ISO 16000-23:2009

(Main)Indoor air — Part 23: Performance test for evaluating the reduction of formaldehyde concentrations by sorptive building materials

Indoor air — Part 23: Performance test for evaluating the reduction of formaldehyde concentrations by sorptive building materials

ISO 16000-23:2009 specifies a general laboratory test method for evaluating the reduction of formaldehyde concentrations by sorptive building materials. This method applies to boards, wallpapers, carpets, paint products, and other building materials. The sorption of formaldehyde can be brought about by adsorption, absorption and chemisorption. The performance of the material with respect to its ability to reduce the concentration of formaldehyde in indoor air is evaluated by measuring sorption flux and saturation mass per area. The former directly indicates material performance with respect to formaldehyde concentration reduction at a point in time; the latter relates to the ability of a product to maintain that performance. The method specified in ISO 16000-23:2009 employs formaldehyde-spiked supply air to determine the performance of building materials in reducing formaldehyde concentrations. The characteristics of formaldehyde sorption depend greatly on humidity. Formaldehyde is less stable in air than other volatile organic compounds, so it has to be tested on its own. ISO 16000-23:2009 is based on the test chamber method specified in ISO 16000-9. Sampling, transport and storage of materials to be tested, and preparation of test specimens are specified in ISO 16000-11. Air sampling and analytical methods for the determination of formaldehyde are specified in ISO 16000-3, which is part of the complete procedure.

Air intérieur — Partie 23: Essai de performance pour l'évaluation de la réduction des concentrations en formaldéhyde par des matériaux de construction sorptifs

L'ISO 16000-23:2009 spécifie une méthode générale d'essai de laboratoire en vue de l'évaluation de la réduction des concentrations en formaldéhyde grâce à l'utilisation de matériaux de construction sorptifs. Cette méthode s'applique aux planches, papiers peints, tapis, produits de peinture et autres matériaux de construction. La sorption de formaldéhyde peut être réalisée par adsorption, absorption et chimisorption. La performance du matériau, au regard de sa capacité de réduction de la concentration en formaldéhyde en air intérieur, est évaluée en mesurant le flux de sorption et la masse surfacique de saturation. Le premier indique directement la performance du matériau de construction en fonction de la réduction de la concentration en formaldéhyde à un instant donné; la dernière indique la capacité d'un produit à maintenir cette performance. La méthode spécifiée dans l'ISO 16000-23:2009 emploie une alimentation en air marqué au formaldéhyde pour déterminer l'aptitude du produit de construction à réduire les concentrations en formaldéhyde. Les caractéristiques de la sorption du formaldéhyde dépendent largement de l'humidité. Le formaldéhyde est moins stable dans l'air que d'autres composés organiques volatils (COV) et il doit donc faire l'objet d'un essai distinct. L'ISO 16000-23:2009 est basée sur la méthode de la chambre d'essai telle que spécifiée dans l'ISO 16000‑9. L'échantillonnage, le transport et le stockage des matériaux à soumettre à essai, ainsi que la préparation des éprouvettes pour essai, sont spécifiés dans l'ISO 16000‑11. L'échantillonnage de l'air et les méthodes d'analyse en vue de la détermination du formaldéhyde sont spécifiés dans l'ISO 16000‑3, qui fait partie de la procédure complète.

Notranji zrak - 23. del: Zmogljivostni preskus za vrednotenje zmanjšanja koncentracije formaldehida z vpojnimi stavbnimi gradbenimi materiali

Ta del standarda ISO 16000 določa splošne laboratorijske preskusne metode za vrednotenje zmanjšanja koncentracije formaldehida z vpojnimi gradbenimi materiali. Ta metoda se uporablja za plošče, tapete, preproge, barve in druge gradbene materiale. Vpijanje formaldehida se lahko doseže z adsorpcijo, absorpcijo in kemisorpcijo. Učinek materiala glede na njegovo sposobnost zmanjševanja koncentracije formaldehida v notranjem zraku se vrednoti z merjenjem toka vpijanja in mase nasičenosti na površino. Prvi neposredno nakazuje, kakšen je učinek materiala na zmanjševanje koncentracije formaldehida v nekem trenutku; slednja pa se nanaša na sposobnost izdelka, da ta učinek vzdržuje. Za metodo, opisano v tem delu standarda ISO 16000, se za določanje učinka gradbenih materialov za zmanjševanje koncentracij formaldehida uporablja zrak, ki vsebuje nizko koncentracijo formaldehida. Značilnosti vpijanja formaldehida so v veliki meri odvisne od vlažnosti. Formaldehid je manj stabilen v zraku kot v drugih hlapljivih organskih spojinah (VOC), zato ga je treba preskusiti samostojno. Ta del standarda ISO 16000 temelji na metodi preskusne komore, navedene v standardu ISO 16000-9. Vzorčenje, prevoz in skladiščenje materialov, ki se jih bo preskušalo, ter priprava preskušancev so navedeni v standardu ISO 16000-11. Vzorčenje zraka in analizne metode za ugotavljanje prisotnosti formaldehida so navedene v standardu ISO 16000-3, ki je del celotnega postopka.

General Information

Relations

Buy Standard

Standards Content (Sample)

SLOVENSKI STANDARD

SIST ISO 16000-23:2013

01-december-2013

Notranji zrak - 23. del: Zmogljivostni preskus za vrednotenje zmanjšanja

koncentracije formaldehida z vpojnimi stavbnimi gradbenimi materiali

Indoor air - Part 23: Performance test for evaluating the reduction of formaldehyde

concentrations by sorptive building materials

Air intérieur - Partie 23: Essai de performance pour l'évaluation de la réduction des

concentrations en formaldéhyde par des matériaux de construction sorptifs

Ta slovenski standard je istoveten z: ISO 16000-23:2009

ICS:

13.040.20 Kakovost okoljskega zraka Ambient atmospheres

SIST ISO 16000-23:2013 en,fr

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

---------------------- Page: 1 ----------------------

SIST ISO 16000-23:2013

---------------------- Page: 2 ----------------------

SIST ISO 16000-23:2013

INTERNATIONAL ISO

STANDARD 16000-23

First edition

2009-12-15

Indoor air —

Part 23:

Performance test for evaluating the

reduction of formaldehyde

concentrations by sorptive building

materials

Air intérieur —

Partie 23: Essai de performance pour l'évaluation de la réduction des

concentrations en formaldéhyde par des matériaux de construction

sorptifs

Reference number

ISO 16000-23:2009(E)

©

ISO 2009

---------------------- Page: 3 ----------------------

SIST ISO 16000-23:2013

ISO 16000-23:2009(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2009 – All rights reserved

---------------------- Page: 4 ----------------------

SIST ISO 16000-23:2013

ISO 16000-23:2009(E)

Contents Page

Foreword .iv

Introduction.vi

1 Scope.1

2 Normative references.1

3 Terms and definitions .2

4 Symbols.4

5 Principle.5

6 Apparatus and materials.5

7 Test conditions .6

7.1 General .6

7.2 Test conditions for concentration reduction performance determination.7

7.3 Factors affecting the concentration reduction performance.8

8 Verification of test conditions.8

8.1 Monitoring of test conditions.8

8.2 Air tightness of test chamber.8

8.3 Air change rate in test chamber.8

8.4 Efficiency of the internal test chamber air mixing .9

8.5 Recovery.9

9 Preparation of test chamber.9

10 Preparation of test specimens .9

11 Test methods .9

11.1 Background concentration and spiked supply air.9

11.2 Placing the test specimen in the test chamber .9

11.3 Time intervals for measurement of test chamber concentration .10

11.4 Air sampling.10

12 Determination of formaldehyde .10

13 Expression of results.11

13.1 Calculation of sorption flux.11

13.2 Calculation of equivalent ventilation rate per area .11

13.3 Calculation of total mass per area of sorption and saturation mass per area.11

14 Test report.11

Annex A (normative) Sample tube test for long-term reduction performance.14

Annex B (normative) System for quality assurance and quality control .18

Annex C (informative) Example measurements of construction materials .20

Annex D (informative) Long-term reduction performance (example procedure).25

Bibliography.28

© ISO 2009 – All rights reserved iii

---------------------- Page: 5 ----------------------

SIST ISO 16000-23:2013

ISO 16000-23:2009(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 16000-23 was prepared by Technical Committee ISO/TC 146, Air quality, Subcommittee SC 6, Indoor air.

