ISO/TS 21396:2017

(Main)Rubber - Determination of mass concentration of tire and road wear particles (TRWP) in soil and sediments - Pyrolysis-GC/MS method

Rubber - Determination of mass concentration of tire and road wear particles (TRWP) in soil and sediments - Pyrolysis-GC/MS method

ISO/TS 21396:2017 specifies a method for the determination of the soil or sediment mass concentration (μg/g) of tyre and road wear particles (TRWP) in environmental samples. ISO/TS 21396:2017 establishes principles for soil or sediment sample collection, the generation of pyrolysis fragments from the sample, and the quantification of the generated polymer fragments. The quantified polymer mass is used to calculate the concentration of TRWP in soil or sediment. These quantities are expressed on a TRWP basis, which includes the mass of tyre tread and mass of road wear encrustations, and can also be expressed on a tyre rubber polymer or tyre tread basis. NOTE Tyre and road wear particles are a discrete mass of elongated particles generated at the frictional interface between the tyre and roadway surface during the service life of a tyre. The particles consist of tyre tread enriched with mineral encrustations from the roadway surface.

Caoutchouc — Détermination de la concentration massique en particules de pneus et d'usure de la route (TWRP) dans le sol et les sédiments — Méthode par pyrolyse-GC/MS

General Information

Overview

ISO/TS 21396:2017 - Rubber - Determination of mass concentration of tire and road wear particles (TRWP) in soil and sediments - Pyrolysis‑GC/MS method specifies a laboratory procedure to quantify the mass concentration (µg/g) of tyre and road wear particles (TRWP) in soil and sediment samples. The technique uses pyrolysis followed by gas chromatography/mass spectrometry (pyrolysis‑GC/MS) to generate and quantify polymer dimer fragments that are specific to tyre rubber polymers. Results can be reported on a TRWP, tyre rubber polymer, or tyre tread basis.

Key topics and technical requirements

- Principle: Thermal decomposition of tyre polymers produces characteristic dimeric pyrolysis fragments (NR, SBR, BR dimers) that are separated by GC and identified by MS. Dimer markers provide greater specificity than monomer markers, which can be interfered with by non‑TRWP sources (e.g., styrene from diesel).

- Sample collection & preparation:

- Field sampling using pre‑cleaned trowels, corers or dredges.

- Oven drying at 105 °C for 24 h is specified for dry mass determination.

- Dry sieving/homogenization (nominal sieve opening ~1 mm) to prepare material for pyrolysis.

- Precision balance requirements (accuracy to 0.01 mg) for mass measurements.

- Analytical method:

- Addition of a deuterated internal standard to correct for matrix effects, instrument drift and recovery.

- Preparation of calibration curves from stock solutions and internal standards.

- Pyrolyser operation at 670 °C for 5 s in a helium atmosphere; high‑purity helium specified for carrier gas.

- Quantification & reporting:

- Calculation of polymer mass in the sample from dimer peak areas and internal standard calibration.

- Conversion of polymer mass to TRWP concentration (µg/g), accounting for tyre tread and mineral encrustation fractions.

- Performance: The specification addresses measuring range, method detection limits, repeatability, and test report requirements.

Applications

- Environmental monitoring of TRWP in urban soils, roadside sediments, and aquatic sediments.

- Comparative and trend studies to assess temporal changes in TRWP loads.

- Supporting environmental impact assessments, source apportionment, and mitigation studies for microplastic and tyre wear pollution.

- Research into tyre composition, road abrasion, and fate/transport of TRWP.

Who should use this standard

- Environmental testing laboratories and analytical service providers.

- Academic and government researchers studying microplastics, particulate pollution, or soil/sediment contamination.

- Regulatory agencies, road authorities and consultants performing baseline or monitoring studies.

- Tire manufacturers and material scientists investigating abrasion and wear.

Related standards

- ISO 7270‑1 - Rubber - Analysis by pyrolytic GC methods - Part 1: Identification of polymers (referenced normatively for pyrolysis‑GC identification procedures).

