ISO 13608:2014

(Main)Plywood — Decorative veneered plywood

Plywood — Decorative veneered plywood

ISO 13608:2014 specifies the terms, classifications, requirements, test methods, marking, for decorative veneered plywood with natural wood veneer, coloured veneer, laminated veneer, multilaminar veneer, and other types of veneer as decorative surface and plywood as a core panel, where the surface veneer thickness is less than 0,55 mm.

Contreplaqué — Contreplaqué à placage décoratif

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13608

First edition

2014-02-15

Plywood — Decorative veneered

plywood

Contreplaqué — Contreplaqué à placage décoratif

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

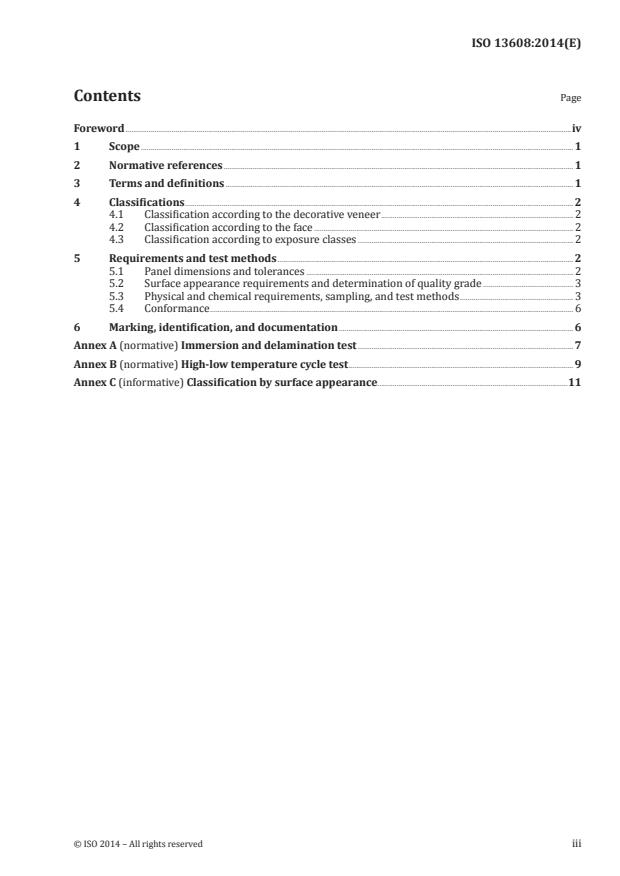

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Classifications . 2

4.1 Classification according to the decorative veneer . 2

4.2 Classification according to the face . 2

4.3 Classification according to exposure classes . 2

5 Requirements and test methods . 2

5.1 Panel dimensions and tolerances . 2

5.2 Surface appearance requirements and determination of quality grade . 3

5.3 Physical and chemical requirements, sampling, and test methods . 3

5.4 Conformance . 6

6 Marking, identification, and documentation . 6

Annex A (normative) Immersion and delamination test . 7

Annex B (normative) High-low temperature cycle test . 9

Annex C (informative) Classification by surface appearance .11

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 89, Wood based panels, Subcommittee SC 3,

Plywood.

iv © ISO 2014 – All rights reserved

INTERNATIONAL STANDARD ISO 13608:2014(E)

Plywood — Decorative veneered plywood

1 Scope

This International Standard specifies the terms, classifications, requirements, test methods, marking,

for decorative veneered plywood with natural wood veneer, coloured veneer, laminated veneer,

multilaminar veneer, and other types of veneer as decorative surface and plywood as a core panel,

where the surface veneer thickness is less than 0,55 mm.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 1954, Plywood — Tolerances on dimensions

ISO 2074:2007, Plywood — Vocabulary

ISO 2426-1, Plywood — Classification by surface appearance — Part 1: General

ISO 2426-2, Plywood — Classification by surface appearance — Part 2: Hardwood

ISO 2426-3, Plywood — Classification by surface appearance — Part 3: Softwood

ISO 9426, Wood-based panels — Determination of dimensions of panels

ISO 12460-1, Wood-based panels — Determination of formaldehyde release — Part 1: Formaldehyde

emission by the 1-cubic-metre chamber method

ISO 12460-3, Wood-based panels — Determination of formaldehyde release — Part 3: Gas analysis method

ISO 12460-4, Wood-based panels — Determination of formaldehyde release — Part 4: Desiccator method

ISO 12465, Plywood — Specifications

ISO 12466-1, Plywood — Bonding quality — Part 1: Test methods

ISO 12466-2, Plywood — Bonding quality — Part 2: Requirements

ISO 16979, Wood-based panels — Determination of moisture content

ISO 18775, Veneers — Terms and definitions, determination of physical characteristics and tolerances

ISO/IEC 17065, Conformity assessment requirements for bodies certifying products, processes and services

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 2074, ISO 12465, ISO 18775,

and the following apply.

3.1

decorative veneered plywood

plywood with natural wood veneer, coloured veneer, laminated veneer, multilaminar veneer, and any

other types of veneer as decorative surface and plywood as a core panel, where the surface veneer

thickness is less than 0,55 mm

3.2

coloured veneer

wood veneer produced from either bleaching or dying procedure

3.3

laminated wood veneer

veneer sliced from wood flitch that is assembled from small pieces of wood strips with joints parallel to

grain

3.4

colour difference

difference between surface colour of the decorative veneer and the control colour of the sample veneer

colour or uneven colour of the surface in some case

Note 1 to entry: It does not include the colour difference between early wood and later wood, as well as the natural

grain colour difference on the wood surface itself.