ISO 16000 consists of the following parts, under the general title Indoor air :

⎯ Part 1: General aspects of sampling strategy

⎯ Part 2: Sampling strategy for formaldehyde

⎯ Part 3: Determination of formaldehyde and other carbonyl compounds — Active sampling method

⎯ Part 4: Determination of formaldehyde — Diffusive sampling method

⎯ Part 5: Sampling strategy for volatile organic compounds (VOCs)

⎯ Part 6: Determination of volatile organic compounds in indoor and test chamber air by active sampling on

®

Tenax TA sorbent, thermal desorption and gas chromatography using MS/FID

⎯ Part 7: Sampling strategy for determination of airborne asbestos fibre concentrations

⎯ Part 8: Determination of local mean ages of air in buildings for characterizing ventilation conditions

⎯ Part 9: Determination of the emission of volatile organic compounds from building products and

furnishing — Emission test chamber method

⎯ Part 10: Determination of the emission of volatile organic compounds from building products and

furnishing — Emission test cell method

⎯ Part 11: Determination of the emission of volatile organic compounds from building products and

furnishing — Sampling, storage of samples and preparation of test specimens

⎯ Part 12: Sampling strategy for polychlorinated biphenyls (PCBs), polychlorinated dibenzo-p-dioxins

(PCDDs), polychlorinated dibenzofurans (PCDFs) and polycyclic aromatic hydrocarbons (PAHs)

⎯ Part 13: Determination of total (gas and particle-phase) polychlorinated dioxin-like biphenyls (PCBs) and

polychlorinated dibenzo-p-dioxins/dibenzofurans (PCDDs/PCDFs) — Collection on sorbent-backed filters

iv © ISO 2009 – All rights reserved

---------------------- Page: 6 ----------------------

SIST ISO 16000-23:2013

ISO 16000-23:2009(E)

⎯ Part 14: Determination of total (gas and particle-phase) polychlorinated dioxin-like biphenyls (PCBs) and

polychlorinated dibenzo-p-dioxins/dibenzofurans (PCDDs/PCDFs) — Extraction, clean-up and analysis by

high-resolution gas chromatography and mass spectrometry

⎯ Part 15: Sampling strategy for nitrogen dioxide (NO )

2

⎯ Part 16: Detection and enumeration of moulds — Sampling by filtration

⎯ Part 17: Detection and enumeration of moulds — Culture-based method

⎯ Part 18: Detection and enumeration of moulds — Sampling by impaction

⎯ Part 23: Performance test for evaluating the reduction of formaldehyde concentrations by sorptive

building materials

⎯ Part 24: Performance test for evaluating the reduction of volatile organic compounds (except

formaldehyde) concentrations by sorptive building materials

⎯ Part 25: Determination of the emission of semi-volatile organic compounds by building products —

Micro-chamber method

The following parts are under preparation:

⎯ Part 19: Sampling strategy for moulds

⎯ Part 26: Measurement strategy for carbon dioxide (CO )

2

⎯ Part 28: Sensory evaluation of emissions from building materials and products

The following parts are planned:

⎯ Part 20: Detection and enumeration of moulds — Sampling from house dust

⎯ Part 21: Detection and enumeration of moulds — Sampling from materials

⎯ Part 22: Detection and enumeration of moulds — Molecular methods

⎯ Part 27: Standard method for the quantitative analysis of asbestos fibres in settled dust

⎯ Part 30: Sensory testing of indoor air

Furthermore

⎯ ISO 12219-1, Indoor air — Road vehicles — Part 1: Whole vehicle test chamber — Specification and

method for the determination of volatile organic compounds in car interiors [planned document]

⎯ ISO 16017-1, Indoor, ambient and workplace air — Sampling and analysis of volatile organic compounds

by sorbent tube/thermal desorption/capillary gas chromatography — Part 1: Pumped sampling

⎯ ISO 16017-2, Indoor, ambient and workplace air — Sampling and analysis of volatile organic compounds

by sorbent tube/thermal desorption/capillary gas chromatography — Part 2: Diffusive sampling

focus on volatile organic compound (VOC) measurements.

© ISO 2009 – All rights reserved v

---------------------- Page: 7 ----------------------

SIST ISO 16000-23:2013

ISO 16000-23:2009(E)

Introduction

Sorptive building materials have been marketed in the form of sheet and board products for removing airborne

pollutants via physical sorption or chemical reaction.

Harmonized test methods for evaluating sorptive effects are important for comparative assessment of the

performance of sorptive building materials that are used for reducing levels of indoor air contaminants.

This part of ISO 16000 specifies procedures for evaluating the performance of sorptive building materials for

reducing indoor air formaldehyde concentrations over time.

The performance of sorptive building materials is evaluated by sorption flux and saturation mass per area and

is affected by a number of factors. Specific test conditions are therefore defined in this part of ISO 16000.

This part of ISO 16000 can be applied to most sorptive building materials used indoors and for formaldehyde

as an indoor air contaminant.

This part of ISO 16000 is based on the test chamber method as specified in ISO 16000-9.

vi © ISO 2009 – All rights reserved

---------------------- Page: 8 ----------------------

SIST ISO 16000-23:2013

INTERNATIONAL STANDARD ISO 16000-23:2009(E)

Indoor air —

Part 23:

Performance test for evaluating the reduction of formaldehyde

concentrations by sorptive building materials

1 Scope

This part of ISO 16000 specifies a general laboratory test method for evaluating the reduction of formaldehyde

concentrations by sorptive building materials. This method applies to boards, wallpapers, carpets, paint

products, and other building materials. The sorption of formaldehyde can be brought about by adsorption,

absorption and chemisorption. The performance of the material with respect to its ability to reduce the

concentration of formaldehyde in indoor air is evaluated by measuring sorption flux and saturation mass per

area. The former directly indicates material performance with respect to formaldehyde concentration reduction

at a point in time; the latter relates to the ability of a product to maintain that performance.

The method specified in this part of ISO 16000 employs formaldehyde-spiked supply air to determine the

performance of building materials in reducing formaldehyde concentrations. The characteristics of

formaldehyde sorption depend greatly on humidity. Formaldehyde is less stable in air than other volatile

organic compounds (VOCs), so it has to be tested on its own.

This part of ISO 16000 is based on the test chamber method specified in ISO 16000-9. Sampling, transport

and storage of materials to be tested and preparation of test specimens are specified in ISO 16000-11. Air

sampling and analytical methods for the determination of formaldehyde are specified in ISO 16000-3, which is

part of the complete procedure.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 554, Standard atmospheres for conditioning and/or testing — Specifications

ISO 6353-3, Reagents for chemical analysis — Part 3: Specifications — Second series

ISO 16000-3, Indoor air — Part 3: Determination of formaldehyde and other carbonyl compounds — Active

sampling method

ISO 16000-6, Indoor air — Part 6: Determination of volatile organic compounds in indoor and test chamber air

®

by active sampling on Tenax TA sorbent, thermal desorption and gas chromatography using MS/FID

ISO 16000-9:2006, Indoor air — Part 9: Determination of the emission of volatile organic compounds from

building products and furnishing — Emission test chamber method

ISO 16000-11, Indoor air — Part 11: Determination of the emission of volatile organic compounds from

building products and furnishing — Sampling, storage of samples and preparation of test specimens

© ISO 2009 – All rights reserved 1

---------------------- Page: 9 ----------------------

SIST ISO 16000-23:2013

ISO 16000-23:2009(E)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

breakthrough time

t

b

〈indoor air〉 time at which the formaldehyde concentration in the air eluting from the sample tube reaches

0,5 % of the concentration in the supplied air

NOTE Adapted from ISO 16000-24:2009, 3.1.

3.2

degradation coefficient

〈indoor air〉 ratio of the mass of formaldehyde removed by the initial performance divided by the mass of the

same compound lost by deterioration

NOTE Adapted from ISO 16000-24:2009, 3.2.

