ISO 23848-1:2009

(Main)Machine tools — Ball splines — Part 1: General characteristics and requirements

Machine tools — Ball splines — Part 1: General characteristics and requirements

ISO 23848-1:2009 specifies and standardizes the following characteristics for ball splines: - the shapes and dimensions; - the test methods; - the inspection; - the designation; - the marking.

Machines-outils — Guidages cannelés à billes — Partie 1: Exigences et caractéristiques générales

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 23848-1

First edition

2009-11-15

Machine tools — Ball splines —

Part 1:

General characteristics and requirements

Machines-outils — Guidages cannelés à billes —

Partie 1: Exigences et caractéristiques générales

Reference number

©

ISO 2009

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2009 – All rights reserved

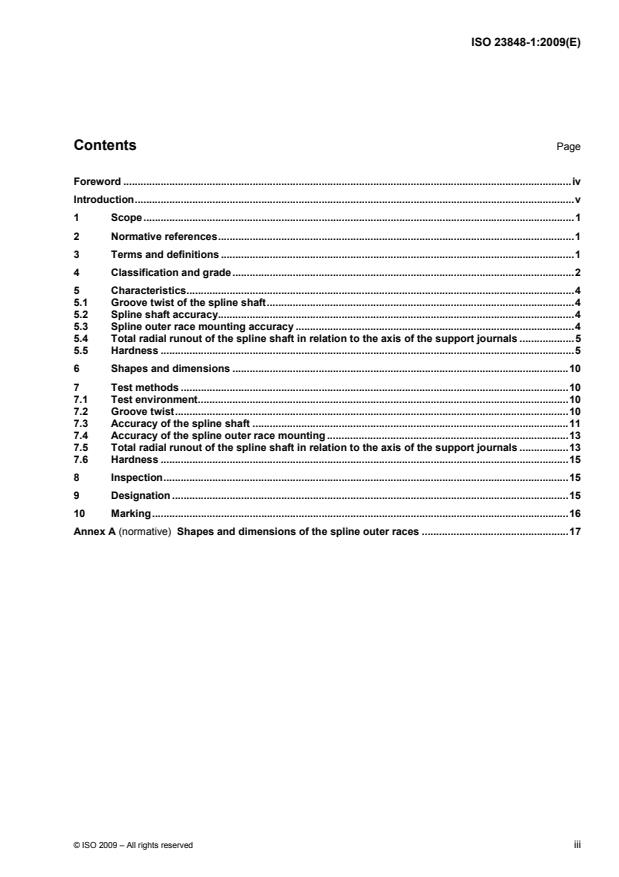

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Terms and definitions .1

4 Classification and grade.2

5 Characteristics.4

5.1 Groove twist of the spline shaft.4

5.2 Spline shaft accuracy.4

5.3 Spline outer race mounting accuracy .4

5.4 Total radial runout of the spline shaft in relation to the axis of the support journals .5

5.5 Hardness .5

6 Shapes and dimensions .10

7 Test methods .10

7.1 Test environment.10

7.2 Groove twist.10

7.3 Accuracy of the spline shaft .11

7.4 Accuracy of the spline outer race mounting .13

7.5 Total radial runout of the spline shaft in relation to the axis of the support journals .13

7.6 Hardness .15

8 Inspection.15

9 Designation .15

10 Marking.16

Annex A (normative) Shapes and dimensions of the spline outer races .17

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 23848-1 was prepared by Technical Committee ISO/TC 39, Machine tools.

ISO 23848 consists of the following parts, under the general title Machine tools — Ball splines:

⎯ Part 1: General characteristics and requirements

⎯ Part 2: Dynamic and static load ratings and rating life

iv © ISO 2009 – All rights reserved

Introduction

The ball spline is a power transmission component based on recirculating balls, which is designed to translate

axially while transmitting torque by an anti-friction means. The ball spline is selected for its smooth operation,

high speed capability, low friction and high-radial and high-torsional load capacity.

This part of ISO 23848 specifies and standardizes the following characteristics of ball splines:

⎯ the shapes and dimensions;

⎯ the test methods;

⎯ the inspection;

⎯ the designation;

⎯ the marking.

ISO 23848-2 specifies and standardizes the following properties of ball splines:

⎯ the basic static and dynamic load ratings;

⎯ the basic static and dynamic torque ratings;

⎯ the rating life.

INTERNATIONAL STANDARD ISO 23848-1:2009(E)

Machine tools — Ball splines —

Part 1:

General characteristics and requirements

1 Scope

This part of ISO 23848 specifies and standardizes the following characteristics for ball splines:

⎯ the shapes and dimensions;

⎯ the test methods;

⎯ the inspection;

⎯ the designation;

⎯ the marking.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 554, Standard atmospheres for conditioning and/or testing — Specifications

ISO 6507-1, Metallic materials — Vickers hardness test — Part 1: Test method

ISO 6507-2, Metallic materials — Vickers hardness test — Part 2: Verification and calibration of testing

machines

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

NOTE See Figure 1.