4 Classifications

4.1 Classification according to the decorative veneer

a) natural wood veneered plywood;

b) coloured veneered plywood;

c) laminated wood veneered plywood;

d) multilaminar decorative veneered plywood.

4.2 Classification according to the face

a) single-faced decorative veneered plywood;

b) double-faced decorative veneered plywood.

4.3 Classification according to exposure classes

a) Exposure Class 1: for use in dry conditions;

b) Exposure Class 2: for use in tropical-dry/humid conditions.

5 Requirements and test methods

5.1 Panel dimensions and tolerances

5.1.1 General

Test methods and requirements as given in ISO 1954 and ISO 9426 apply to determine length, width,

squareness, and edge straightness of the panel.

5.1.2 Panel thickness and tolerances

Tolerance of thickness of decorative veneered plywood refers to the nominal thickness marked on the

product label and shall satisfy the requirements given in Table 1.

Tolerance of thickness within one panel shall satisfy the requirements given in Table 1.

2 © ISO 2014 – All rights reserved

Table 1 — Thickness tolerance for decorative veneered plywood

Dimension in millimetres

Thickness, Thickness tolerance within one

Tolerance on nominal thickness

t panel

t < 4 0,3 ±0,20

4 ≤ t < 7 0,5 ±0,30

7 ≤ t < 20 0,6 ±0,40

t ≥ 20 0,6 ±0,50

5.2 Surface appearance requirements and determination of quality grade

5.2.1 Determination of surface appearance

5.2.1.1 Apparatus

— Scale magnifier glass;

— Photoelectric integrating colour measurement instrument;

— Steel rule, to an accuracy of 0,5 mm.

5.2.1.2 Test method

— Inspect visually the surface appearance for each panel tested;

— Classify the decorative veneered plywood in accordance with criteria given in Annex C.

5.2.2 Quality grades

Decorative veneered plywood shall be classified by the surface appearance.

The list of characteristics which shall be taken into account is given in ISO 2426-1.

NOTE 1 An example of classification according to appearance classes is given in ISO 2426-2 and ISO 2426-3.

The classes of the surface are chosen from classes E, I, or II. (See Annex C.)

NOTE 2 The quality grades of the face and back surface appearance are usually defined by contract.

Colour difference allowance shall follow the agreement or contract. Photoelectric integrating colour

measurement instrument or photo electricity integral colourimeter shall be employed for arbitration,

and

a) indiscernible refers to the total colour difference lower than 1,5,

b) inconspicuous refers to the total colour difference between 1,5 approximately 3,0, and

c) obvious refers to the total colour difference higher than 3,0.

5.3 Physical and chemical requirements, sampling, and test methods

5.3.1 Requirements

Unless otherwise specified, requirements and test methods given in Table 2 shall be fulfilled.

Determination of the formaldehyde release shall be carried out in accordance with ISO 12460-1 as the

reference method and ISO 12460-3 or ISO 12460-4 for factory production control.

Table 2 — Specifications

Characteristics Test method Requirements

Moisture content (%) ISO 16979 6,0 — 14,0

Immersion and delamination test Annex A Length of failure or delamination between surface

veneer and plywood shall be less than 25 mm on each

side.

High-low temperature cycle test Annex B No crack, blister, crinkle, on surface

a 3

Formaldehyde release ISO 12460-1 ≤0,124 mg/m

NOTE If there is specific national or local law setting a lower limit of formaldehyde release, it applies.

a

If factory production control methods are employed to determine formaldehyde release, a correlation between the

utilized method and the 1-cubic-meter chamber method as in ISO 12460-1 shall be established.

When the faced decorative veneered plywood is manufactured in a two-stage process, the substrate

plywood shall meet the requirements of ISO 12465.

5.3.2 Sampling and preparation of test pieces

Preparation of test pieces for properties determination is given in Figure 1 and Figure 2. Three samples

shall be cut from one panel to be tested as shown in Figure 1. Then test pieces for moisture content

test, immersion and delamination test, high-low temperature cycle test, and formaldehyde release

determination are cut as shown in Figure 2. All the test pieces shall be coded in sequence.

Key

1, 2, and 3 samples

4 length of panel

5 half-length of panel

6 width of panel

Figure 1 — Example of cutting plan for test sample preparation

4 © ISO 2014 – All rights reserved

Key

1, 2, 3, and 4 samples as given in Table 3

5 length of panel

6 width of panel

Figure 2 — Example of cutting plan for test pieces preparation

When cutting test pieces, it is possible to change the cutting position to avoid any defect that could affect

the accuracy of test results. The surface of the test pieces shall be kept clean.

The dimension and number of test pieces shall follow the requirements in Table 3 with marking.

Table 3 — Dimension and number of test pieces

Dimension

Marking of

Property (length × width) Number Note

samples

mm

Moisture content 100 × 100 or at least 3 ① —

20 g

Immersion delamination 75 × 75 6 ② —

High-low temperature cycle 150 × 150 3 ③ —

Formaldehyde 1-Cubic-metre 500 × 500 2 ④ Two test pieces could be taken from

release chamber any position from test sample as

method shown in Figure 1.

Desiccator 150 × 50

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.