3.3

elapsed time

t

e

〈indoor air〉 time from start of test to the start of air sampling

NOTE Elapsed time is expressed in days.

[ISO 16000-24:2009, 3.3.]

3.4

equivalent ventilation rate per area

F

V, eq

〈indoor air〉 increased clean air ventilation rate giving the same reduction in formaldehyde concentration as the

building material

NOTE Adapted from ISO 16000-24:2009, 3.4.

3.5

guideline concentration

〈indoor air〉 guideline indoor air concentration for formaldehyde as specified by the the WHO

NOTE Adapted from ISO 16000-24:2009, 3.5.

3.6

half-lifetime

〈indoor air〉 time elapsed from the start of the test until the formaldehyde concentration decreases to one-half

of the initial concentration

NOTE Adapted from ISO 16000-24:2009, 3.6.

3.7

lifetime

t

lt

〈indoor air〉 time period over which the product continues to reduce formaldehyde concentrations

NOTE 1 The lifetime is given in days or years.

NOTE 2 The lifetime is estimated from the sorption flux and sorption capacity measured by the sample tube test.

NOTE 3 Adapted from ISO 16000-24:2009, 3.7.

2 © ISO 2009 – All rights reserved

---------------------- Page: 10 ----------------------

SIST ISO 16000-23:2013

ISO 16000-23:2009(E)

3.8

mass transfer coefficient

k

a

〈indoor air〉 coefficient arising from the concentration difference between the test specimen and ambient air

over its surface

NOTE Mass transfer coefficient is expressed in meters per hour.

[ISO 16000-24:2009, 3.8]

3.9

recovery

〈indoor air〉 measured mass of formaldehyde in the air leaving the test chamber with no sample present

conditioned over a given time period divided by the mass of formaldehyde added to the test chamber in the

same time period

NOTE 1 The recovery is expressed as a percentage and provides information about the performance of the entire

method.

NOTE 2 Adapted from ISO 16000-24:2009, 3.9.

3.10

saturation mass per area

ρ

Aa

theoretical maximum mass of formaldehyde that could be removed per area of the sorptive material

NOTE 1 Saturation mass per area is expressed in micrograms per area. It corresponds to the total mass per area of

sorption at the half-lifetime, or is extrapolated from the sorption capacity derived from the test referenced in Annex A.

NOTE 2 Adapted from ISO 16000-24:2009, 3.10.

3.11

sorption capacity

w

s

total mass of formaldehyde sorbed at breakthrough time per mass of sorbent

NOTE 1 Sorption capacity is expressed in micrograms per gram and is measured using the test specified in Annex A.

NOTE 2 Adapted from ISO 16000-24:2009, 3.11.

3.12

sorption flux

F

m

mass of formaldehyde sorbed per time per area at the specified elapsed time from the test start

NOTE Adapted from ISO 16000-24:2009, 3.12.

3.13

supply air concentration

ρ

s

mass concentration of formaldehyde in the air for supply to the test chamber

NOTE Adapted from ISO 16000-24:2009, 3.13.

3.14

test chamber concentration

〈indoor air〉 concentration of formaldehyde measured at the outlet of a test chamber, derived by dividing the

mass of the formaldehyde sampled at the outlet of the chamber by the volume of sampled air

NOTE Adapted from ISO 16000-24:2009, 3.14.

© ISO 2009 – All rights reserved 3

---------------------- Page: 11 ----------------------

SIST ISO 16000-23:2013

ISO 16000-23:2009(E)

3.15

total mass per area of sorption

ρ

A

integral over time of sorptive flux from the start of the test to the specified elapsed time measured with the test

chamber

NOTE Total mass per area of sorption is expressed in micrograms per area.

[ISO 16000-24:2009, 3.15]

3.16

vapour sampling period

〈indoor air〉 period of time during which air is sampled from the outlet of the test chamber using sampling tubes

or other devices

[ISO 16000-24:2009, 3.16]

4 Symbols

Symbol Meaning Unit

ρ mass of sorptive material per area (surface density) grams per square metre

A

ρ saturation mass per area micrograms per square metre

Aa

ρ total mass per area of sorption measured by chamber micrograms per square metre

Ac

test

ρ concentration of formaldehyde at test chamber inlet at micrograms per cubic metre

in, t

elapsed time t

ρ test chamber concentration at elapsed time t micrograms per cubic metre

out, t

ρ supply air concentration in sample tube micrograms per cubic metre

s

A surface area of test specimen square metres

F sorption flux per time per area micrograms per square metre per hour

m

F air flow rate per area cubic metres per square metre per hour

V, a

F equivalent ventilation rate cubic metres per square metre per hour

V, eq

k mass transfer coefficient determined using water vapour metres per hour

a

L product loading factor square metres per cubic metre

m actual mass of test specimen in sample tube grams

n air change rate changes per hour

q air flow rate of test chamber cubic metres per hour

c

q air flow rate of sample tube litres per minute

s

t breakthrough time minutes

b

t elapsed time hours or days

e

t lifetime of the pollutant-removing performance hours or days or years

lt

V air volume of test chamber cubic metres

w sorption capacity measured by sample tube micrograms per gram

s

4 © ISO 2009 – All rights reserved

---------------------- Page: 12 ----------------------

SIST ISO 16000-23:2013

ISO 16000-23:2009(E)

5 Principle

The performance of a building material, the test material, with respect to its ability to reduce the concentration

of formaldehyde is evaluated by monitoring the reduction of the vapour concentration inside a test chamber

containing a test specimen of that material. The test includes an assessment of both the initial performance of

the material and how long that performance is maintained.

In this test method, formaldehyde-spiked air is supplied to a test chamber containing the material under test.

The spiked air should be prepared approximately at the WHO guideline level for formaldehyde in indoor air.

Reference to national standards is possible if this is clearly highlighted in the test report and certificate.

Performance is determined by monitoring the difference in concentration of formaldehyde vapour at the inlet

and outlet of the test chamber. Testing should be continued for the half-lifetime, i.e. until the concentration of

formaldehyde drops to half that at the start of the test under constant ventilation conditions. With this test,

sorption flux, F , and total mass per area of sorption, ρ , at the half-lifetime are determined. The measured

m Ac

ρ at the half-lifetime is defined as the saturation mass per area, ρ .

Ac Aa

If a test material continues to reduce formaldehyde concentrations for longer than 28 days, alternative

methods specified in Annex A for determining ρ may be applied.

Aa

The performance of sorptive building materials is mainly determined by the formaldehyde concentration, the

mass transfer coefficient of formaldehyde to the surface, and the sorption characteristics of the building

materials themselves (adsorption isotherm, diffusion resistance, and so on). Therefore, the performance test

method shall specify both the concentration of formaldehyde and the mass transfer coefficient associated with

the sorptive building material.

This method does not apply to materials capable of decomposing formaldehyde by catalytic reaction in the

presence of ultraviolet and visible rays.

NOTE The long-term formaldehyde reduction performance is represented by the saturation mass per area, ρ , and,

Aa

if necessary, the lifetime of the pollutant-removing performance, t , as the subsidiary index.

lt

6 Apparatus and materials

Usual laboratory equipment, and in particular the following.

