation, the structure of HITL simulation system is more complex. It can

reflect the hardware/software characteristics of control system, and verify the functions/ performances

of control system (e.g. interface matching properties). Generally, HITL simulation should be done after

mathematical simulation.

The corresponding relationship between simulation types and practical control system is listed in Table 2.

Table 2 — Relationship between simulation types and practical control system

Parts of control sys- Mathematical

HITL simulation

tem simulation

Mathematical model and

Vehicle dynamics

motion simulator (turn table, robotic arm, air bearing)

Physical device (either flight hardware or engineering

Sensors development hardware) or

equivalent mathematical model of sensors

Mathematical mod-

Flight control com- Physical device (either flight hardware, engineering hardware,

els

puter or emulator)

Equivalent servo/actuator mathematical model or

Servos and actuators Physical device (either flight hardware or engineering

development hardware)

Flight environment Emulator or mathematical model

4.4 Simulation in different phases

Design of control system is not a simple iterative process. It can be divided into conceptual design phase,

detailed design phase, prototype phase, and integrated system phase. Simulation is demanded in each

phase in order to realize flight equivalent examples for the control system validation or equipment

verification. Relationship between each design phase and simulation can be described in Figure 2.

© ISO 2013 – All rights reserved 5

---------------------- Page: 11 ----------------------

ISO 16781:2013(E)

Figure 2 — Relationship between each design phase and simulation

In the conceptual design phase simulation, mathematical simulation is used for control system

architecture and conceptual design studies. This pure software simulation environment supports

the identification of optional control system architecture/top level design that meets both mission

performance requirements and stability robustness requirements. Low order/low fidelity models and

simple operational environment models are adopted for mathematical simulation. Multiple co-existing

models and simulation tools are managed by individual engineers.

6 © ISO 2013 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 16781:2013(E)

In detailed design phase simulation, mathematical simulation is used for system optimizations,

parameter sensitivity assessments, performance evaluations, stability robustness assessments, etc.

This simulation environment supports the identification of the final control system design that matches

mission performance and stability robustness requirements. High order/high fidelity, possibly nonlinear

models and detailed flight-equivalent operational environment models are adopted. Some formal

configuration management/control of models, parameter databases, and simulations are required in

this simulation environment.

HITL simulation, which combines hardware and software, is often introduced in the prototype phase

simulation. The basic components of control system are realized by prototype. In this phase, correctness

of control algorithm prototype and flight software and compatibility between various interfaces

are validated, in order to reduce the integrated risk of control system and the entire spacecraft.

This simulation environment can allow substitution of control system sensors/actuators models for

hardware engineering units as needed. Simple software plant and environment models are used to close

the control system loop. Also, some formal configuration management/control of this HITL simulation

environment is required.

Testing of control system flight software nominal functionality as well as failure mode functions is

accomplished by HITL simulation in integrated system phase simulation. The basic components of

control system are realized by real devices, at least including a flight processor hosting the control

algorithm as well as other relevant flight software elements. Consistency of all parts of control system

is certified to ensure that requirements of space system are satisfied. This M&S environment is often

maintained after space system launch to allow the following.

a) Model validation via comparing operational performance of actual in-flight control system with

pre-launch M&S results.

b) The checkout and verification of control system flight software modifications (e.g. a flight software

“patch”) prior to implementing the change to on-board space system.

c) The support of space system anomaly resolution. Very high degree of formal configuration

management/control of this simulation environment is needed.

Basic characteristic of the four phases in Figure 2 is listed in Table 3.

© ISO 2013 – All rights reserved 7

---------------------- Page: 13 ----------------------

ISO 16781:2013(E)

Table 3 — Basic characteristic of the four phases

Conceptual Detailed design

Prototype phase Integrated system

design phase phase

simulation phase simulation

simulation simulation

hybrid hardware/ hybrid

Simulation pure software, pure software,

software, Prototype or hardware/software,

environment non-real-time non-real-time

simulators, real-time HITL, real-time

signal/data/timing

functional

mission mission nominal flight

compatibility, inter-

performance, performance, software function-

Demonstrated items face

stability robust- stability robust- ality, failure mode

compatibility, soft-

ness requirements ness requirements functions

ware processing func-

tions

high order/high

low order/low

fidelity detailed

fidelity simple

model, nonlinear,

Model fidelity model, linear, e.g. detailed model detailed model

e.g. flexible body

rigid body

dynamics, distur-

dynamics

bances

flight-equivalent code,

Control law not necessarily in on-board flight

modular form not necessarily on-

algorithms coding modular form software

board

mathematic model mathematic model

mathematic model V&V, simulation soft- V&V, simulation

mathematic model

Simulation system V&V V&V, simulation ware V&V, software V&V, simu-

V&V

software V&V simulation hardware lation

V&V hardware V&V

Configuration very high degree

little or no formal partly formal partly formal

management/control formal

4.5 Simulation process

In each control system development phase, simulation process should include the following.

a) Requirements analysis

Identifying the input of simulation task, e.g. mathematical model of control plant, control algorithm,

control system criterion, control system specification, and corresponding documents.

Identifying the output of simulation task, e.g. simulation data, simulation result analysis, and

corresponding documents.

Identifying the simulation functions and all the resources needed (e.g. human resource, staff

responsibility, field, equipment).

b) Simulation system design

Designing simulation system, deciding to realize each part of control system by software, prototype

or real equipment, determining interface in the simulation system, compiling simulation plan and

simulation system design report.

c) Simulation software development

Coding and debugging simulation software, implementing mathematical models (e.g. vehicle dynamics,

flight environment, servo) with software.

d) Simulation hardware development

8 © ISO 2013 – All rights reserved

---------------------- Page: 14 ----------------------

ISO 16781:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.