Keywords: ISO/TS 21396:2017, TRWP, tyre and road wear particles, pyrolysis‑GC/MS, soil, sediments, tyre rubber polymer, dimer markers, deuterated internal standard, environmental monitoring.

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 21396

First edition

2017-12

Rubber — Determination of mass

concentration of tire and road

wear particles (TRWP) in soil and

sediments — Pyrolysis-GC/MS method

Caoutchouc — Détermination de la concentration massique en

particules de pneus et d'usure de la route (TWRP) dans le sol et les

sédiments — Méthode par pyrolyse-GC/MS

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

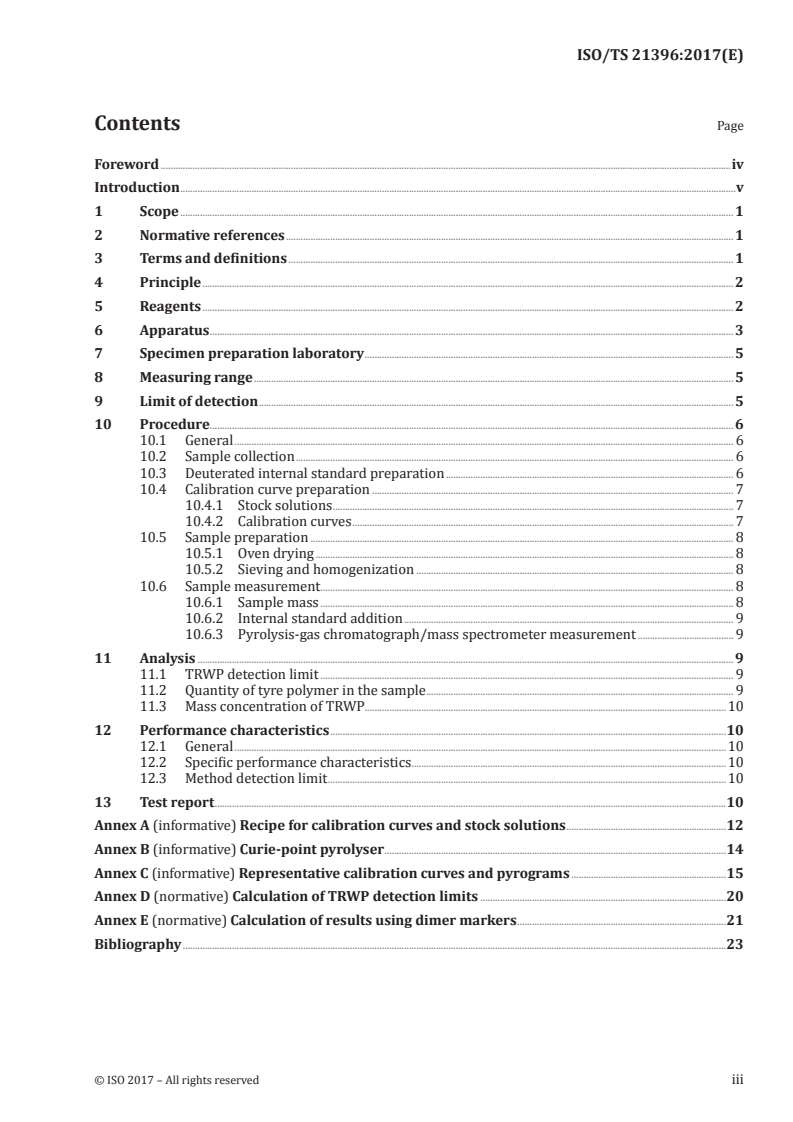

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 2

5 Reagents . 2

6 Apparatus . 3

7 Specimen preparation laboratory . 5

8 Measuring range . 5

9 Limit of detection . 5

10 Procedure. 6

10.1 General . 6

10.2 Sample collection . 6

10.3 Deuterated internal standard preparation . 6

10.4 Calibration curve preparation . 7

10.4.1 Stock solutions . 7

10.4.2 Calibration curves . 7

10.5 Sample preparation . 8

10.5.1 Oven drying . 8

10.5.2 Sieving and homogenization . 8

10.6 Sample measurement . 8

10.6.1 Sample mass . 8

10.6.2 Internal standard addition . 9

10.6.3 Pyrolysis-gas chromatograph/mass spectrometer measurement . 9

11 Analysis . 9

11.1 TRWP detection limit . 9

11.2 Quantity of tyre polymer in the sample . 9

11.3 Mass concentration of TRWP.10

12 Performance characteristics .10

12.1 General .10

12.2 Specific performance characteristics .10

12.3 Method detection limit .10

13 Test report .10

Annex A (informative) Recipe for calibration curves and stock solutions .12

Annex B (informative) Curie-point pyrolyser .14

Annex C (informative) Representative calibration curves and pyrograms .15

Annex D (normative) Calculation of TRWP detection limits .20

Annex E (normative) Calculation of results using dimer markers .21

Bibliography .23

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 45, Rubber and Rubber Products.

iv © ISO 2017 – All rights reserved

Introduction

Tyre and road wear particles (TRWP) are formed as a result of tread abrasion from the road surface,

and subsequent particle release to the environment. TRWP consist of tyre tread particles which include

[1]

incorporated material from the road surface (Kreider et al. 2010 ). The elastomeric fraction in TRWP

contained in soil or sediment materials is quantified in this document by direct pyrolysis-GC/MS

analysis. Mass concentration can be expressed on the basis of the rubber polymer, tyre tread, or TRWP.

This method has been used to measure the TRWP concentration in soil and sediment samples from three

[2] [3]