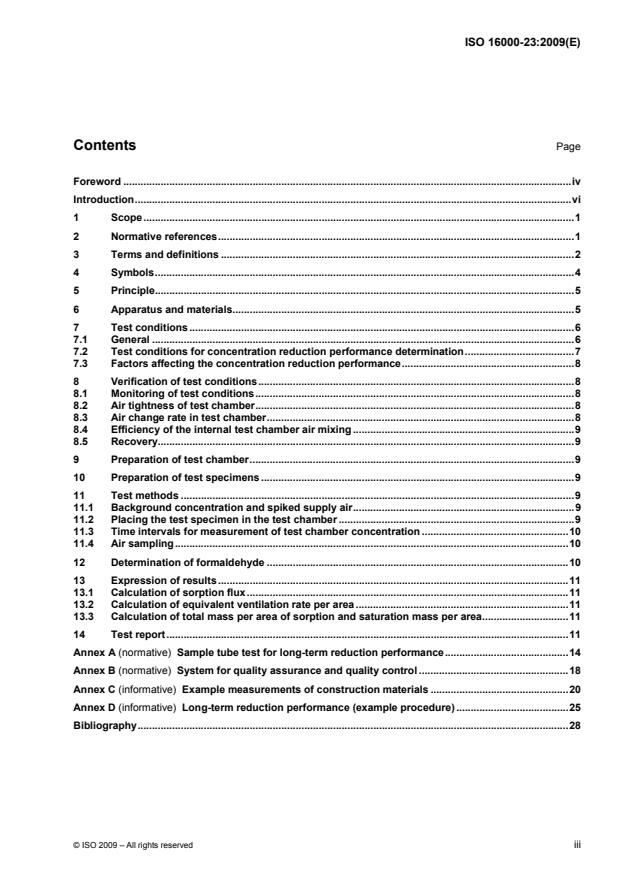

6.1 Test chamber, complying with relevant specifications and requirements of ISO 16000-9 (see Figure 1).

No air shall be allowed to circulate from the outlet back to the inlet.

6.2 Sealing material for test specimens, such as aluminum foil or a tape covered with aluminum foil

to cover the edges and the back of the test specimen, if only the surface normally directly exposed to the

indoor environment under the intended conditions of use is the subject of the test.

6.3 Air purifier or cylinder of clean air. The purifier shall ensure the supply air is as clean as possible

before being spiked with formaldehyde, i.e. shall not contain any contaminants at levels greater than the

chamber background requirements. In order to prevent a rise in background concentration, an air purifier shall

be provided or a cylinder of clean air shall be used.

6.4 Supply air spiked with formaldehyde. Apply a standard gas (with known formaldehyde concentration)

to the test chamber. Alternatively, use a stable source like a formaldehyde solution as specified in

ISO 6353-3), or paraformaldehyde, to generate air spiked with formaldehyde that can be supplied to the test

chamber. The stability of the spiked formaldehyde concentration shall be monitored.

6.5 Temperature and humidity control. Temperature shall be maintained either by installing a test

chamber in a place maintained at the required temperature, such as a constant-temperature climate chamber,

or by maintaining the required temperature in the chamber. Relative humidity shall be maintained at the

required humidity of the supply air. Temperature and humidity controls of the supply air are described in

ISO 16000-9.

6.6 Air flow meter, installed at the inlet or the outlet of the test chamber to measure the air flow rate

through the chamber.

© ISO 2009 – All rights reserved 5

---------------------- Page: 13 ----------------------

SIST ISO 16000-23:2013

ISO 16000-23:2009(E)

Key

1 supply air spiked with formaldehyde

2 sampling device

3 test specimen

4 test chamber

5 device to circulate air and control of air velocity

6 temperature/humidity monitoring apparatus

7 test chamber outlet

8 sampling device

Figure 1 — Outline of the test chamber system

6.7 Air sampling devices. Use the inlet and outlet air of the test chamber for sampling. When a separate

sampling port is used, sample directly from the inlet or outlet of the chamber.

If a duct or tube is used, it shall be as short as possible and maintained at the same air temperature as that in

the test chamber. Such a duct or tube shall be made of a material with a very low sorption capacity, e.g.

polytetrafluoroethylene.

The sum of sampling air flow rates shall be smaller than the air flow rate into the chamber. Sampling devices

shall comply with the specifications of ISO 16000-3. When the air is sampled from the inlet, ensure the supply

air flow rate remains constant.

A multiport sampling manifold may be used to provide flexibility for duplicate air sampling. A mixing chamber

between the test chamber and the manifold or between the air inlet and the test chamber can be included to

permit addition and mixing of internal standard gases with the test chamber air stream.

The exhaust from the test chamber should be ducted into a fume hood, ensuring that formaldehyde-spiked air

and any chemicals emitted from the test material are isolated from the laboratory environment.

6.8 Analytical instrument. A high performance liquid chromatograph (HPLC) shall be used as specified in

ISO 16000-3.

7 Test conditions

7.1 General

The test conditions shall comply with 7.2 and 7.3. This test shall be conducted under atmospheric pressure

conditions.

6 © ISO 2009 – All rights reserved

---------------------- Page: 14 ----

...

INTERNATIONAL ISO

STANDARD 16000-23

First edition

2009-12-15

Indoor air —

Part 23:

Performance test for evaluating the

reduction of formaldehyde

concentrations by sorptive building

materials

Air intérieur —

Partie 23: Essai de performance pour l'évaluation de la réduction des

concentrations en formaldéhyde par des matériaux de construction

sorptifs

Reference number

ISO 16000-23:2009(E)

©

ISO 2009

---------------------- Page: 1 ----------------------

ISO 16000-23:2009(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2009 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 16000-23:2009(E)

Contents Page

Foreword .iv

Introduction.vi

1 Scope.1

2 Normative references.1

3 Terms and definitions .2

4 Symbols.4

5 Principle.5

6 Apparatus and materials.5

7 Test conditions .6

7.1 General .6

7.2 Test conditions for concentration reduction performance determination.7

7.3 Factors affecting the concentration reduction performance.8

8 Verification of test conditions.8

8.1 Monitoring of test conditions.8

8.2 Air tightness of test chamber.8

8.3 Air change rate in test chamber.8

8.4 Efficiency of the internal test chamber air mixing .9

8.5 Recovery.9

9 Preparation of test chamber.9

10 Preparation of test specimens .9

11 Test methods .9

11.1 Background concentration and spiked supply air.9

11.2 Placing the test specimen in the test chamber .9

11.3 Time intervals for measurement of test chamber concentration .10

11.4 Air sampling.10

12 Determination of formaldehyde .10

13 Expression of results.11

13.1 Calculation of sorption flux.11

13.2 Calculation of equivalent ventilation rate per area .11

13.3 Calculation of total mass per area of sorption and saturation mass per area.11

14 Test report.11

Annex A (normative) Sample tube test for long-term reduction performance.14

Annex B (normative) System for quality assurance and quality control .18

Annex C (informative) Example measurements of construction materials .20

Annex D (informative) Long-term reduction performance (example procedure).25

Bibliography.28

© ISO 2009 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 16000-23:2009(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 16000-23 was prepared by Technical Committee ISO/TC 146, Air quality, Subcommittee SC 6, Indoor air.

ISO 16000 consists of the following parts, under the general title Indoor air :

⎯ Part 1: General aspects of sampling strategy

⎯ Part 2: Sampling strategy for formaldehyde

⎯ Part 3: Determination of formaldehyde and other carbonyl compounds — Active sampling method

⎯ Part 4: Determination of formaldehyde — Diffusive sampling method

⎯ Part 5: Sampling strategy for volatile organic compounds (VOCs)

⎯ Part 6: Determination of volatile organic compounds in indoor and test chamber air by active sampling on

®

Tenax TA sorbent, thermal desorption and gas chromatography using MS/FID

⎯ Part 7: Sampling strategy for determination of airborne asbestos fibre concentrations

⎯ Part 8: Determination of local mean ages of air in buildings for characterizing ventilation conditions

⎯ Part 9: Determination of the emission of volatile organic compounds from building products and

furnishing — Emission test chamber method

⎯ Part 10: Determination of the emission of volatile organic compounds from building products and

furnishing — Emission test cell method

⎯ Part 11: Determination of the emission of volatile organic compounds from building products and

furnishing — Sampling, storage of samples and preparation of test specimens

⎯ Part 12: Sampling strategy for polychlorinated biphenyls (PCBs), polychlorinated dibenzo-p-dioxins

(PCDDs), polychlorinated dibenzofurans (PCDFs) and polycyclic aromatic hydrocarbons (PAHs)

⎯ Part 13: Determination of total (gas and particle-phase) polychlorinated dioxin-like biphenyls (PCBs) and

polychlorinated dibenzo-p-dioxins/dibenzofurans (PCDDs/PCDFs) — Collection on sorbent-backed filters

iv © ISO 2009 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 16000-23:2009(E)