3.1

ball spline

machine element consisting of the spline shaft, spline outer race, balls and recirculation devices and seals, for

providing smooth relative axial motion between the shaft and the outer race, while preventing their relative

rotation for the purpose of transmitting torque

3.2

effective spline length

actual available length of axial travel for the spline outer race on the spline shaft

3.3

groove twist of the ball spline

value of rotational deviation of the spline outer race over the effective travel length

3.4

nominal diameter of the spline shaft

outer diameter of the spline shaft representing the size of the ball spline without tolerance, sometimes

expressed as the pitch circle diameter without tolerance

NOTE The pitch circle diameter, D , refers to the diameter specifying the location of the rolling ball centres in the ball

p

spline assembly with their theoretical contacts on the groove surfaces of both the spline shaft and the spline outer race.

3.5

spline groove

groove ground or rolled along the axial direction on the shaft periphery or the inner surface of the spline outer

race to facilitate the smooth rolling of balls inside the assembly

3.6

spline outer race

assembly comprising the body with internal spline grooves, balls, recirculation devices and/or additional

embodiments

3.7

spline shaft

shaft consisting of axial spline grooves, which are matched with the grooves of a compatible spline outer race

and can accommodate recirculating balls

4 Classification and grade

Ball splines shall be classified as type A (angular) or type R (radial), as shown in Figure 1 and Table 1. Each

ball spline type shall be divided into three grades, C1, C3 and C5, according to the quality and precision and

may be represented by symbols such as:

⎯ P for C1;

⎯ H for C3;

⎯ no symbol for C5.

2 © ISO 2009 – All rights reserved

a) Type AI b) Type AII

c) Type R

Key

1 seal

2 keyway

3 spline shaft

4 spline outer race

5 balls

6 retainer and/or end cap

NOTE These drawings are examples of a construction.

Figure 1 — Names of the parts of typical ball splines

Table 1 — Type and symbol of ball splines

Name Type Flange on the spline outer race Seal

without

a

without

one side (U)

AI

with

a

both sides (UU)

Ball spline AII

without

R

a a

with (F) one side (U)

with

a

both sides (UU)

a

Letters in parentheses in this table are indication symbols, the application of which is given in Clause 9.

5 Characteristics

5.1 Groove twist of the spline shaft

The tolerance on the groove twist of a ball spline, when measured by the method given in 7.2, shall meet the

requirement of Table 2 with respect to 100 mm taken at random within the effective spline length.

In cases where it is impossible to take 100 mm or more relative travel distance between the spline shaft and

spline outer race, apply a converted value of Table 2 in proportion to the travel distance.

Table 2 — Groove twist of the ball spline

Dimensions in micrometres

Grade C1 C3 C5

Twist tolerance (max.) 6 13 33

NOTE See Figure 3.

5.2 Spline shaft accuracy

The radial runout of the spline grooves, part mounting journals and the axial runout of the end face of the

spline shaft in relation to the axis of support journals of the spline shaft, when measured by the methods given

in 7.3.1 to 7.3.3, shall meet the specifications in Tables 3 to 5, respectively (see Figures 2, 4, 5 and 6).

5.3 Spline outer race mounting accuracy

The axial runout of the spline outer race reference face or the flange mounting face of the flange, and the

radial runout of the spline outer race in relation to the axis of the spline shaft, when measured using the

methods given in 7.4.1 and 7.4.2, shall meet the specifications in Tables 6 and 7, respectively (see Figures 2,

7 and 8).

NOTE Figures 2 to 9 typically show type AI, as an example.

4 © ISO 2009 – All rights reserved

Key

1 part mounting journal

2 spline groove

3 spline outer race

4 support journal

5 spline shaft

NOTE 1 The support journals refer to the portions, where bearings will support the spline shaft.

NOTE 2 The part mounting journals refer to the portions intended for mounting a gear wheel or other machine

elements.

NOTE 3 Not applicable to those without support journals and/or part mounting journal.

Figure 2 — Accuracy of the ball spline

5.4 Total radial runout of the spline shaft in relation to the axis of the support journals

The tolerance on the total radial runout of the spline shaft in relation to the axis of the support journals, when

measured using the method given in 7.5, shall meet the specifications in Table 8 (see Figures 2 and 9).

5.5 Hardness

The hardness of spline groove surfaces, when determined according to the method given in 7.6, shall be at

least W 653 HV (W 58 HRC).

Table 3 — Radial runout of the spline grooves in relation to the axis of the support journals

Runout tolerance

Nominal diameter, d µm

a

mm

max.

Grade

Over Up to and including C1 C3 C5

— 8 8 14 33

8 12 10 17 41

12 20 12 19 46

20 32 13 22 53

32 50 15 25 62

50 80 17 29 73

80 125 20 34 86

NOTE See Figure 4.

a

As the influence of the runouts of the axis of the spline shaft is included in this value, a correction is needed. For the correction,

obtain the correc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.