geographically separated regions (Unice et al. 2012 ; Unice et al. 2013 ). The airborne concentration

[4]

of TRWP in the PM fraction has also been characterized by a similar method (Panko et al. 2013 ).

Specific chemical markers are generated from intact TRWP by pyrolysis of sample specimens. The

chemical markers consist of characteristic and specific pyrolysis dimeric fragments of passenger

and truck tyre tread polymers including butadiene rubber, styrene-butadiene rubber, and isoprene

rubber. The polymer fragments generated by sample pyrolysis are subsequently separated by gas

chromatography, and identified by mass spectroscopy. The TRWP mass concentration is calculated

based on market average polymer use rates in tread, and prior characterization of the mineral content

of TRWP. Rubber polymer specificity is achieved by quantification of dimeric polymer fragments

[5] [6]

consisting of two monomer units (Kitamura et al. 2007 ; Harada et al. 2009 ). Repeatability is

achieved by the use of a deuterated internal standard of similar polymeric structure to the tyre tread

polymers. The internal standard corrects for variable analyte recovery caused by sample size, matrix

effects, and temporal variation in instrument response. The method is suitable for monitoring changes

in soil or sediment TRWP concentrations over time.

TECHNICAL SPECIFICATION ISO/TS 21396:2017(E)

Rubber — Determination of mass concentration of tire

and road wear particles (TRWP) in soil and sediments —

Pyrolysis-GC/MS method

WARNING 1 — Persons using this document should be familiar with normal laboratory practice.

This document does not purport to address all of the safety problems, if any, associated with its

use. It is the responsibility of the user to establish appropriate safety and health practices.

WARNING 2 — Certain procedures specified in this document may involve the use or generation

of substances, or the generation of waste, that could constitute a local environmental hazard.

Reference should be made to appropriate documentation on safe handling and disposal after use.

1 Scope

This document specifies a method for the determination of the soil or sediment mass concentration

(μg/g) of tyre and road wear particles (TRWP) in environmental samples.

This document establishes principles for soil or sediment sample collection, the generation of pyrolysis

fragments from the sample, and the quantification of the generated polymer fragments. The quantified

polymer mass is used to calculate the concentration of TRWP in soil or sediment. These quantities are

expressed on a TRWP basis, which includes the mass of tyre tread and mass of road wear encrustations,

and can also be expressed on a tyre rubber polymer or tyre tread basis.