⎯ Part 14: Determination of total (gas and particle-phase) polychlorinated dioxin-like biphenyls (PCBs) and

polychlorinated dibenzo-p-dioxins/dibenzofurans (PCDDs/PCDFs) — Extraction, clean-up and analysis by

high-resolution gas chromatography and mass spectrometry

⎯ Part 15: Sampling strategy for nitrogen dioxide (NO )

2

⎯ Part 16: Detection and enumeration of moulds — Sampling by filtration

⎯ Part 17: Detection and enumeration of moulds — Culture-based method

⎯ Part 18: Detection and enumeration of moulds — Sampling by impaction

⎯ Part 23: Performance test for evaluating the reduction of formaldehyde concentrations by sorptive

building materials

⎯ Part 24: Performance test for evaluating the reduction of volatile organic compounds (except

formaldehyde) concentrations by sorptive building materials

⎯ Part 25: Determination of the emission of semi-volatile organic compounds by building products —

Micro-chamber method

The following parts are under preparation:

⎯ Part 19: Sampling strategy for moulds

⎯ Part 26: Measurement strategy for carbon dioxide (CO )

2

⎯ Part 28: Sensory evaluation of emissions from building materials and products

The following parts are planned:

⎯ Part 20: Detection and enumeration of moulds — Sampling from house dust

⎯ Part 21: Detection and enumeration of moulds — Sampling from materials

⎯ Part 22: Detection and enumeration of moulds — Molecular methods

⎯ Part 27: Standard method for the quantitative analysis of asbestos fibres in settled dust

⎯ Part 30: Sensory testing of indoor air

Furthermore

⎯ ISO 12219-1, Indoor air — Road vehicles — Part 1: Whole vehicle test chamber — Specification and

method for the determination of volatile organic compounds in car interiors [planned document]

⎯ ISO 16017-1, Indoor, ambient and workplace air — Sampling and analysis of volatile organic compounds

by sorbent tube/thermal desorption/capillary gas chromatography — Part 1: Pumped sampling

⎯ ISO 16017-2, Indoor, ambient and workplace air — Sampling and analysis of volatile organic compounds

by sorbent tube/thermal desorption/capillary gas chromatography — Part 2: Diffusive sampling

focus on volatile organic compound (VOC) measurements.

© ISO 2009 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 16000-23:2009(E)

Introduction

Sorptive building materials have been marketed in the form of sheet and board products for removing airborne

pollutants via physical sorption or chemical reaction.

Harmonized test methods for evaluating sorptive effects are important for comparative assessment of the

performance of sorptive building materials that are used for reducing levels of indoor air contaminants.

This part of ISO 16000 specifies procedures for evaluating the performance of sorptive building materials for

reducing indoor air formaldehyde concentrations over time.

The performance of sorptive building materials is evaluated by sorption flux and saturation mass per area and

is affected by a number of factors. Specific test conditions are therefore defined in this part of ISO 16000.

This part of ISO 16000 can be applied to most sorptive building materials used indoors and for formaldehyde

as an indoor air contaminant.

This part of ISO 16000 is based on the test chamber method as specified in ISO 16000-9.

vi © ISO 2009 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 16000-23:2009(E)

Indoor air —

Part 23:

Performance test for evaluating the reduction of formaldehyde

concentrations by sorptive building materials

1 Scope

This part of ISO 16000 specifies a general laboratory test method for evaluating the reduction of formaldehyde

concentrations by sorptive building materials. This method applies to boards, wallpapers, carpets, paint

products, and other building materials. The sorption of formaldehyde can be brought about by adsorption,

absorption and chemisorption. The performance of the material with respect to its ability to reduce the

concentration of formaldehyde in indoor air is evaluated by measuring sorption flux and saturation mass per

area. The former directly indicates material performance with respect to formaldehyde concentration reduction

at a point in time; the latter relates to the ability of a product to maintain that performance.

The method specified in this part of ISO 16000 employs formaldehyde-spiked supply air to determine the

performance of building materials in reducing formaldehyde concentrations. The characteristics of

formaldehyde sorption depend greatly on humidity. Formaldehyde is less stable in air than other volatile

organic compounds (VOCs), so it has to be tested on its own.

This part of ISO 16000 is based on the test chamber method specified in ISO 16000-9. Sampling, transport

and storage of materials to be tested and preparation of test specimens are specified in ISO 16000-11. Air

sampling and analytical methods for the determination of formaldehyde are specified in ISO 16000-3, which is

part of the complete procedure.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 554, Standard atmospheres for conditioning and/or testing — Specifications

ISO 6353-3, Reagents for chemical analysis — Part 3: Specifications — Second series

ISO 16000-3, Indoor air — Part 3: Determination of formaldehyde and other carbonyl compounds — Active

sampling method

ISO 16000-6, Indoor air — Part 6: Determination of volatile organic compounds in indoor and test chamber air

®

by active sampling on Tenax TA sorbent, thermal desorption and gas chromatography using MS/FID

ISO 16000-9:2006, Indoor air — Part 9: Determination of the emission of volatile organic compounds from

building products and furnishing — Emission test chamber method

ISO 16000-11, Indoor air — Part 11: Determination of the emission of volatile organic compounds from

building products and furnishing — Sampling, storage of samples and preparation of test specimens

© ISO 2009 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 16000-23:2009(E)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

breakthrough time

t

b

〈indoor air〉 time at which the formaldehyde concentration in the air eluting from the sample tube reaches

0,5 % of the concentration in the supplied air

NOTE Adapted from ISO 16000-24:2009, 3.1.

3.2

degradation coefficient

〈indoor air〉 ratio of the mass of formaldehyde removed by the initial performance divided by the mass of the

same compound lost by deterioration

NOTE Adapted from ISO 16000-24:2009, 3.2.

3.3

elapsed time

t

e

〈indoor air〉 time from start of test to the start of air sampling

NOTE Elapsed time is expressed in days.

[ISO 16000-24:2009, 3.3.]

3.4

equivalent ventilation rate per area

F

V, eq

〈indoor air〉 increased clean air ventilation rate giving the same reduction in formaldehyde concentration as the

building material

NOTE Adapted from ISO 16000-24:2009, 3.4.

3.5

guideline concentration

〈indoor air〉 guideline indoor air concentration for formaldehyde as specified by the the WHO

NOTE Adapted from ISO 16000-24:2009, 3.5.

3.6

half-lifetime

〈indoor air〉 time elapsed from the start of the test until the formaldehyde concentration decreases to one-half

of the initial concentration

NOTE Adapted from ISO 16000-24:2009, 3.6.

3.7

lifetime

t

lt

〈indoor air〉 time period over which the product continues to reduce formaldehyde concentrations

NOTE 1 The lifetime is given in days or years.

NOTE 2 The lifetime is estimated from the sorption flux and sorption capacity measured by the sample tube test.

NOTE 3 Adapted from ISO 16000-24:2009, 3.7.

2 © ISO 2009 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 16000-23:2009(E)

3.8

mass transfer coefficient

k

a

〈indoor air〉 coefficient arising from the concentration difference between the test specimen and ambient air

over its surface

NOTE Mass transfer coefficient is expressed in meters per hour.

[ISO 16000-24:2009, 3.8]

3.9

recovery

〈indoor air〉 measured mass of formaldehyde in the air leaving the test chamber with no sample present

conditioned over a given time period divided by the mass of formaldehyde added to the test chamber in the

same time period

NOTE 1 The recovery is expressed as a percentage and provides information about the performance of the entire

method.

NOTE 2 Adapted from ISO 16000-24:2009, 3.9.

3.10

saturation mass per area

ρ

Aa

theoretical maximum mass of formaldehyde that could be removed per area of the sorptive material

NOTE 1 Saturation mass per area is expressed in micrograms per area. It corresponds to the total mass per area of

sorption at the half-lifetime, or is extrapolated from the sorption capacity derived from the test referenced in Annex A.

NOTE 2 Adapted from ISO 16000-24:2009, 3.10.

3.11

sorption capacity

w

s

total mass of formaldehyde sorbed at breakthrough time per mass of sorbent

NOTE 1 Sorption capacity is expressed in micrograms per gram and is measured using the test specified in Annex A.

NOTE 2 Adapted from ISO 16000-24:2009, 3.11.

3.12

sorption flux

F

m

mass of formaldehyde sorbed per time per area at the specified elapsed time from the test start

NOTE Adapted from ISO 16000-24:2009, 3.12.

3.13

supply air concentration

ρ

s

mass concentration of formaldehyde in the air for supply to the test chamber

NOTE Adapted from ISO 16000-24:2009, 3.13.

3.14

test chamber concentration

〈indoor air〉 concentration of formaldehyde measured at the outlet of a test chamber, derived by dividing the

mass of the formaldehyde sampled at the outlet of the chamber by the volume of sampled air

NOTE Adapted from ISO 16000-24:2009, 3.14.

© ISO 2009 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO 16000-23:2009(E)

3.15

total mass per area of sorption

ρ

A

integral over time of sorptive flux from the start of the test to the specified elapsed time measured with the test

chamber

NOTE Total mass per area of sorption is expressed in micrograms per area.

[ISO 16000-24:2009, 3.15]

3.16

vapour sampling period

〈indoor air〉 period of time during which air is sampled from the outlet of the test chamber using sampling tubes

or other devices

[ISO 16000-24:2009, 3.16]

4 Symbols

Symbol Meaning Unit

ρ mass of sorptive material per area (surface density) grams per square metre

A

ρ saturation mass per area micrograms per square metre

Aa

ρ total mass per area of sorption measured by chamber micrograms per square metre

Ac

test

ρ concentration of formaldehyde at test chamber inlet at micrograms per cubic metre

in, t

elapsed time t

ρ test chamber concentration at elapsed time t micrograms per cubic metre

out, t

ρ supply air concentration in sample tube micrograms per cubic metre

s

A surface area of test specimen square metres

F sorption flux per time per area micrograms per square metre per hour

m

F air flow rate per area cubic metres per square metre per hour

V, a

F equivalent ventilation rate cubic metres per square metre per hour

V, eq

k mass transfer coefficient determined using water vapour metres per hour

a

L product loading factor square metres per cubic metre

m actual mass of test specimen in sample tube grams

n air change rate changes per hour

q air flow rate of test chamber cubic metres per hour

c

q air flow rate of sample tube litres per minute

s

t breakthrough time minutes

b

t elapsed time hours or days

e

t lifetime of the pollutant-removing performance hours or days or years

lt

V air volume of test chamber cubic metres

w sorption capacity measured by sample tube micrograms per gram

s

4 © ISO 2009 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 16000-23:2009(E)

5 Principle

The performance of a building material, the test material, with respect to its ability to reduce the concentration

of formaldehyde is evaluated by monitoring the reduction of the vapour concentration inside a test chamber

containing a test specimen of that material. The test includes an assessment of both the initial performance of

the material and how long that performance is maintained.

In this test method, formaldehyde-spiked air is supplied to a test chamber containing the material under test.

The spiked air should be prepared approximately at the WHO guideline level for formaldehyde in indoor air.

Reference to national standards is possible if this is clearly highlighted in the test report and certificate.

Performance is determined by monitoring the difference in concentration of formaldehyde vapour at the inlet

and outlet of the test chamber. Testing should be continued for the half-lifetime, i.e. until the concentration of

formaldehyde drops to half that at the start of the test under constant ventilation conditions. With this test,

sorption flux, F , and total mass per area of sorption, ρ , at the half-lifetime are determined. The measured

m Ac

ρ at the half-lifetime is defined as the saturation mass per area, ρ .

Ac Aa

If a test material continues to reduce formaldehyde concentrations for longer than 28 days, alternative

methods specified in Annex A for determining ρ may be applied.

Aa

The performance of sorptive building materials is mainly determined by the formaldehyde concentration, the

mass transfer coefficient of formaldehyde to the surface, and the sorption characteristics of the building

materials themselves (adsorption isotherm, diffusion resistance, and so on). Therefore, the performance test

method shall specify both the concentration of formaldehyde and the mass transfer coefficient associated with

the sorptive building material.

This method does not apply to materials capable of decomposing formaldehyde by catalytic reaction in the

presence of ultraviolet and visible rays.

NOTE The long-term formaldehyde reduction performance is represented by the saturation mass per area, ρ , and,

Aa

if necessary, the lifetime of the pollutant-removing performance, t , as the subsidiary index.

lt

6 Apparatus and materials

Usual laboratory equipment, and in particular the following.

6.1 Test chamber, complying with relevant specifications and requirements of ISO 16000-9 (see Figure 1).

No air shall be allowed to circulate from the outlet back to the inlet.

6.2 Sealing material for test specimens, such as aluminum foil or a tape covered with aluminum foil

to cover the edges and the back of the test specimen, if only the surface normally directly exposed to the

indoor environment under the intended conditions of use is the subject of the test.

6.3 Air purifier or cylinder of clean air. The purifier shall ensure the supply air is as clean as possible

before being spiked with formaldehyde, i.e. shall not contain any contaminants at levels greater than the

chamber background requirements. In order to prevent a rise in background concentration, an air purifier shall

be provided or a cylinder of clean air shall be used.

6.4 Supply air spiked with formaldehyde. Apply a standard gas (with known formaldehyde concentration)

to the test chamber. Alternatively, use a stable source like a formaldehyde solution as specified in

ISO 6353-3), or paraformaldehyde, to generate air spiked with formaldehyde that can be supplied to the test

chamber. The stability of the spiked formaldehyde concentration shall be monitored.

6.5 Temperature and humidity control. Temperature shall be maintained either by installing a test

chamber in a place maintained at the required temperature, such as a constant-temperature climate chamber,

or by maintaining the required temperature in the chamber. Relative humidity shall be maintained at the

required humidity of the supply air. Temperature and humidity controls of the supply air are described in

ISO 16000-9.

6.6 Air flow meter, installed at the inlet or the outlet of the test chamber to measure the air flow rate

through the chamber.

© ISO 2009 – All rights reserved 5

---------------------- Page: 11 ----------------------

ISO 16000-23:2009(E)

Key

1 supply air spiked with formaldehyde

2 sampling device

3 test specimen

4 test chamber

5 device to circulate air and control of air velocity

6 temperature/humidity monitoring apparatus

7 test chamber outlet

8 sampling device

Figure 1 — Outline of the test chamber system

6.7 Air sampling devices. Use the inlet and outlet air of the test chamber for sampling. When a separate

sampling port is used, sample directly from the inlet or outlet of the chamber.

If a duct or tube is used, it shall be as short as possible and maintained at the same air temperature as that in

the test chamber. Such a duct or tube shall be made of a material with a very low sorption capacity, e.g.

polytetrafluoroethylene.

The sum of sampling air flow rates shall be smaller than the air flow rate into the chamber. Sampling devices

shall comply with the specifications of ISO 16000-3. When the air is sampled from the inlet, ensure the supply

air flow rate remains constant.

A multiport sampling manifold may be used to provide flexibility for duplicate air sampling. A mixing chamber

between the test chamber and the manifold or between the air inlet and the test chamber can be included to

permit addition and mixing of internal standard gases with the test chamber air stream.

The exhaust from the test chamber should be ducted into a fume hood, ensuring that formaldehyde-spiked air

and any chemicals emitted from the test material are isolated from the laboratory environment.

6.8 Analytical instrument. A high performance liquid chromatograph (HPLC) shall be used as specified in

ISO 16000-3.

7 Test conditions

7.1 General

The test conditions shall comply with 7.2 and 7.3. This test shall be conducted under atmospheric pressure

conditions.

6 © ISO 2009 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 16000-23:2009(E)

7.2 Test conditions for concentration reduction performance determination

7.2.1 Temperature and relative humidity

Building materials for use in Europe and America shall be tested in accordance with ISO 554 at a temperature

of 23 °C ± 2 °C and relative humidity 50 % ± 5 % during the test.

Building materials for use in Japan shall be tested at a temperature of 28 °C ± 1 °C and relative humidity

50 % ± 5 % during the test.

For building materials with applications under other climatic conditions, alternative temperatures and air

humidity conditions may be used, preferably as specified in ISO 554. State the conditions in the test report.