NOTE Tyre and road wear particles are a discrete mass of elongated particles generated at the frictional

interface between the tyre and roadway surface during the service life of a tyre. The particles consist of tyre

tread enriched with mineral encrustations from the roadway surface.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 7270-1, Rubber — Analysis by pyrolytic gas-chromatographic methods — Part 1: Identification of

polymers (single polymers and polymer blends)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

deuterated internal standard

compound containing at least one deuterium molecule added to a sample in a fixed amount that is nearly

identical to the target analyte used to correct for instrument drift and matrix interference

3.2

dry mass

mass of solid dried in an oven for a specified time and at a specified temperature

3.3

monitoring

repeated measurement to follow changes over a period of time

3.4

percent moisture

mass of water in soil expressed as a percentage of oven dried mass

3.5

pyrolysis analysis

decomposition of organic polymeric molecules into characteristic fragments separated by gas

chromatography and quantified by mass spectroscopy

4 Principle

Tyre tread polymer is quantified using internal standard calibration and the peak area of characteristic

fragment ions corresponding to dimers of the raw polymer by pyrolysis-GC/MS. The thermal

decomposition products of cross-linked natural rubber (NR), styrene-butadiene rubber (SBR) and

butadiene rubber (BR) polymers depend on the abundance of polymers in the sample. SBR pyrolysis

generates butadiene, vinylcyclohexene (butadiene dimer) and styrene, whereas BR generates only

butadiene monomer and vinylcyclohexene. NR is associated with isoprene monomer and dipentene

(isoprene dimer). The dimer fragments have good specificity for rubber polymers, whereas both

[5]

anthropogenic and natural organic substances are sources of the monomer markers (Kitamura 2007 ).

Therefore, the monomeric pyrolysis marker compounds are subject to interference from non-TRWP

environmental sources, and are not suitable for quantification of TRWP mass concentration in soil or

sediment. One well-known example is styrene, which is generated from pyrolysis of both SBR and diesel

[7]

exhaust particles (Pierson and Brachaczek 1974 ). The tyre polymers, and pyrolysis fragment dimers

used for quantification of TRWP are shown in Figure 1.

Figure 1 — Dimeric pyrolysis products of tyre rubber polymers

5 Reagents

Use only reagents of recognized analytical grade.

5.1 Chloroform, analytical grade.

2 © ISO 2017 – All rights reserved

5.2 Helium, purity 99,999 5 % by volume.

6 Apparatus

6.1 Soil or sediment sampling — Equipment and consumable supplies.

6.1.1 Sampling device.

The sampling device shall be suitable for the collection of soil or sediment samples. Suitable devices

include pre-cleaned stainless steel hand trowels, coring tools or clamshell dredge devices. The collection

of a sediment sample with a clamshell dredge device is illustrated in Figure 2.

NOTE Photo courtesy of Cardno ChemRisk.

Figure 2 — Collection of sample with clamshell dredge device

6.1.2 Sample containers.

Samples should be collected in clean sample containers supplied by the laboratory, or clean sample

container handled in a manner consistent with laboratory standard operating procedures. The

placement of a soil sample into a sample container with a trowel is illustrated in Figure 3.

NOTE Photo courtesy of Cardno ChemRisk.

Figure 3 — Placement of sample in container with trowel

6.2 Equipment for analysis.

6.2.1 Laboratory oven, for drying field collected sample(s) at a temperature of 105 °C for 24 h in a

suitably clean laboratory-supplied container.

6.2.2 Sieve, for removing large aggregates unsuitable for the pyrolyser unit. The nominal opening for

dry sieving can be 1 mm.

6.2.3 Precision analytical balance, for determination of sample mass as collected, after oven drying,

and after dry sieving. Measurements shall be conducted in an environment of controlled temperature

and humidity. The balance shall be accurate to 0,01 mg and be maintained, calibrated and certified in

accordance with the manufacturer’s recommendations.

6.2.4 Pyrolyser, operating at a temperature of 670 °C for 5 s in a helium atmosphere with an induction

time of less than 0,2 s. A single-use or reusable sample holder shall be selected in accordance with the

manufacturer's recommendation. Examples of pyrolyser systems are provided in ISO 7270-1, and include

micro-furnace with quartz tube, Curie-point with holder, and platinum filament with holder. An example

of one type of pyrolyser that can be used is described in Annex B.