Initial variations can be observed in the test chamber climate after opening the test chamber door and loading

a test specimen. These variations should be recorded.

NOTE Temperature and relative humidity can affect sorption flux and re-desorption from the test material.

7.2.2 Supply air quality and background concentration

The background concentration of the supply air for the test chamber and the air prior to spiking with

formaldehyde shall be low enough not to interfere with the test. The t

...

NORME ISO

INTERNATIONALE 16000-23

Première édition

2009-12-15

Air intérieur —

Partie 23:

Essai de performance pour l'évaluation

de la réduction des concentrations en

formaldéhyde par des matériaux de

construction sorptifs

Indoor air —

Part 23: Performance test for evaluating the reduction of formaldehyde

concentrations by sorptive building materials

Numéro de référence

ISO 16000-23:2009(F)

©

ISO 2009

---------------------- Page: 1 ----------------------

ISO 16000-23:2009(F)

PDF – Exonération de responsabilité

Le présent fichier PDF peut contenir des polices de caractères intégrées. Conformément aux conditions de licence d'Adobe, ce fichier

peut être imprimé ou visualisé, mais ne doit pas être modifié à moins que l'ordinateur employé à cet effet ne bénéficie d'une licence

autorisant l'utilisation de ces polices et que celles-ci y soient installées. Lors du téléchargement de ce fichier, les parties concernées

acceptent de fait la responsabilité de ne pas enfreindre les conditions de licence d'Adobe. Le Secrétariat central de l'ISO décline toute

responsabilité en la matière.

Adobe est une marque déposée d'Adobe Systems Incorporated.

Les détails relatifs aux produits logiciels utilisés pour la création du présent fichier PDF sont disponibles dans la rubrique General Info

du fichier; les paramètres de création PDF ont été optimisés pour l'impression. Toutes les mesures ont été prises pour garantir

l'exploitation de ce fichier par les comités membres de l'ISO. Dans le cas peu probable où surviendrait un problème d'utilisation,

veuillez en informer le Secrétariat central à l'adresse donnée ci-dessous.

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2009

Droits de reproduction réservés. Sauf prescription différente, aucune partie de cette publication ne peut être reproduite ni utilisée sous

quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les microfilms, sans l'accord écrit

de l'ISO à l'adresse ci-après ou du comité membre de l'ISO dans le pays du demandeur.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Publié en Suisse

ii © ISO 2009 – Tous droits réservés

---------------------- Page: 2 ----------------------

ISO 16000-23:2009(F)

Sommaire Page

Avant-propos .iv

Introduction.vii

1 Domaine d'application .1

2 Références normatives.1

3 Termes et définitions .2

4 Symboles.4

5 Principe.5

6 Appareillage et matériaux.5

7 Conditions d'essai.7

7.1 Généralités .7

7.2 Conditions d'essai pour la détermination de la performance en matière de réduction de la

concentration.7

7.3 Facteurs affectant la performance en matière de réduction de la concentration.8

8 Vérification des conditions d'essai .9

8.1 Surveillance des conditions d'essai.9

8.2 Étanchéité à l'air de la chambre d'essai.9

8.3 Taux de renouvellement d'air dans la chambre d'essai .9

8.4 Efficacité du mélange de l'air dans la chambre d'essai interne .9

8.5 Récupération.9

9 Préparation de la chambre d'essai .10

10 Préparation des éprouvettes pour essai.10

11 Méthodes d'essai.10

11.1 Concentration de fond et air d'alimentation dopé .10

11.2 Installation de l'éprouvette dans la chambre d'essai .10

11.3 Intervalles de temps pour le mesurage de la concentration de la chambre d'essai.10

11.4 Prélèvement d'air.11

12 Détermination du formaldéhyde .11

13 Expression des résultats.11

13.1 Calcul du flux de sorption .11

13.2 Calcul du débit surfacique de ventilation équivalent .12

13.3 Calcul de la masse surfacique totale de sorption et de la masse surfacique de saturation.12

14 Rapport d'essai.12

Annexe A (normative) Essai relatif à la performance longue durée en matière de réduction au

moyen d'un tube de prélèvement .14

Annexe B (normative) Système d'assurance qualité et de contrôle qualité.18

Annexe C (informative) Exemples de mesurages de matériaux de construction .20

Annexe D (informative) Performances en matière de réduction de la concentration à long terme

(exemple de mode opératoire) .25

Bibliographie.28

© ISO 2009 – Tous droits réservés iii

---------------------- Page: 3 ----------------------

ISO 16000-23:2009(F)

Avant-propos

L'ISO (Organisation internationale de normalisation) est une fédération mondiale d'organismes nationaux de

normalisation (comités membres de l'ISO). L'élaboration des Normes internationales est en général confiée

aux comités techniques de l'ISO. Chaque comité membre intéressé par une étude a le droit de faire partie du

comité technique créé à cet effet. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec l'ISO participent également aux travaux. L'ISO collabore étroitement avec

la Commission électrotechnique internationale (CEI) en ce qui concerne la normalisation électrotechnique.

Les Normes internationales sont rédigées conformément aux règles données dans les Directives ISO/CEI,

Partie 2.

La tâche principale des comités techniques est d'élaborer les Normes internationales. Les projets de Normes

internationales adoptés par les comités techniques sont soumis aux comités membres pour vote. Leur

publication comme Normes internationales requiert l'approbation de 75 % au moins des comités membres

votants.

L'attention est appelée sur le fait que certains des éléments du présent document peuvent faire l'objet de

droits de propriété intellectuelle ou de droits analogues. L'ISO ne saurait être tenue pour responsable de ne

pas avoir identifié de tels droits de propriété et averti de leur existence.

L'ISO 16000-23 a été élaborée par le comité technique ISO/TC 146, Qualité de l'air, sous-comité SC 6, Air

intérieur.

L'ISO 16000 comprend les parties suivantes, présentées sous le titre général Air intérieur:

⎯ Partie 1: Aspects généraux de la stratégie d'échantillonnage

⎯ Partie 2: Stratégie d'échantillonnage du formaldéhyde

⎯ Partie 3: Dosage du formaldéhyde et d'autres composés carbonylés — Méthode par échantillonnage actif

⎯ Partie 4: Dosage du formaldéhyde — Méthode par échantillonnage diffusif

⎯ Partie 5: Stratégie d'échantillonnage pour les composés organiques volatils (COV)

⎯ Partie 6: Dosage des composés organiques volatils dans l'air intérieur des locaux et enceintes d'essai par

®

échantillonnage actif sur le sorbant Tenax TA , désorption thermique et chromatographie en phase

gazeuse utilisant MS/FID

⎯ Partie 7: Stratégie d'échantillonnage pour la détermination des concentrations en fibres d'amiante en

suspension dans l'air

⎯ Partie 8: Détermination des âges moyens locaux de l'air dans des bâtiments pour caractériser les

conditions de ventilation

⎯ Partie 9: Dosage de l'émission de composés organiques volatils de produits de construction et d'objets

d'équipement — Méthode de la chambre d'essai d'émission

⎯ Partie 10: Dosage de l'émission de composés organiques volatils de produits de construction et d'objets

d'équipement — Méthode de la cellule d'essai d'émission

⎯ Partie 11: Dosage de l'émission de composés organiques volatils de produits de construction et d'objets

d'équipement — Échantillonnage, conservation des échantillons et préparation d'échantillons pour essai

iv © ISO 2009 – Tous droits réservés

---------------------- Page: 4 ----------------------

ISO 16000-23:2009(F)

⎯ Partie 12: Stratégie d'échantillonnage des polychlorobiphényles (PCB), des polychlorodibenzo-p-dioxines

(PCDD), des polychlorodibenzofuranes (PCDF) et des hydrocarbures aromatiques polycycliques (HAP)

⎯ Partie 13: Dosage des polychlorobiphényles (PCB) de type dioxine et des polychlorodibenzo-p-dioxines

(PCDD)/polychlorodibenzofuranes (PCDF) totaux (en phase gazeuse et en phase particulaire) —

Collecte sur des filtres adsorbants

⎯ Partie 14: Dosage des polychlorobiphényles (PCB) de type dioxine et des polychlorodibenzo-p-dioxines

(PCDD)/polychlorodibenzofuranes (PCDF) totaux (en phase gazeuse et en phase particulaire) —

Extraction, purification et analyse par chromatographie en phase gazeuse haute résolution et

spectrométrie de masse

⎯ Partie 15: Stratégie d'échantillonnage du dioxyde d'azote (NO )

2

⎯ Partie 16: Détection et dénombrement des moisissures — Échantillonnage par filtration

⎯ Partie 17: Détection et dénombrement des moisissures — Méthode par culture

⎯ Partie 18: Détection et dénombrement des moisissures — Échantillonnage par impaction

⎯ Partie 23: Essai de performance pour l'évaluation de la réduction des concentrations en formaldéhyde

par des matériaux de construction sorptifs

⎯ Partie 24: Essai de performance pour l'évaluation de la réduction des concentrations en composés

organiques volatils (sauf formaldéhyde) par des matériaux de construction sorptifs

⎯ Partie 25: Dosage de l'émission de composés organiques semi-volatils des produits de construction —

Méthode de la micro-chambre

Les parties suivantes sont en cours d'élaboration:

⎯ Partie 19: Stratégie d'échantillonnage des moisissures

⎯ Partie 26: Stratégie de mesure du dioxyde de carbone (CO )

2

⎯ Partie 28: Évaluation sensorielle des émissions des matériaux et des produits de construction

Les parties suivantes sont prévues:

⎯ Partie 20: Détection et dénombrement des moisissures — Échantillonnage à partir de poussières

domestiques

⎯ Partie 21: Détection et dénombrement des moisissures — Échantillonnage à partir de matériaux

⎯ Partie 22: Détection et dénombrement des moisissures — Méthodes moléculaires

⎯ Partie 27: Méthode normalisée pour l'analyse quantitative des fibres d'amiante dans la poussière

déposée

⎯ Partie 30: Essai sensoriel de l'air intérieur

En outre,

⎯ l'ISO 12219-1, Air intérieur, Véhicules routiers — Partie 1: Enceinte d'essai d'un véhicule complet —

Spécification et méthode de détermination des composés organiques volatils dans les habitacles de

voitures [document prévu]

© ISO 2009 – Tous droits réservés v

---------------------- Page: 5 ----------------------

ISO 16000-23:2009(F)

⎯ l'ISO 16017-1, Air intérieur, air ambiant et air des lieux de travail — Échantillonnage et analyse des

composés organiques volatils par tube à adsorption/désorption thermique/chromatographie en phase

gazeuse sur capillaire — Partie 1: Échantillonnage par pompage, et

⎯ l'ISO 16017-2, Air intérieur, air ambiant et air des lieux de travail — Échantillonnage et analyse des

composés organiques volatils par tube à adsorption/désorption thermique/chromatographie en phase

gazeuse sur capillaire — Partie 2: Échantillonnage par diffusion

traitent plus particulièrement des mesurages relatifs aux composés organiques volatils (COV).

vi © ISO 2009 – Tous droits réservés

---------------------- Page: 6 ----------------------

ISO 16000-23:2009(F)

Introduction

Les matériaux de construction sorptifs ont fait l'objet d'une diffusion sous forme de produits en tôle et en

planche servant à éliminer les polluants dans l'air par sorption physique ou par réaction chimique.

L'harmonisation des méthodes d'essai relatives à l'évaluation des effets sorptifs est essentielle pour effectuer

une analyse comparative des performances des matériaux de construction sorptifs utilisés pour réduire les

niveaux des contaminants dans l'air intérieur.

La présente partie de l'ISO 16000 spécifie des procédures d'évaluation des performances, dans le temps, des

matériaux de construction sorptifs en matière de réduction des concentrations en formaldéhyde dans l'air

intérieur.

La performance des matériaux de construction sorptifs est évaluée par flux de sorption et par masse

surfacique de saturation, et elle est affectée par plusieurs facteurs. Des conditions d'essai spécifiques sont

donc définies dans la présente partie de l'ISO 16000.

La présente partie de l'ISO 16000 peut s'appliquer à la plupart des matériaux de construction sorptifs utilisés

en intérieur ainsi qu'au formaldéhyde, en tant que contaminant de l'air intérieur.

La présente partie de l'ISO 16000 est basée sur la méthode de la chambre d'essai spécifiée dans

l'ISO 16000-9.

© ISO 2009 – Tous droits réservés vii

---------------------- Page: 7 ----------------------

NORME INTERNATIONALE ISO 16000-23:2009(F)

Air intérieur —

Partie 23:

Essai de performance pour l'évaluation de la réduction des

concentrations en formaldéhyde par des matériaux de

construction sorptifs

1 Domaine d'application

La présente partie de l'ISO 16000 spécifie une méthode générale d'essai de laboratoire en vue de l'évaluation

de la réduction des concentrations en formaldéhyde grâce à l'utilisation de matériaux de construction sorptifs.

Cette méthode s'applique aux planches, papiers peints, tapis, produits de peinture et autres matériaux de

construction. La sorption de formaldéhyde peut être réalisée par adsorption, absorption et chimisorption. La

performance du matériau, au regard de sa capacité de réduction de la concentration en formaldéhyde en air

intérieur, est évaluée en mesurant le flux de sorption et la masse surfacique de saturation. Le premier indique

directement la performance du matériau de construction en fonction de la réduction de la concentration en

formaldéhyde à un instant donné; la dernière indique la capacité d'un produit à maintenir cette performance.

La méthode spécifiée dans la présente partie de l'ISO 16000 emploie une alimentation en air marqué au

formaldéhyde pour déterminer l'aptitude du produit de construction à réduire les concentrations en

formaldéhyde. Les caractéristiques de la sorption du formaldéhyde dépendent largement de l'humidité. Le

formaldéhyde est moins stable dans l'air que d'autres composés organiques volatils (COV) et il doit donc faire

l'objet d'un essai distinct.

La présente partie de l'ISO 16000 est basée sur la méthode de la chambre d'essai telle que spécifiée dans

l'ISO 16000-9. L'échantillonnage, le transport et le stockage des matériaux à soumettre à essai, ainsi que la

préparation des éprouvettes pour essai, sont spécifiés dans l'ISO 16000-11. L'échantillonnage de l'air et les

méthodes d'analyse en vue de la détermination du formaldéhyde sont spécifiés dans l'ISO 16000-3, qui fait

partie de la procédure complète.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent document. Pour les

références datées, seule l'édition citée s'applique. Pour les références non datées, la dernière édition du

document de référence (y compris les éventuels amendements) s'applique.

ISO 554, Atmosphères normales de conditionnement et/ou d'essai — Spécifications

ISO 6353-3, Réactifs pour analyse chimique — Partie 3: Spécifications — Deuxième série

ISO 16000-3, Air intérieur — Partie 3: Dosage du formaldéhyde et d'autres composés carbonylés — Méthode

par échantillonnage actif

ISO 16000-6, Air intérieur — Partie 6: Dosage des composés organiques volatils dans l'air intérieur des

®

locaux et enceintes d'essai par échantillonnage actif sur le sorbant Tenax TA , désorption thermique et

chromatographie en phase gazeuse avec MS/FID

ISO 16000-9:2006, Air intérieur — Partie 9: Dosage de l'émission de composés organiques volatils de

produits de construction et d'objets d'équipement — Méthode de la chambre d'essai d'émission

ISO 16000-11, Air intérieur — Partie 11: Dosage de l'émission de composés organiques volatils de produits

de construction et d'objets d'équipement — Échantillonnage, conservation des échantillons et préparation

d'échantillons pour essai

© ISO 2009 – Tous droits réservés 1

---------------------- Page: 8 ----------------------

ISO 16000-23:2009(F)

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s'appliquent.

3.1

temps de claquage

t

b

〈air intérieur〉 moment où la concentration en formaldéhyde dans l'air éluant du tube de prélèvement atteint

0,5 % de la concentration dans l'air d'alimentation

NOTE Adapté de l'ISO 16000-24:2009, définition 3.1.

3.2

coefficient de dégradation