6.2.5 Gas chromatograph/mass spectrometer, operated and maintained in accordance with the

manufacturer’s instructions.

6.2.5.1 Gas chromatograph, as specified below:

— carrier gas flow rate: 1,0 ml/min to 2,0 ml/min;

— injector temperature: 300 °C;

— oven temperature programme: initial temperature 50 °C for 5 min, heating at 25 °C /min up to

300 °C, maintained at 300 °C for 10 min.

6.2.5.2 Column, as specified below:

— length: 25 m to 60 m;

— diameter: 0,25 mm to 0,35 mm;

4 © ISO 2017 – All rights reserved

— liquid phase: 5 % diphenyl-, 95 % polydimethylsiloxane;

— film thickness: 0,20 µm to 1,0 µm.

6.2.5.3 Mass spectrometer, quadrupole mass spectrometer, magnetic-sector-type mass spectrometer

or any other suitable type, having the characteristics specified below:

— interface temperature: 300 °C to 350 °C;

— ionization method: electron ionization;

— ion source temperature: 230 °C;

— ionizing voltage: 70 eV;

— scan range: mass/charge ratio: 35 m/z to 500 m/z.

7 Specimen preparation laboratory

The specimen preparation laboratories and sample containers selected for analysis shall be sufficiently

free of contamination that blank analyses demonstrate an absence of polymer as established by the

method detection limit (MDL). At least one laboratory blank analysis shall be performed for each type

of sample container used for sample collection, and following modifications to laboratory standard

operating procedures or equipment.

8 Measuring range

The range of SBR/BR polymer that can be determined in a soil or sediment sample is approximately

0,09 μg to 90 μg, and the range of NR polymer that can be determined is approximately 0,03 μg to 50 μg.

Assuming a total sample mass of 0,020 g, this mass range corresponds to a TRWP concentration range

in soil or sediment of approximately 24 μg/g to 28 000 μg/g.

NOTE The TRWP concentration range is based on Formula (E.2). For example, the low end of the TRWP

concentration range is (0,09 μg + 0,03 μg) / 0,5 / 0,5 / 0,020 g = 24 μg/g. The first factor of 0,5 accounts for

the polymer fraction in tyre tread. TRWP consists of tyre tread enriched with mineral encrustations from the

roadway surface. The second factor of 0,5 accounts for the fraction of tyre tread in TRWP.

9 Limit of detection

The TRWP limit of detection depends on mass of sample pyrolysed. In practice, sampling constraints

and the capacity of the pyrolysis unit determine the lowest achievable limit of detection. For a nominal

sample mass of 0,020 g, the limit of detection is approximately 24 μg/g TRWP in soil or sediment.

An alternative limit of detection can be achieved by changing the calibration curve range and mass

of internal standard used in the analysis. Alternative limits of detection based on adjustment of the

calibration curve range and internal standard masses shall be verified by a method detection limit study.

The target TRWP detection limit shall be determined as part of the sampling plan prior to sample

collection. The sample plan shall specify field and laboratory conditions sufficient to ensure that the

target detection limit satisfies the sample campaign goals and objectives. A sample-specific detection

limit shall be calculated based on the conditions of the analysis. The detection limit calculations are

specified in 11.1.

10 Procedure

10.1 General

The method is defined for a sample mass of oven-dried soil or sediment suitable for the pyrolyser

unit. Thermal energy is applied to a sample encapsulated in a pyrolyser in the absence of oxygen to

decompose the sample. Secondary reactions are minimized by rapid heating of the pyrolyser to the

target temperature. The nominal sample mass for the example pyrolysis unit described in Annex B is

0,020 g. The sample collection and laboratory pyrolysis-GC/MS procedure consists of the following six

steps and is described in 10.2 to 10.6 respectively:

a) sample collection;

b) deuterated internal standard preparation;

c) calibration curve preparation;

d) sample preparation;

e) sample pyrolysis with polymer decomposition under defined thermal conditions;

f) dimer measurement using gas-chromatographic (GC) separation and mass spectroscopy (MS).

The procedure relies on deuterated homopolymer internal standards to increase the precision and

accuracy of the measured TRWP concentration. The internal standard is used to correct for matrix

effects that affect polymer pyrolysis and fragment recovery. The internal standard also corrects for

changes in the mass spectrometer ion source condition and fluctuations in carrier gas flow rates. The

internal standards are deuterated polyisoprene (d-PI) and deuterated polybutadiene (d-PB), which are

polymers labelled with the minor stable hydrogen isotope deuterium. The pyrolysis-GC/MS thermal

decomposition products of d-PI and d-PB are discriminated based on retention time and mass to charge

ratio from the dipentene and vinylcyclohexene markers associated with NR and SBR/BR, respectively.

10.2 Sample collection

A soil or sediment sample is collected in clean laboratory supplied or approved sample containers.

The sample shall be collected using a clean device suitable for the collection of soil or sediment

samples, such as stainless steel hand trowels, coring tools or clamshell dredge devices. The standard

operating procedure for sample collection shall be approved by the laboratory. A chain-of-custody form

documenting sample collection and relinquishment shall be maintained. A soil or sediment mass of at

least 10 g to 50 g should be collected to ensure adequate homogenization.

10.3 Deuterated internal standard preparation

Deuterated standards d-PI (1,4-d8) and d-PB (1,4-d6) of known purity shall be obtained prior to

analysis (see Table 1). The purity of the standards shall be sufficiently high to prevent interference for

TRWP sample concentrations at or above the detection limit or reporting limit of the analysis.

A recipe for stock internal standard solution preparation that should be used is specified in Annex A.

Alternative recipes may be used to meet the objectives of the analysis. To prepare the stock solutions,

raw d-PI or d-PB polymer is weighed and placed in a graduated flask. Chloroform shall be poured

to two-thirds of the tot

...

Frequently Asked Questions

ISO/TS 21396:2017 is a technical specification published by the International Organization for Standardization (ISO). Its full title is "Rubber - Determination of mass concentration of tire and road wear particles (TRWP) in soil and sediments - Pyrolysis-GC/MS method". This standard covers: ISO/TS 21396:2017 specifies a method for the determination of the soil or sediment mass concentration (μg/g) of tyre and road wear particles (TRWP) in environmental samples. ISO/TS 21396:2017 establishes principles for soil or sediment sample collection, the generation of pyrolysis fragments from the sample, and the quantification of the generated polymer fragments. The quantified polymer mass is used to calculate the concentration of TRWP in soil or sediment. These quantities are expressed on a TRWP basis, which includes the mass of tyre tread and mass of road wear encrustations, and can also be expressed on a tyre rubber polymer or tyre tread basis. NOTE Tyre and road wear particles are a discrete mass of elongated particles generated at the frictional interface between the tyre and roadway surface during the service life of a tyre. The particles consist of tyre tread enriched with mineral encrustations from the roadway surface.

ISO/TS 21396:2017 specifies a method for the determination of the soil or sediment mass concentration (μg/g) of tyre and road wear particles (TRWP) in environmental samples. ISO/TS 21396:2017 establishes principles for soil or sediment sample collection, the generation of pyrolysis fragments from the sample, and the quantification of the generated polymer fragments. The quantified polymer mass is used to calculate the concentration of TRWP in soil or sediment. These quantities are expressed on a TRWP basis, which includes the mass of tyre tread and mass of road wear encrustations, and can also be expressed on a tyre rubber polymer or tyre tread basis. NOTE Tyre and road wear particles are a discrete mass of elongated particles generated at the frictional interface between the tyre and roadway surface during the service life of a tyre. The particles consist of tyre tread enriched with mineral encrustations from the roadway surface.

ISO/TS 21396:2017 is classified under the following ICS (International Classification for Standards) categories: 13.020.40 - Pollution, pollution control and conservation; 83.060 - Rubber; 83.160.01 - Tyres in general. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase ISO/TS 21396:2017 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...